Device for conveniently heating aluminum alloy blank materials

An aluminum alloy and billet technology, applied in the field of forging, can solve the problems of billet cracking, low billet temperature, billet over-burning and scrapping, etc., and achieve the effect of reducing the probability of cracking and scrapping, uniform heat distribution, and reducing environmental differences.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

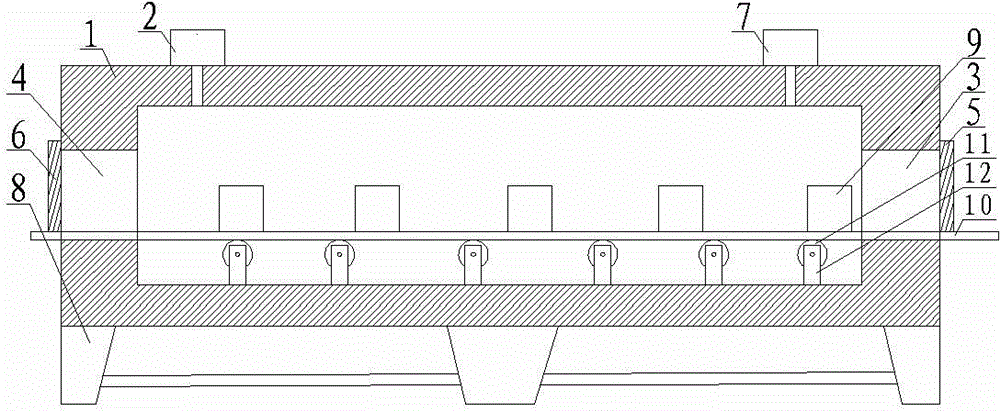

[0014] Such as figure 1 As shown, the device for heating aluminum alloy blanks includes a furnace body 1, a blower 2, an exhaust fan 7, a support plate 10 and a load-bearing mechanism, wherein the bottom of the furnace body 1 is provided with a plurality of supporting seats for supporting the furnace body 1, and the furnace body 1 The left and right sides are respectively opened to form the discharge port 4 and the feed port 3, and the feed port 3 and the discharge port 4 in this embodiment are at the same level. The air blower 2 and the exhaust fan 7 of the present embodiment are all connected to the inside of the body of furnace 1, and the connecting passages between the air blower 2 and the exhaust fan 7 and the body of furnace 1 are located at the tops of the left and right ends of the body of furnace 1 respectively. The support plate 10 of this embodiment passes through the furnace body 1, and its left and right ends are respectively arranged at the feed port 3 and the di...

Embodiment 2

[0017] In order to monitor the temperature in the furnace body 1, this embodiment further defines the following on the basis of Embodiment 1: this embodiment also includes a thermocouple 8, wherein the thermocouple 8 passes through the furnace body 1 and is embedded in the furnace body. In body 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com