Patents

Literature

113 results about "Strain stiffening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Strain hardening is generally defined as heating at a relatively low temperature after cold-working. During strain hardening the strenth of the metal is increased and ductility decreased. To go a step further in explaining,...

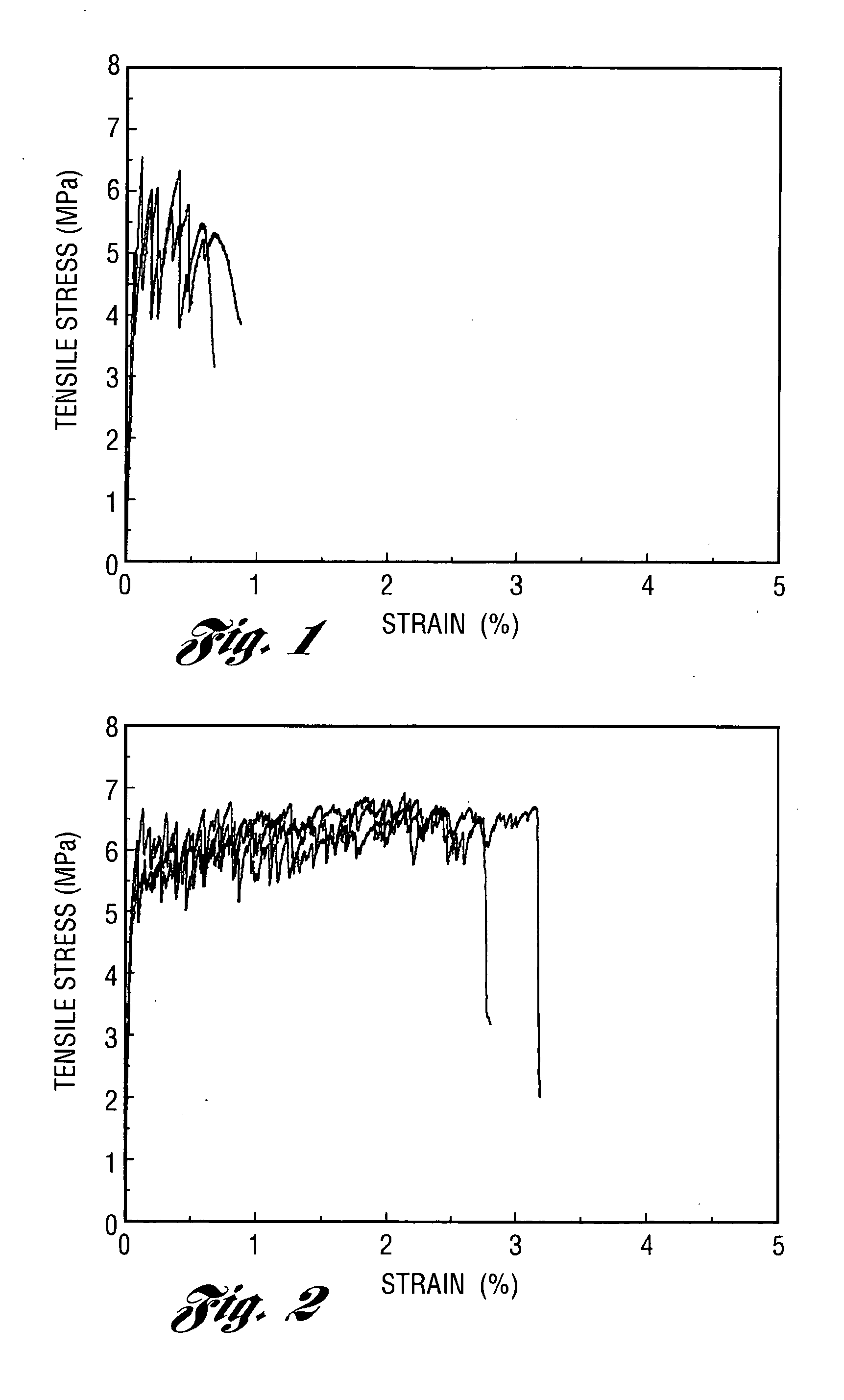

Coated optical fibers

InactiveUS20020146225A1Sufficient high cavitation strengthLow modulusGlass optical fibreSynthetic resin layered productsHigh resistanceCavitation

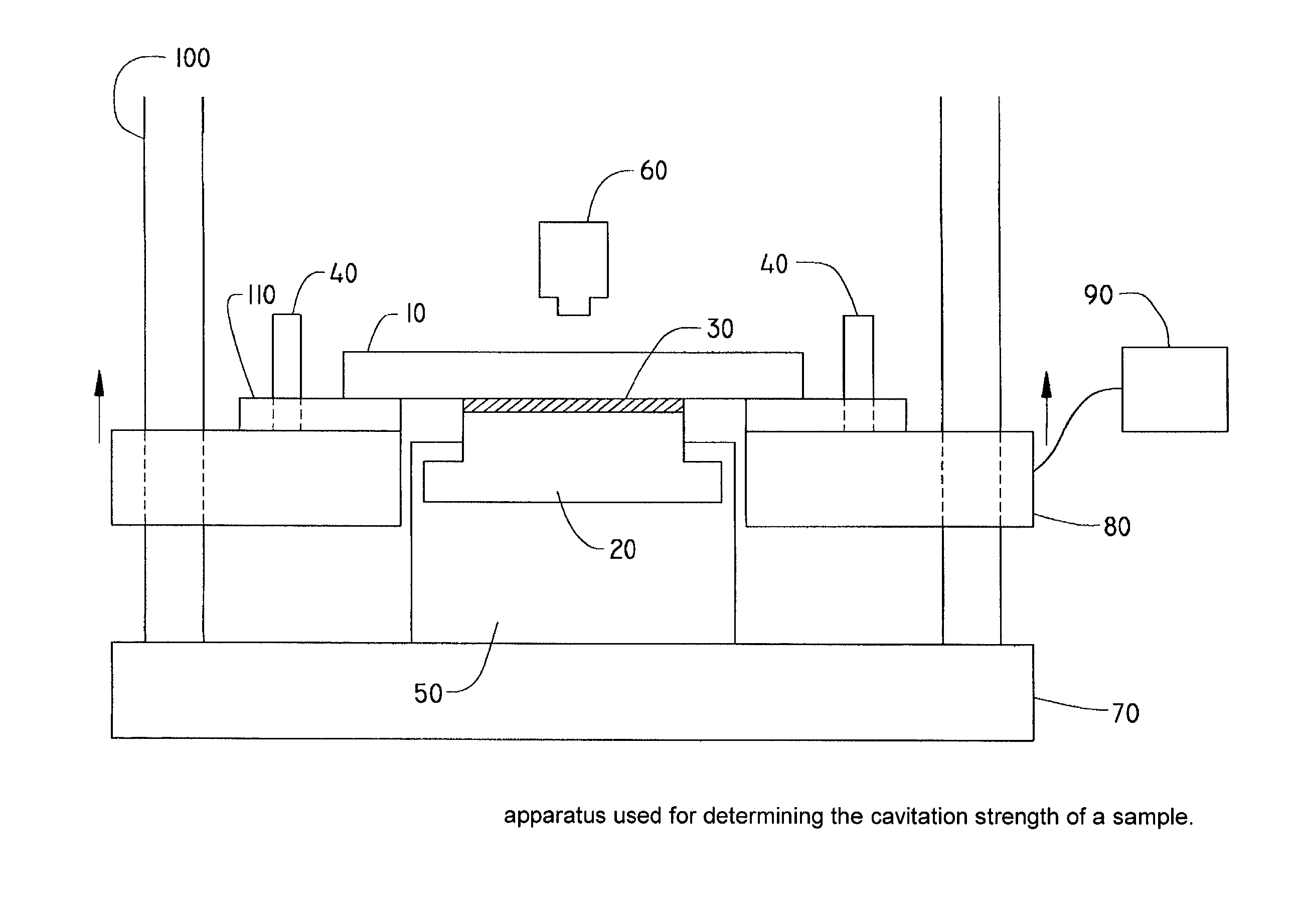

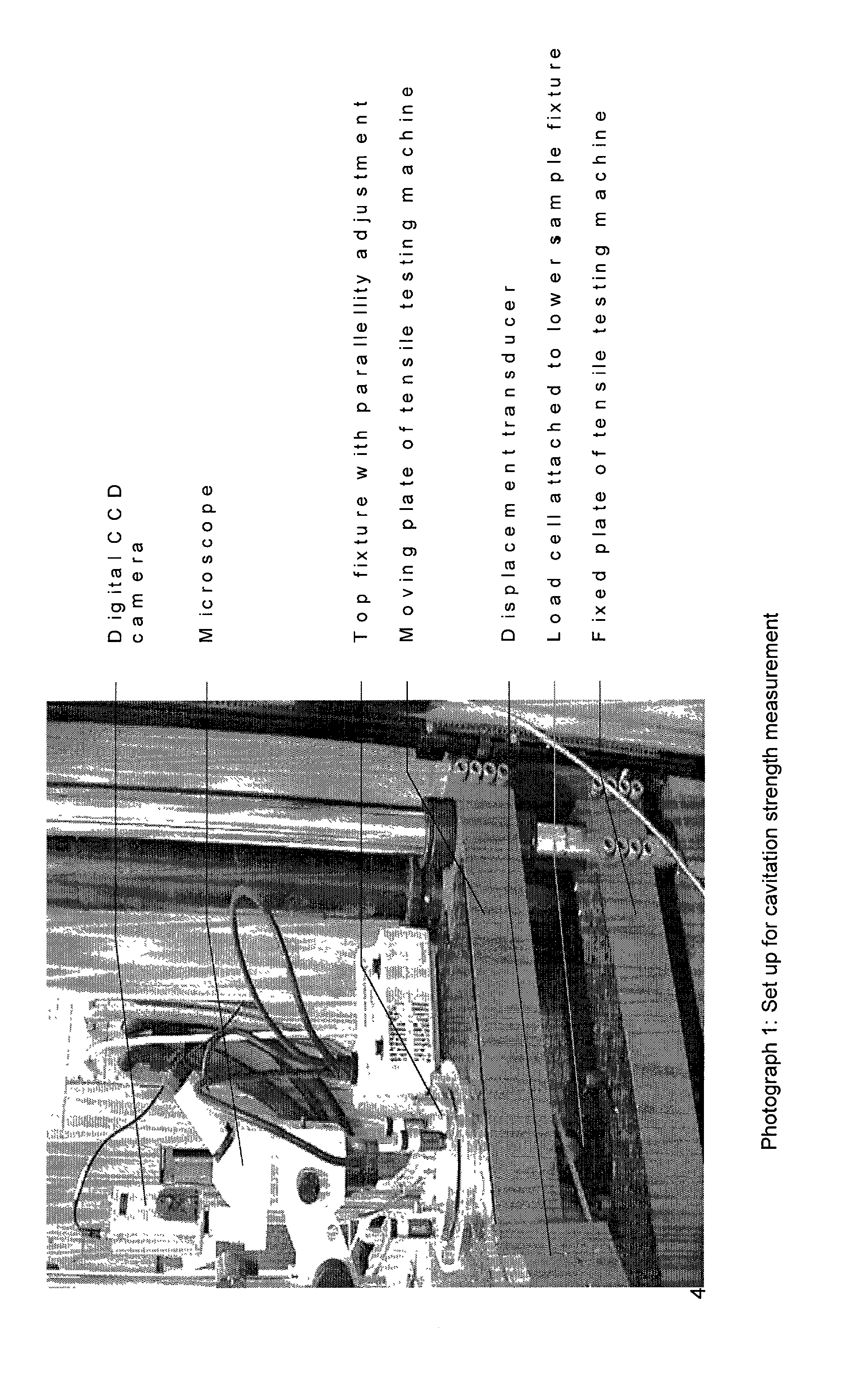

The invention relates to coated optical fibers comprising soft primary coatings and to such primary coatings for protecting glass optical fibers having a sufficient high resistance against cavitation. In particular, the primary coatings have a cavitation strength at which a tenth cavitation appears (sigma10cav) of at least about 1.0 MPa as measured at a deformation rate of 0.20% min-1 and of at least about 1.4 times their storage modulus at 23° C. The coating preferably shows strain hardening in a relative Mooney plot, preferably has a strain energy release rate Go of about 20 J / m2 or more, and preferably has a low volumetric thermal expansion coefficient. The invention furthermore provides a method and apparatus for measuring the cavitation strength of a primary coating.

Owner:DSM IP ASSETS BV

Anti-large-deformation pipe line steel prepared by thermal treatment method and preparation method thereof

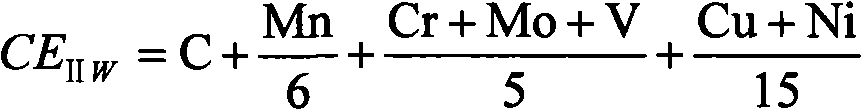

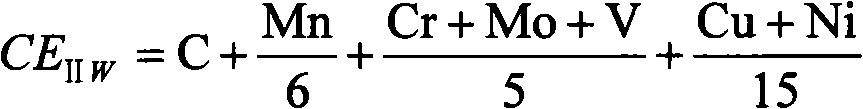

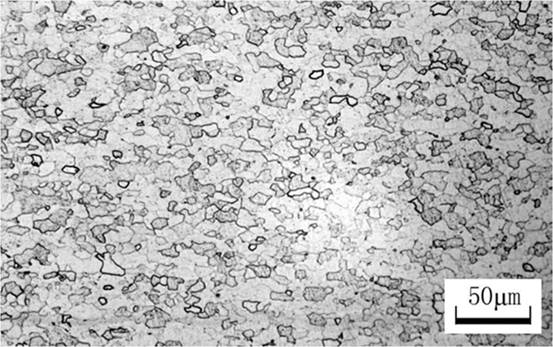

The invention discloses anti-large-deformation pipe line steel prepared by a thermal treatment method and a preparation method thereof. The steel comprises the following chemical components of: not less than 0.02% and not greater than 0.12% of C, not less than 0.5% and not greater than 2.0% of Mn, not more than 0.25% of Si, not more than 0.02% of P, not more than 0.01% of S, not more than 0.11% of Nb, not more than 0.08% of V, not more than 0.05% of Ti, not more than 0.06% of Al, not more than 0.012% of N, not more than 0.50% of Cu, not more than 0.60% of Cr, not more than 0.50% of Mo, not more than 0.60% of Ni, not more than 0.005% of B, not more than 0.01% of Ca and the balance of Fe and inevitable impurities, wherein the CEIIW is not less than 0.3% and not greater than 0.45%, and the CEPcm is not more than 0.2%. The preparation method comprises the following steps of: heating steel at 700-950 DEG C in a thermal treatment furnace, maintaining the temperature for 6-15 min, cooling with the rate of 1-400 DEG C / s to room temperature, and simultaneously tempering from room temperature to 500 DEG C to obtain steel with ferrite as a first phase and bainite, martensite, degenerate perlite or any mixture thereof as a second phase. The steel has the advantages of high tensile strength, low yield strength, low yield ratio, high uniform elongation rate and high strain hardening exponent, thereby having good toughness and deformation performance.

Owner:NANJING IRON & STEEL CO LTD

Polypropylene based resin composition, expanded moldings comprising the same and method for production thereof

ActiveUS7423071B2Good fluidityHigh in in tensionLayered productsThin material handlingPolymer scienceFoaming agent

A polypropylene-based resin composition for injection foam molding, containing (A) 50 to 95 parts by weight of a linear polypropylene-based resin having a melt flow rate of from 10 g / 10 min. to 100 g / 10 min. and a melt tension of 2 cN or less and (B) 5 to 50 parts by weight of a modified polypropylene having a melt flow rate of from 0.1 g / 10 min. to less than 10 g / 10 min. and a melt tension of 5 cN or more and exhibiting a strain hardening property (provided that a total of the resin (A) and the resin (B) is 100 parts by weight) and a foaming agent are supplied to an injection molding machine to be injected into a die, thereby achieving a foam molding. It is thus possible to obtain a injection foamed molded article which has a satisfactory injection foam moldability, a skin layer having little silver streaks or the like on its surface, and an internal core layer having a foam of high expansion ratio and uniformly fine and a excellent appearance glossiness, lightweightness, and rigidity at a low cost.

Owner:KANEKA CORP

Aircraft structural member made of an Al-Cu-Mg alloy

ActiveUS7294213B2Improve propertiesIncrease costThin material handlingMetal layered productsAlloyDissolution

The invention relates to a work-hardened product, particularly a rolled, extruded or forged product, made of an alloy with the following composition (% by weight):Cu 3.8-4.3; Mg 1.25-1.45; Mn 0.2-0.5; Zn 0.4-1.3; Fe<0.15; Si<0.15; Zr≦0.05; Ag<0.01,other elements <0.05 each and <0.15 total, remainder Al treated by dissolution, quenching and cold strain-hardening, with a permanent deformation of between 0.5% and 15%, and preferably between 1.5% and 3.5%. Cold strain-hardening can be achieved by controlled tension and / or cold transformation, for example rolling, die forging or drawing. This cladded metal plate type product is a suitable element to be used as aircraft fuselage skin.

Owner:CONSTELLIUM ISSOIRE

Strain hardening brittle matrix composites with high strength and high tensile ductility

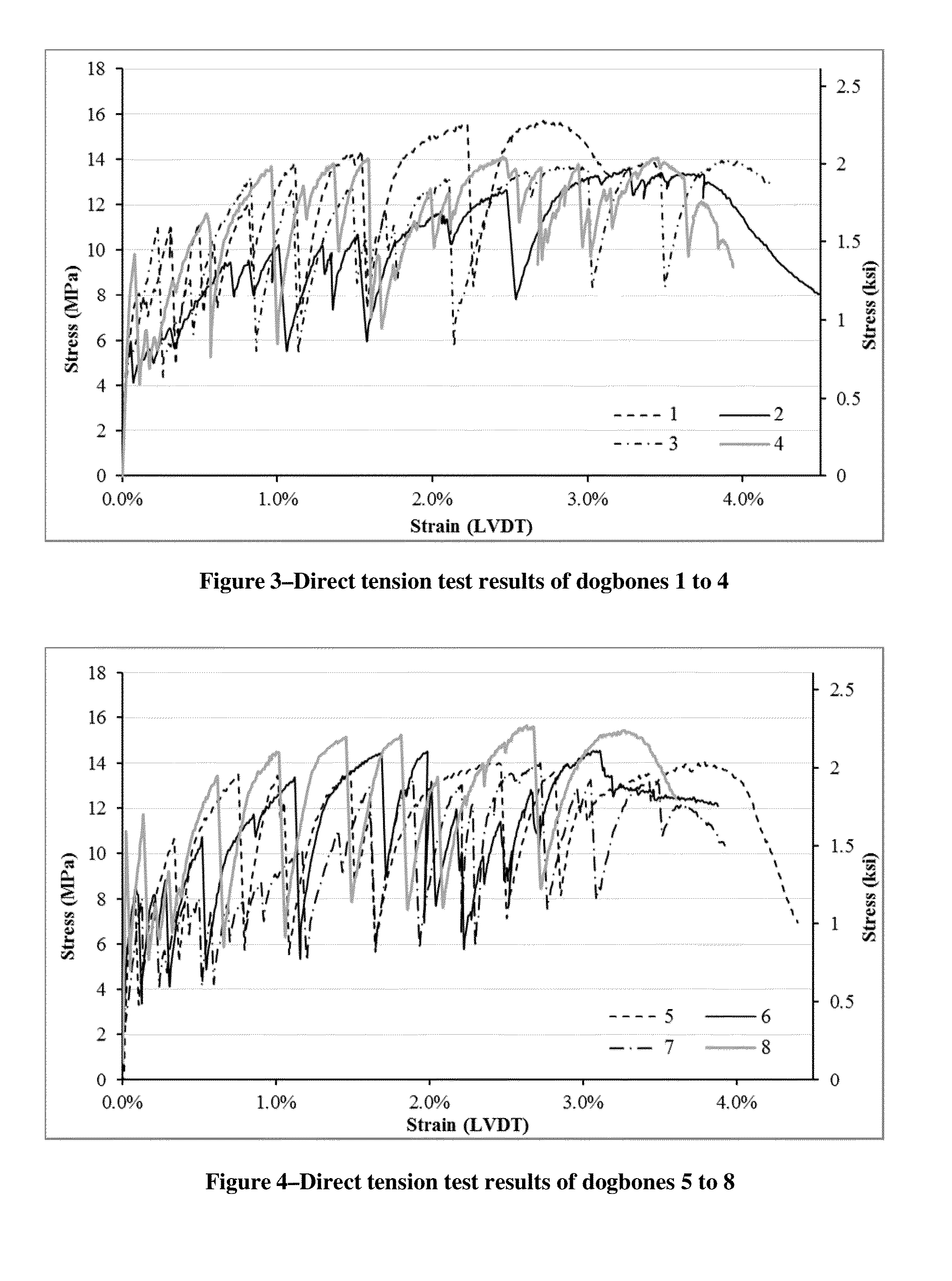

InactiveUS20130012625A1Increase deflectionEnhance load bearing and energy absorption capacitySolid waste managementPolymer scienceEnergy absorption

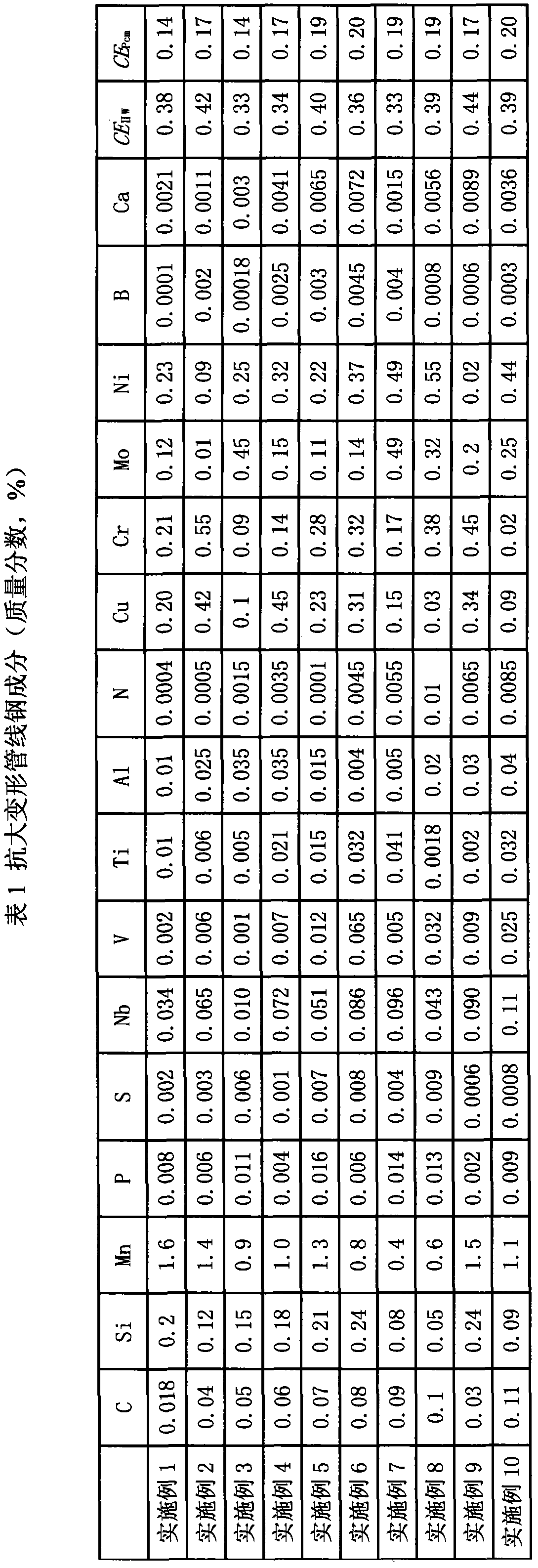

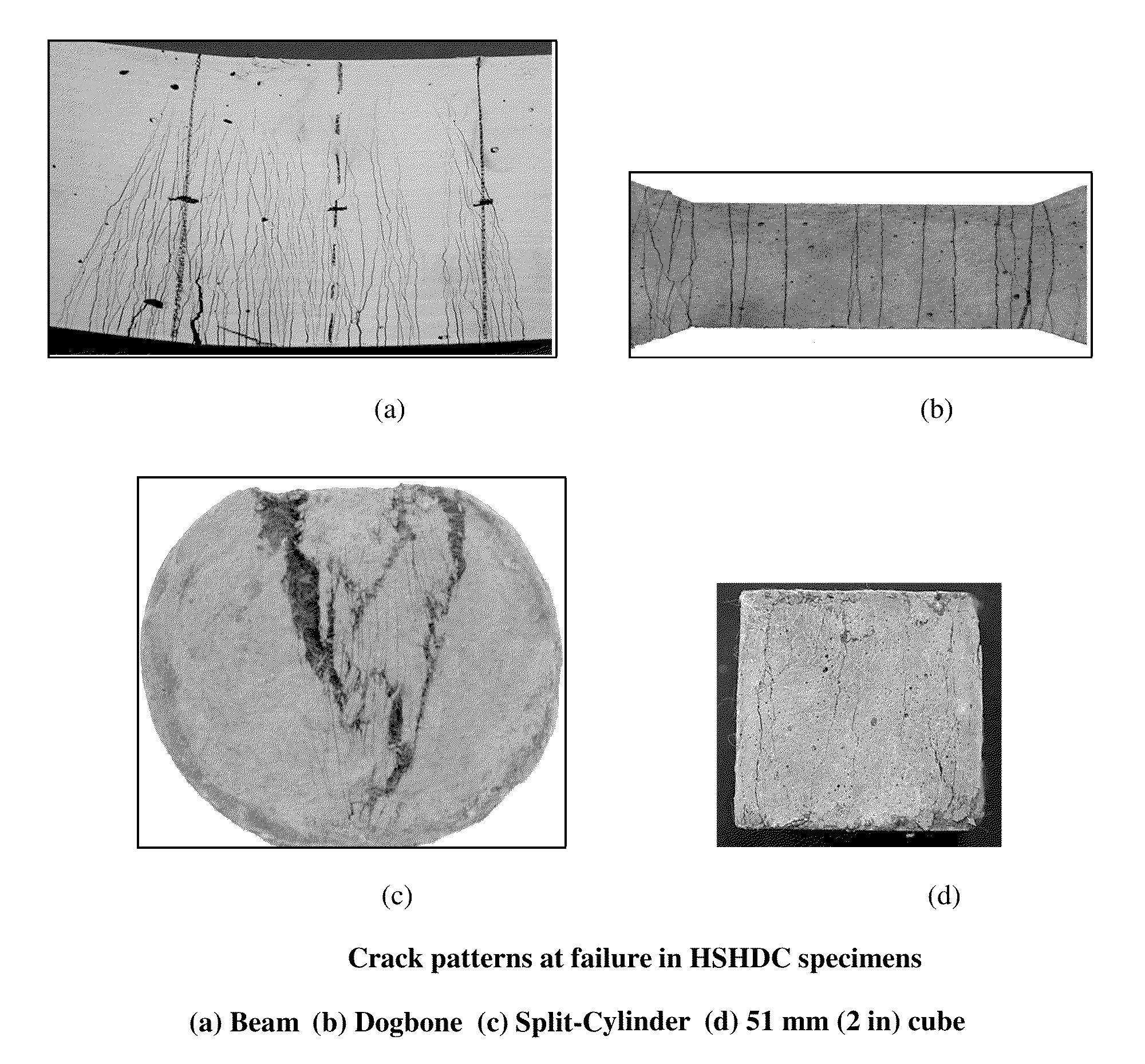

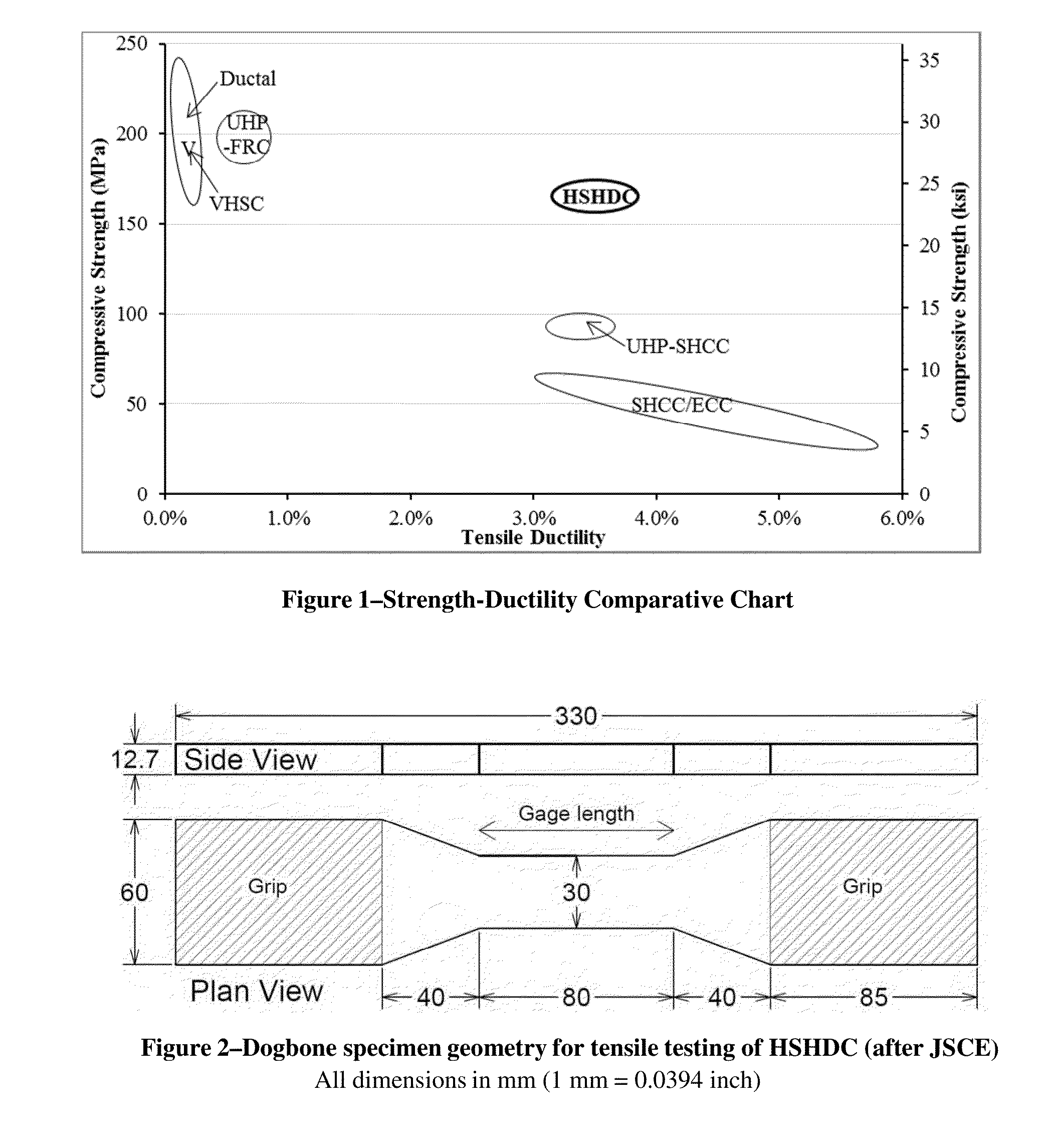

A new class of ultra-high performance concrete with very high strength and very high tensile ductility (High Strength High Ductility Concrete) is provided that represents the culmination of two high performance cement-based composite systems, namely those of very high strength, and those of very high tensile ductility into a single composite system. The integration of high strength and ductility has been attained via the adoption of micromechanical analysis and design of fiber reinforced brittle matrix composites. In doing so, the new High Strength High Ductility Concrete material dramatically increases the energy absorption capabilities of structural systems employing this material, making it a very good candidate material where hurricanes, earthquake, impact and blast loads are a concern.

Owner:RGT UNIV OF MICHIGAN

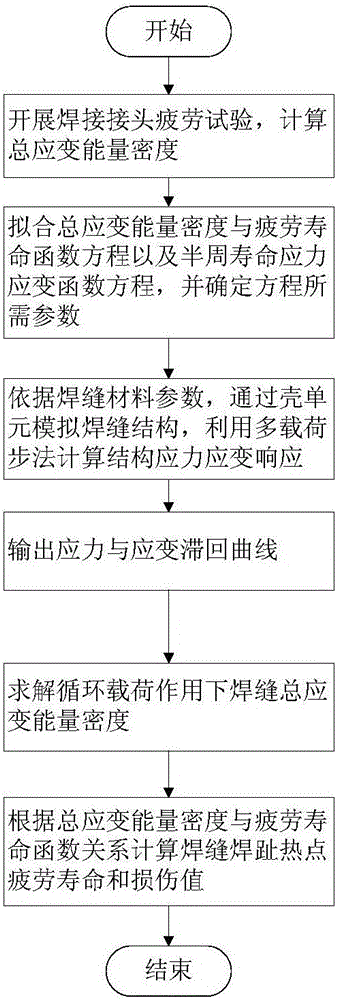

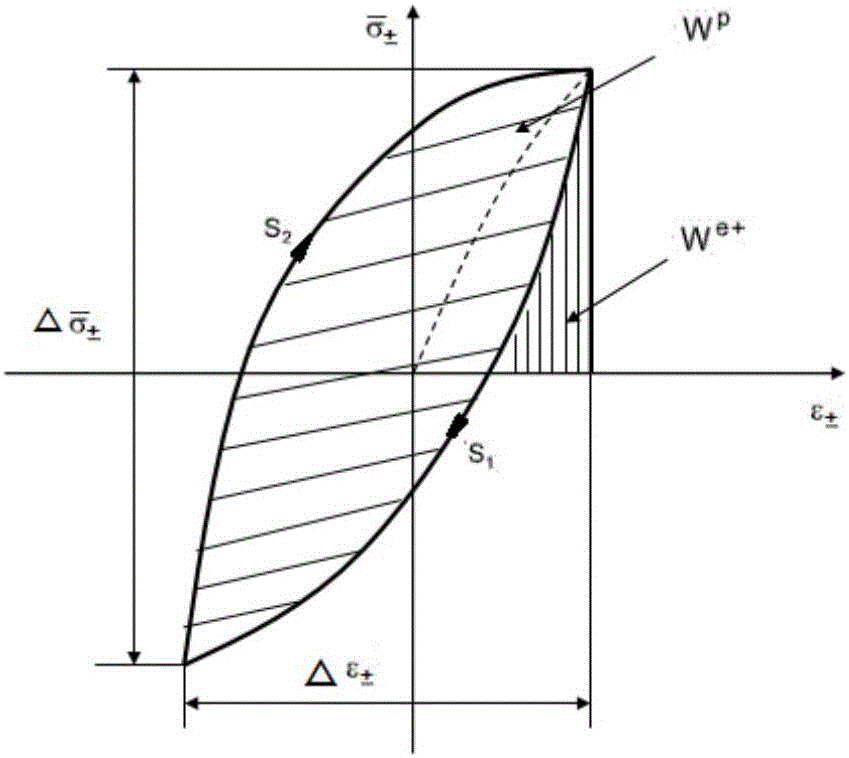

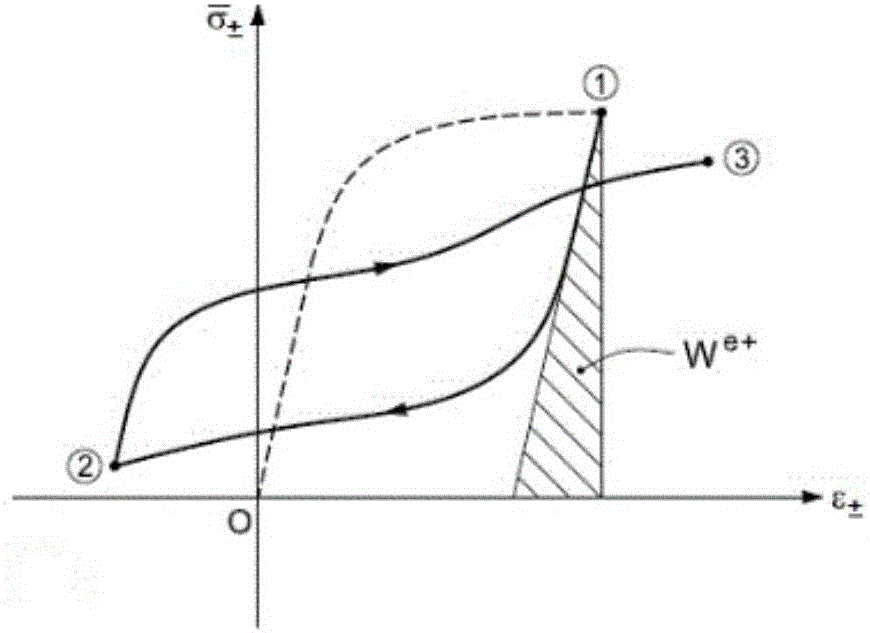

Weld seam fatigue life calculation method based on total strain energy density

ActiveCN106354898AImprove the accuracy of fatigue life calculationAvoid sureDesign optimisation/simulationSpecial data processing applicationsFatigue IntensityFatigue damage

The invention discloses a weld seam fatigue life calculation method based on total strain energy density. The method mainly comprises the steps that 1, the weld-seam total strain energy density, a life function equation and a fatigue strength coefficient, a fatigue strength index, a cyclic strengthening coefficient and a cyclic strain hardening index which are needed by half-cycle life stress and a strain function equation are acquired through a welded joint fatigue test; 2, the weld seam structure is simulated through a shell unit module, the stress-strain response of the weld seam structure under the cyclic load action is calculated through a multi-load step method, and a stress-strain hysteretic curve is output; 3, the total strain energy density is calculated according to the stress-strain response, and the hot point fatigue life and a damage value of a weld toe of the weld seam are calculated by combining the energy density with the life function equation. According to the method, contribution of elastic-plastic stress and strain to the fatigue damage is comprehensively taken into account, scalar quantities are taken as damage parameters, the position and direction problems related to vectors are effectively avoided, the calculation precision is improved, and the time is saved.

Owner:HUNAN UNIV OF TECH

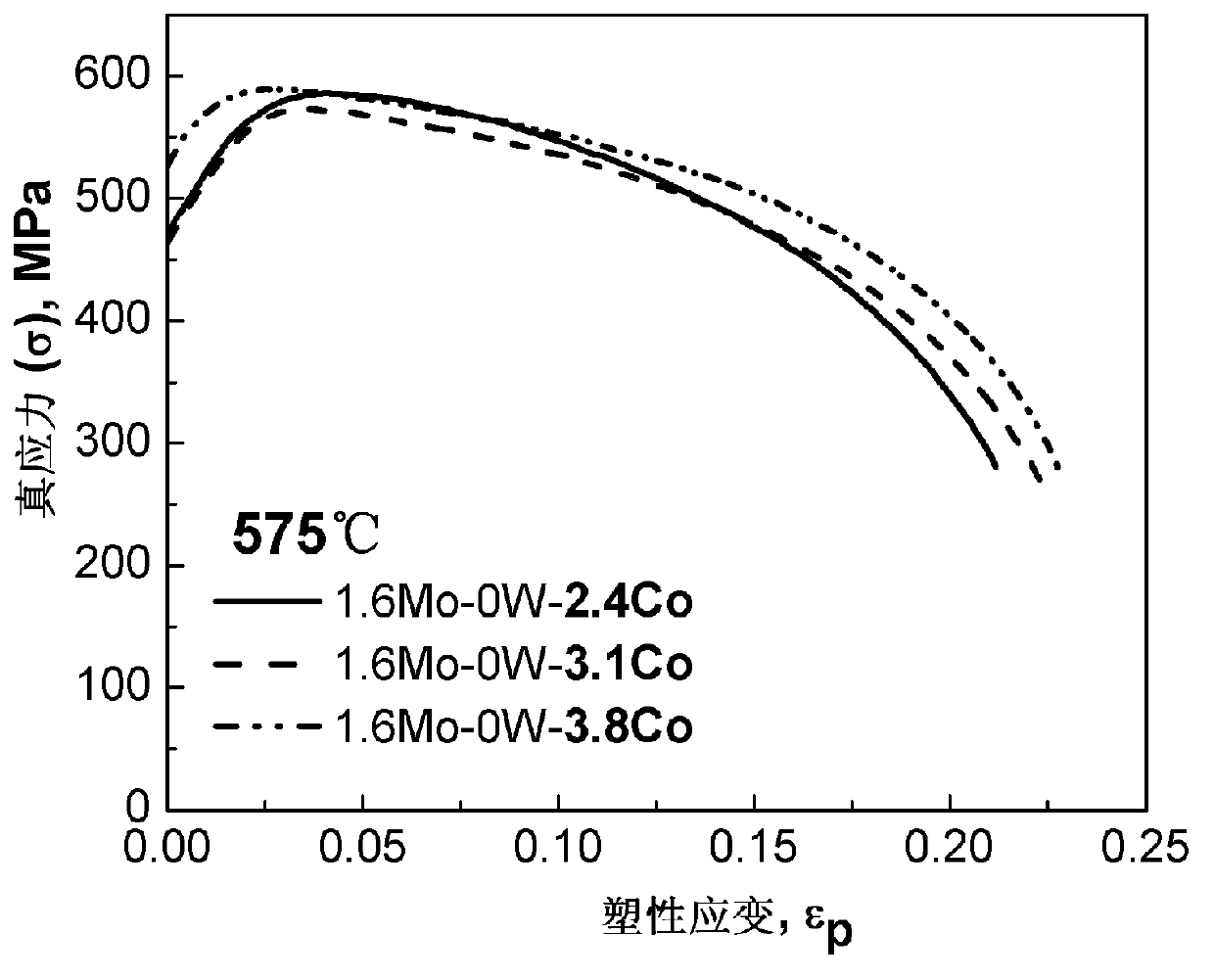

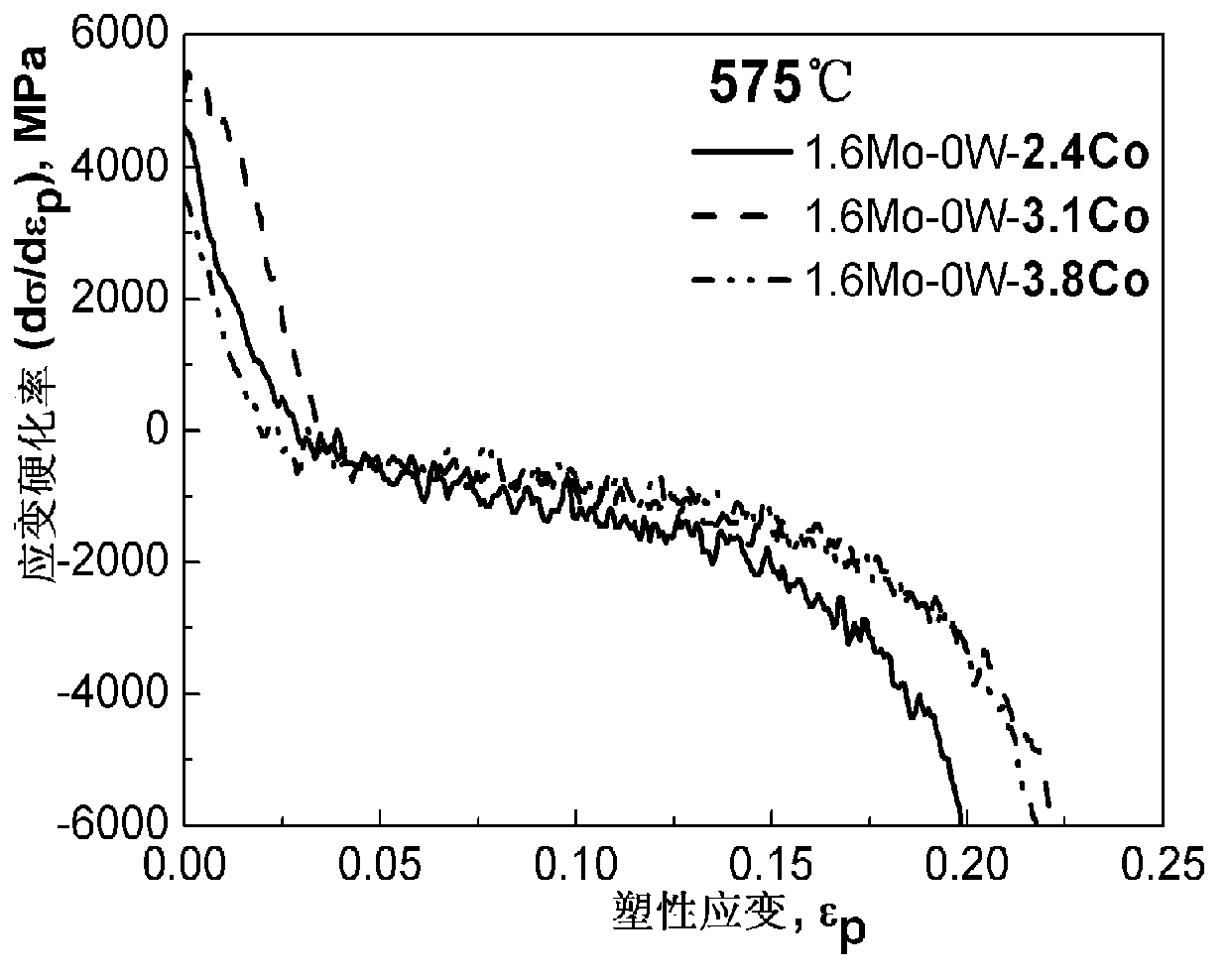

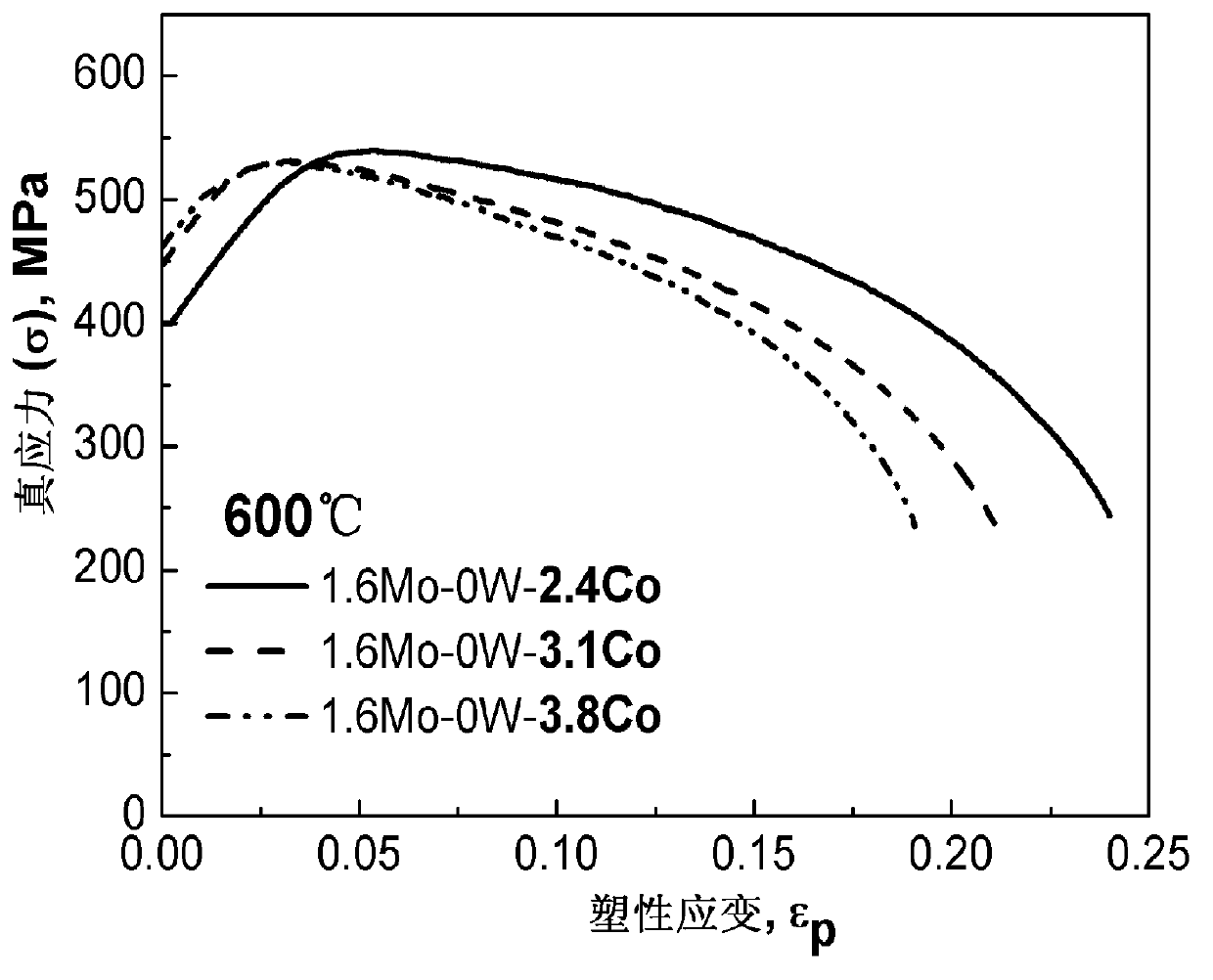

Method for predicting high-temperature creep property of heat resistant steel

InactiveCN103105335AEasy to analyzeEasy to operateMaterial strength using tensile/compressive forcesAdditive ingredientAlloy

The invention provides a method for predicting high-temperature and long-term creep property of heat resistant steel, and is particularly suitable for prediction of the high-temperature and long-term creep property of 9-12% of Cr ferrite heat resistant steel. Strain hardening and strain softening behaviors of the materials in a high-temperature stretching process are obtained by a constant slow-speed and high-temperature tensile testing method at the strain rate which is smaller than or equal to 10-5S-1, so as to represent dislocation creep and predict the creep deformation behavior which is the same as the deformation mechanism. Thus, the long-term creep property of the material is estimated in advance. Compared with a creep test, the method is simple to operate, short in test period and high in efficiency, and can be used for primarily screening alloy ingredients when a new steel variety of the 9-12% of Cr ferrite heat resistant steel is designed. Compared with the traditional creep test assessment method, the design cycle of alloy is greatly shortened; and the development cost of the alloy is saved.

Owner:WUXI TURBINE BLADE

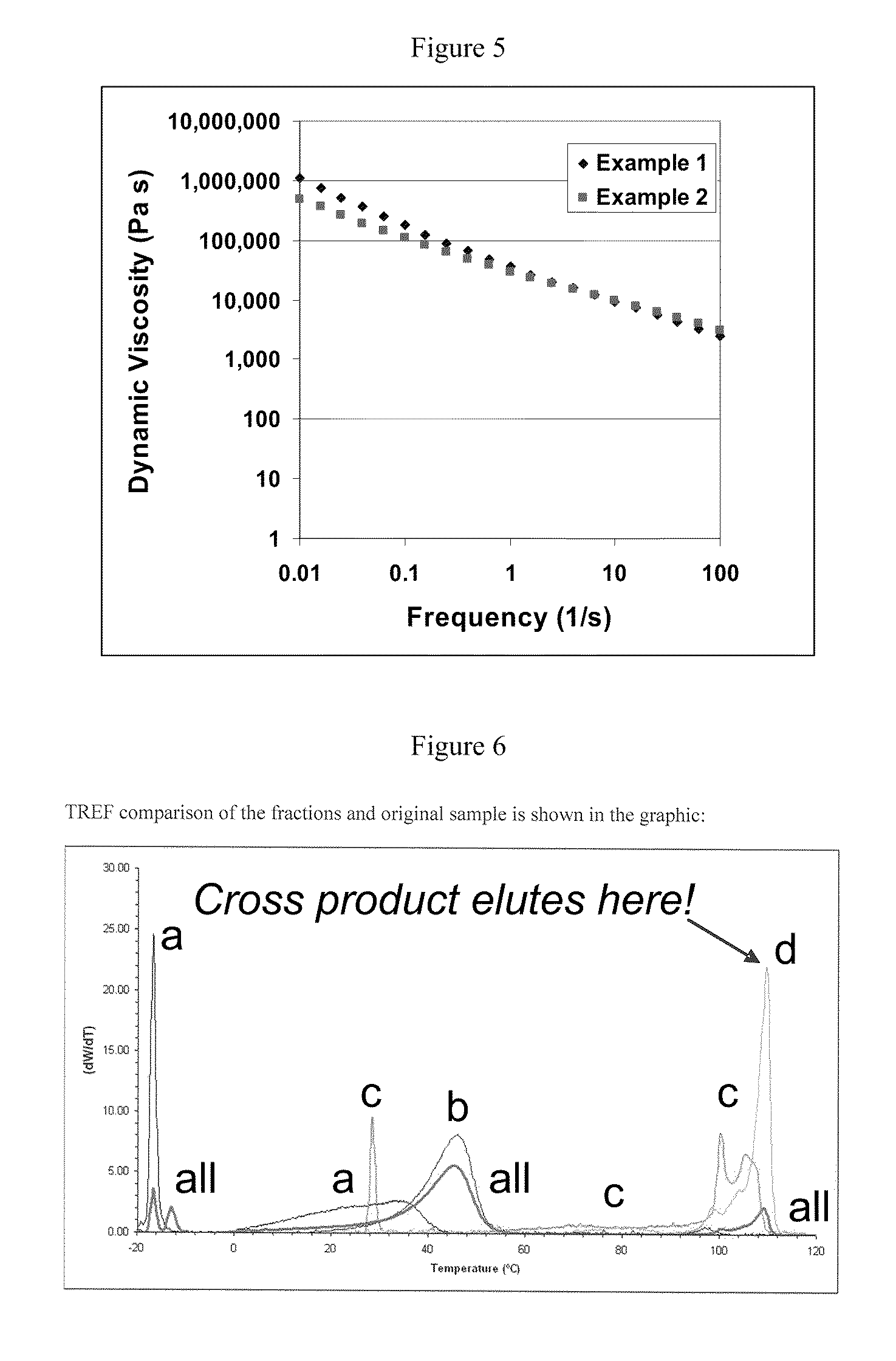

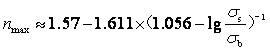

High Melt Strength Thermoplastic Elastomer Composition

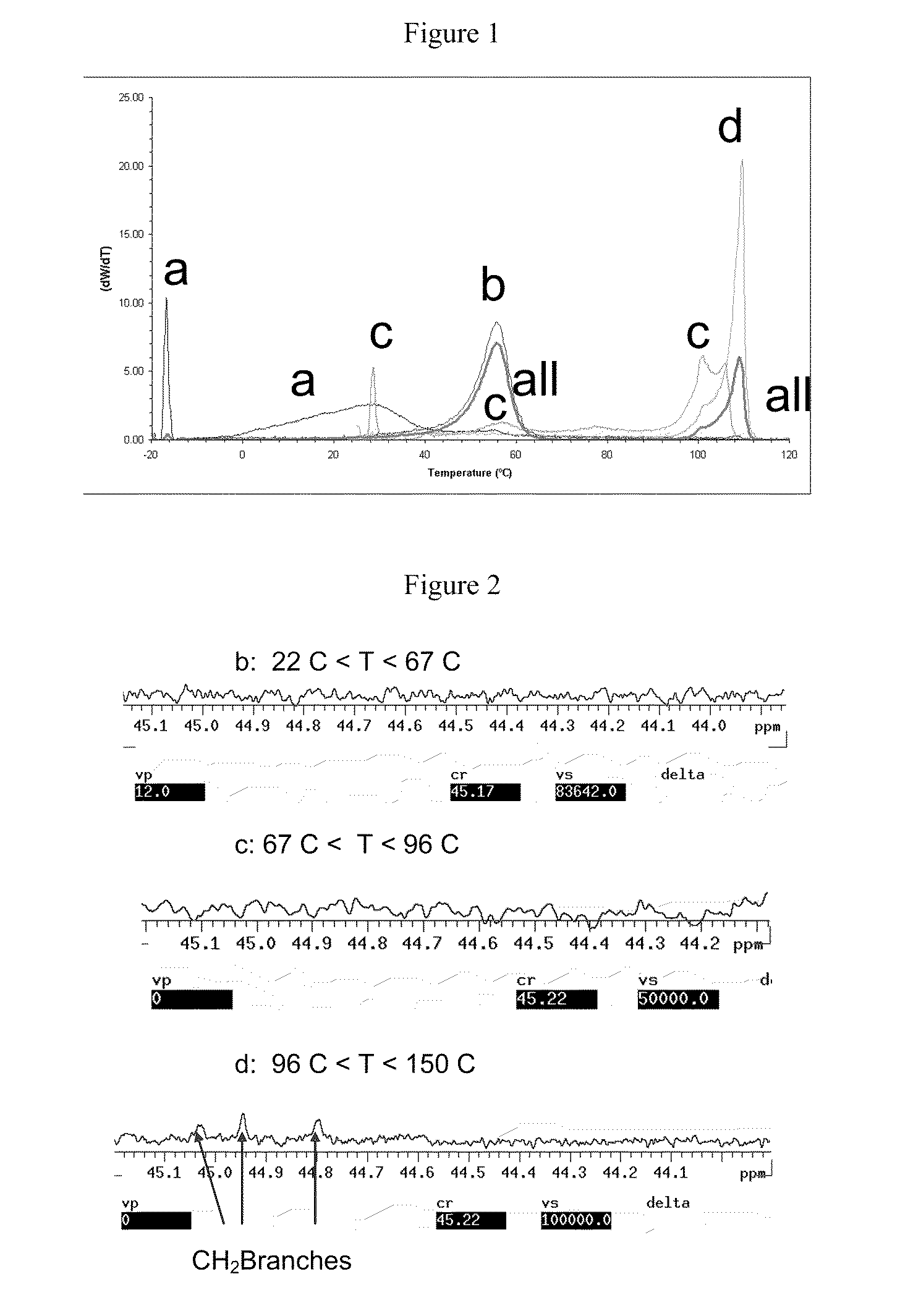

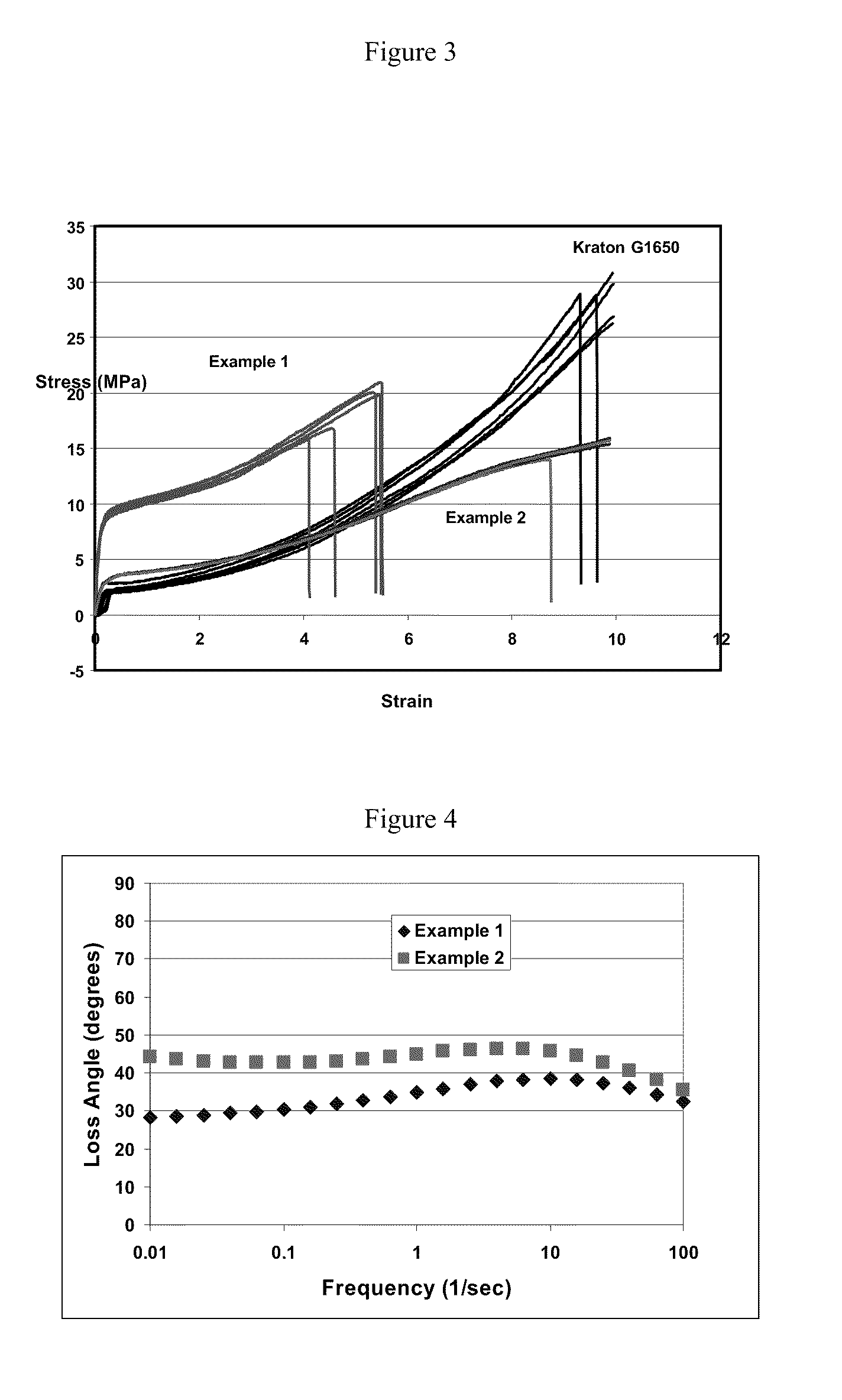

A high melt strength thermoplastic elastomer composition, comprising:(i) at least one linear crystalline polyolefin, having a melting temperature (Tm) of at least 100° C. and a Polydispersity Index (PI) of more than 20, determined by means of an isothermal dynamic frequency sweep at 190° C. and calculated by means of the equation PI=100,000 / Gc, wherein Gc is expressed in Pascal and represents the crossover modulus (Gc=G′=G″) and(ii) at least one thermoplastic elastomer (TPE) or a blend behaving as TPE, wherein the TPE or the blend are compatible with the polyolefin (i), and have a compression set below 50% at ambient temperature after 24 h compression (ASTM D395-03, “Compression Set under constant deflection in air”), wherein the amount of component (i) is in the range of 0.1 to 15 wt % calculated on the whole of (i) and (ii); a premix (iii) useful as a homogeneous melt strain hardening additive for the preparation of this composition; a process for the preparation of shaped polymeric articles thereof, and shaped polymeric articles so prepared.

Owner:KRATON POLYMERS US LLC

Process for increasing the ductility of high performance fiber-reinforced brittle matrix composites, and composites produced thereby

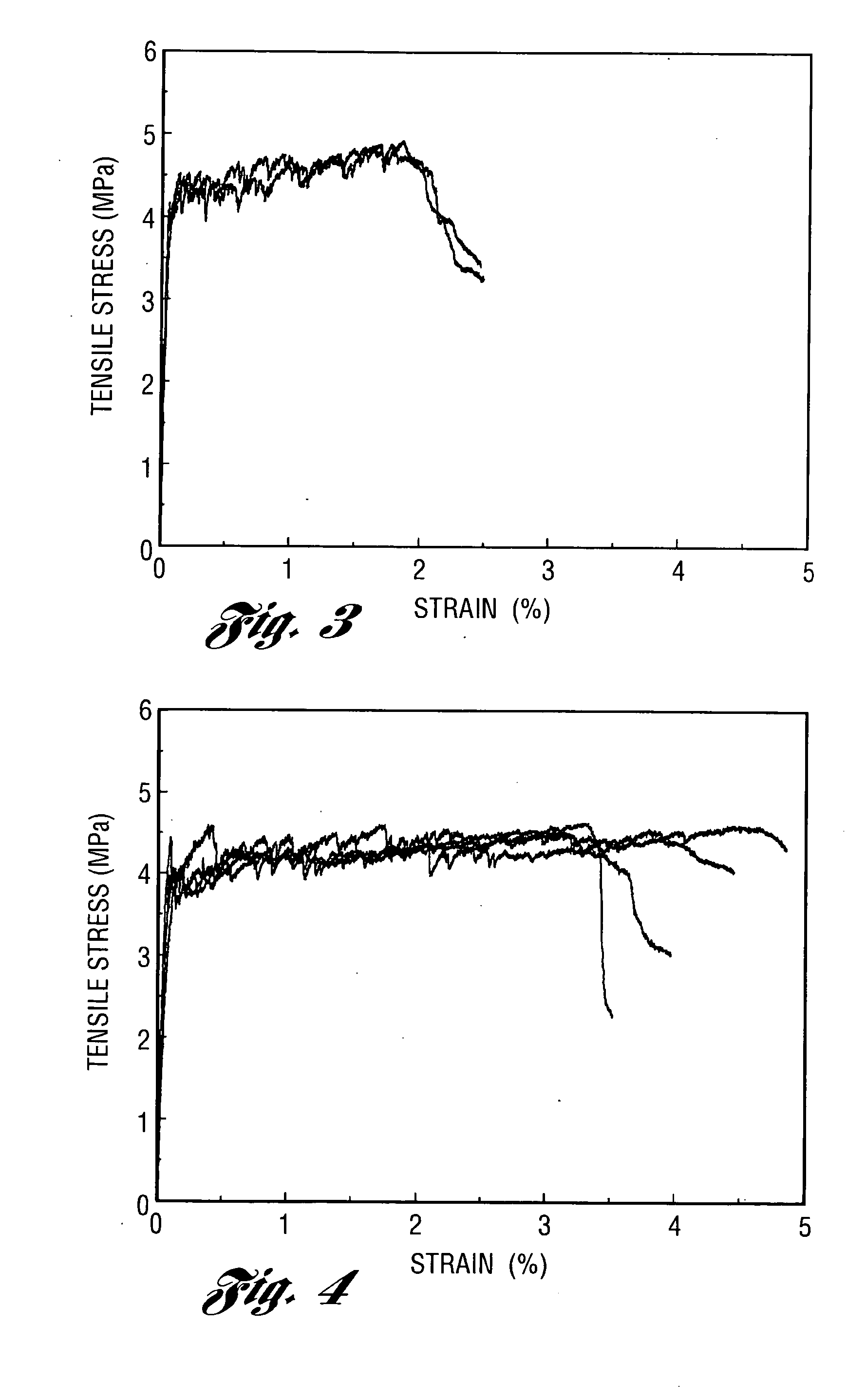

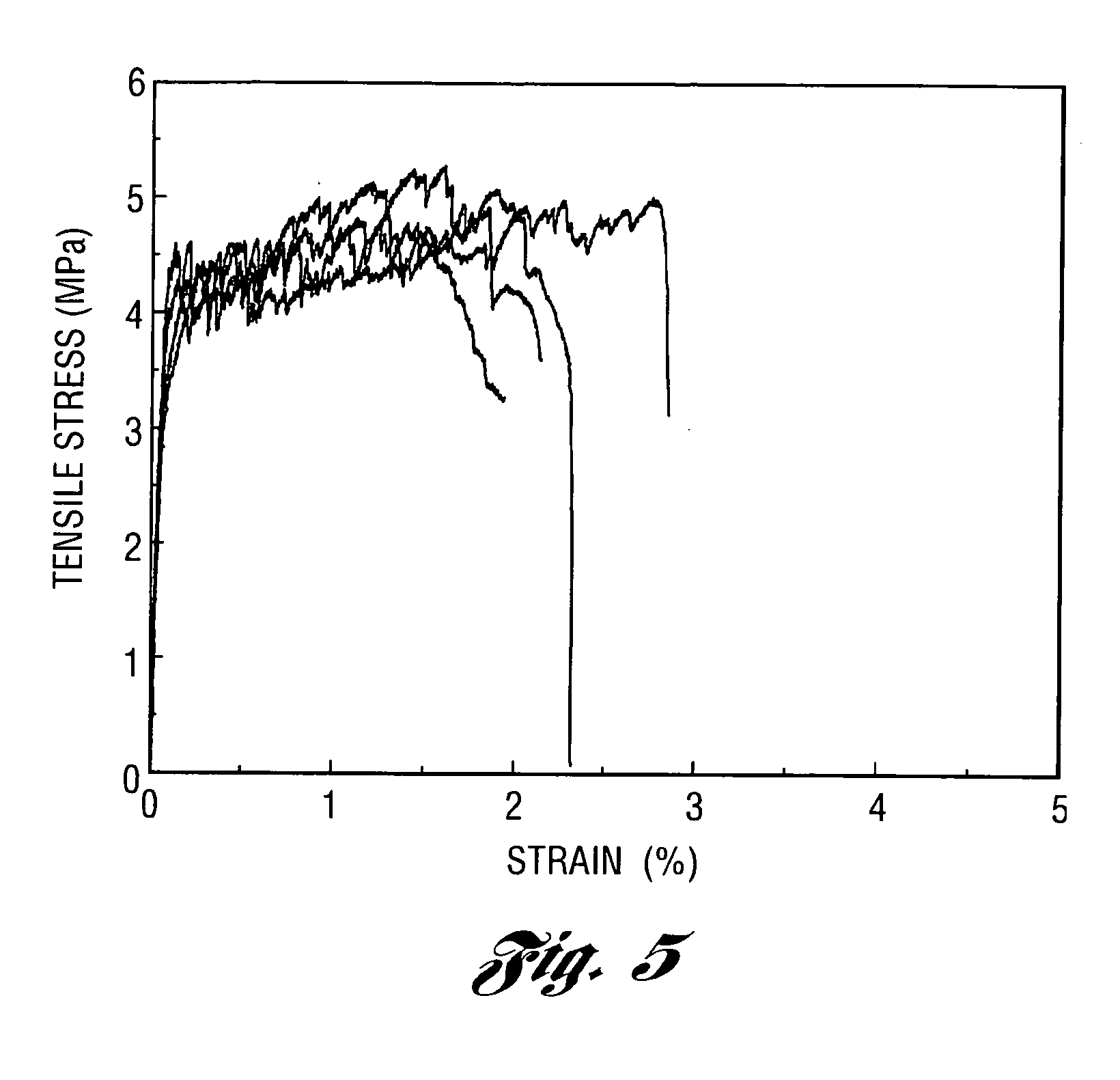

Purposeful addition of crack-initiating voids in the form of low tensile strength particulates, particulates having low matrix interaction, or gas bubbles formed by chemical reaction, in a size range of 0.5 mm to about 5 mm, and preferably of a size commensurate with or larger than naturally occurring crack-initiating gaseous voids, to fiber-reinforced strain hardening cementitious composites generates controlled and uniform cracking which increases strain hardening behavior in conventionally dense cementitious compositions.

Owner:RGT UNIV OF MICHIGAN

Heterogeneous in-reactor polymer blends

Owner:EXXONMOBIL CHEM PAT INC

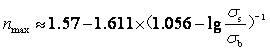

Method for determining maximum strain hardening exponent according to strength of steel-iron material

InactiveCN102628775AThe maximum strain hardening exponent obtainedLow costMaterial strength using tensile/compressive forcesUltimate tensile strengthStrain stiffening

The invention discloses a method for determining the maximum strain hardening exponent according to the strength of a steel-iron material. The method comprises the following steps of: I, deducing a formula among the yield strength, tensile strength and maximum strain hardening exponent of the steel-iron material; II, determining the yield strength and tensile strength of the steel-iron material to be detected; and III, calculating the maximum strain hardening exponent of the steel-iron material according to the formula deduced in the step I. The method has the characteristic of quick, convenient and accurate acquisition of the maximum strain hardening exponent according to the strength of the steel-iron material.

Owner:XI'AN PETROLEUM UNIVERSITY

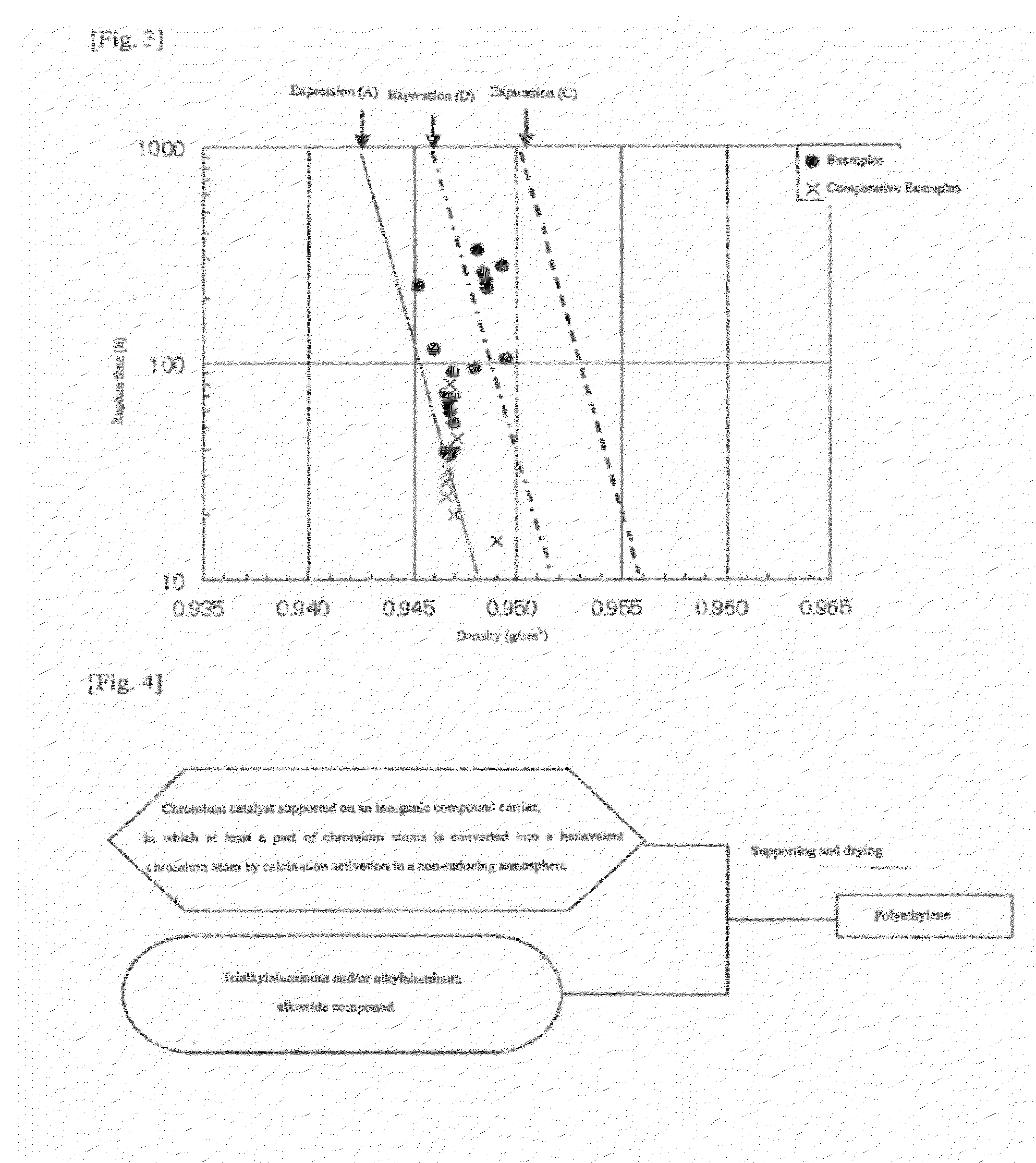

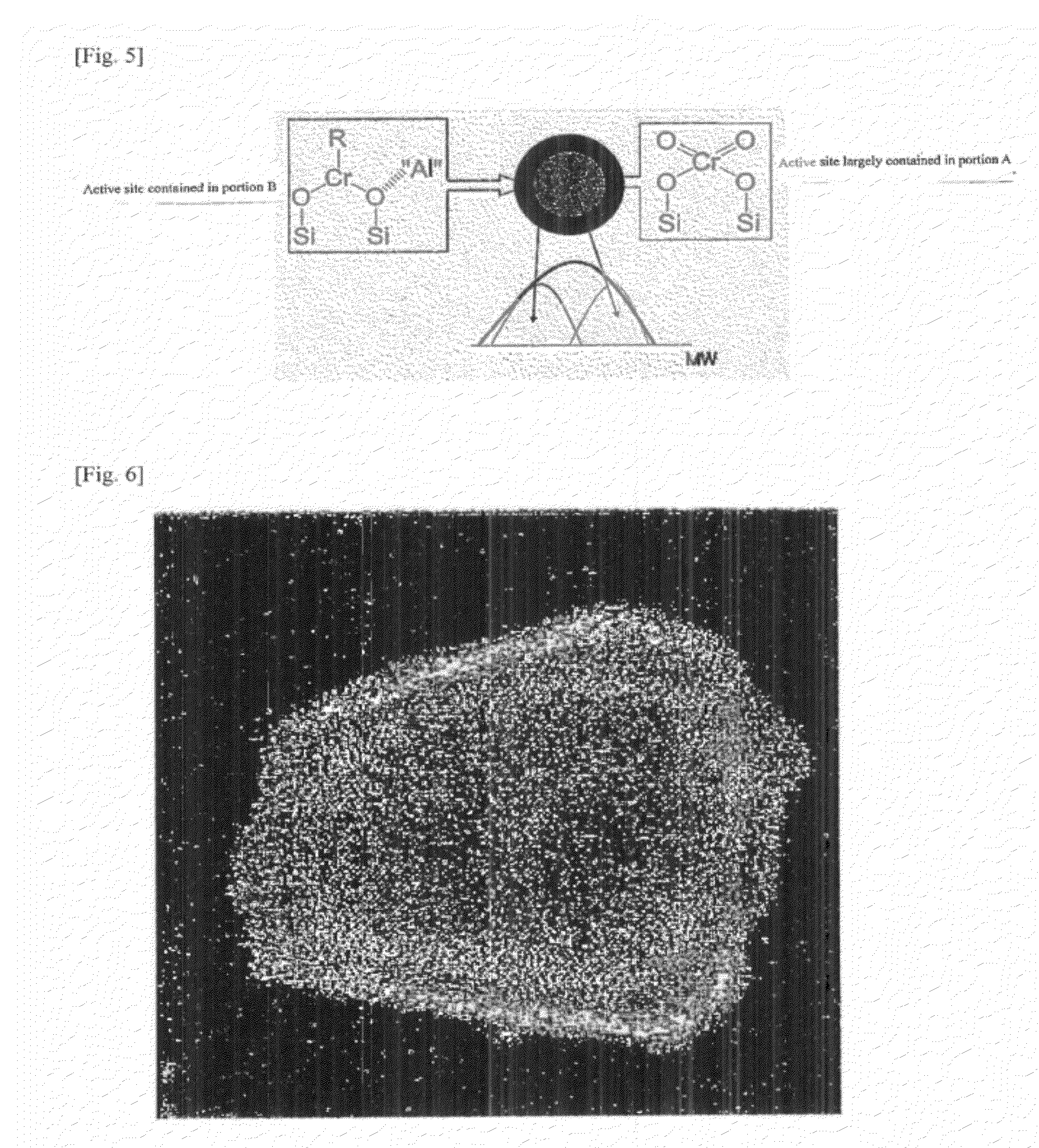

Polyethylene based resin, producing catalyst for the same, method for producing the same, hollow plastic molded article containing polyethylene based resin, and use of the same

ActiveUS20120058288A1Increased durabilityGood moldabilityLayered productsOrganic-compounds/hydrides/coordination-complexes catalystsExtensional viscosityHigh load

A polyethylene based resin exhibiting excellent moldability and durability and having an excellent balance between impact resistance and stiffness; and a hollow plastic molded article using the foregoing resin, which exhibits excellent moldability, durability and barrier properties and has an excellent balance between impact resistance and stiffness, are provided. The polyethylene based resin satisfies the following requirements (1) to (4): (1) a high-load melt flow rate (HLMFR) is from 1 to 100 g / 10 min; (2) a density is from 0.940 to 0.960 g / cm3; (3) a strain hardening parameter λmax of elongational viscosity is from 1.05 to 1.50; and (4) a rupture time in a full notch tensile creep test and a density satisfy the following relational expression (A): log (rupture time)≧−355×(density)+337.6 (A).

Owner:JAPAN POLYETHYLENE CORP

Polypropylene foam

ActiveUS20090176902A1Improved foam surface propertyHigh surface flatnessPolymer sciencePolypropylene

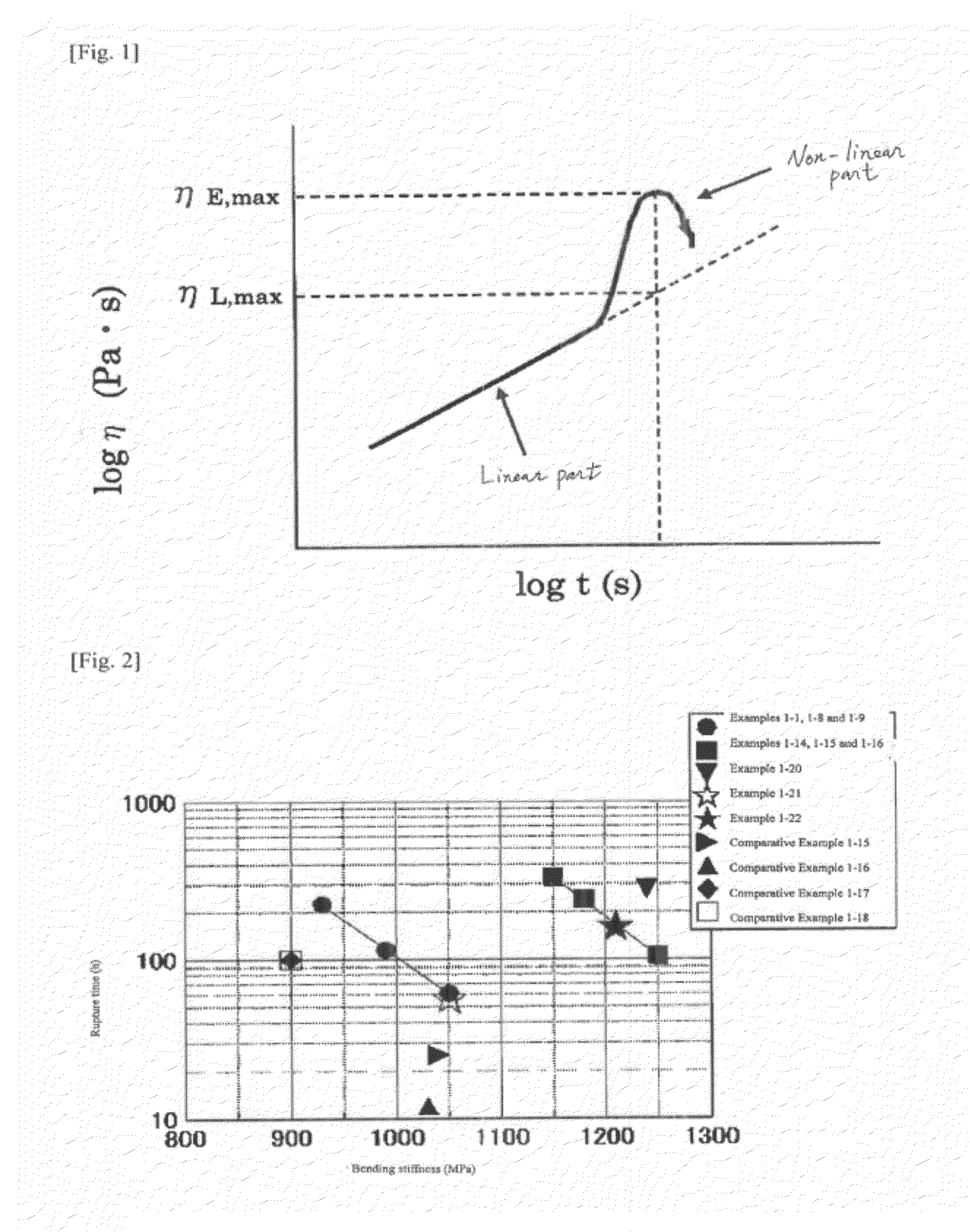

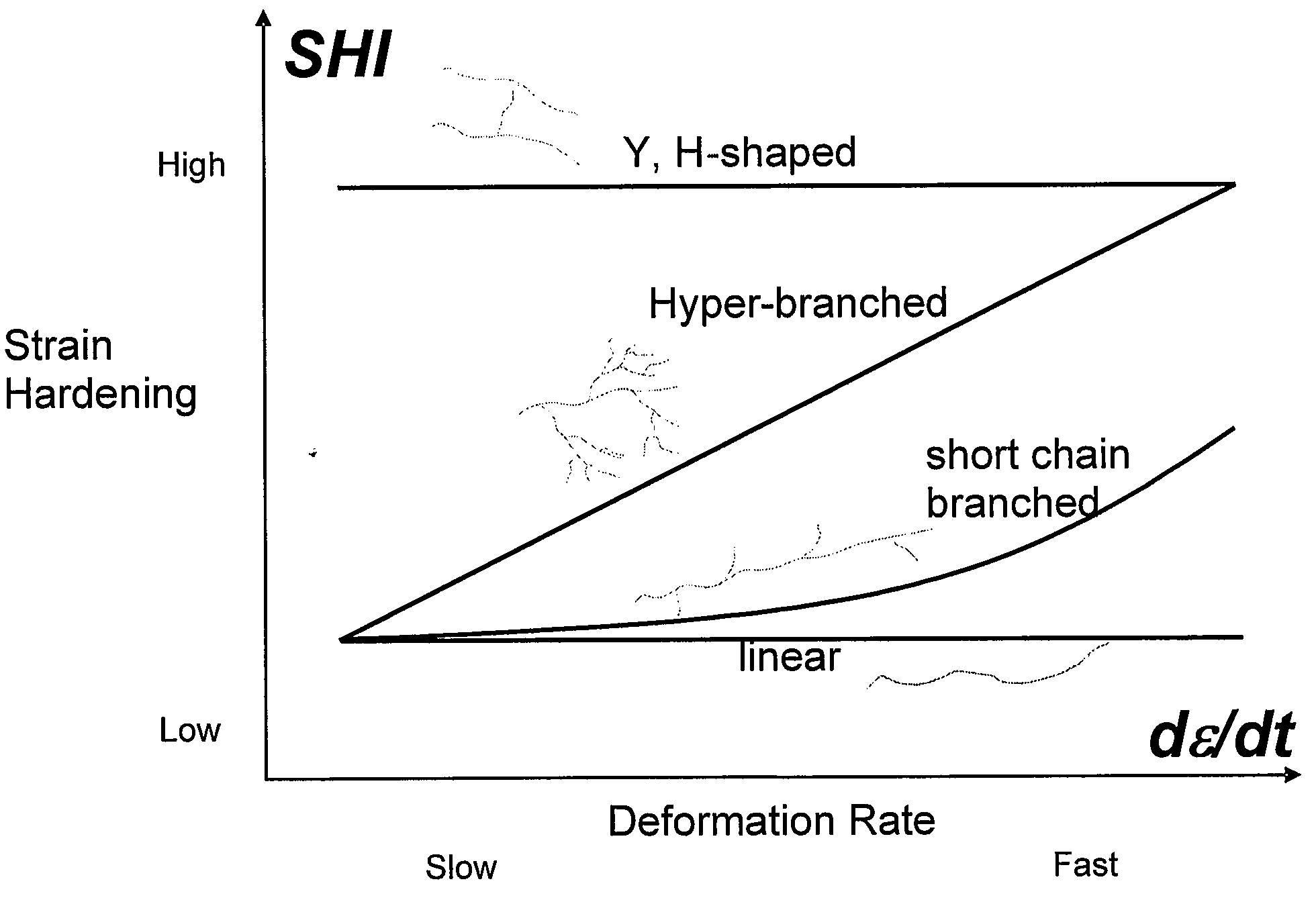

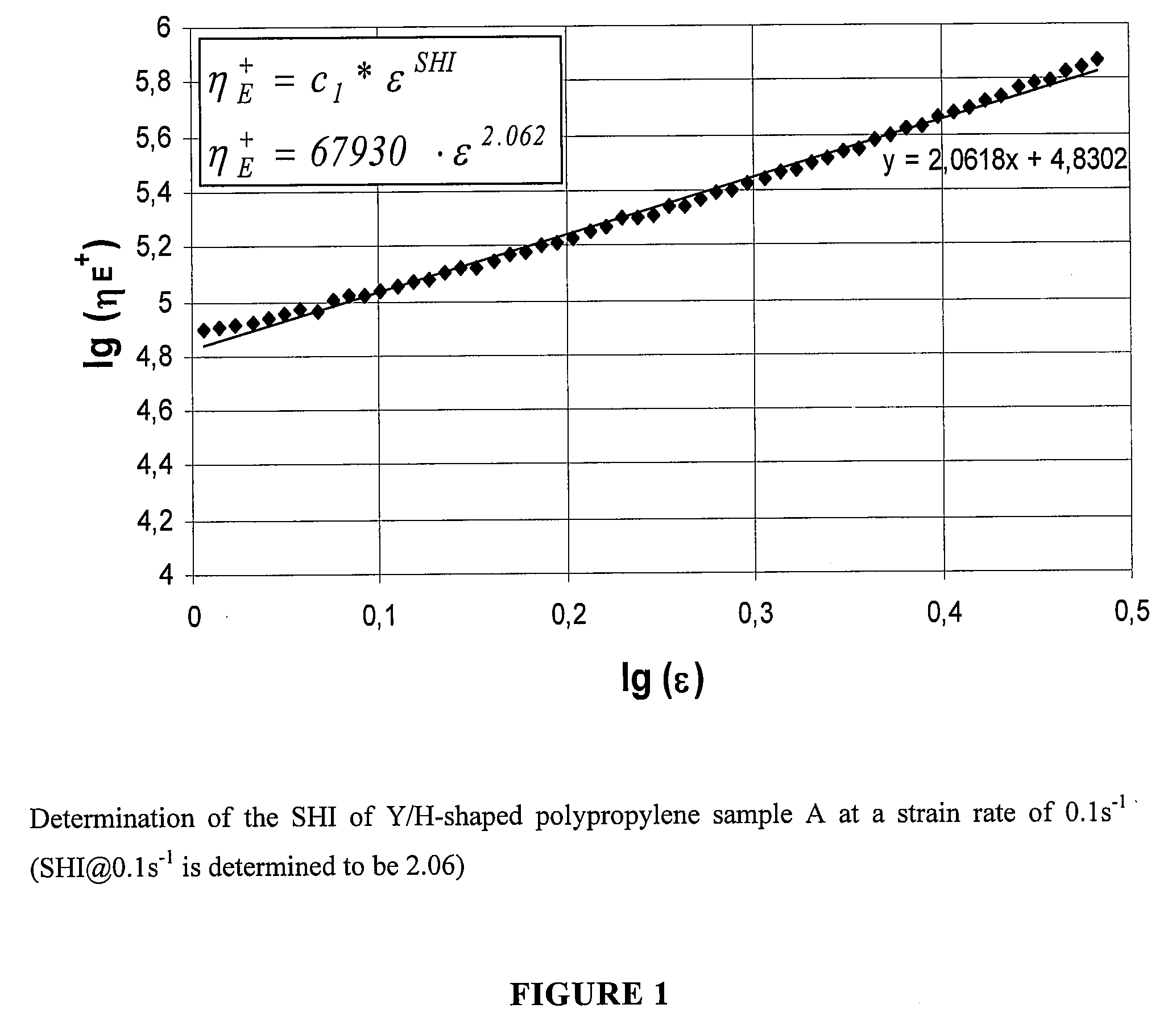

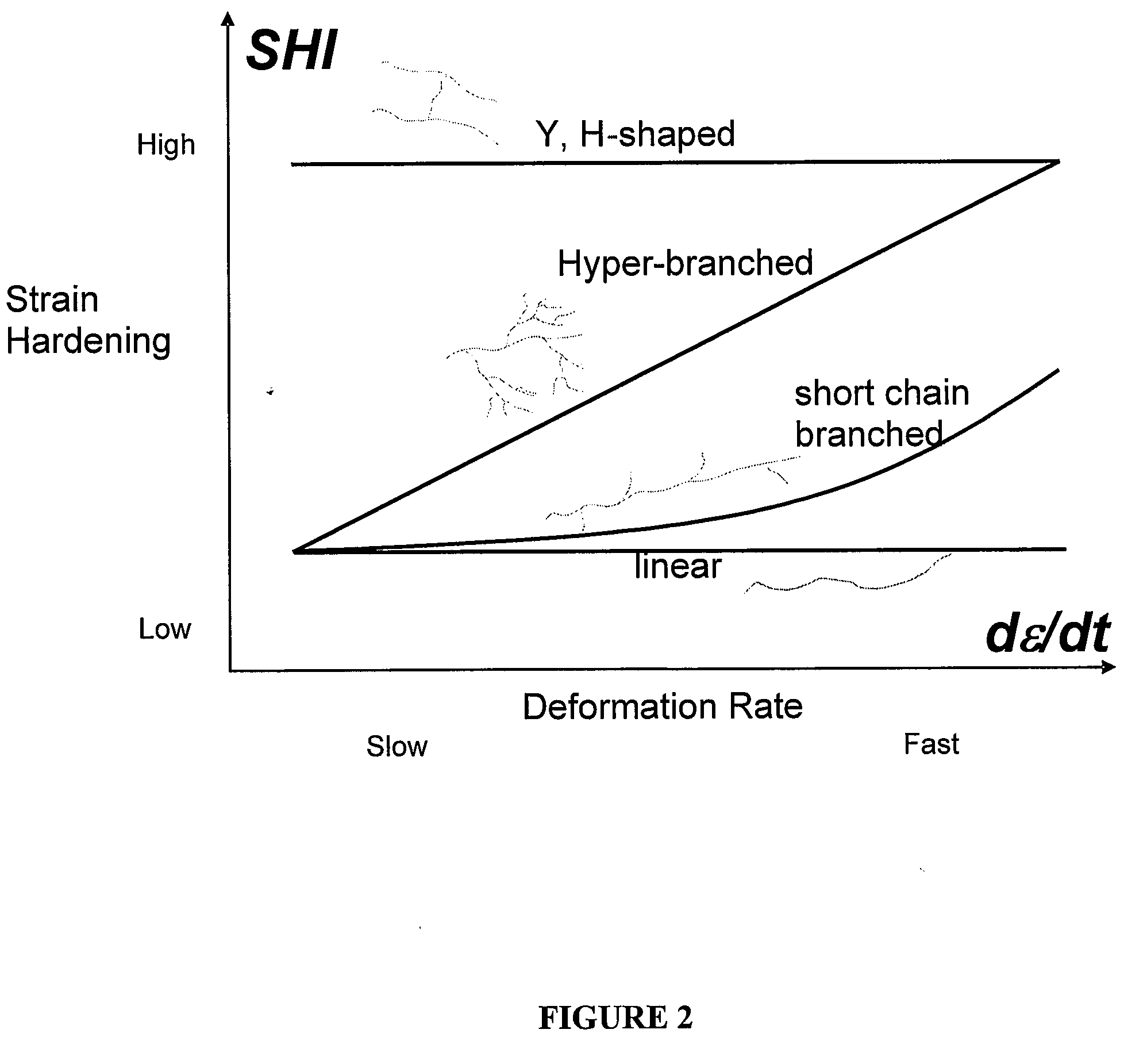

The present technology relates to a foam comprising a polypropylene material. The polypropylene material is produced in the presence of a metallocene catalyst, and the foam and / or the polypropylene has a branching index g′ of less than 1.00 and a strain hardening index (SHI@1 s−1) of at least 0.30 measured by a deformation rate dε / dt of 1.00 s−1 at a temperature of 180° C., where the strain hardening index (SHI) is defined as the slope of the logarithm to the basis 10 of the tensile stress growth function (log(ηE+)) as a function of the logarithm to the basis 10 of the Hencky strain (log(ε)) in the range of Hencky strains between 1 and 3.

Owner:BOREALIS TECH OY

Method for improving elongation rate and strain hardening index n value of cold-rolled deep-drawing steel

PendingCN110438312AImprove deformation abilityImprove forming stabilityProduction lineStrain stiffening

The invention discloses a method for improving elongation rate and strain hardening index n value of cold-rolled deep-drawing steel. The method comprises the steps of carrying out cold rolling by adopting a cold rolling reduction rate of 58%-77%, then carrying out cover annealing, and flattening to obtain the cold-rolled deep-drawing steel. The elongation rate of the cold-rolled deep-drawing steelis more than 40%, and the strain hardening index n value is 0.22-0.25. According to the method for improving the elongation rate and the strain hardening index n value of the cold-rolled deep-drawingsteel, through optimizing the production process method, the obtained cold-rolled deep-drawing steel has higher elongation rate and strain hardening index n value, the expansion and ductility performance of a steel plate material is improved, and the probability of fracture of the steel material in the expansion process is reduced; the production qualified rate is improved; and the method for improving the elongation rate and the strain hardening index n value of the cold-rolled deep-drawing steel is improved on the basis of an original steel production line, process parameter control is optimized, and industrial production improvement is facilitated.

Owner:BAOTOU IRON & STEEL GRP

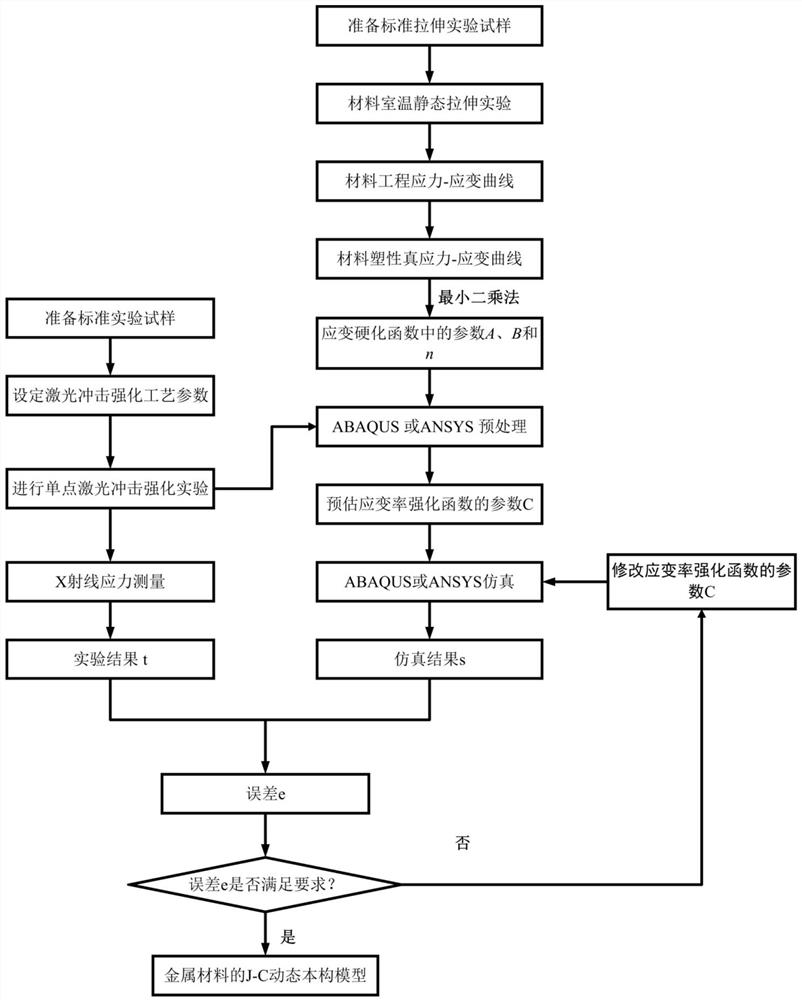

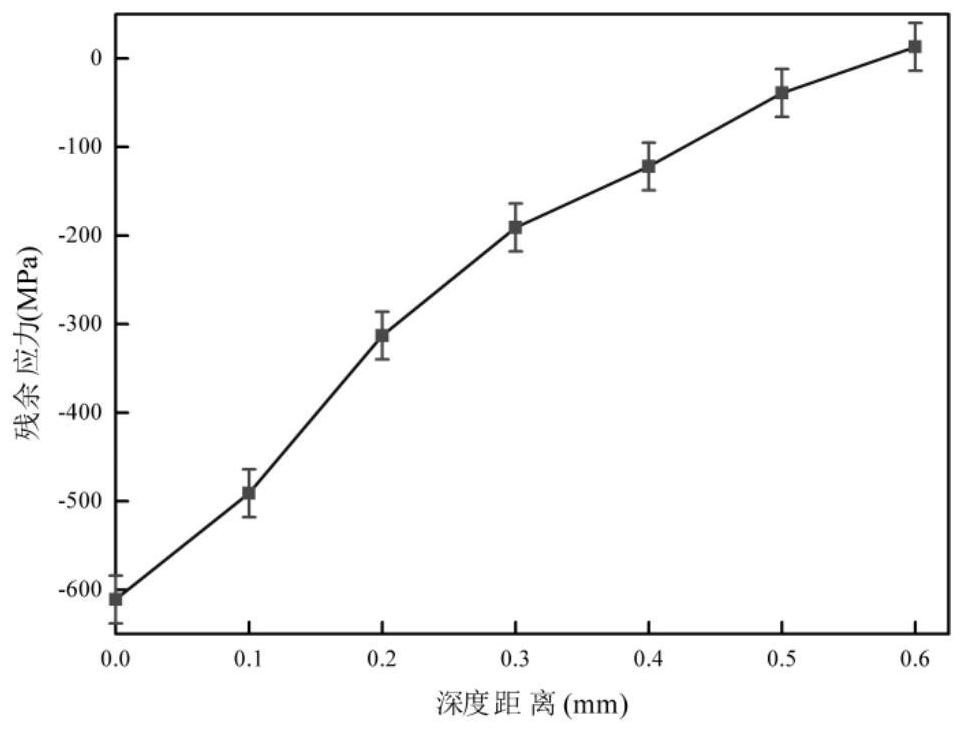

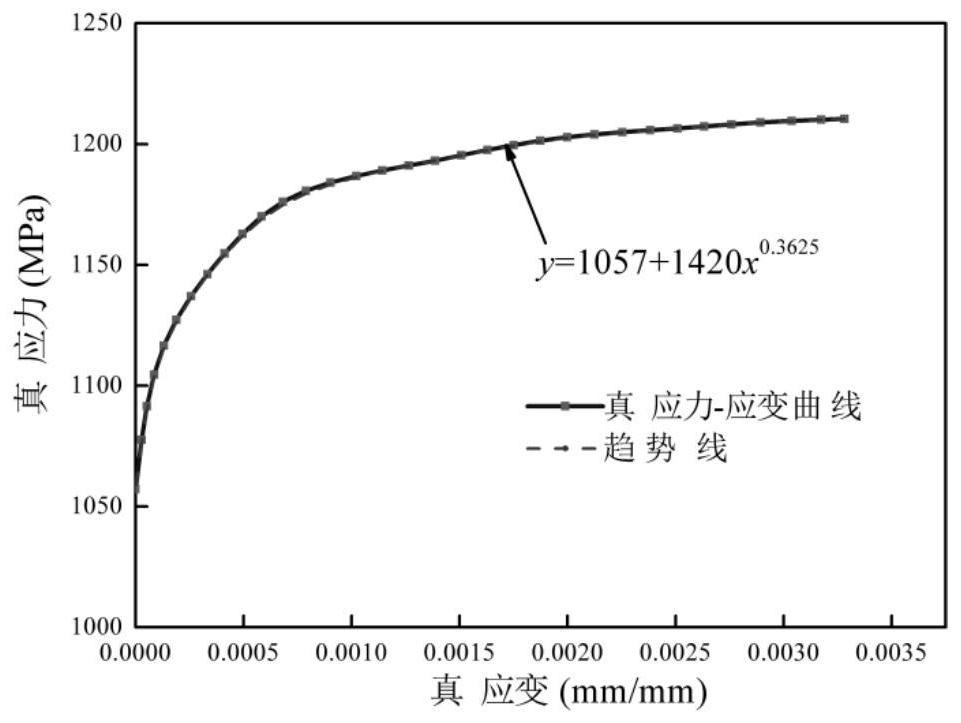

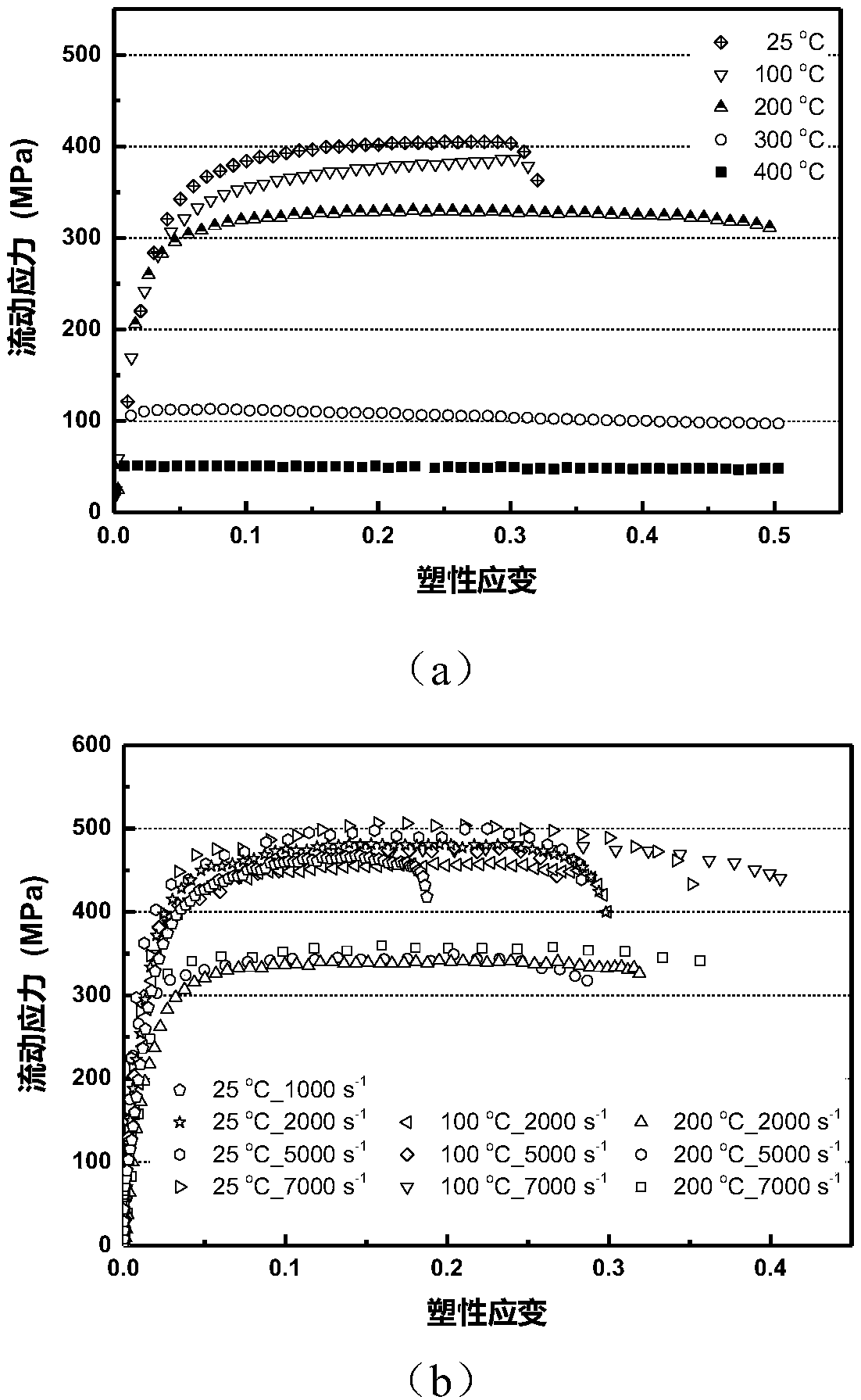

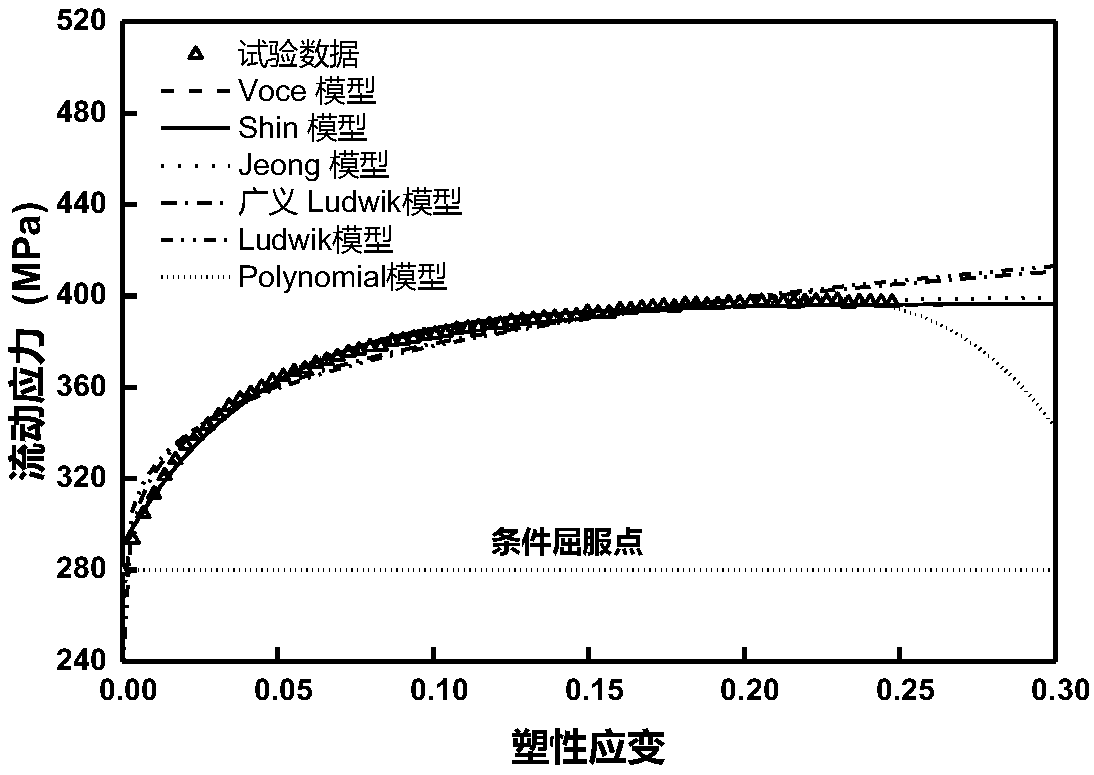

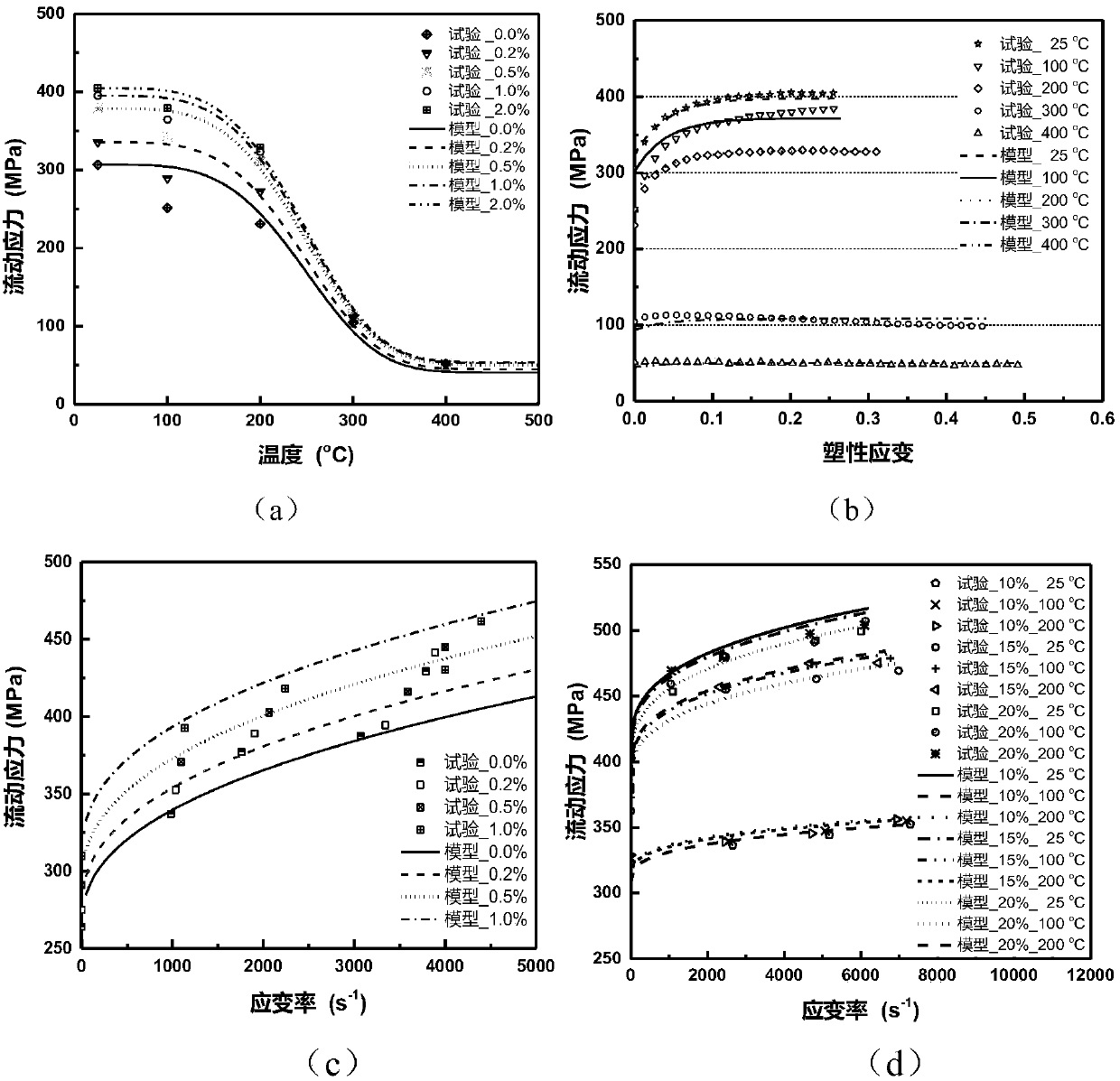

Method for establishing J-C constitutive model of metal material

InactiveCN112180065AUniversal application meaningHigh precisionForce measurementMaterial strength using tensile/compressive forcesElement modelMetallic materials

The invention relates to the field of laser shock peening and material constitutive, and particularly relates to a method for establishing a J-C constitutive model of a metal material. The method comprises the steps of obtaining the maximum residual stress of a laser shock peening area; carrying out a room-temperature static tensile experiment on the metal material to obtain an engineering stress-strain curve; converting the engineering stress-strain curve into a true stress-true strain curve; fitting the true stress-true strain curve to obtain parameters A, B and n in a strain hardening function; establishing a corresponding finite element model according to a laser shock peening experiment to obtain a strain rate function; estimating a strain rate coefficient C in the strain rate function, and inputting the C and the parameters A, B and n into finite element numerical simulation software to obtain simulated maximum residual stress; and judging that the error e meets an error threshold value to obtain a J-C constitutive model of the metal material. The method is not only suitable for establishing parameters of a single-variable constitutive model, but also suitable for establishing a multivariable constitutive model.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

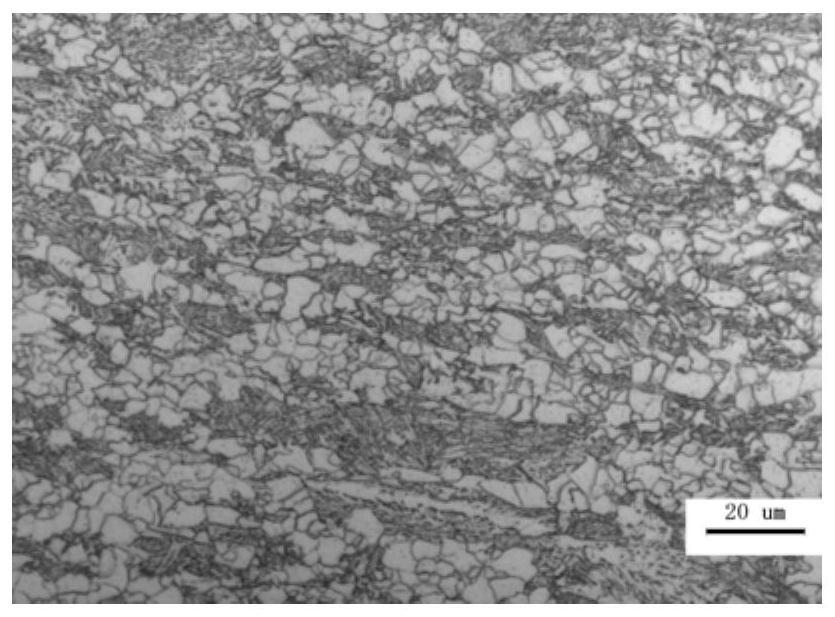

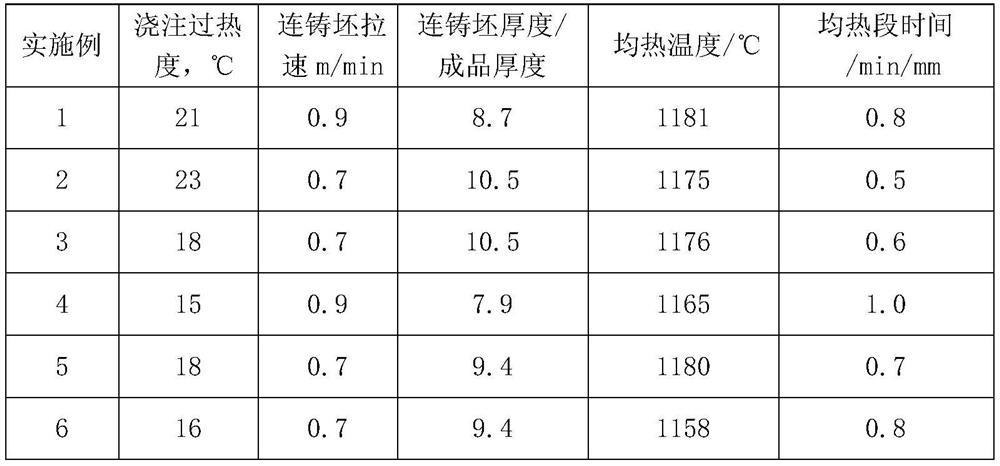

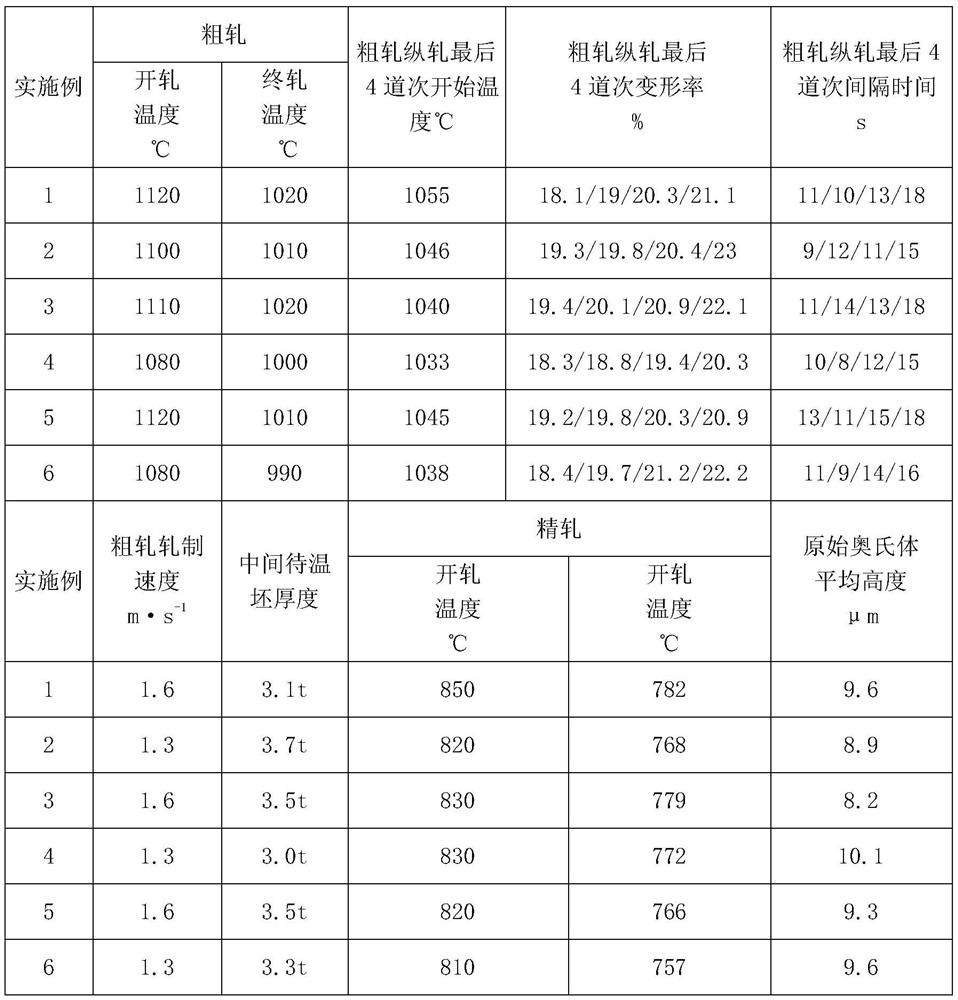

Thick plate with excellent plasticity and toughness for pipelines and production method of thick plate

The invention provides a thick plate with excellent plasticity and toughness for pipelines and a production method of the thick plate. The thick plate is prepared from components in percent by weight:0.025%-0.055% of C, 0.26%-0.40% of Si, 1.51%-1.75% of Mn, smaller than or equal to 0.010% of P, smaller than or equal to 0.0015% of S, 0.02%-0.05% of Nb, 0.010%-0.030% of Ti, 0.16%-0.35% of Cr, 0.06%-0.19% of Mo, smaller than or equal to 0.20% of Ni, smaller than or equal to 0.15% of Cu, 0.010%-0.025% of Al, 0.0010%-0.0040% of N, 0.0015%-0.0040% of Ca and the balance iron and inevitable impurities, wherein Ca / S is larger than or equal to 1.6. The production method includes the steps of converter smelting, external refining, continuous casting, heating, rolling and cooling. The thickness of the thick plate produced through the method is larger than 26 mm, and the transverse yield ratio does not exceed 0.83; and the longitudinal yield strength is 450-530 MPa, the longitudinal tensile strength is 590-670 MPa, the longitudinal uniform elongation UEL is larger than or equal to 10%, the longitudinal yield ratio does not exceed 0.82, and the strain hardening exponent n is larger than or equal to 0.1.

Owner:ANGANG STEEL CO LTD

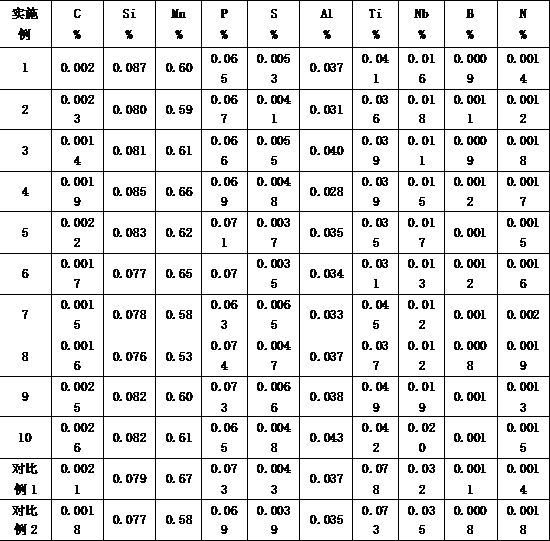

Strip steel with excellent performance at low temperature secondary processing and with tensile strength being 390 MPa and production method

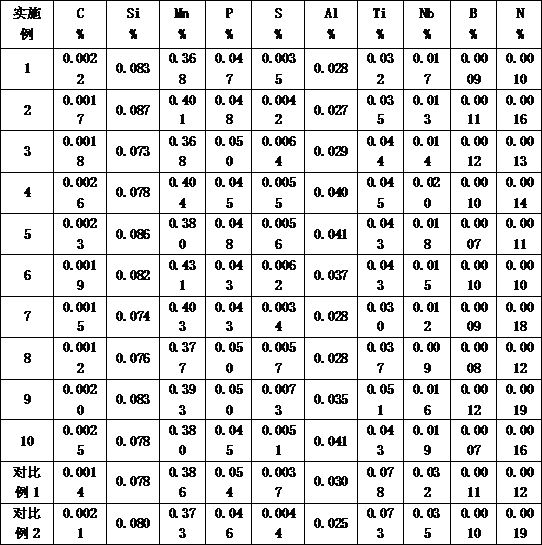

The invention discloses strip steel with excellent performance at low temperature secondary processing and with tensile strength being 390 MPa. The steel comprises the following components of, by wt%,0.0008%-0.0028% of C, 0.07%-0.1% of Si, 0.5%-0.7% of Mn, 0.060%-0.075% of P, less than or equal to 0.008% of S, 0.02-0.05% of Al, 0.02%-0.06% of Ti, 0.006%-0.022% of Nb, 0.0005%-0.0015% of B, and less than or equal to 0.002% of N. The production steps comprise smelting and casting into a blank, cast blank heating, rough rolling, finish rolling, coiling, cold rolling after acid pickling, continuous annealing treatment, slow cooling, rapid cooling, aging treatment and flattening. According to the steel, under the premise of guaranteeing mechanical property, a plastic strain ratio is 1.6-1.8r<90>, a strain hardening index is 18-0.19n<90>, a brittle transition temperature of the secondary processing is stabilized at minus 60-minus 70 DEG C, the quantities of the elements Ti and the Nb are reduced, the cost is reduced by no less than 5%, the surface of a steel plate is free of carbonization edges and bonding defects, and the steel is used for an outer cover of an automobile in a more severe cold area.

Owner:武汉钢铁有限公司

180 MPa-grade cold-rolled ultralow carbon baking hardened steel and production method thereof

The invention discloses 180 MPa-grade cold-rolled ultralow carbon baking hardened steel and a production method thereof. The steel comprises the following improved chemical components in percentage by weight: 0.0015-0.0025% of C, 0.006-0.010% of Si, 0.40-0.75% of Mn, and 0.030-0.050% of P; C% / Nb% is 0.16-0.28; the hot-rolled tapping temperature is 1240-1250 DEG C; the front section is cooled after finish rolling; the plumbing ratio is 1: 1.2; the continuous annealing soaking temperature is 830-835 DEG C; the slow cooling temperature is 680-750 DEG C; the rapid cooling temperature is 340-360 DEG C; the cooling degree is 50-85 DEG C / s; and 14.0-17.0% of high hydrogen is fed in the rapid cooling section. The steel contains no precious elements, is low in production cost, is excellent in product surface quality, and is uniform in structure; the stress strain index r value reaches 2.65; the strain hardening ratio n value is stabilized at 0.23; and the stamping forming performance is excellent.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

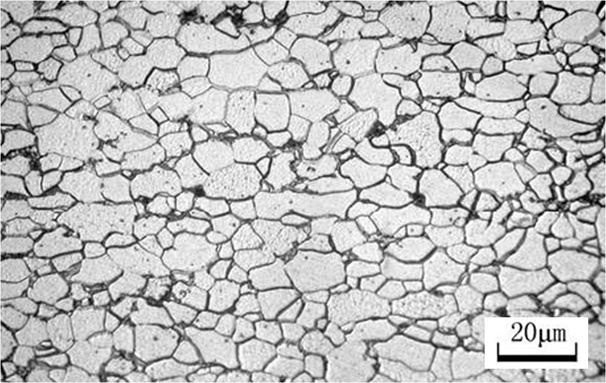

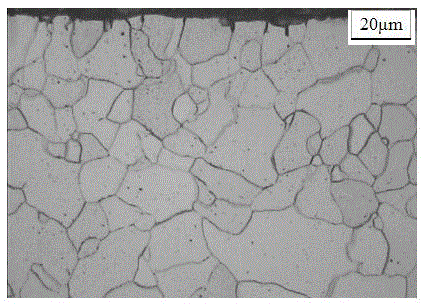

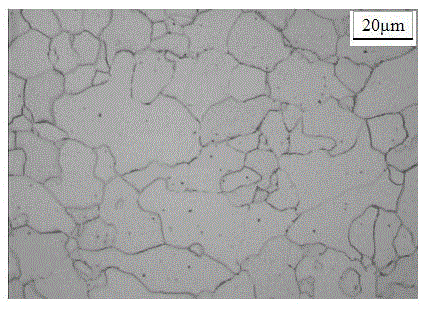

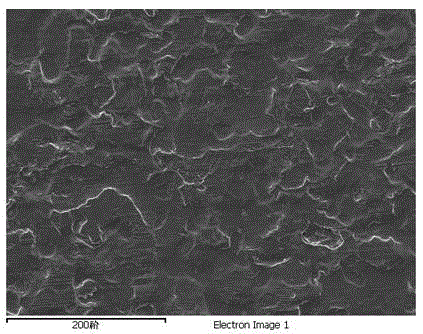

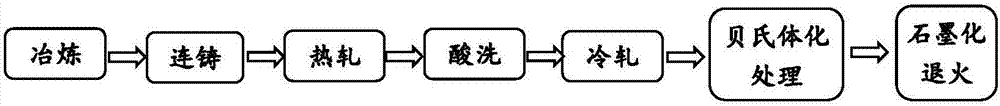

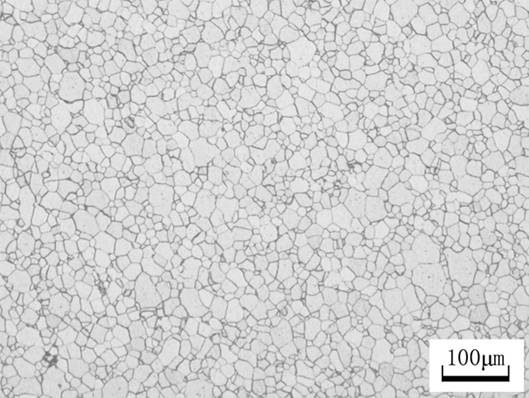

Preparation method of graphitized cold-rolled high-carbon steel plate for stamping forming

The invention discloses a preparation method of a graphitized cold-rolled high-carbon steel plate for stamping forming, and belongs to the technical field of metallurgy. The preparation method is characterized in that besides conventional methods like smelting, continuous casting, hot rolling, acid pickling and cold rolling, technological processes like bainite treatment and graphitizing annealing are adopted, wherein the bainite treatment is adopted for providing a good preparation structure for the graphitizing annealing; isothermal transformation is carried out in a manner that isothermal treatment with the temperature being 30-50 DEG C above Ac3 is carried out and then rapid cooling to a lower bainite transition temperature range is carried out; and the graphitizing annealing mainly adopts the isothermal treatment with the temperature being 620 DEG C to Ac1. The steel plate prepared by the preparation method mainly consists of graphite and ferrite grains structurally, graphite particles are distributed uniformly, the mean diameter of the graphite particles is approximately 5 micrometers, and the mean diameter of the ferrite grains is approximately 20 micrometers. Due to such structural characteristics, the high-carbon steel plate has the same plasticity and softness as low-carbon steel, and thus has the good stamping forming property, a yield ratio of the high-carbon steel plate is less than or equal to 0.60, the strain hardening exponent is greater than or equal to 0.2, and the planar anisotropy is less than or equal to 0.20.

Owner:UNIV OF SCI & TECH BEIJING

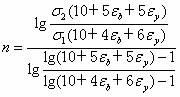

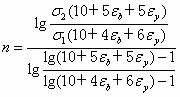

Method for quickly determining metal material strain hardening index

InactiveCN102507326AEasy accessConvenient and accurate access toMaterial strength using tensile/compressive forcesMetallic materialsStrain stiffening

The invention relates to a method for quickly determining a metal material strain hardening index. The method comprises the following steps of: first, according to the tension test data, drawing a tension curve sigma-epsilon; second, determining a starting point for generating strain hardening effect; third, determining an end point for generating strain hardening effect; fourth, determining two key points: namely (epsilon1, sigma1) and (epsilon2, sigma2) on the tension curve; and fifth, according to a formula, calculating the strain hardening index. The method provided by the invention has the characteristics of easy operation, high efficiency and no influence of human factors.

Owner:XI'AN PETROLEUM UNIVERSITY

Strip steel with tensile strength of 440 MPa and excellent low-temperature secondary machining performance and production method

The invention discloses a strip steel with the tensile strength of 440 MPa and excellent low-temperature secondary machining performance. The strip steel comprises the components of, in parts by weight, 0.0008%-0.0028% of C, 0.07%-0.1% of Si, 1.4%-1.8% of Mn, 0.06%-0.09% of P, less than or equal to 0.008% of S, 0.02%-0.05% of Al, 0.02%-0.06% of Ti, 0.006%-0.022% of Nb, 0.0005%-0.0015% of B and less than or equal to 0.002% of N. The production method comprises the following steps of smelting and casting into a blank; heating a casting blank; rough rolling; finish rolling; coiling; cold rollingafter pickling; carrying out continuous annealing treatment; slowly cooling; rapidly cooling; aging treatment; and leveling. According to the strip steel and the production method thereof, on the premise that the mechanical property is guaranteed, the plastic strain ratio is larger than or equal to 1.5 <r90>, and the strain hardening index is larger than or equal to 1.0 <n90>; and the secondary machining brittle transition temperature is stabilized below minus 50 DEG C, the amount of elements Ti and Nb is reduced, so that the cost is reduced by not less than 5%, the surface of the steel plateis free of carbonization edges and bonding defects, and therefore the steel plate can be used for preparing automobile outer covering parts applied to more severe cold areas.

Owner:武汉钢铁有限公司

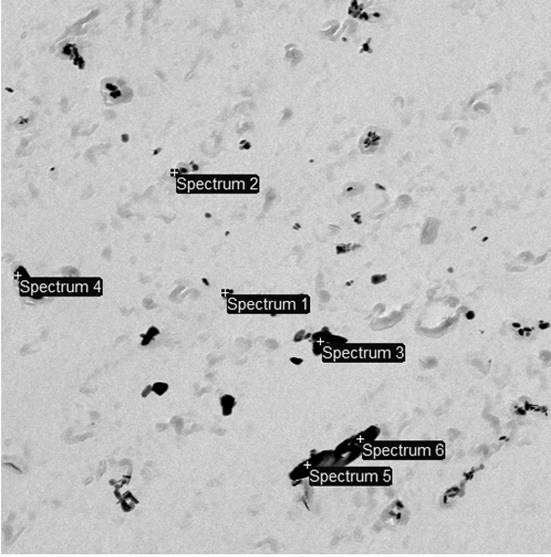

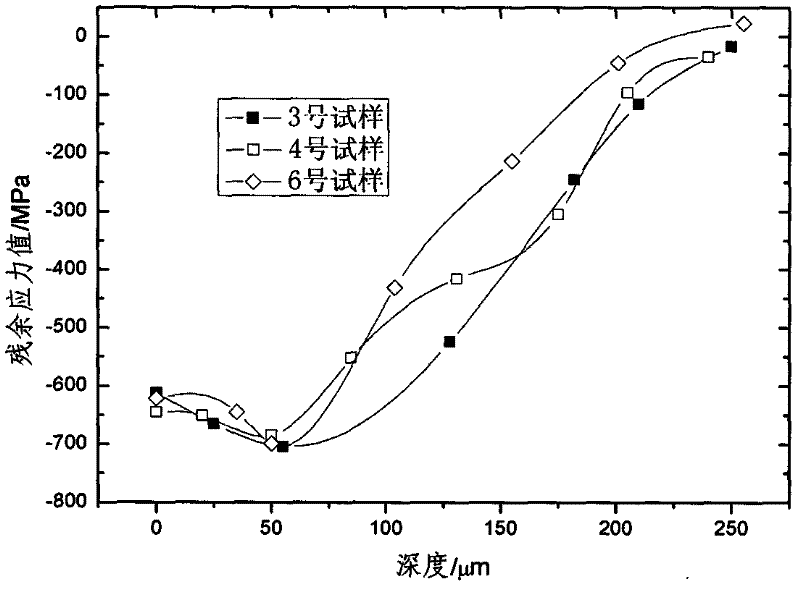

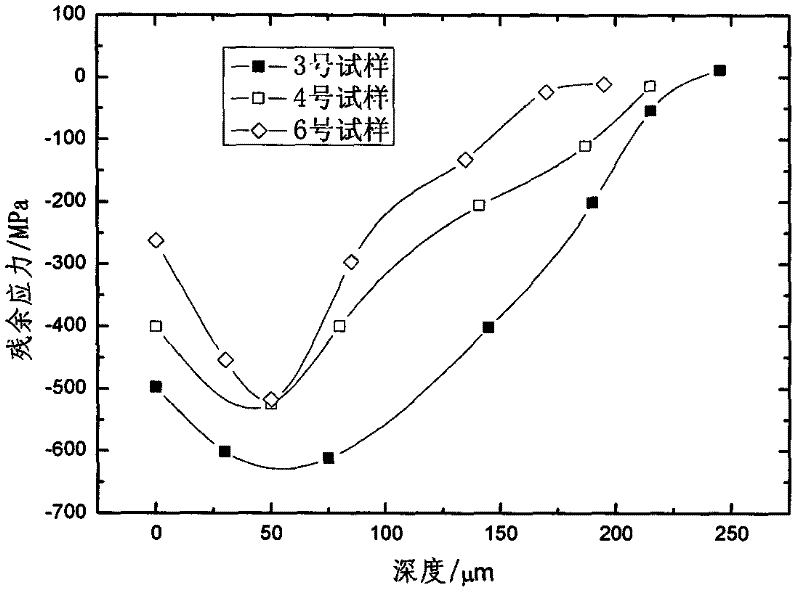

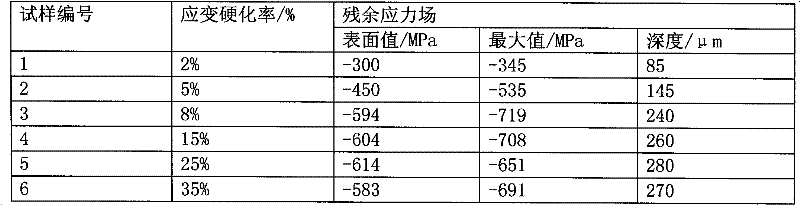

Shot peening strengthening method for controlling strain hardening rate of high temperature alloy surface

The invention provides a shot peening strengthening method for controlling a strain hardening rate of a high temperature alloy surface, which comprises the following steps: 1, finding a critical strain hardening rate under a material saturated residual compressive stress field through a test; 2, determining shot peening strengthening technological parameters of the material critical strain hardening rate; and 3, utilizing the technological parameters obtained in step 2 to carry out shot peening strengthening treatment. Compared with the prior art, the technical scheme of the invention has the characteristic of low strain hardening rate, so the thermal stability of the shot peening residual compressive stress field is strong, the method is suitable for the surface peening treatment of metal parts used at a higher temperature so as to prolong the fatigue life of the metal parts and improve the fatigue resistance of the metal parts.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

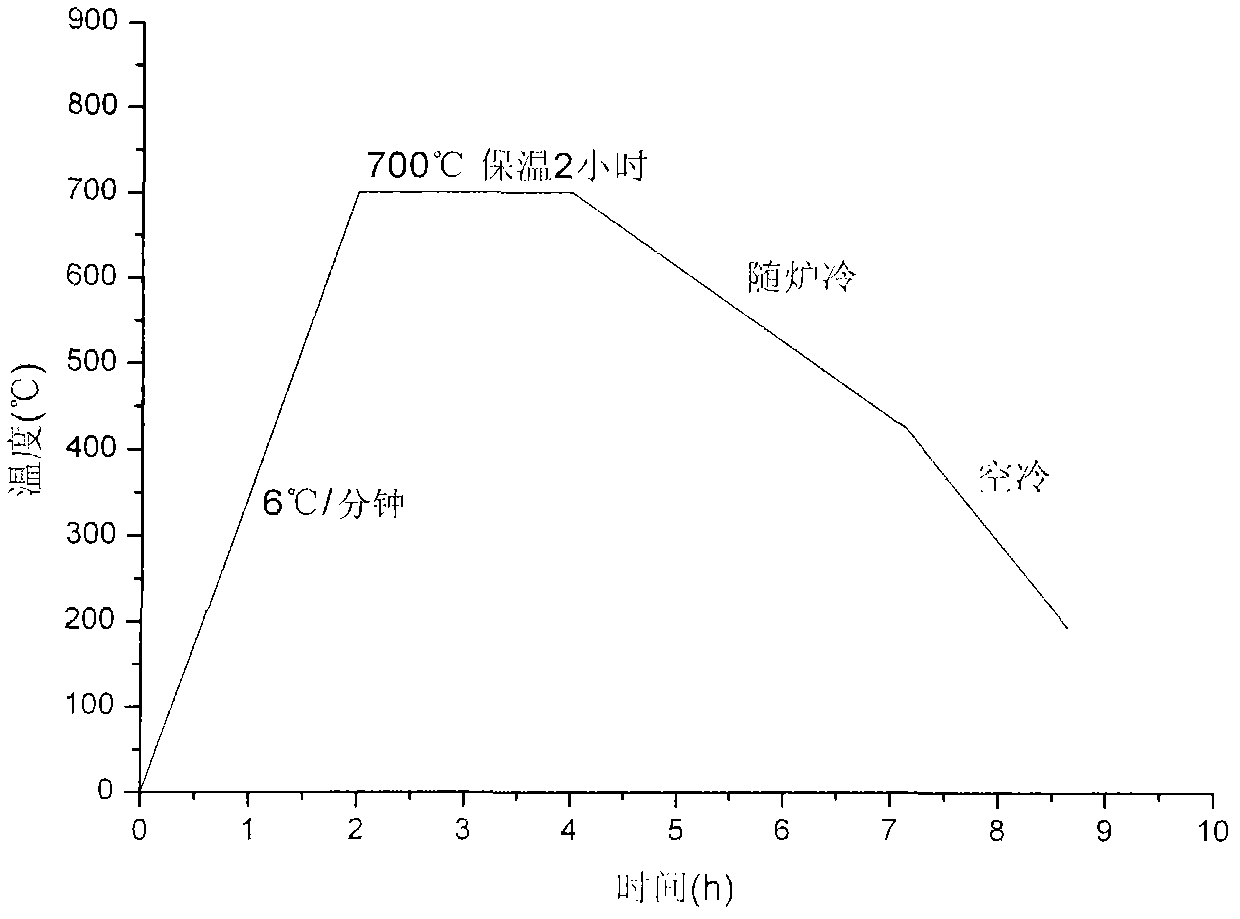

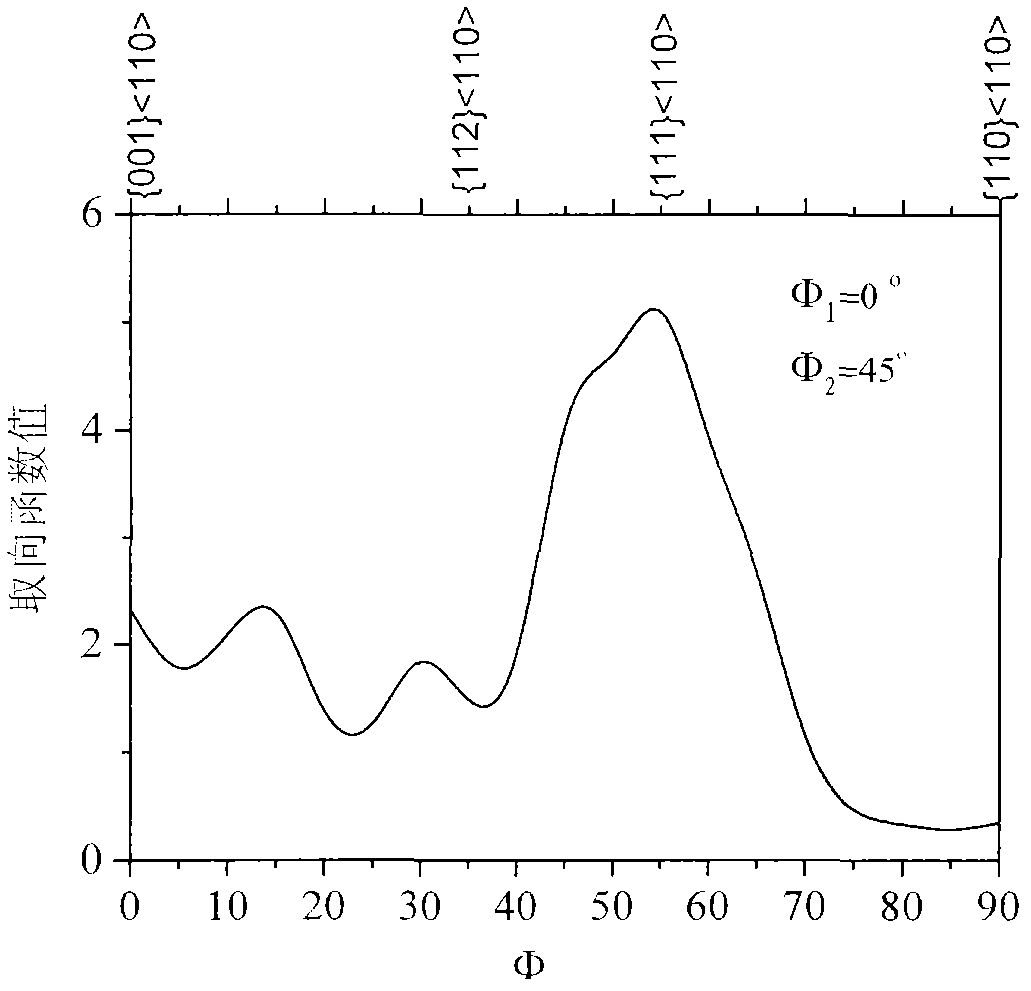

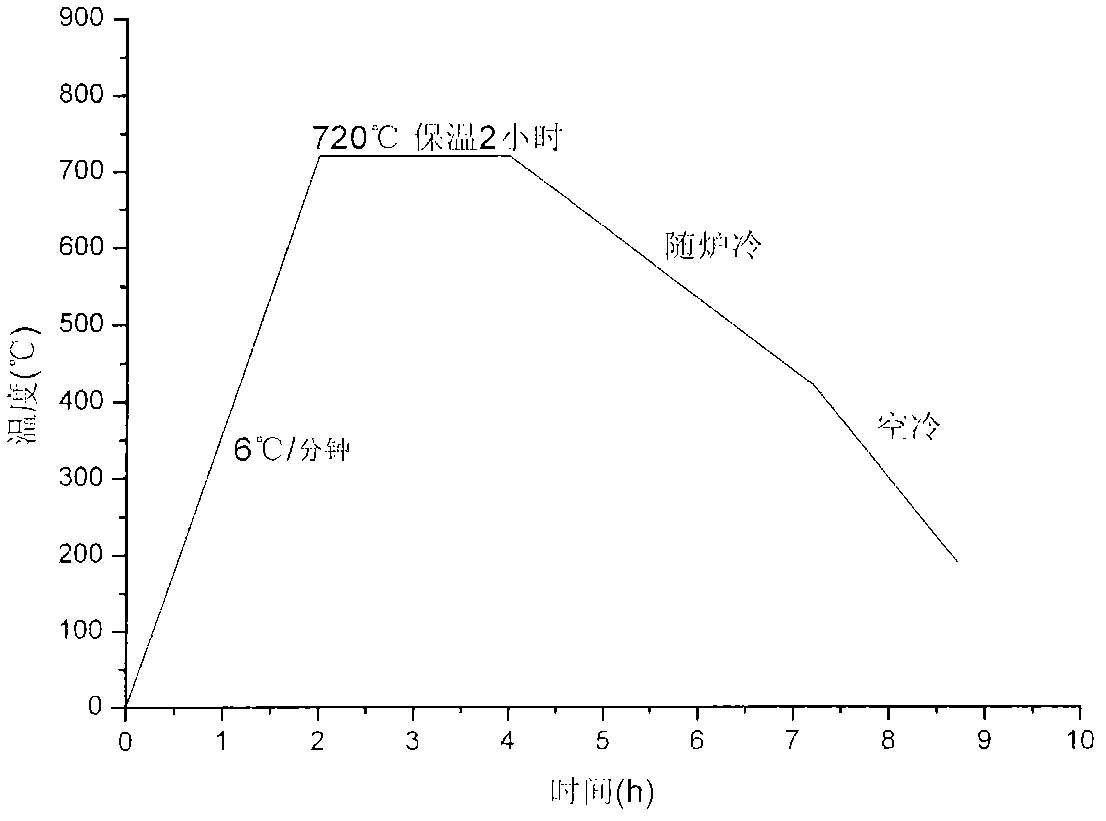

IF steel containing niobium and titanium for advanced automobile and annealing process

InactiveCN102517498AIncrease productivityImprove performanceFurnace typesHeat treatment furnacesTest sampleNiobium

The invention relates to IF steel containing niobium and titanium for an advanced automobile and an annealing process, which belong to the technical field of metallurgy. The IF steel containing the niobium and the titanium for the advanced automobile and the annealing process are characterized in that continuous heating is adopted in the annealing procedure, the heating rate is 4 to 8 DEG C / minute, the annealing temperature is 700 to 750 DEG C, the heat-preservation time is 1 to 10 hours, and the material is cooled to 400 to 450 DEG C along with a furnace and is taken out of the furnace for air cooling. By the mode, IF steel with excellent deep drawability can be obtained; a test sample of the IF steel after being processed by the process has excellent deep drawability; in a longitudinal direction, the tensile strength reaches 290 to 330MPa, the yield strength is 125 to 155MPa, and the elongation rate is 40 to 55 percent; in a transverse direction, the tensile strength reaches 310 to 340MPa, the yield strength is 120 to 190MPa, and the elongation rate is 40 to 55 percent; and the plane anisotropy delta r of the strain hardening index is not greater than 0.25.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

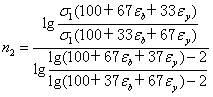

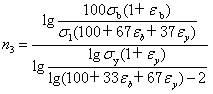

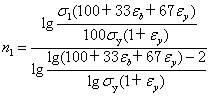

Method for precisely determining hardening index of material

InactiveCN102607949AMaterial strength using tensile/compressive forcesMetallic materialsGreek letter epsilon

The invention relates to a method for precisely determining a hardening index of a material. The method comprises the following steps of: 1, drawing a tensile curve Sigma-Epsilon according to tensile test data; 2, determining a starting point for generating a strain hardening action and determining a terminal point for generating the strain hardening action; 3, determining two key points (Epsilon 1, Sigma 1), (Epsilon 2, Sigma 2) on the tensile curve; and 4, dividing a strain hardening interval into three sections by using the key points, respectively determining and comparing strain hardening indexes of the three sections, dividing one section with the maximum strain hardening index into three sections, respectively determining the strain hardening indexes of the three sections, and comparing the maximum strain hardening index of the three current sections with the maximum strain hardening index of the last circulation, if the error is in a specified range, determining the maximum strain hardening index of the three current sections as the strain hardening index of the material, and if the error is beyond the specified range, circulating till the error meets the provision. The method disclosed by the invention has the characteristics of high precision, controllable precision according to the demands and freedom of influences of personal factors.

Owner:XI'AN PETROLEUM UNIVERSITY

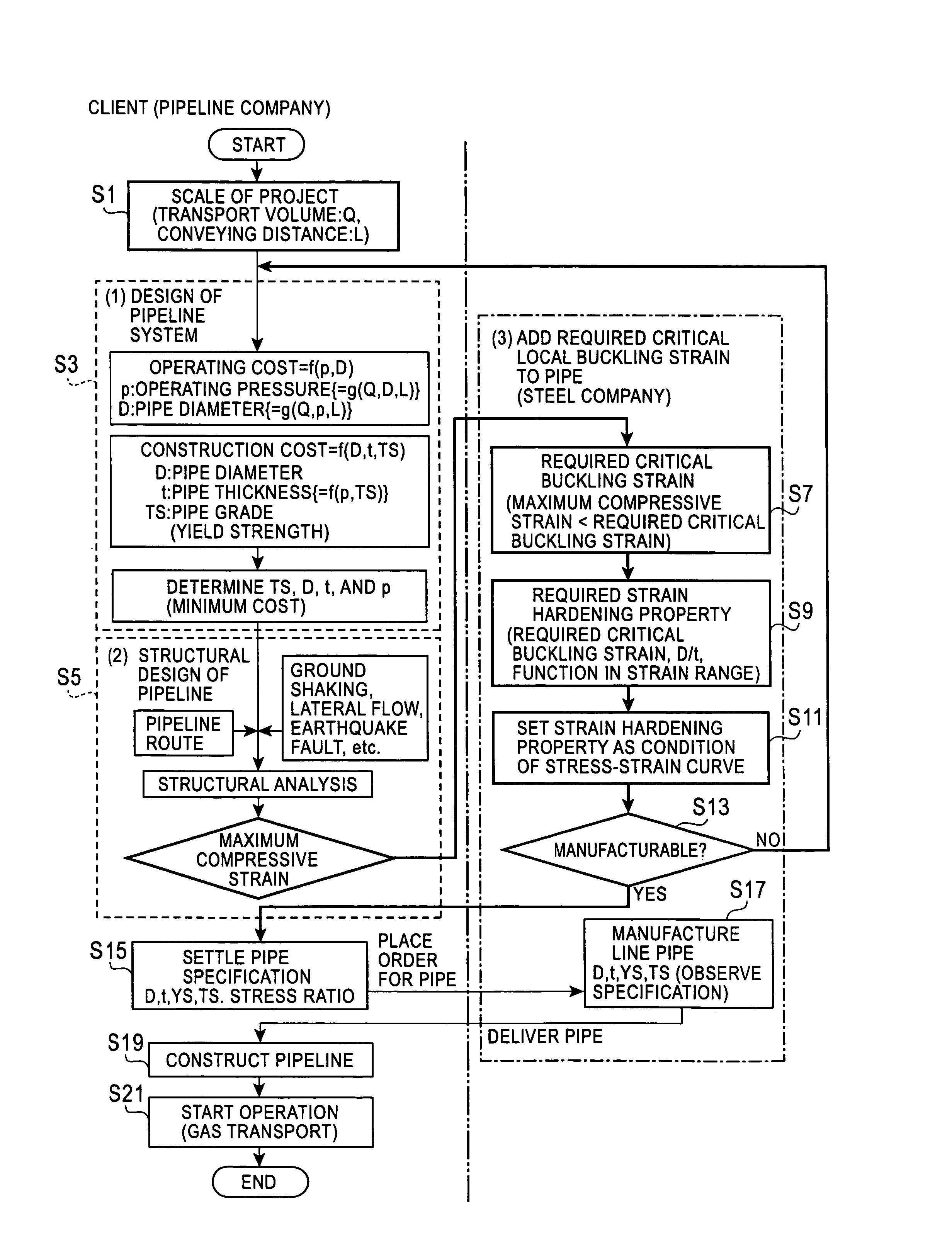

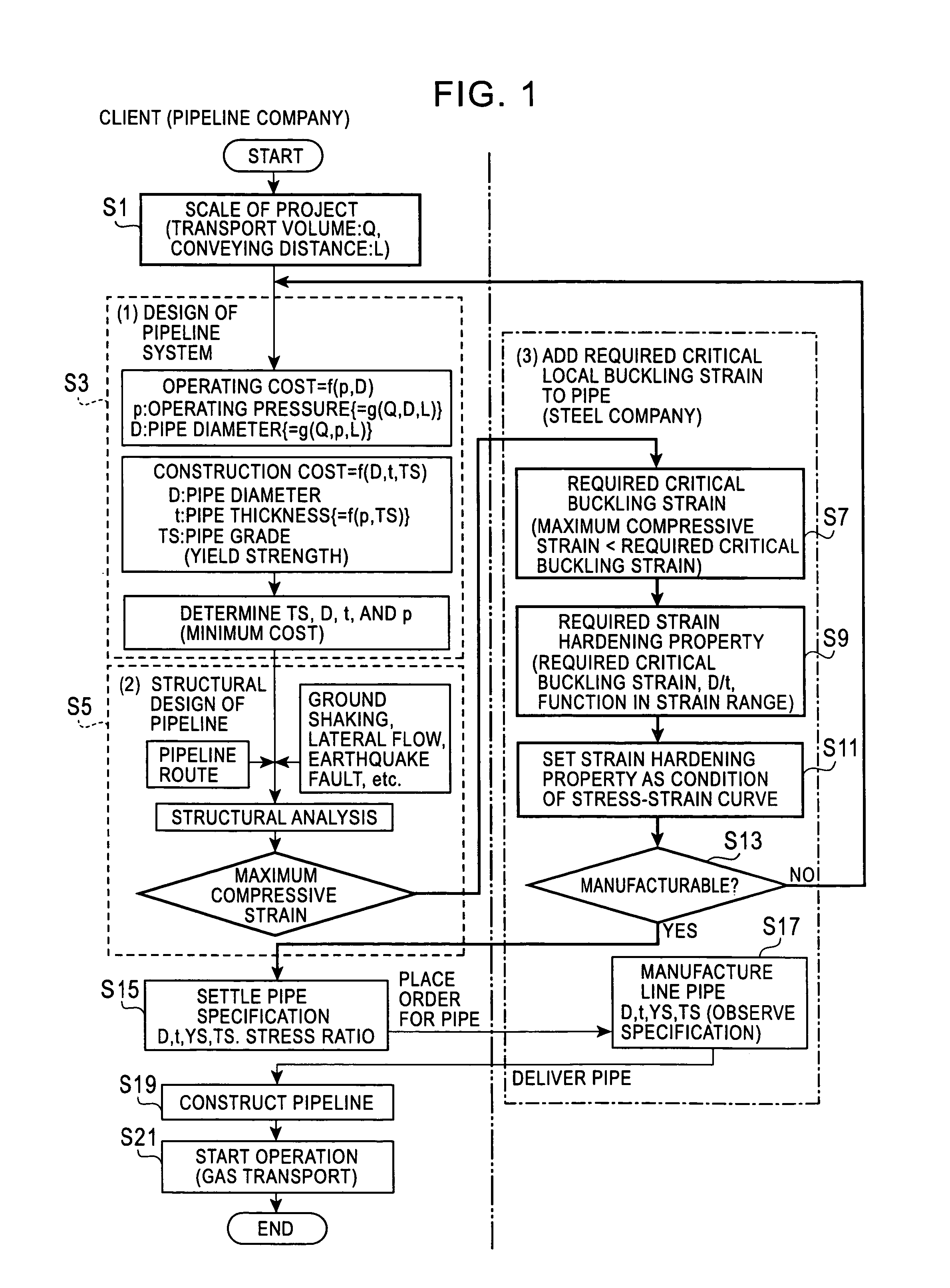

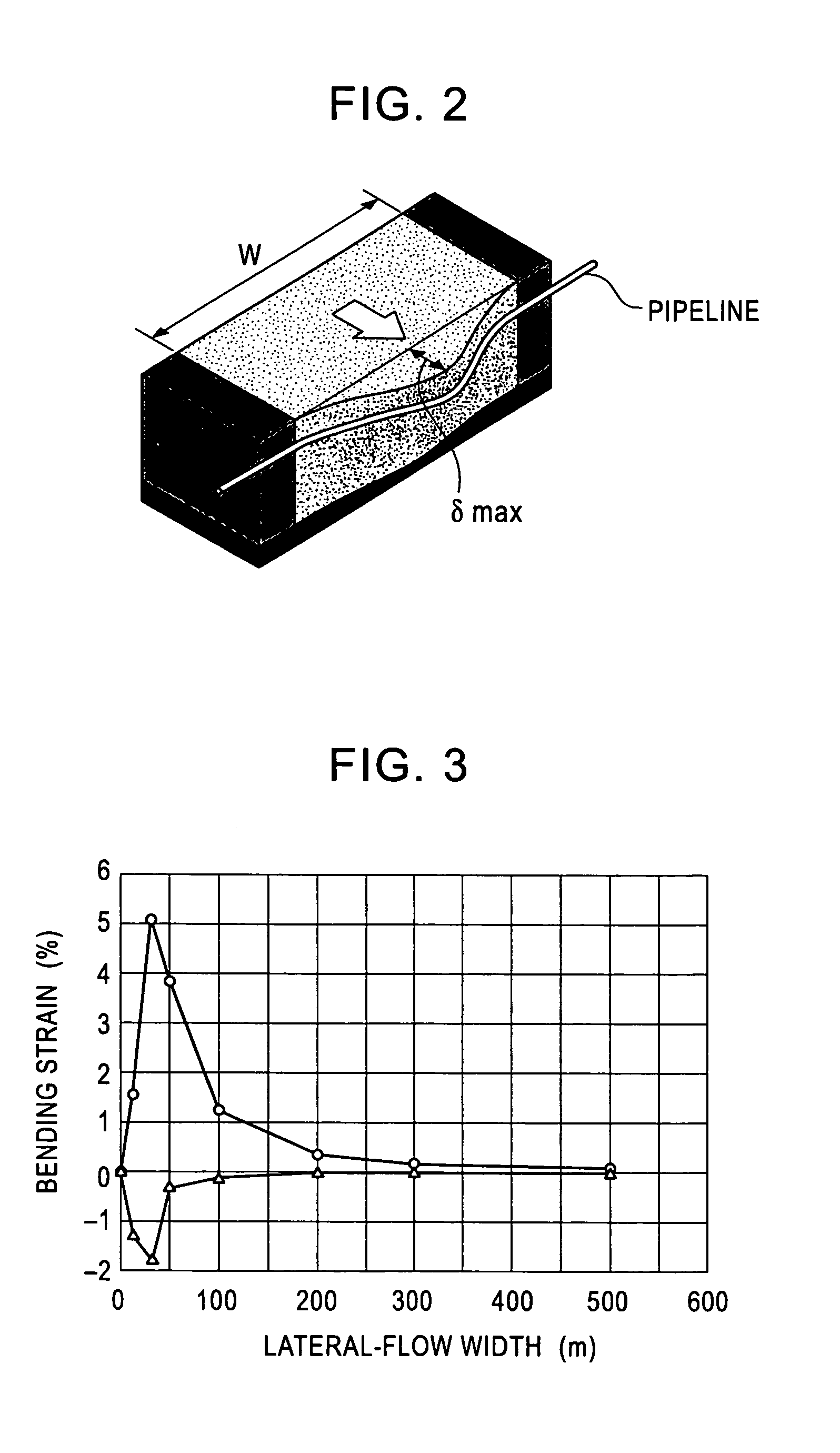

Method for determining strain hardening property of line pipe

ActiveUS7513165B2Reduce welding costsLarge caliberForce measurementMeasurement/indication equipmentsStress–strain curveStrain stiffening

A method for determining a strain hardening property of a pipe enabling reduction of costs while ensuring pipeline integrity is provided. Moreover, a method for manufacturing a pipe based on the method for determining the strain hardening property of the pipe, a pipe manufactured by means of the method for manufacturing the pipe, and a pipeline are proposed. The method for determining the strain hardening property of the pipe according to the present invention includes a step of defining pipe dimensions where a diameter D, a thickness t, and a required critical local buckling strain εreq of the pipe are set as conditions to be satisfied; a step of acquiring a strain hardening property for acquiring the strain hardening property in the vicinity of a buckling point of the pipe satisfying the conditions set in the step of defining the pipe dimensions; and a step of setting the strain hardening property as a condition to be satisfied by the stress-strain curve of the pipe.

Owner:JFE STEEL CORP

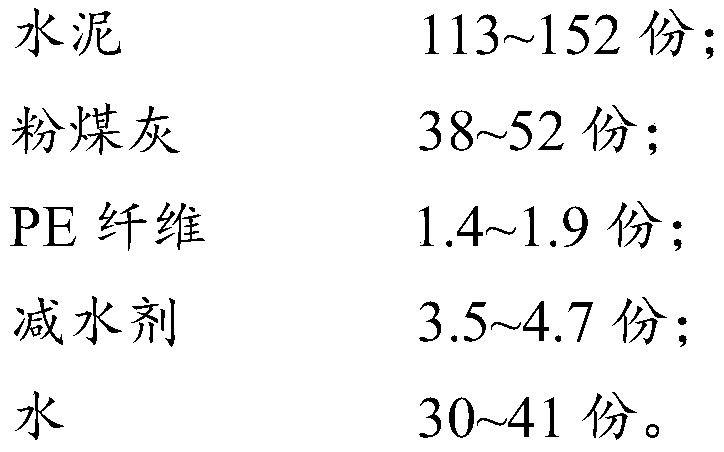

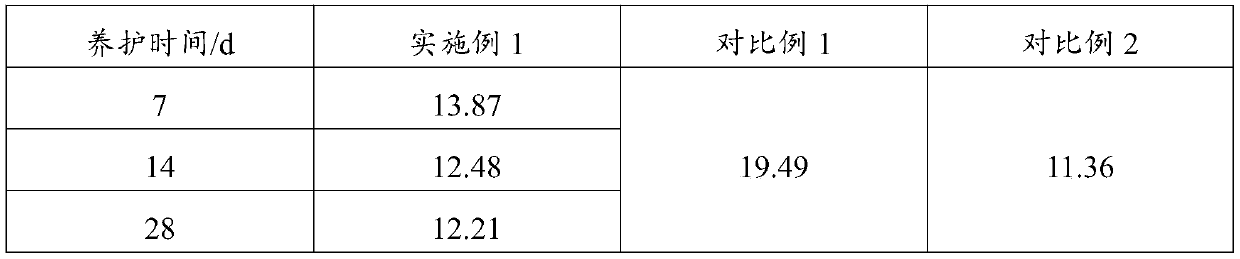

Application of a kind of ECC material in the reinforcement of recycled aggregate, recycled reinforced aggregate and its preparation method and application

ActiveCN110498629BReduced mechanical propertiesReduced durabilitySolid waste managementClimate change adaptationCompressive strengthStrain stiffening

The invention belongs to the field of building material, and especially relates to applications of an ECC material in recycled aggregate reinforcement, a recycled reinforced aggregate, and a preparation method and applications. The ECC material is excellent in strain hardening characteristic after being hardened, and multiple crack cracking is caused under stretching effect, so that the ECC material is capable of improving the quality of recycled aggregate obviously. The recycled reinforced aggregate is disclosed, and comprises a recycled aggregate, and an ECC layer used for coating the surface of the recycled aggregate; the ECC layer is adopted to fill recycled aggregate pores and coat the surface, so that a compact interface transition zone is formed, and the mechanical properties of therecycled aggregate are improved. The preparation method is capable of improving concrete ductility, and increasing energy consumption level of concrete structures under static force and dynamic loading. It is shown by tests that the 28d crush index of the recycled reinforced aggregate is 12.21%, and 28d compressive strength reaches 49MPa.

Owner:SHENZHEN UNIV

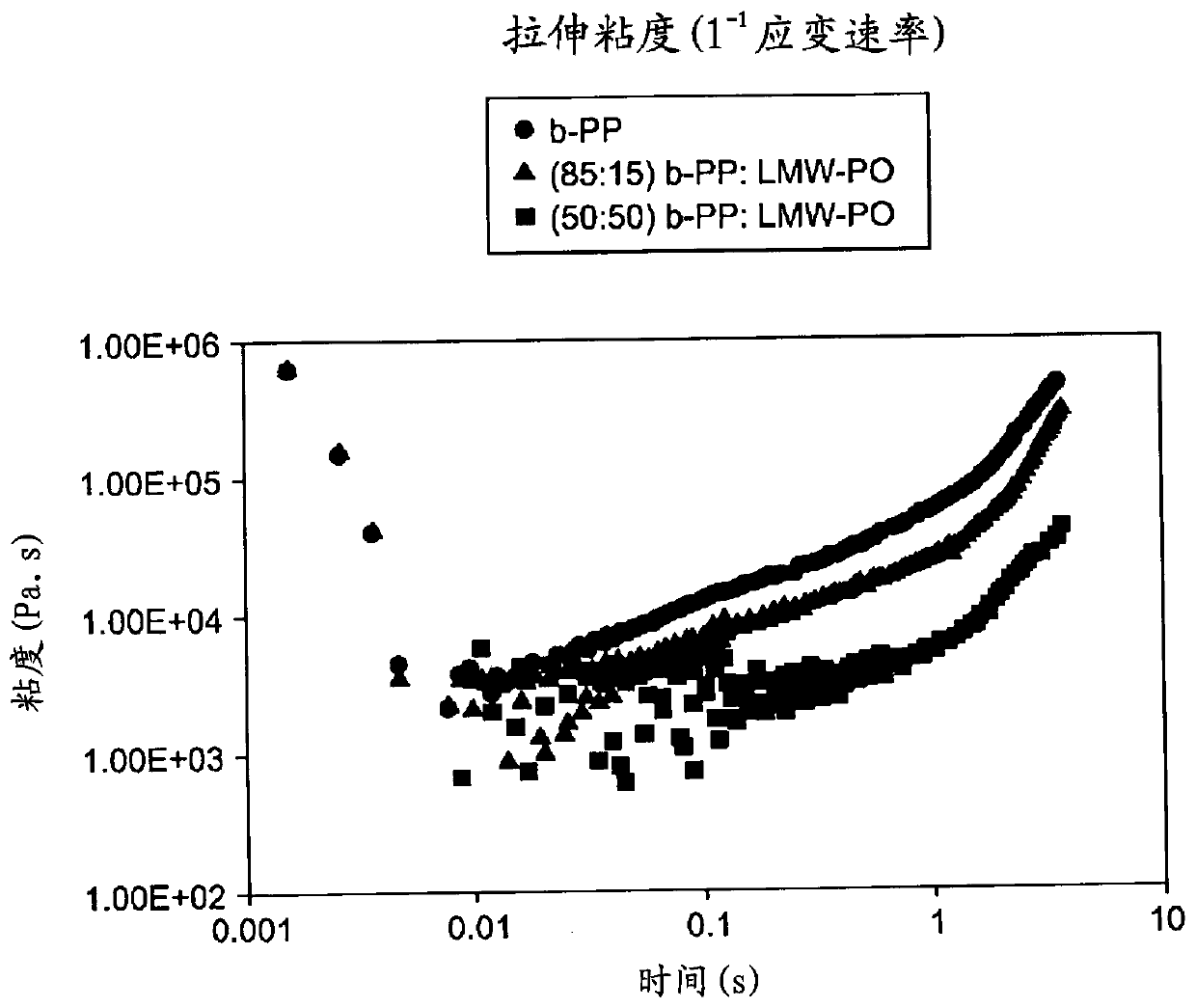

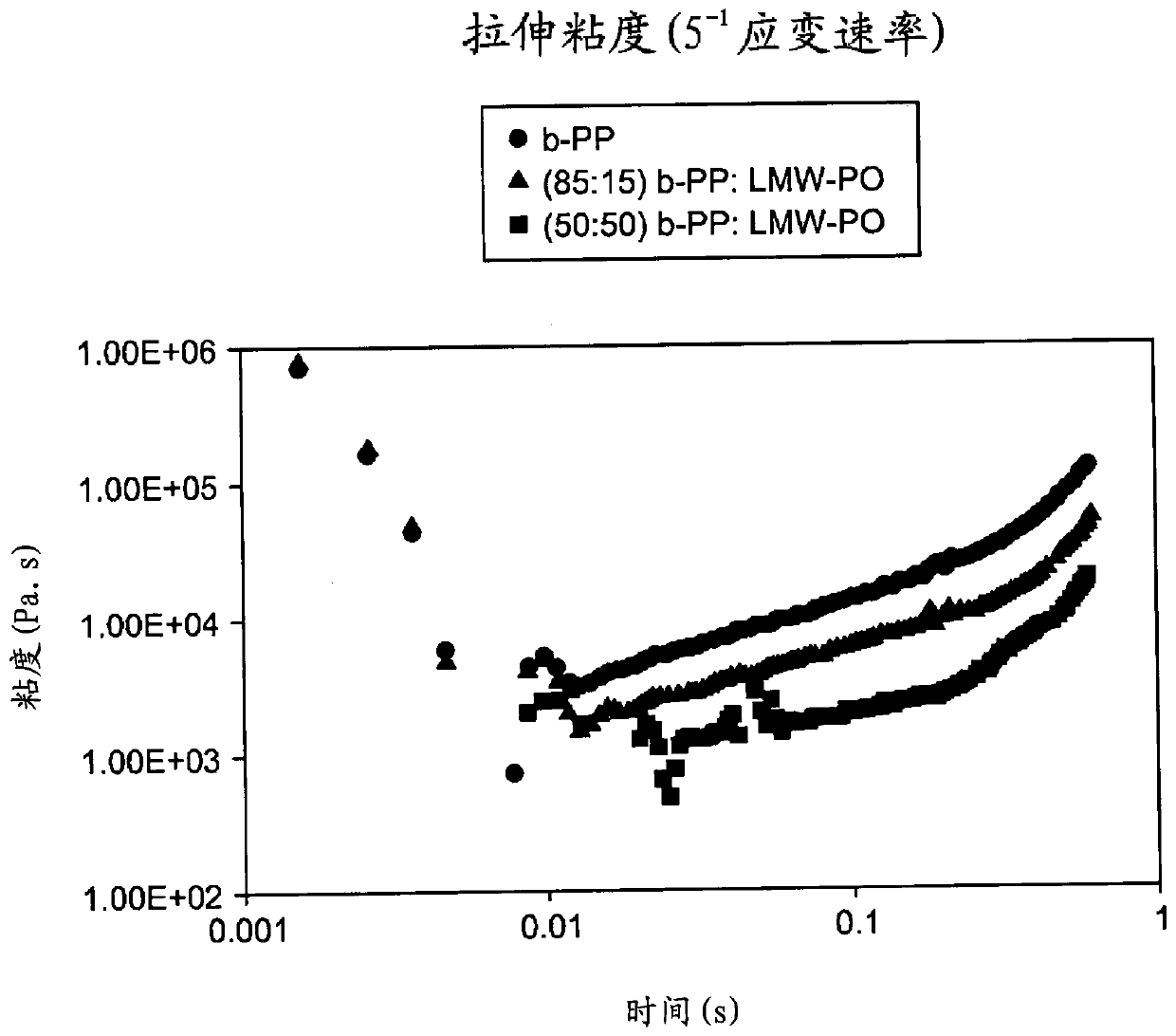

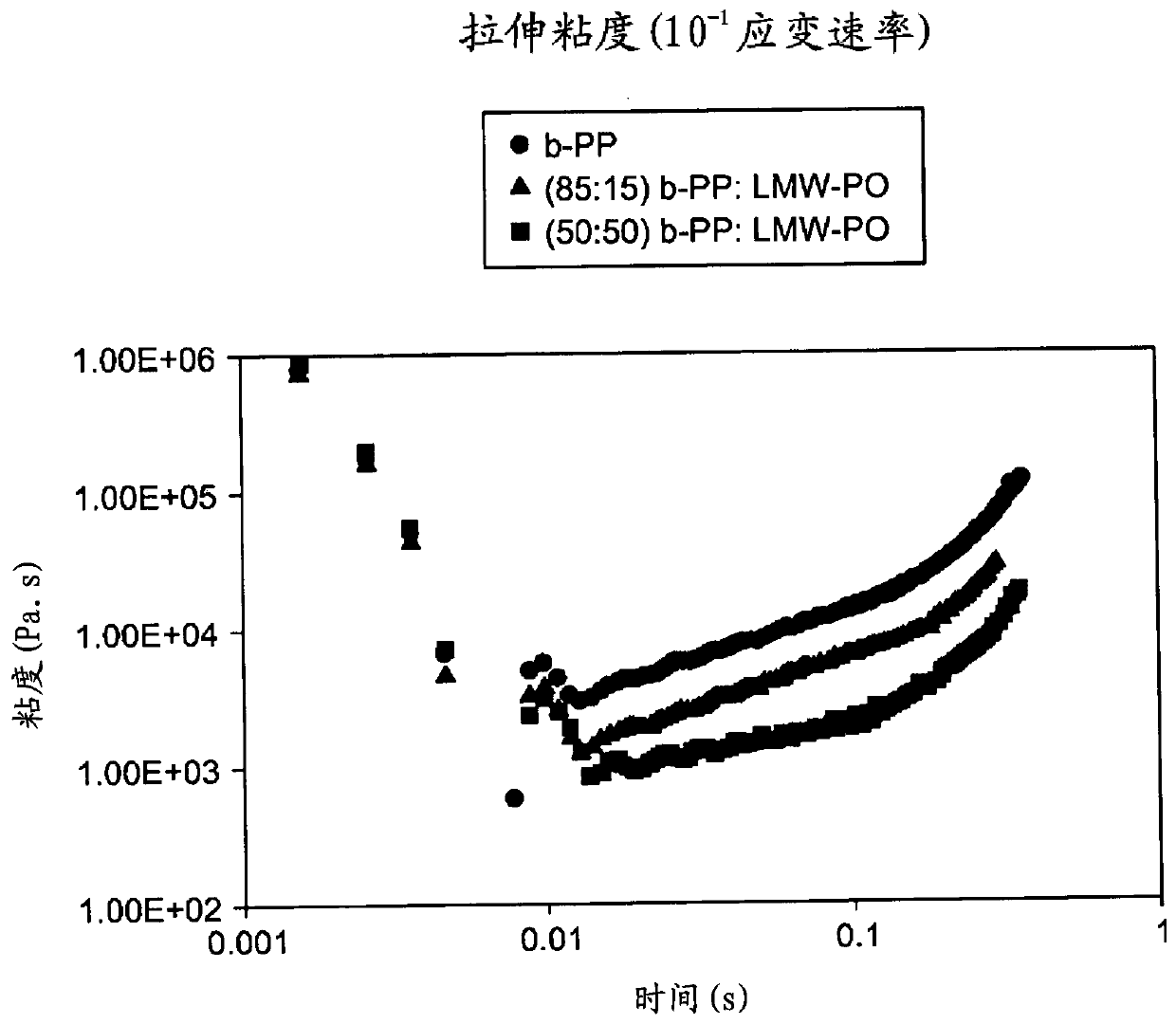

High melt strength polypropylenes with improved processability

A polypropylene composition suitable for foaming having improved processability but maintained strain hardening and the process to produce the polypropylene composition comprising combining a linear polypropylene having a melt strength within a range from 10 to 40 cN (190DC) with an organic peroxide to obtain a branched polypropylene having a melt strength within a range from 20 to 80 cN (190DC), wherein the melt strength of the branched polypropylene is greater than the melt strength of the linear polypropylene; and combining the branched polypropylene having a melt flow rate within a range of 0.1 to 20 g / 10 min and an Mw / Mn of at least 5 with within a range from 5 to 40 wt% of a low molecular weight polyolefin having a melt flow rate of at least 50g / 10 min and an Mw / Mn of less than 5 to obtain the polypropylene composition.

Owner:EXXONMOBIL CHEM PAT INC

Strip steel with excellent low-temperature secondary machining performance and tensile strength being 370 MPa level and production method

The invention provides strip steel with excellent low-temperature secondary machining performance and the tensile strength being 370 MPa level. Components of the strip steel with the excellent low-temperature secondary machining performance and the tensile strength being 370 MPa level comprise, by weight, 0.0008-0.0028% of carbon, 0.07-0.10% of silicon, 0.30-0.50% of manganese, 0.04-0.055% of phosphorous, smaller than or equal to 0.008% of sulphur, 0.02-0.045% of aluminum, 0.02-0.06% of titanium, 0.006-0.022% of niobium, 0.0005-0.0013% of boron and smaller than or equal to 0.002% of nitrogen.Production of the strip steel comprises the steps of smelting and casting into billets, heating the cast billets, rough rolling, finish rolling, coiling, cold rolling after acid pickling, continuous annealing treatment, slow cooling, rapid cooling, aging treatment and levelling. According to the strip steel with the excellent low-temperature secondary machining performance and the tensile strengthbeing 370 MPa level, under the premise that the mechanical property is guaranteed, the plastic strain ratio ranges between 1.8 and 2.0 r90, and the strain hardening exponent ranges between 0.2 and 0.21 n90; the secondary machining brittle transition temperature is stabilized between minus 60 DEG C and minus 70 DEG C; the quantity of the titanium element and the niobium element is reduced so thatthe cost is lowered by 5% or more; no carbonized edges or bonding defects exist on the steel plate surface; and the strip steel is used for automobile outer covering parts used in more severe cold areas.

Owner:武汉钢铁有限公司

Dependence-based multi-objective optimization method of integrated phenomenological constitutive model

ActiveCN107784167AImplement cross-couplingAccurately realize the definition of coupling relationshipDesign optimisation/simulationMulti-objective optimisationObservational errorStrength of materials

The invention discloses a dependence-based multi-objective optimization method of an integrated phenomenological constitutive model and belongs to the technical field of material mechanics properties,machine manufacturing and numerical analysis. The multi-objective optimization method is constructed by introducing three kinds of weighting factors in consideration of measuring errors and the sameoptimization opportunity of data point number or constitutive parameter number and quasi-static and dynamic states under different loading conditions, a non-coupled strain hardening function under quasi-static deformation, a thermal softening function under quasi-static deformation, a strain hardening function of coupling temperature under quasi-static deformation, a non-coupled strain rate sensitive function under quasi-static and dynamic deformation and a strain rate sensitive function of coupling temperature under quasi-static and dynamic deformation are sequentially determined according tooptimization quality criteria, and the basic form of the phenomenological constitutive model is determined; the specific form of the determined constitutive model is fit according to test data underall loading conditions with the multi-weight and multi-objective optimization method.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

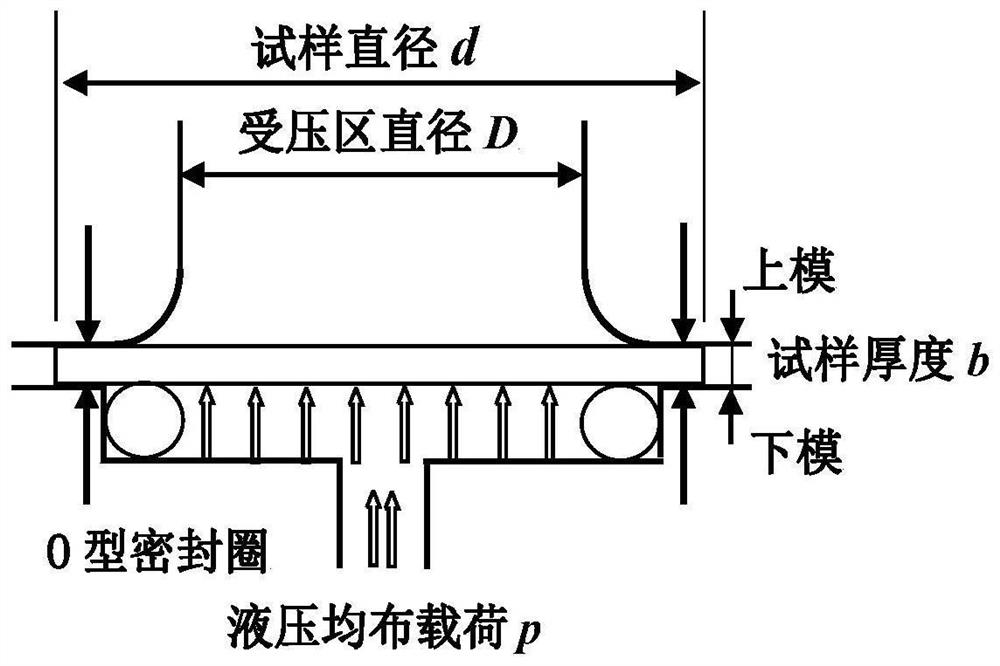

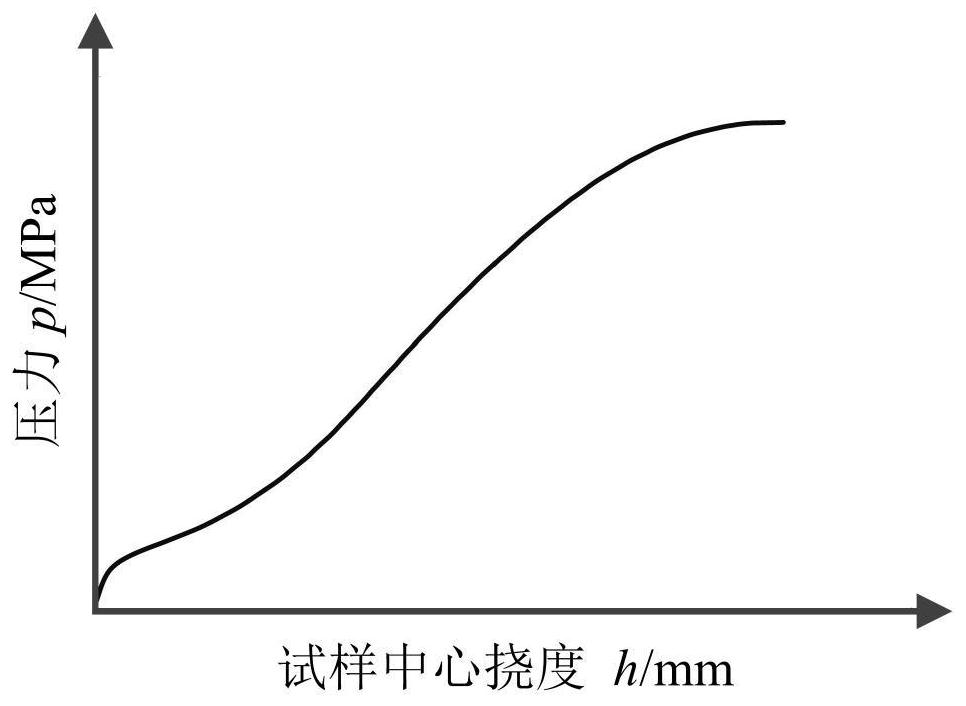

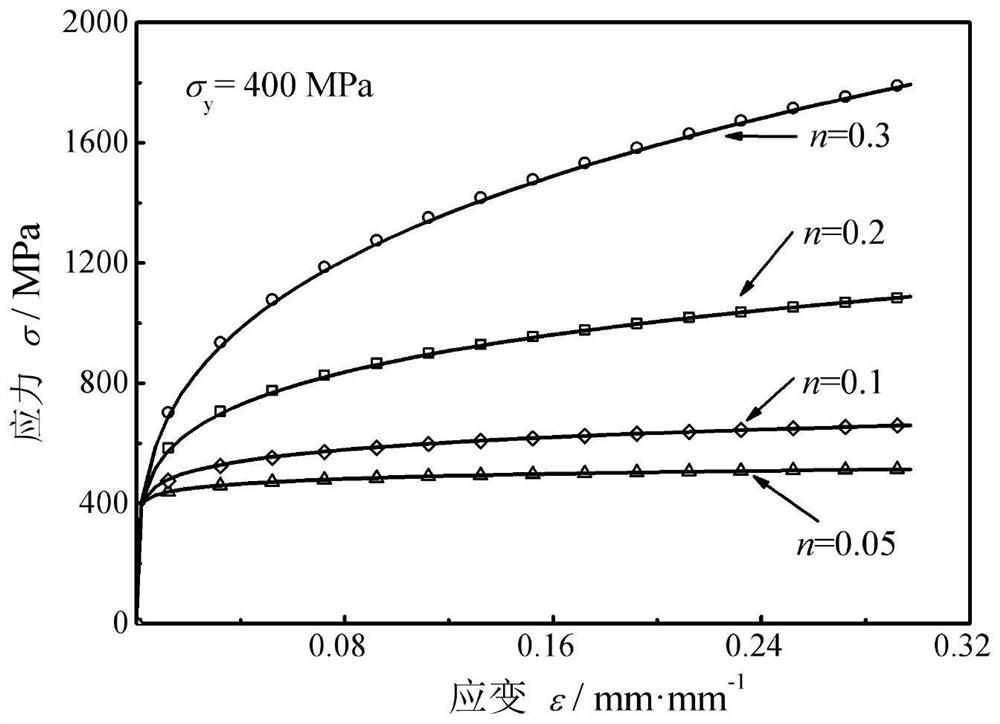

Method for determining uniaxial stress-strain relationship of material based on high-temperature hydraulic bulging sample test

ActiveCN112284921ASimple test methodHigh precisionMaterial strength using tensile/compressive forcesTest sampleEngineering

The invention discloses a method for determining uniaxial stress-strain relationship of a material based on a high-temperature hydraulic bulging sample test, and the method comprises the following steps: preparing a test sample, carrying out a hydraulic bulging test on the test sample to obtain a pressure center deflection test curve of the test sample, and obtaining an external force work centerdeflection curve of the sample based on the pressure center deflection test curve, obtaining the yield strength and the strain hardening index of the material by utilizing the external force work center deflection curve, and further determining the uniaxial stress-strain relationship of the material. According to the method for determining the uniaxial stress-strain relationship of the material, the uniaxial stress-strain relationship of the material is obtained through a hydraulic bulging micro-sample test technology, and material parameters of the uniaxial stress-strain relationship curve ofthe material can be obtained only by simply analyzing and calculating a pressure center deflection test curve obtained through the test; the obtained result is high in precision, a large number of tests are not needed, the test method and the test principle are relatively simple, and engineering application is very convenient.

Owner:SUZHOU NUCLEAR POWER RES INST +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com