Method for predicting high-temperature creep property of heat resistant steel

A technology of high-temperature creep and heat-resistant steel, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of inability to accurately predict the creep life of high-temperature materials, and achieve the intuitive and easy-to-characterize dislocation deformation mechanism Control, operation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to facilitate understanding of the present invention, the present invention enumerates the following examples. It should be clear to those skilled in the art that the embodiments are only for helping to understand the present invention, and should not be regarded as specific limitations on the present invention.

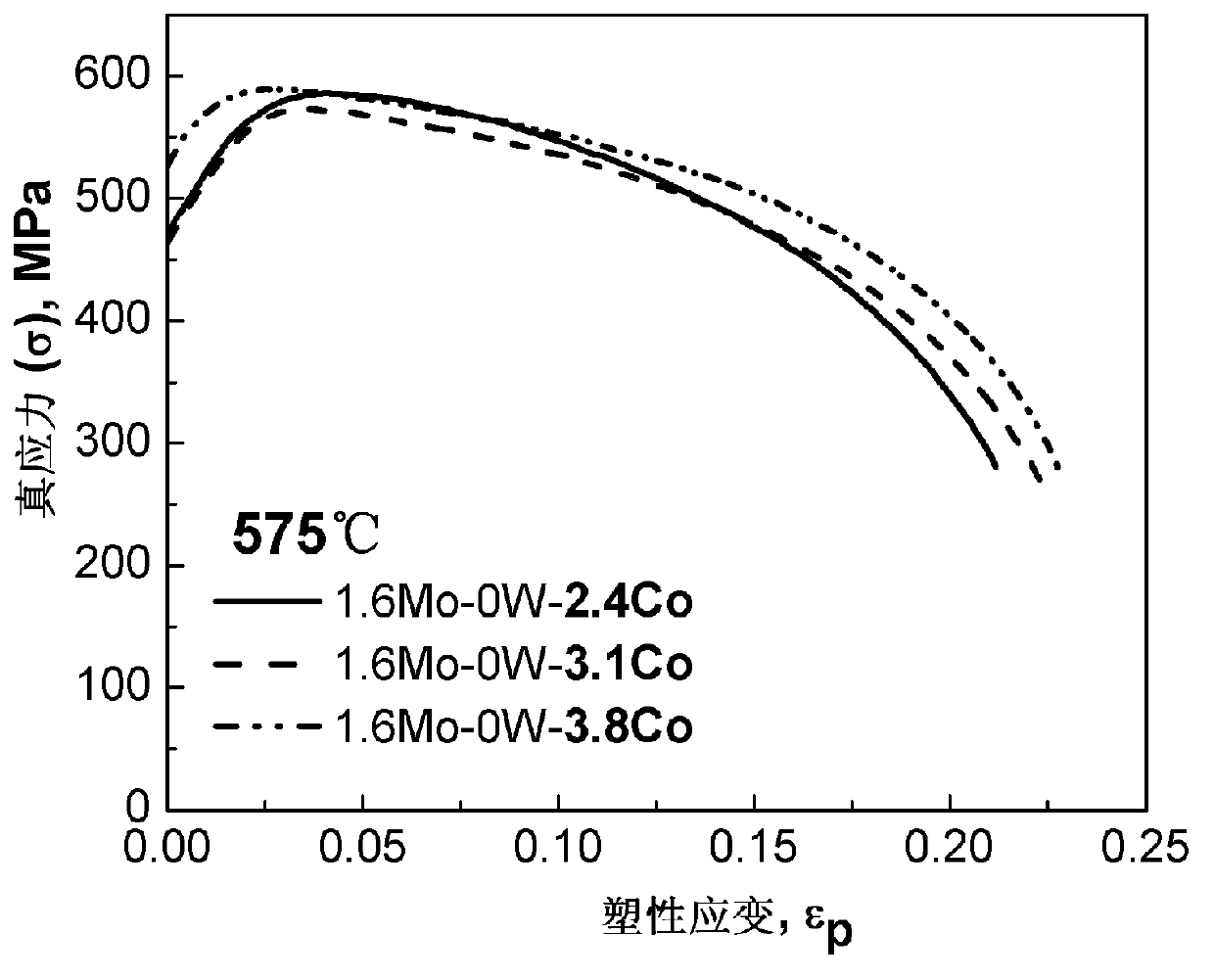

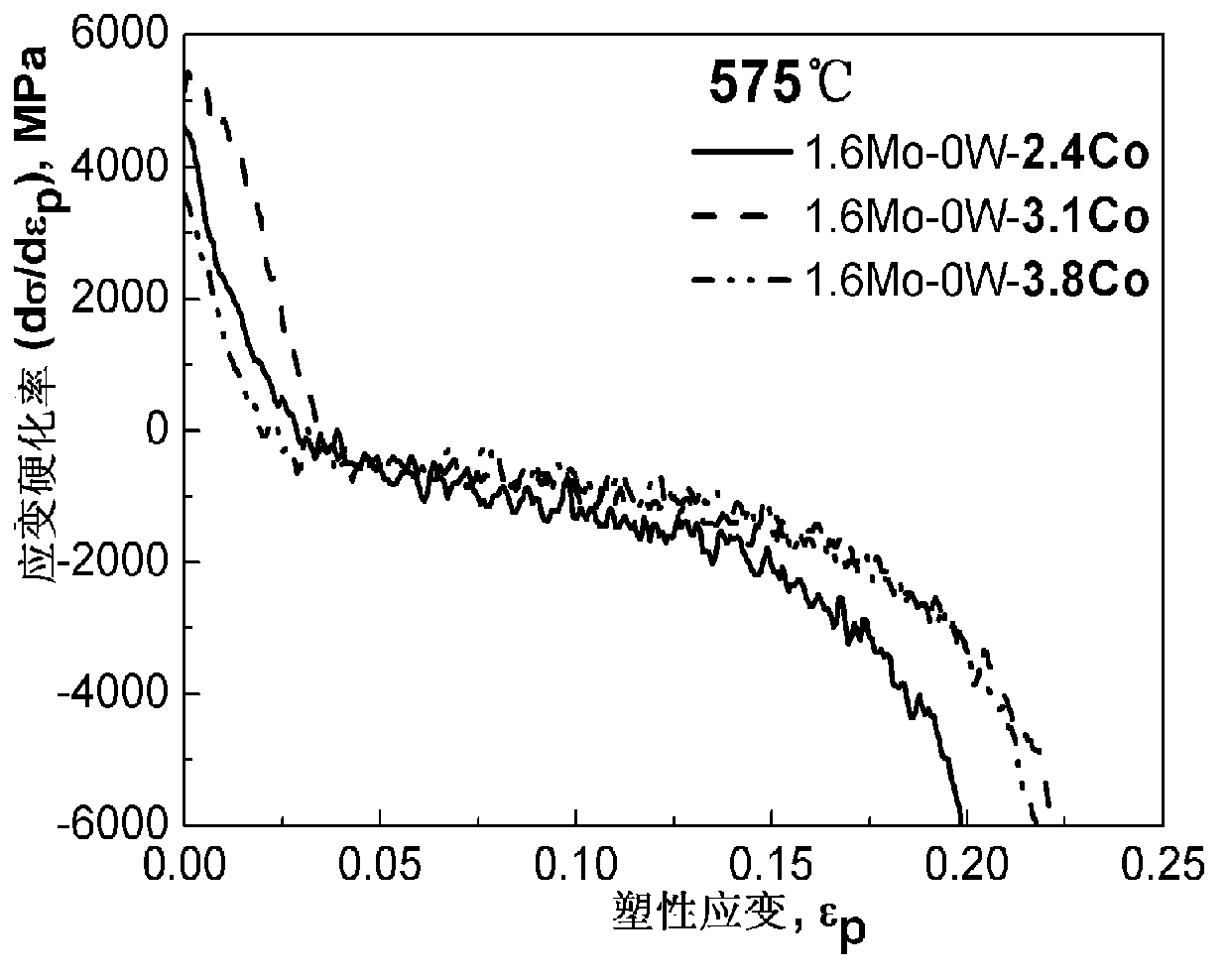

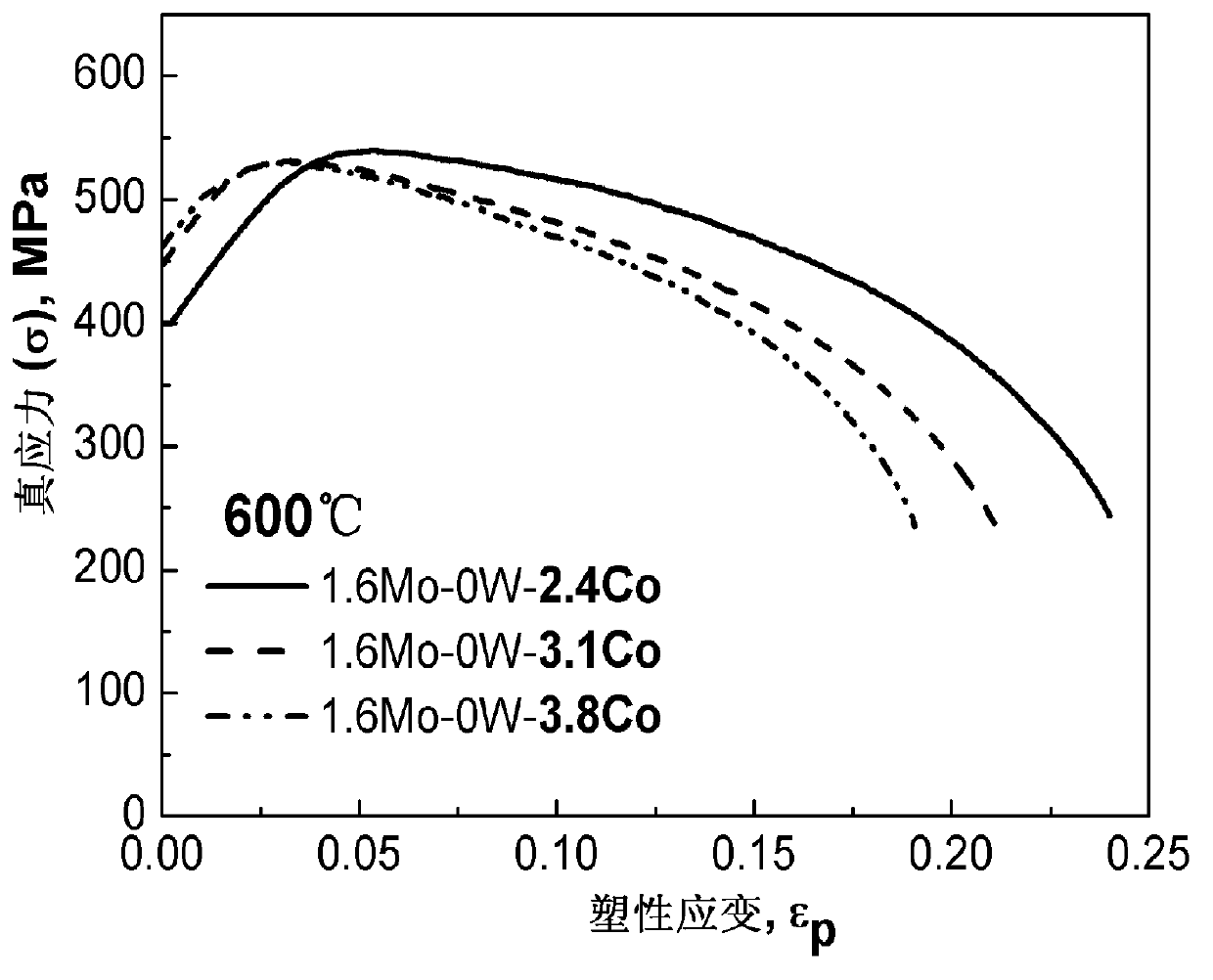

[0033] According to the design principle of 9-12%Cr ferritic heat-resistant steel, on the basis of X12CrMoWVNbN10-1-1 steel, Co element was added, and the content of Mo and W was adjusted to design 9 new types of Co-containing ferritic heat-resistant steel ( The chemical composition is shown in Table 1). At 575°C, 600°C and 625°C respectively, a high temperature tensile testing machine (strain rate: 1×10 -6 S -1 ), conduct a slow-rate high-temperature tensile test, and use data acquisition software to record the load and displacement data during the tensile process in real time, and draw the obtained load and displacement data into a load-displaceme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com