Application of a kind of ECC material in the reinforcement of recycled aggregate, recycled reinforced aggregate and its preparation method and application

A technology for recycled aggregates and aggregates, applied in climate change adaptation, sustainable waste treatment, solid waste management, etc., can solve the problems of damaged recycled aggregates, high cost of chemical solutions, high mechanical energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

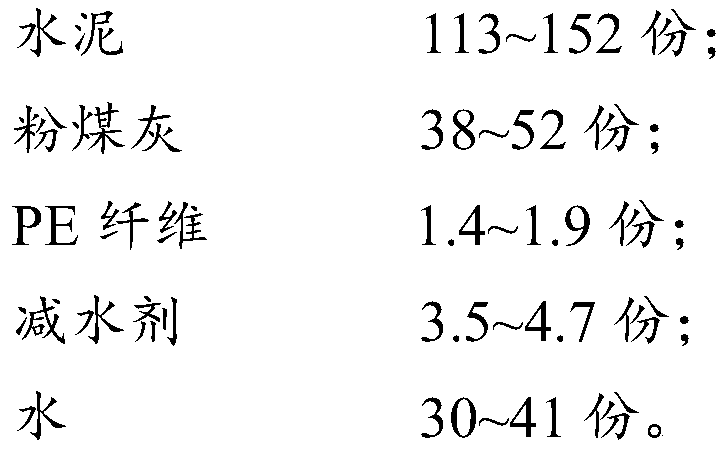

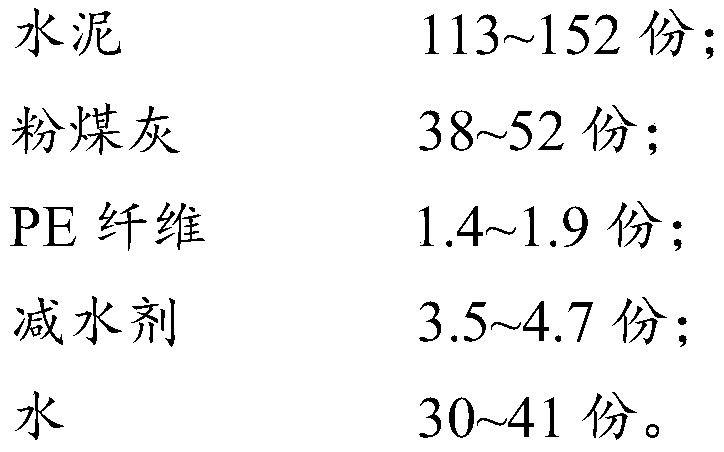

[0035] In the present invention, the preparation method of the ECC material preferably comprises the following steps:

[0036] mixing cement and fly ash to obtain a first mixture;

[0037] Stirring the first mixture, water reducing agent and water for the first time to obtain the second mixture;

[0038] performing a second agitation of the second mixture and the PE fiber to obtain an ECC material;

[0039] The first stirring time is 4-5 minutes; the second stirring time is 1-2 minutes.

[0040] In the present invention, there is no special limitation on the stirring rates of the first stirring and the second stirring, and the stirring rates well-known to those skilled in the art can be used. The invention ensures good dispersion of PE fibers in the ECC material through step-by-step mixing.

[0041] The invention also provides a regenerated reinforced aggregate, which includes a regenerated aggregate and an ECC layer wrapped on the surface of the regenerated aggregate.

[...

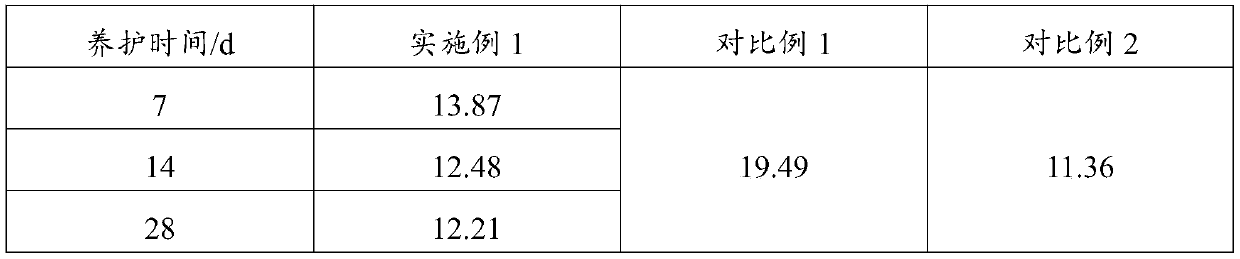

Embodiment 1

[0052] Mix 0.795kg of cement and 0.265kg of fly ash to obtain the first mixture, mix and stir the first mixture, 25g of water reducer and 212g of water for 4.5min to obtain the second mixture, mix and stir the second mixture with 10g of PE fiber 1.5min to get the ECC material. Mix 21.2g of aluminum sulfate and 201g of water to obtain an aqueous solution of aluminum sulfate; mix and stir the obtained ECC material, 222.2g of aqueous solution of aluminum sulfate and 7kg of waste concrete for 1.5min to obtain recycled reinforced aggregate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com