Shot peening strengthening method for controlling strain hardening rate of high temperature alloy surface

A strain hardening rate, superalloy technology, applied in the field of shot peening and surface shot peening of metal materials, it can solve the problems of poor thermal stability of compressive stress field, not suitable for strengthening treatment of superalloy parts, and achieve a mature working principle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments:

[0018] The test material of this embodiment is a high temperature alloy GH4169, and the size of the shot peening sample is 20mm×20mm×20mm small squares.

[0019] The steps of the shot peening method for controlling the surface strain hardening rate of superalloys of the present invention are as follows:

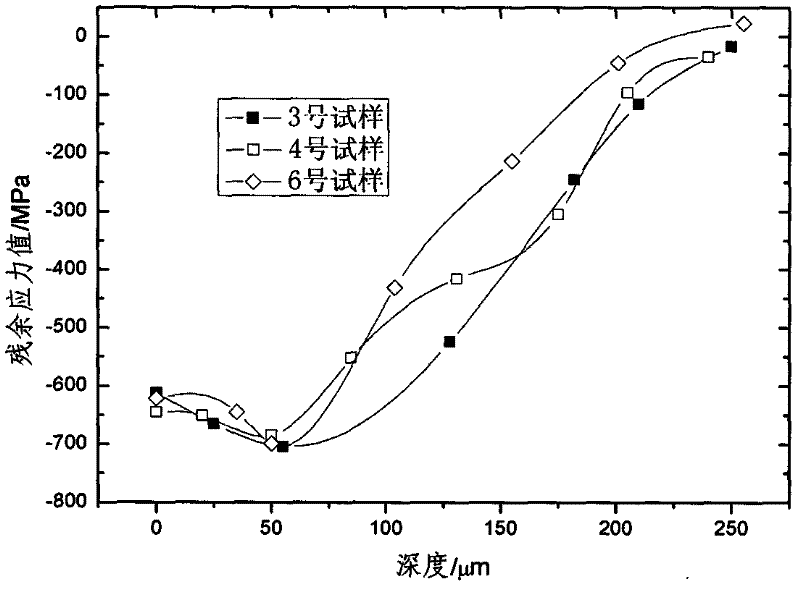

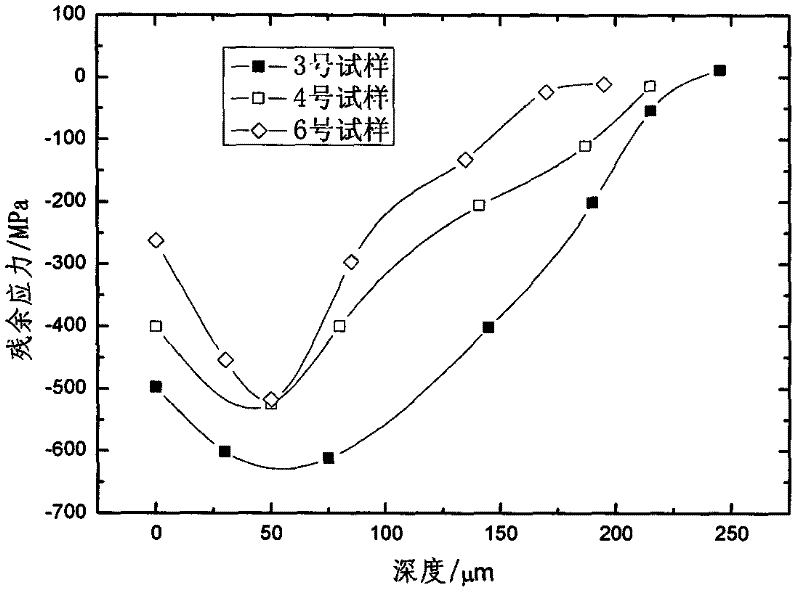

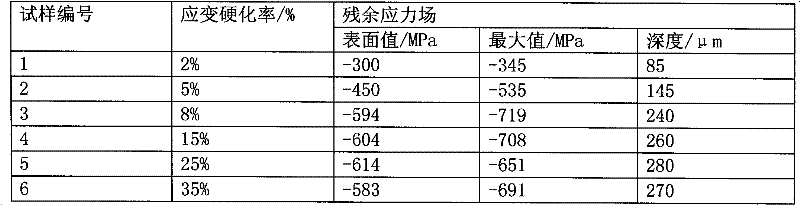

[0020] (1) The surface residual compressive stress value, the depth of residual compressive stress and the maximum residual compressive stress value of the superalloy material are used as the three parameters to characterize the residual compressive stress field, and the X-ray diffraction residual stress measurement method is used to determine the shot peening from small to large Surface residual compressive stress value, residual compressive stress depth and maximum residual compressive stress value under strain hardening ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com