Single-layer four-strand non-rotating steel wire rope and manufacturing process thereof

A manufacturing process and steel wire rope technology, applied in the field of single-layer four-strand non-rotating steel wire rope and its manufacturing process, can solve the problems of insufficient oil storage inside the steel wire rope, loose strands of easy and difficult ropes, core extrusion, and unstable structure of the steel wire rope. Achieve the effect of reducing the sales price, smooth and smooth outer surface, and reducing the probability of scrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

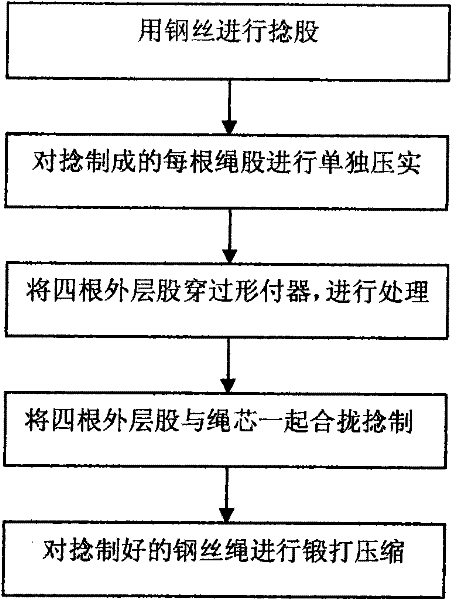

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

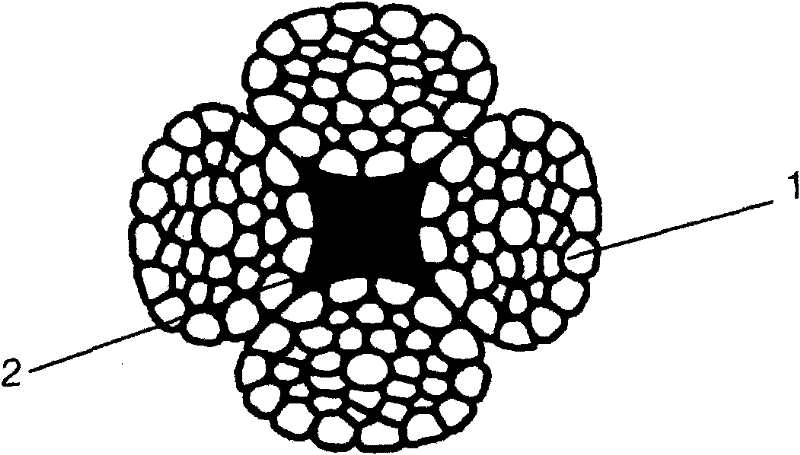

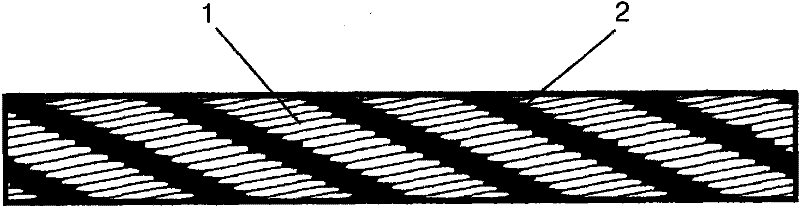

[0022] Non-rotating wire rope refers to a performance that the wire rope does not rotate around its own axis when it is in the working state of vertically suspending heavy objects. The non-rotating performance of the wire rope is extremely important for use. In the case of sinking a new mine, lifting heavy objects by various cranes, etc., it is required that the wire rope does not rotate in order to work normally. If the steel wire rope rotates, it will affect the work efficiency and the safety of property and life. In addition, for the steel wire rope itself, due to the rotation, the fatigue performance will be continuously reduced, which will affect the service life of the steel wire rope. For a single-layer steel wire rope, the lay length of the strands should be reduced, and the lay length of the rope should be increased, and the number of strand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com