Thick plate with excellent plasticity and toughness for pipelines and production method of thick plate

A plastic toughness, pipeline technology, applied in the thick plate for pipeline and its production field, to achieve the effect of reducing deformation load, improving hardenability, and realizing grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

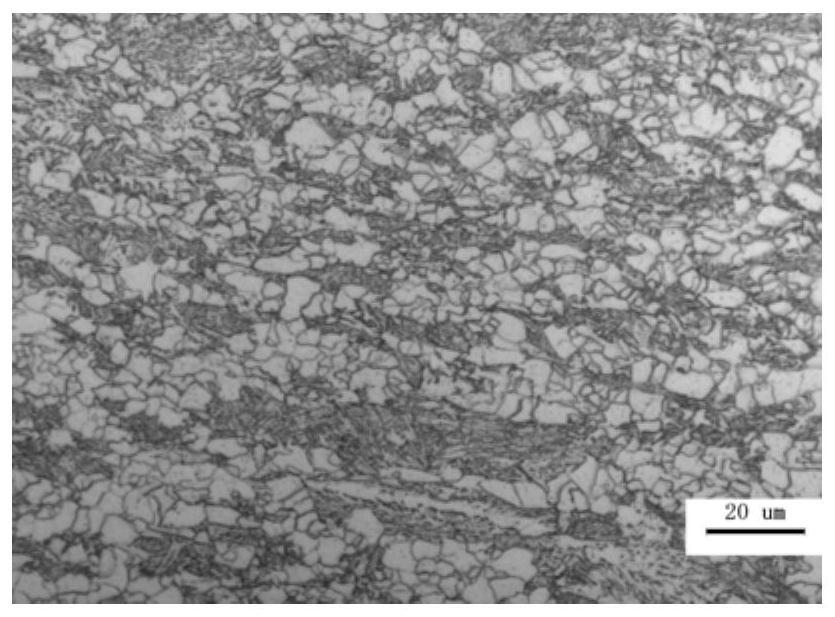

Image

Examples

Embodiment Construction

[0047] Below by embodiment the present invention will be further described.

[0048] In the embodiment of the present invention, according to the composition ratio of the technical solution, converter smelting, refining outside the furnace, continuous casting, rolling, heating and cooling are carried out.

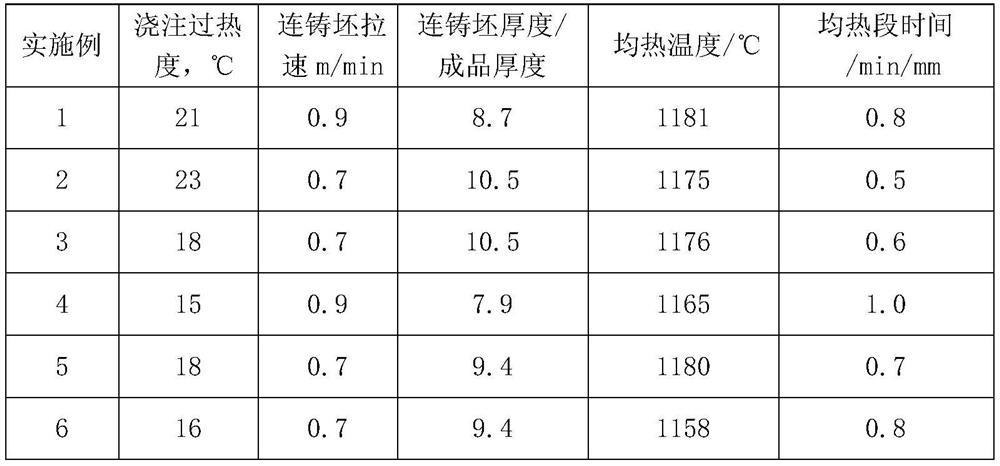

[0049] (1) Continuous casting and heating: the pouring superheat of the continuous casting slab is 10-25°C, the casting speed of the continuous casting slab is 0.6-1.2m / min, the thickness of the continuous casting slab / the thickness of the finished steel plate is ≤11; the temperature of the soaking section of the continuous casting slab is 1140 ~1190℃, soaking time not less than 0.3min / mm;

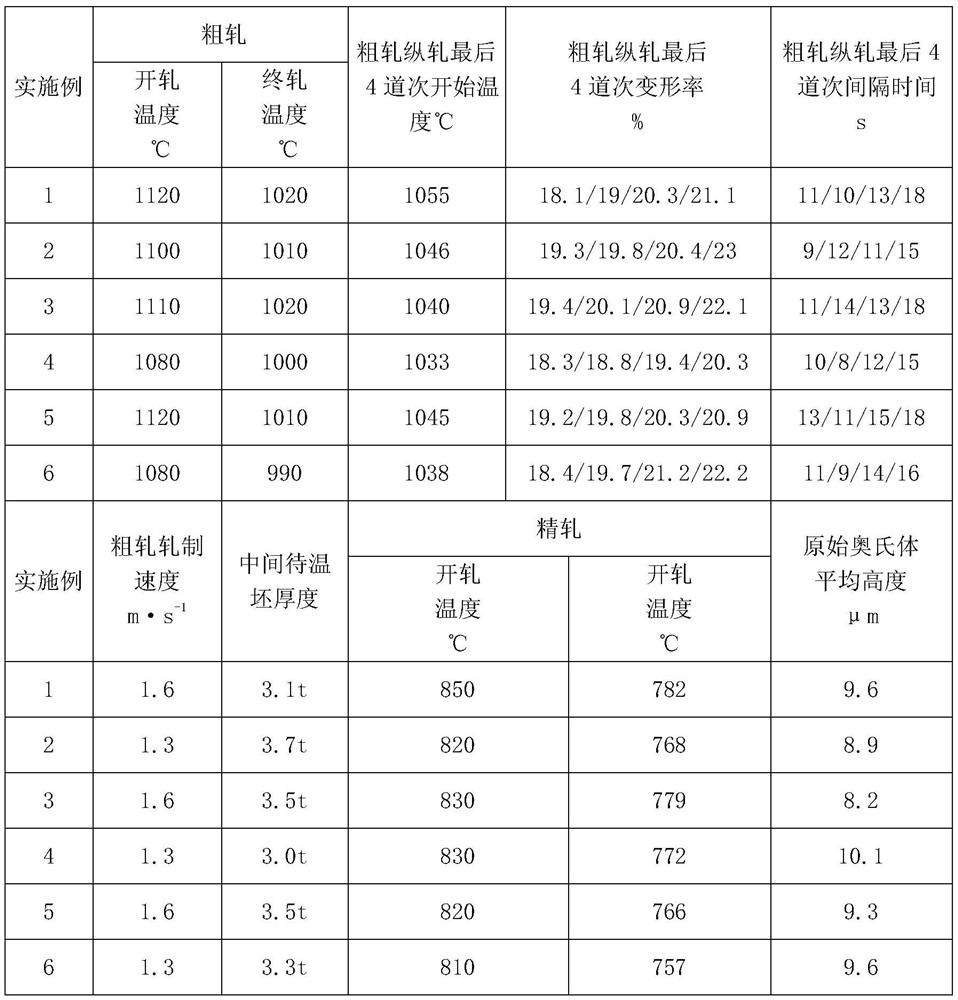

[0050] (2) Rolling: The rough rolling start temperature is 1080-1120°C, the rough rolling finish temperature is 990-1040°C, and the rolling method adopts horizontal and vertical rolling or direct longitudinal rolling. 7 passes, the deformation rate of each pass in the last 4 passes of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com