Anti-large-deformation pipe line steel prepared by thermal treatment method and preparation method thereof

A heat treatment method and a technology for resisting large deformation, applied in the field of metallurgy, can solve problems such as no heat treatment process, production of dual-phase pipeline steel, etc., and achieve the effects of low alloying element content, large uniform elongation, and high uniform elongation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

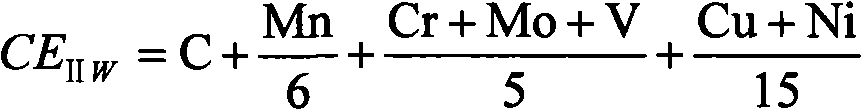

Method used

Image

Examples

Embodiment 1

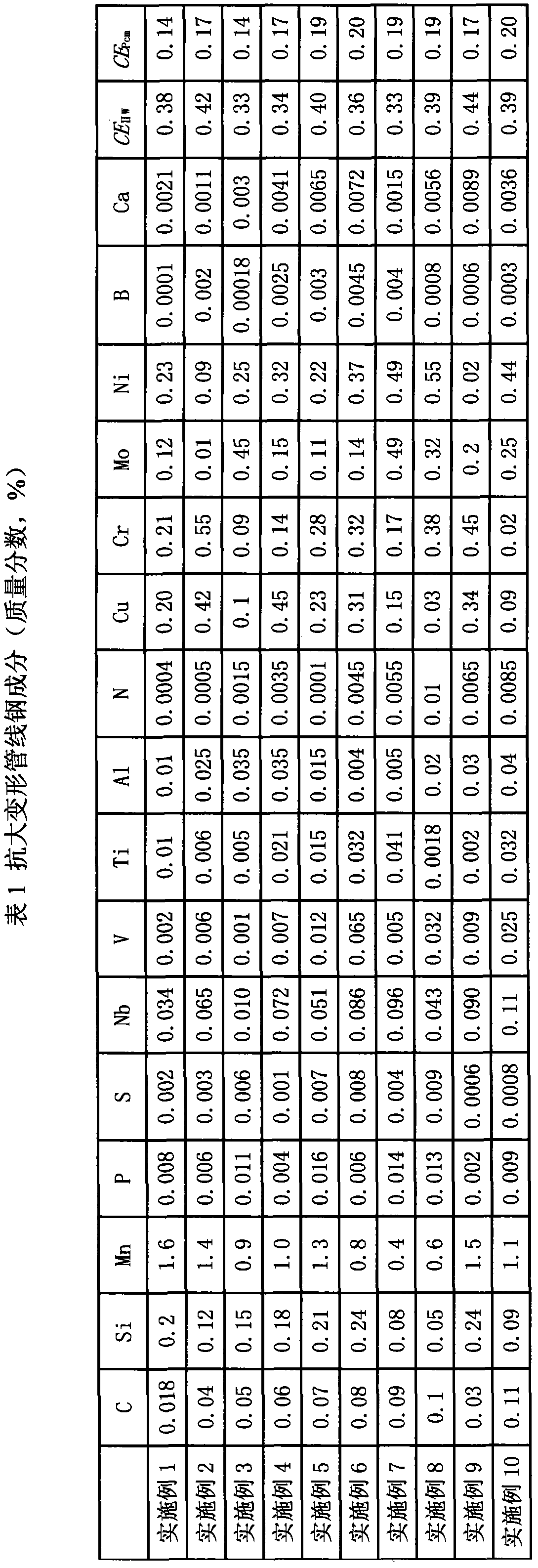

[0021] The mass fraction of each element in the large deformation resistant pipeline steel prepared by the heat treatment method is shown in Example 1 in Table 1. Process by holding temperature, holding time, cooling rate and tempering temperature shown in Table 2 Example 1 in the heat treatment furnace. The ferrite volume percentage, grain average diameter and properties are shown in Table 3, Example 1.

Embodiment 2

[0023] The mass fraction of each element in the large deformation resistant pipeline steel prepared by the heat treatment method is shown in Example 2 in Table 1. Process by holding temperature, holding time, cooling rate and tempering temperature shown in Table 2 Example 2 in the heat treatment furnace. The ferrite volume percentage, grain average diameter and properties are shown in Table 3, Example 2.

Embodiment 3

[0025] The mass fraction of each element in the large deformation resistant pipeline steel prepared by the heat treatment method is shown in Example 3 in Table 1. Process by holding temperature, holding time, cooling rate and tempering temperature shown in Table 2 Example 3 in the heat treatment furnace. The ferrite volume percentage, grain average diameter and properties are shown in Table 3, Example 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com