Optimization control method for heat insulation performance of porous material

A porous material and optimization control technology, applied in the field of porous materials, can solve the problems of inapplicability and unproposed pore control method, etc., and achieve the effects of strong applicability, improved heat insulation performance, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

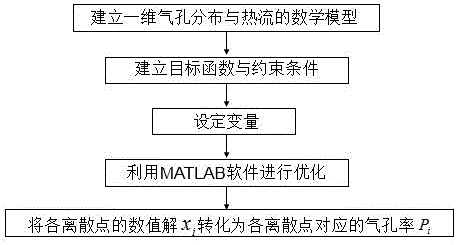

[0065] A kind of mullite Al 6 Si 2 o 13 Optimal control method for thermal insulation performance of porous materials. The optimal control method described in this embodiment is as follows: figure 1 Shown:

[0066] Step 1. Establish a mathematical model of one-dimensional porosity distribution and heat flow

[0067] Let the temperature follow the mullite Al 6 Si 2 o 13 The heat transfer direction of the porous material is linearly distributed, and the mullite Al 6 Si 2 o 13 Thermal conductivity K of porous materials as a function of heat transfer direction, mullite Al 6 Si 2 o 13 The mathematical model f of the one-dimensional porosity distribution and heat flow q of porous materials is

[0068]

[0069] In formula (1):

[0070] n represents mullite Al 6 Si 2 o 13 The total number of discrete points set in the heat transfer direction of the porous material, n=100;

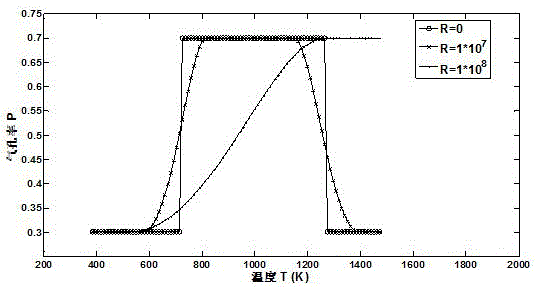

[0071] i means mullite Al 6 Si 2 o 13 The serial number of the discrete point set in the...

Embodiment 2

[0119] An optimal control method for the thermal insulation performance of porous materials with different solid phase matrices. The optimal control method described in this embodiment is as follows: figure 1 Shown:

[0120] Step 1. Establish a mathematical model of one-dimensional porosity distribution and heat flow

[0121] Assuming that the temperature is linearly distributed along the heat transfer direction of different solid matrix porous materials, the thermal conductivity K of different solid matrix porous materials is a function of the heat transfer direction, and the mathematical relationship between the one-dimensional porosity distribution and heat flow q of different solid matrix porous materials Model f is

[0122]

[0123] In formula (1):

[0124] n represents the total number of discrete points set in the direction of heat transfer for different solid matrix porous materials, n=50;

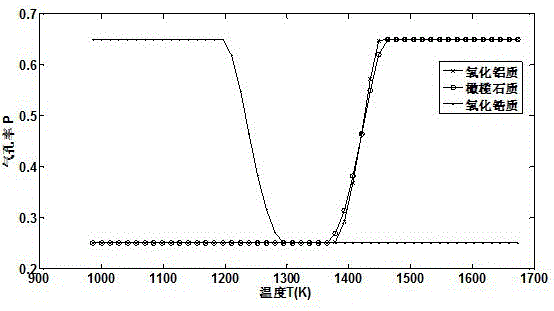

[0125] i represents the serial number of discrete points set in the dir...

Embodiment 3

[0175] A method for optimizing and controlling the thermal insulation performance of alumina porous materials. The optimal control method described in this embodiment is as follows: figure 1 Shown:

[0176] Step 1. Establish a mathematical model of one-dimensional porosity distribution and heat flow

[0177] Assuming that the temperature is linearly distributed along the heat transfer direction of the alumina porous material, the thermal conductivity K of the alumina porous material is a function of the heat transfer direction, and the mathematical model f of the one-dimensional porosity distribution and heat flow q of the alumina porous material is

[0178]

[0179] In formula (1):

[0180] n represents the total number of discrete points set in the heat transfer direction of the alumina porous material, n=60;

[0181] i represents the serial number of the discrete point set in the heat transfer direction of the alumina porous material;

[0182] x i Represents the rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com