Strip steel with excellent performance at low temperature secondary processing and with tensile strength being 390 MPa and production method

A technology of secondary processing and tensile strength, applied in the field of strip steel with a tensile strength of 390MPa and excellent secondary processing performance at low temperature Less than -60 ℃, can not meet the requirements of secondary processing brittleness of the car body, etc., to achieve the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

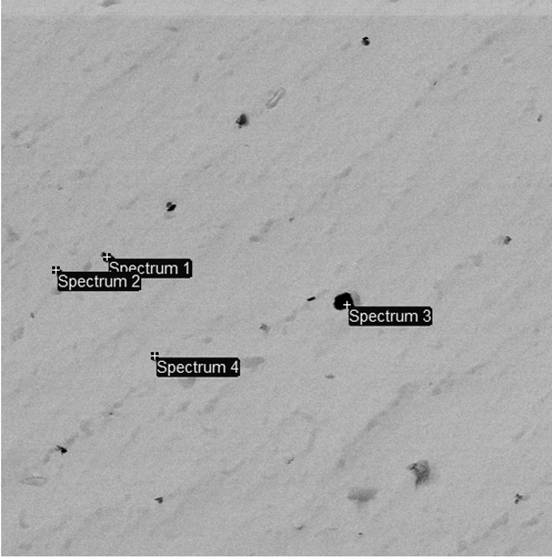

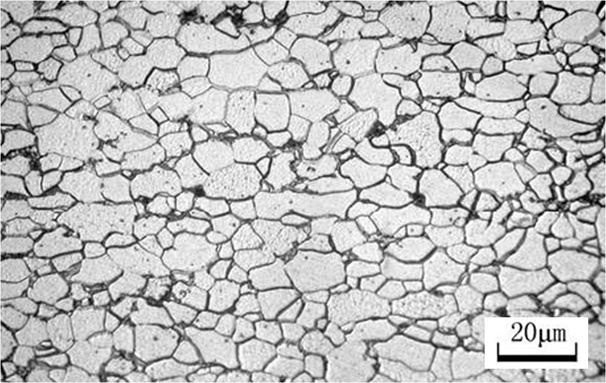

Image

Examples

Embodiment Construction

[0044] The present invention is described in detail below:

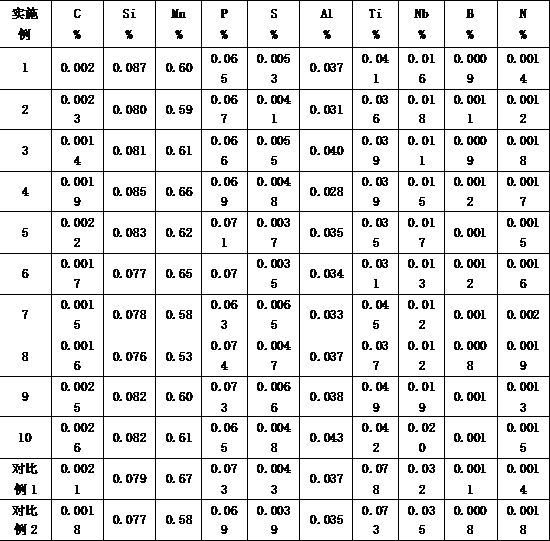

[0045] Table 1 is the value list of each embodiment of the present invention and comparative example chemical composition;

[0046] Table 2 is the value list of the main process parameters of each embodiment of the present invention and comparative examples;

[0047] Table 3 is each embodiment of the present invention and comparative example performance detection and result list;

[0048] Each embodiment is produced according to the following steps:

[0049] 1) Desulfurized molten iron is used to smelt the product according to the predetermined composition and cast it into billets;

[0050] 2) Heating the slab: the heating temperature is controlled at 1240-1280°C, and the heat preservation is at 150-200min;

[0051] 3) Carry out rough rolling, and control the rough rolling temperature at 1060-1090°C;

[0052] 4) Carry out finish rolling, and control the finish rolling temperature at 900-940°C;

[0053] 5) Carry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| brittleness temperature | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com