Method for improving the plastic strain ratio r value of cold-rolled deep-punching steel

A technology of plastic strain ratio and punching steel, which is applied in the field of metallurgical technology, can solve the problems of product scrapping, low product qualification rate, fracture, etc., achieve the effects of low cost, increase production qualification rate, and increase the plastic strain ratio r value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1, the preparation of cold-rolled deep-drawn steel

[0052] The preparation of the cold-rolled deep-drawing steel of this embodiment adopts the following steps:

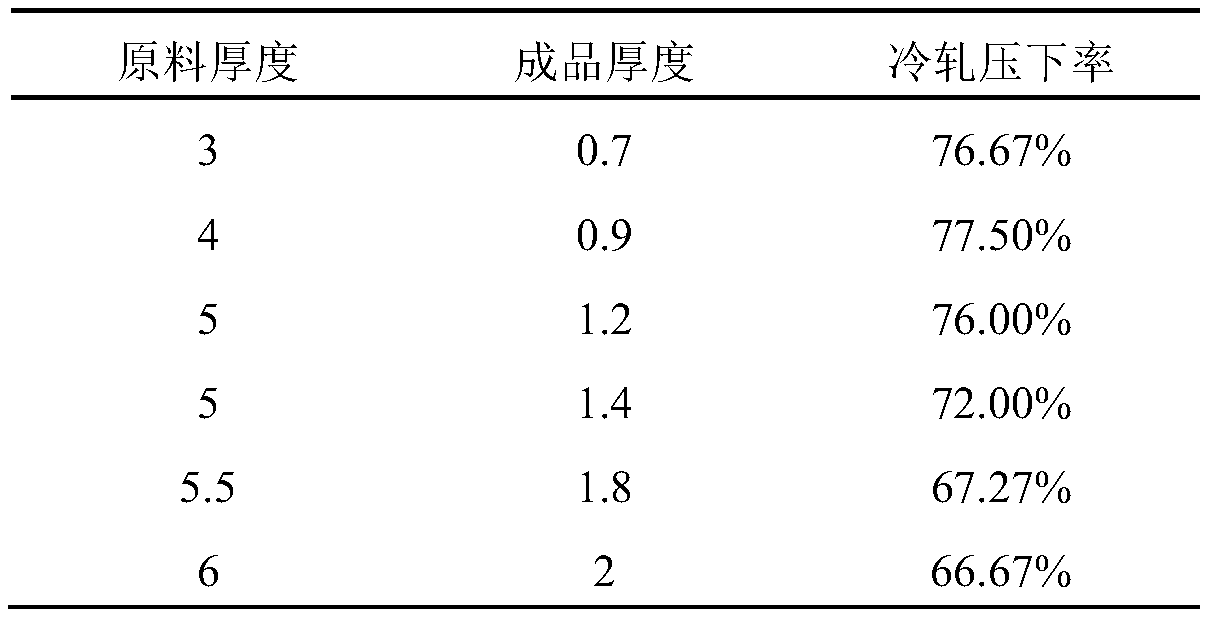

[0053] Desulfurization pretreated molten iron is decarburized by converter smelting, RH refining is carried out to obtain molten steel, the molten steel is subjected to continuous casting to obtain slabs, and the slabs are subjected to hot rolling process to obtain hot-rolled steel coils. The rolling temperature is 927°C, the coiling temperature is 722°C, and the thickness of the hot coil is 3.5mm; the hot-rolled steel coil is pickled to remove scale and then cold-rolled. The thickness of the coil is 0.8mm, and the cold-rolled steel coil is obtained; the cold-rolled steel coil is subjected to bell annealing, the annealing temperature is 720°C, the annealing time is 13h, the slow cooling time is 6h, and the furnace temperature is 78°C; finally, after the smoothing process, the flattening elongation i...

Embodiment 2

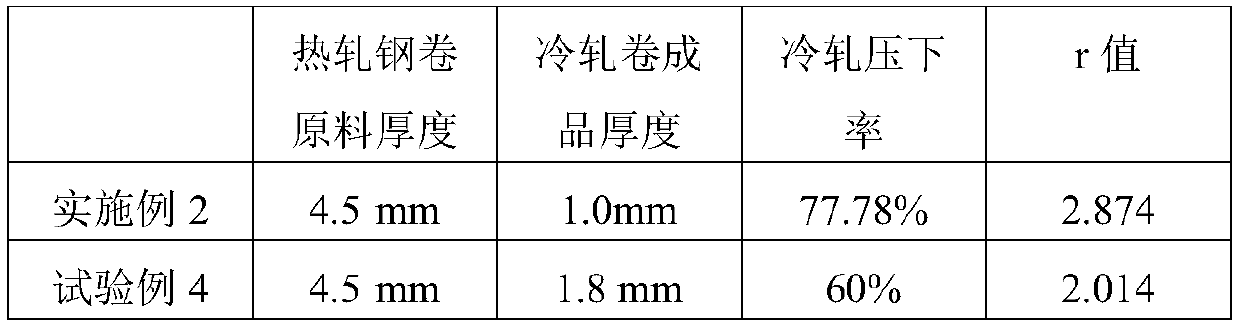

[0055] The preparation of the cold-rolled deep-drawing steel of this embodiment adopts the following steps:

[0056] Desulfurization pretreated molten iron is decarburized by converter smelting, RH refining is carried out to obtain molten steel, the molten steel is subjected to continuous casting to obtain slabs, and the slabs are subjected to hot rolling process to obtain hot-rolled steel coils. The rolling temperature is 915°C, the coiling temperature is 718°C, and the thickness of the hot coil is 4.5mm. The thickness of the coil is 1.0mm, and the cold-rolled steel coil is obtained; the cold-rolled steel coil is subjected to bell annealing, the annealing temperature is 720°C, the annealing time is 13h, the slow cooling time is 6h, and the furnace temperature is 75°C; finally, after the smoothing process, the flattening elongation is 0.6% obtains the cold-rolled deep-drawing steel described in the present invention;

Embodiment 3

[0058] The preparation of the cold-rolled deep-drawing steel of this embodiment adopts the following steps:

[0059] Desulfurization pretreated molten iron is decarburized by converter smelting, RH refining is carried out to obtain molten steel, the molten steel is subjected to continuous casting to obtain slabs, and the slabs are subjected to hot rolling process to obtain hot-rolled steel coils. The rolling temperature is 930°C, the coiling temperature is 726°C, and the thickness of the hot coil is 5.5mm; the hot-rolled steel coil is pickled to remove scale and then cold-rolled. The thickness of the coil is 1.5mm, and the cold-rolled steel coil is obtained; the cold-rolled steel coil is subjected to bell annealing, the annealing temperature is 730°C, the annealing time is 15h, the slow cooling time is 6h, and the furnace temperature is 80°C; finally, after the smoothing process, the flattening elongation is 0.6% obtains the cold-rolled deep-drawing steel described in the pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com