Sample temperature control method

a temperature control and sample technology, applied in the direction of heat measurement, instruments, manufacturing tools, etc., can solve the problems of insufficient heat transfer between the sample stage and the sample placed thereon, and it takes a long time for the temperature of the wafer to reach the desired value, etc., to accurately estimate the sample temperature and stably control the sample temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

[0036]FIG. 6 is a diagram illustrating a microwave plasma etching apparatus having an automatic wafer temperature control function. In this apparatus, a microwave generated by a magnetron 5 is introduced into a decompression treatment chamber 1 via a wave guide 6 and a quartz window 7 to produce a plasma 8. At this time, a treatment gas introduced from a gas inlet 9 is dissociated by the plasma 8 and radicals and positive ions are produced. Also, a butterfly throttle valve 3 is provided between the decompression treatment chamber 1 and a pump and therefore it is possible to regulate a pressure in the decompression treatment chamber by regulating the degree of opening of the throttle valve 3.

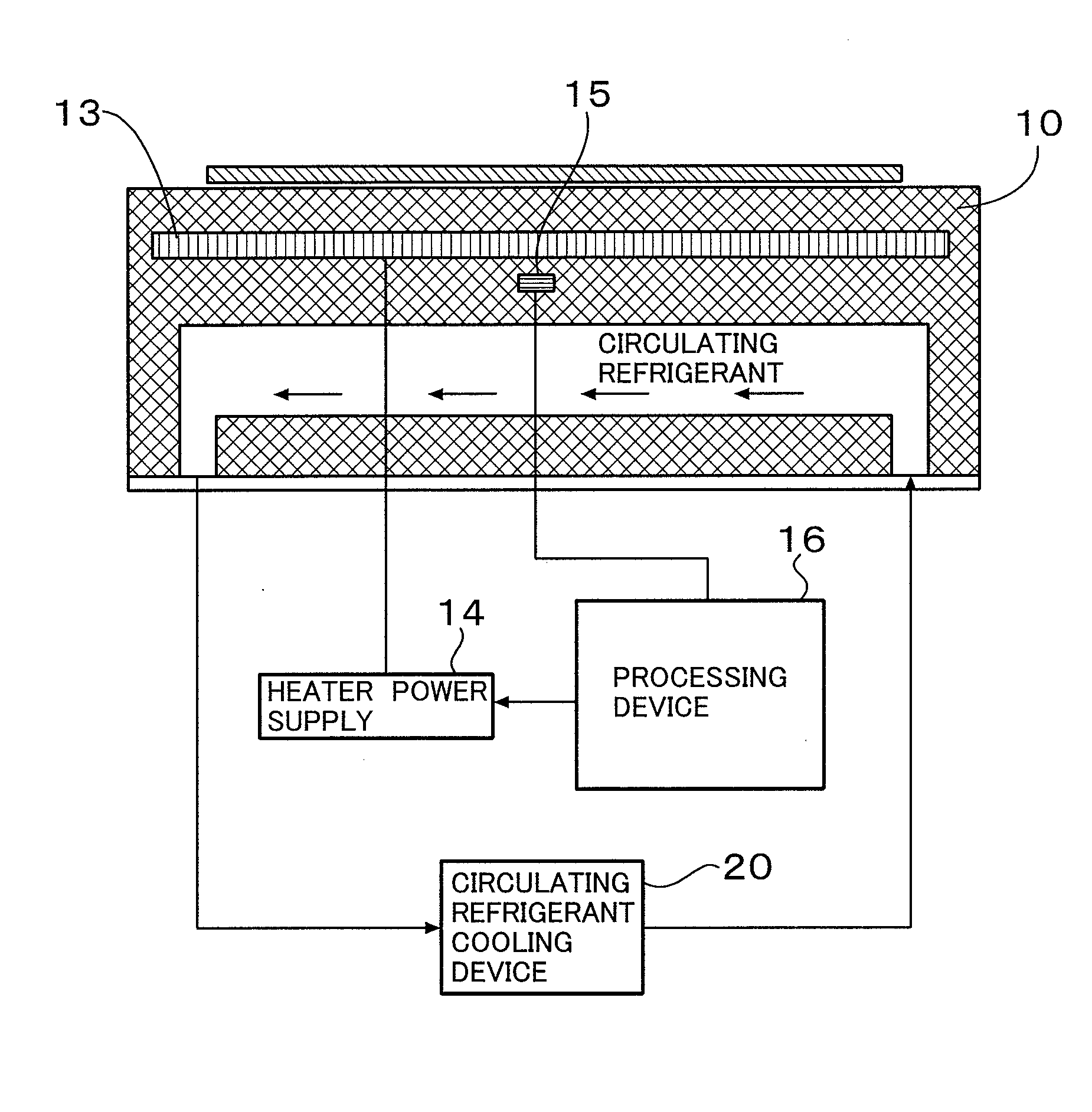

[0037]Furthermore, a wafer 11 to be etched is placed on a sample stage 10 connected to a high frequency power supply. By applying an electric power to the sample stage from the high frequency power supply via a matching box, it is possible to generate a negative bias voltage in the wafer. The sam...

embodiment 2

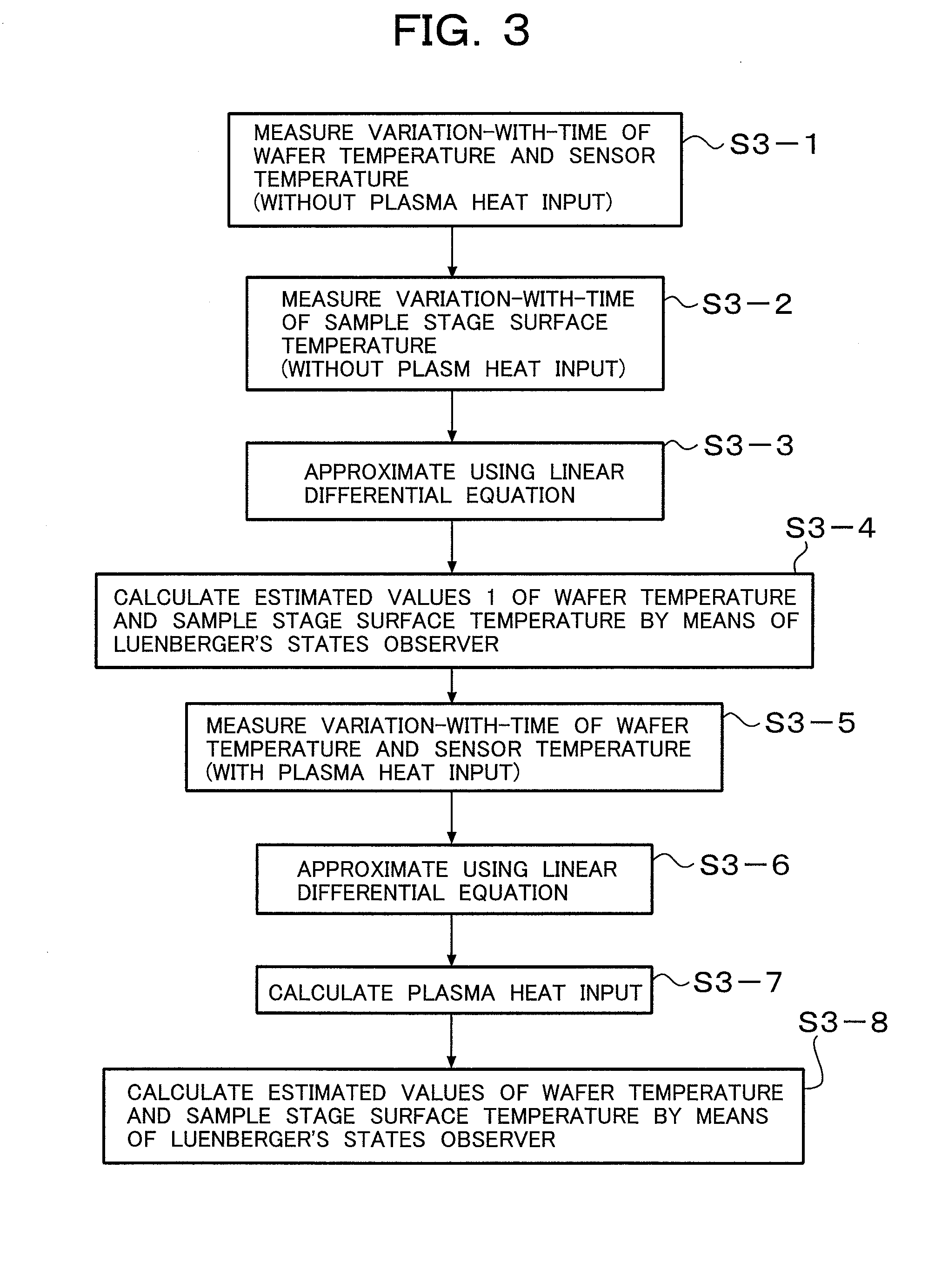

[0052]With reference to the etching apparatus shown in FIG. 6, the method of performing a second wafer temperature estimation control is described according to the procedure in FIG. 2.

[0053]First, at step S2-1, the variation-with-time of wafer temperature x1 and sensor temperature y1 of each of the center, middle, and edge regions are measured the same as at step S1-1 in the embodiment 1. At step S2-2, heater electric power u1 is incrementally increased in exactly the same time sequence as at step S2-1, and the variation of sample stage temperature x3 is measured with a radiation thermometer shown in FIG. 6. At step S2-3, the relation among heater electric power u1, wafer temperature x1, sensor temperature y1, and sample stage temperature x3, which were measured at steps S2-1 and S2-2, is approximated using equation (5). Specifically, the value of a constant matrix A11 to A33, B11 to B31 is determined using the method of least squares.

Equation5t[y1x2x3]=[A11A12A13A21A22A23A31A32A33]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com