Method for establishing J-C constitutive model of metal material

A technology of metal materials and constitutive models, which is applied in the direction of testing metals, material inspection products, and using stable tension/pressure to test the strength of materials, etc., can solve problems such as the inability to carry out laser shock strengthening finite element numerical simulation, and achieve high precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

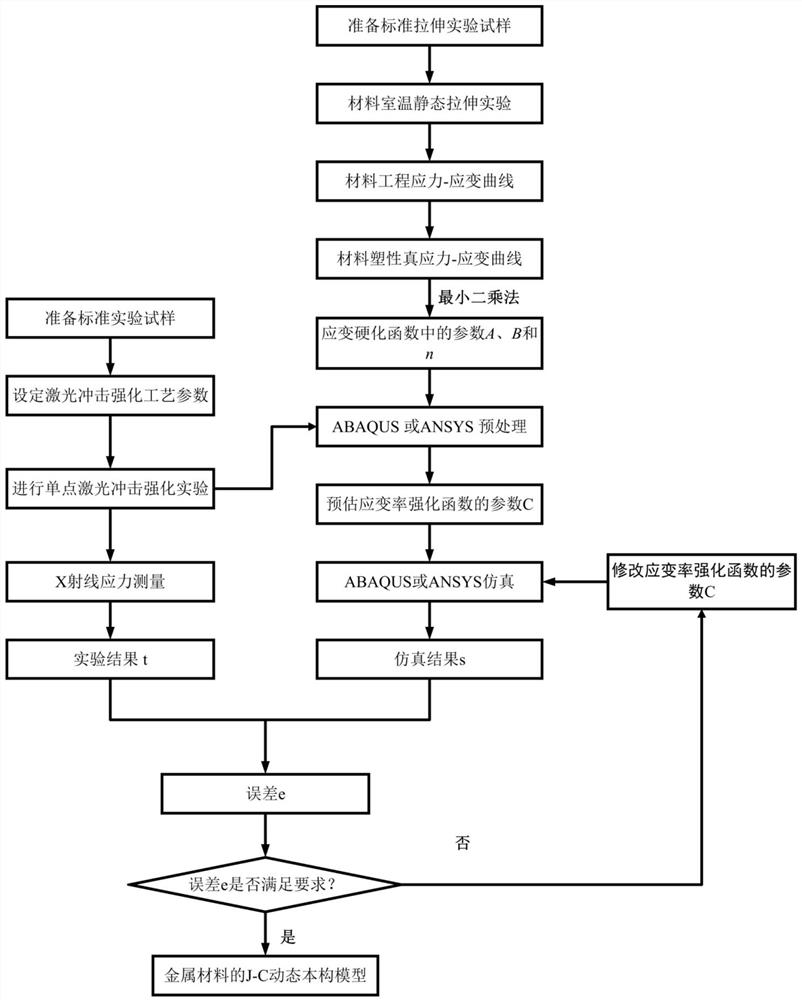

[0041] Aiming at the problem that some new materials cannot carry out laser shock strengthening finite element numerical simulation due to lack of dynamic constitutive model, the present invention proposes a J-C constitutive model establishment method for metal materials, which can be used for laser shock strengthening finite element numerical simulation of new materials Guidance on how to carry out and improve the work.

[0042] Firstly, the result of the material is obtained through the laser shock strengthening experiment, that is, the characteristic parameters, and then the engineering stress-strain curve is obtained through the static tensile test, that is, the characteristic curve, and then the characteristic curve is established based on the characteristic curve and characteristic parameters for laser shock strengthening simulation. The finite element model of the J-C constitutive model belongs to the simulated material model, which is determined according to the simulat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spot diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com