Method for determining maximum strain hardening exponent according to strength of steel-iron material

A hardening index, maximum strain technique used to test material strength and other directions using a stable tension/compression applied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] For a medium-carbon low-alloy steel obtained by normalizing, the structure is ferrite + pearlite, including the following steps:

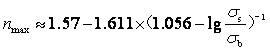

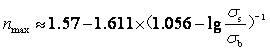

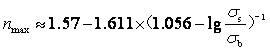

[0084] First, the formula between the yield strength and tensile strength of the steel material and the maximum strain hardening exponent is firstly deduced. The specific operation is:

[0085] The hardened strength of a material can be determined by the Hollomon relation:

[0086] (1)

[0087] In the formula:

[0088] S ——true stress / MPa;

[0089] K ——intensification coefficient / MPa;

[0090] e ——True strain;

[0091] n - strain hardening exponent;

[0092] because n The generalized mechanical definition of the value refers to the sensitivity of deformation stress to strain at any instant in tensile deformation, n The geometric meaning of the value is the slope of the strain hardening curve on the stress-strain logarithmic coordinate plane;

[0093] (2)

[0094] For the data collected by the computer during the tensi...

Embodiment 2

[0162] For a medium-carbon low-alloy steel obtained by quenching and then tempering, the structure is ferrite + upper bainite + tempered sorbite, including the following steps:

[0163] First, the formula between the yield strength and tensile strength of the steel material and the maximum strain hardening exponent is firstly deduced. The specific operation is:

[0164] The hardened strength of a material can be determined by the Hollomon relation:

[0165] (1)

[0166] In the formula:

[0167] S ——true stress / MPa;

[0168] K ——intensification coefficient / MPa;

[0169] e ——True strain;

[0170] n - strain hardening exponent;

[0171] because n The generalized mechanical definition of the value refers to the sensitivity of deformation stress to strain at any instant in tensile deformation, n The geometric meaning of the value is the slope of the strain hardening curve on the stress-strain logarithmic coordinate plane;

[0172] (2)

[0173] For the data c...

Embodiment 3

[0241] For a medium-carbon low-alloy steel that is first quenched and then tempered, the structure is complete martensite, including the following steps:

[0242] First, the formula between the yield strength and tensile strength of the steel material and the maximum strain hardening exponent is firstly deduced. The specific operation is:

[0243] The hardened strength of a material can be determined by the Hollomon relation:

[0244] (1)

[0245] In the formula:

[0246] S ——true stress / MPa;

[0247] K ——intensification coefficient / MPa;

[0248] e ——True strain;

[0249] n - strain hardening exponent.

[0250] because n The generalized mechanical definition of the value refers to the sensitivity of deformation stress to strain at any instant in tensile deformation, n The geometric meaning of the value is the slope of the strain hardening curve on the stress-strain logarithmic coordinate plane;

[0251] (2)

[0252] For the data collected by the compute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com