Die-casting mold multi-point precise temperature control system and method

A die-casting mold and temperature control system technology, applied in the field of temperature control systems, can solve the problems of time delay in thermocouple temperature measurement, data that cannot quickly and accurately reflect temperature, etc., to prevent overheating or overcooling, and reduce the probability of waste products , Realize the effect of real-time control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

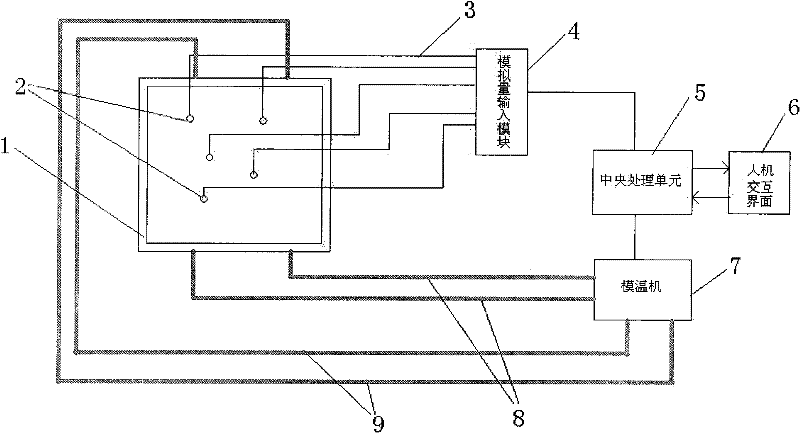

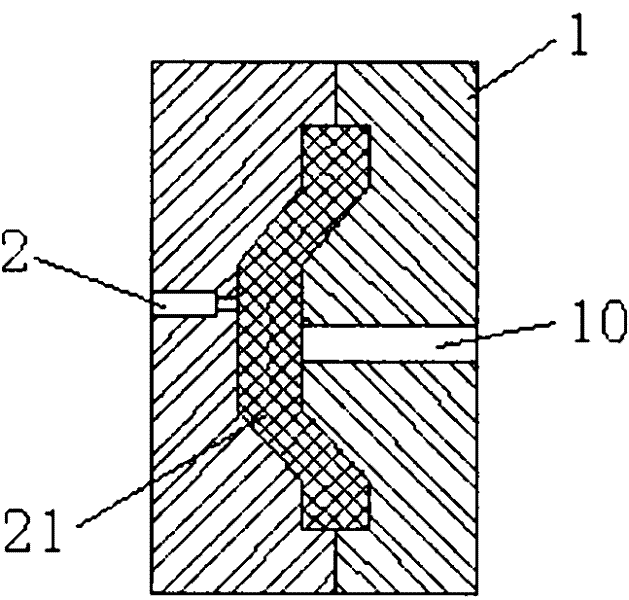

[0021] Such as figure 1 , figure 2 As shown, the temperature control system of the present invention includes a plurality of temperature detection devices 2 embedded in the mold 1, each temperature detection device 2 is connected to an analog input module 4 through a compensation wire 3, and the analog input module 4 is connected to a The central processing unit 5 is connected to a man-machine interface 6 and a mold temperature machine 7 respectively. The mold temperature controller 7 is provided with two oil inlet pipes 8 and two oil outlet pipes 9 (this is just an example, not limited to this). circulation pipes.

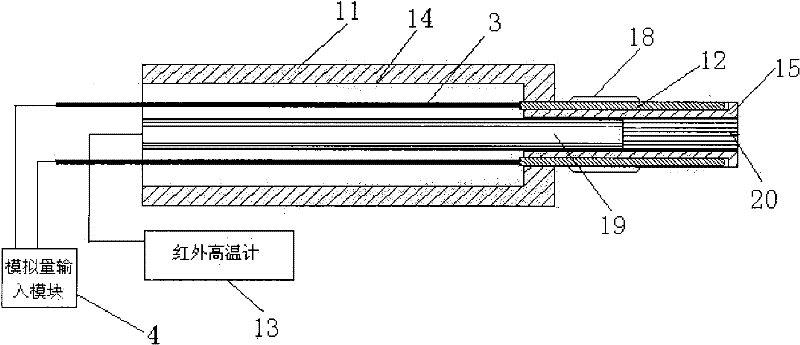

[0022] Such as Figure 3-5 As shown, the temperature detection device 2 includes a temperature measurement auxiliary element 11 , a thermocouple 12 and an infrared pyrometer 13 . The temperature measurement auxiliary element 11 incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com