Preparation method of graphitized cold-rolled high-carbon steel plate for stamping forming

A technology of stamping forming and graphitization, which is applied in the field of metallurgy, can solve the problems affecting the stamping performance of steel plates and the inability to obtain graphite particles, etc., and achieve the effects of low hardness, good stamping performance and high plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

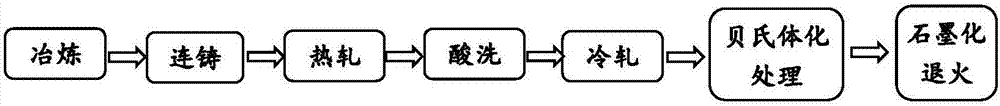

[0021] The preparation of 1.0mm graphitized cold-rolled steel plate, the main process flow: smelting, continuous casting, hot rolling, pickling, cold rolling, bainite treatment and graphitization annealing.

[0022] The chemical composition (mass fraction / %) of the graphitized hot-rolled steel sheet of this embodiment is: 0.46C, 0.17Si, 0.72Mn, 0.010S, 0.009P, 0.026Al, 0.0036B, 0.0050N.

[0023] The main process parameters of bainite treatment are: use 840°C isothermal treatment, and after treatment, rapidly cool to 320°C at a cooling rate greater than 15°C / s for isothermal transformation.

[0024] The main process parameters of the graphitization annealing are: the graphitization temperature is 680°C, and the graphitization annealing time is 6 hours.

[0025] The graphitized cold-rolled high-carbon steel plate prepared by the above method was sampled, analyzed and tested, and the results showed that the graphite particles observed in the structure were evenly distributed, nea...

Embodiment 2

[0027] The preparation of 3.0mm graphitized cold-rolled steel plate, the main process flow: smelting, continuous casting, hot rolling, pickling, cold rolling, bainite treatment and graphitization annealing.

[0028] The chemical composition (mass fraction / %) of the graphitized hot-rolled steel sheet in this embodiment is: 0.67C, 0.12Si, 0.76Mn, 0.008S, 0.006P, 0.025Al, 0.0030B, 0.0040N.

[0029] The main process parameters of bainite treatment are: use 800°C isothermal treatment, and after treatment, rapidly cool to 300°C at a cooling rate greater than 20°C / s for isothermal transformation.

[0030] The main process parameters of the graphitization annealing are: the graphitization temperature is 660° C., and the graphitization annealing time is 5 hours.

[0031]The graphitized cold-rolled high-carbon steel plate prepared by the above method was sampled, analyzed and tested, and the results showed that the graphite particles observed in the structure were evenly distributed, ne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com