Synchronous pulley drilling machine used for manufacturing synchronous pulleys

A technology of synchronous pulley and drilling machine, which is applied in the direction of boring/drilling, drilling/drilling equipment, parts of boring machine/drilling machine, etc. It can solve the problems of high waste products and increase the production cost of synchronous pulleys, and achieve The overall structure is simple, the cost is low, and the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

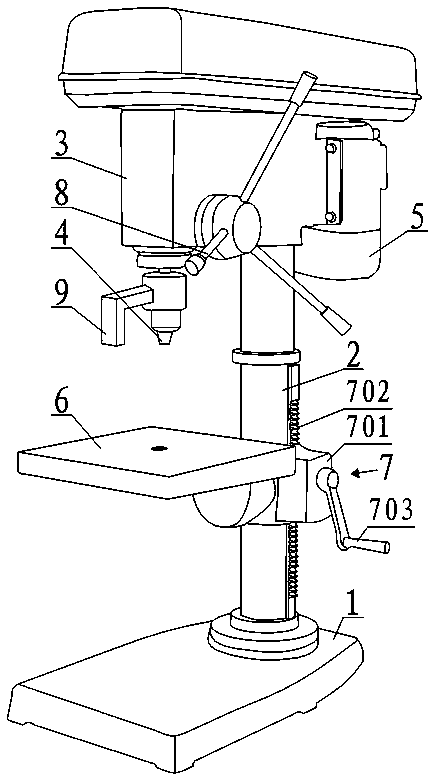

[0018] Such as figure 1 As shown, the drilling machine for synchronous pulleys when producing synchronous pulleys includes a base 1, a column 2, a positioning seat 3, a drill bit 4, a workbench 6 and a drive motor 5, wherein the column 2 is arranged on the base 1, Both the positioning seat 3 and the worktable 6 are connected to the column 2, and the workbench 6 is located below the positioning seat 3. The positioning seat 3 is provided with a drill bit lifting mechanism to control the rise or fall of the drill bit 4. The upper end of the drill bit 4 is connected with the drill bit lifting mechanism. The drill bit 4 is located between the positioning seat 3 and the workbench 6. The synchronous pulley positioning hole, the drive motor 5 is fixed on the positioning seat 3 and is used to drive the drill bit 4 to rotate.

[0019] The drill lifting mechanism comprises the first gear, the first handle 8, the first rotating shaft arranged horizontally, and the first tooth bar arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com