Method for precisely determining hardening index of material

A strain hardening index, accurate technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problem that the error of the measured value cannot be guaranteed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

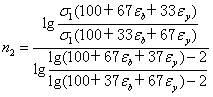

Method used

Image

Examples

Embodiment 1

[0045] For a medium-carbon low-alloy steel obtained by normalizing, the structure is ferrite + pearlite, including the following steps:

[0046] First, draw the tensile curve σ-ε according to the tensile test data;

[0047] Second, determine the "starting point of strain hardening" on the tensile curve drawn in the previous step. The specific method is:

[0048] Because the material has an obvious yield point, the point at which the stress begins to rise monotonously after the material yields is taken as the "starting point of strain hardening", and the corresponding strain at this point is 0.0055;

[0049]Third, determine the "end point of strain hardening" on the tensile curve drawn in the first step,

[0050] The stress reaches the maximum value σ max The corresponding point is "the end point of strain hardening", and the corresponding strain of this point is 0.1135;

[0051] Fourth, determine two "key points" on the stretch curve,

[0052] The first "key point" should ...

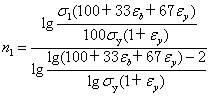

Embodiment 2

[0071] For a medium-carbon low-alloy steel obtained by quenching and then tempering, the structure is ferrite + upper bainite + tempered sorbite, including the following steps:

[0072] First, draw the tensile curve σ-ε according to the tensile test data;

[0073] Second, determine the "starting point of strain hardening" on the tensile curve drawn in the previous step. The specific method is:

[0074] Because the material has an obvious yield point, the point at which the stress begins to rise monotonously after the material yields is taken as the "starting point of strain hardening", and the corresponding strain at this point is 0.01026;

[0075] Third, determine the "end point of strain hardening" on the tensile curve drawn in the first step,

[0076] The stress reaches the maximum value σ max The corresponding point is "the end point of strain hardening", and the corresponding strain of this point is 0.0722;

[0077] Fourth, determine two "key points" on the stretch cur...

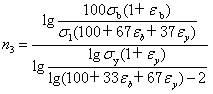

Embodiment 3

[0097] For a medium-carbon low-alloy steel that is first quenched and then tempered, the structure is complete martensite, including the following steps:

[0098] First, draw the tensile curve σ-ε according to the tensile test data;

[0099] Second, determine the "starting point of strain hardening" on the tensile curve drawn in the previous step,

[0100] Because the material has an obvious yield point, the point at which the stress begins to rise monotonously after the material yields is taken as the "starting point of strain hardening", and the corresponding strain at this point is 0.01202;

[0101] Third, determine the "end point of strain hardening" on the tensile curve drawn in the first step,

[0102] The stress reaches the maximum value σ max The corresponding point is "the end point of strain hardening", and the corresponding strain of this point is 0.0643;

[0103] Fourth, determine two "key points" on the stretch curve,

[0104] The first "key point" should be: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com