180 MPa-grade cold-rolled ultralow carbon baking hardened steel and production method thereof

A bake-hardening and production method technology, applied to 180MPa grade cold-rolled ultra-low carbon bake-hardened steel and its production field, can solve the problems of low tensile strength, high cost, lower P content, etc., and achieve excellent stamping performance , low production cost, good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

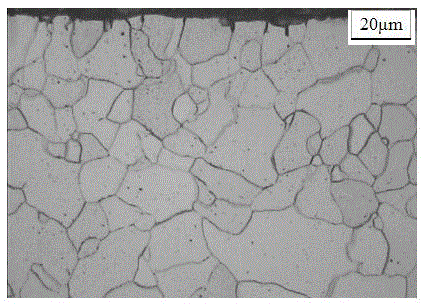

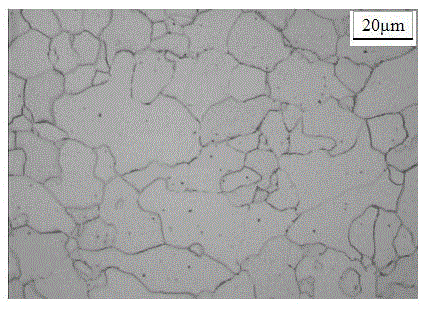

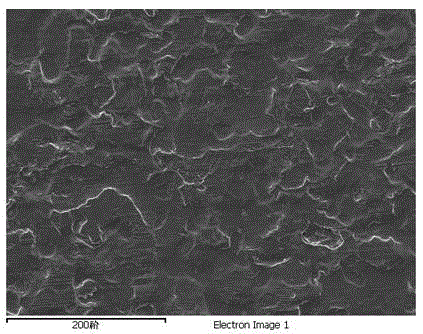

Image

Examples

Embodiment Construction

[0015] A 180MPa grade cold-rolled ultra-low carbon bake-hardening steel of the present invention, its chemical components and component weight percentages are: C: 0.0015-0.0023%; Si: 0.006-0.010%; Mn: 0.40-0.55%; P :0.030~0.045%; Nb:0.008~0.010%; S≤0.012%; Als:0.032~0.040%; N:0.0016~0.0037%, the rest is Fe; where C% / Nb%=0.16~0.28.

[0016] C is the most important strengthening element of strip steel. The precise control of C element can effectively adjust the bake hardening performance of the matrix, but the increase of C content will damage the stamping performance of the material. After a large number of tests, the range of C element selected in the present invention is 0.0015~ 0.0023%.

[0017] The solid solution element P can effectively improve the strength of ultra-low carbon bake-hardening steel, but too high P content (the weight percentage of P ≥ 0.07%) will lead to the embrittlement of the secondary processing of the strip; Mn has a direct impact on the final perform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com