390MPa-grade high-strength IF steel and production method thereof

A production method and high-strength technology, applied in the field of steel manufacturing, can solve the problems of low plastic strain ratio r value, affecting the development of favorable textures, and large gap in performance indicators, so as to achieve the effect of improving the r value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

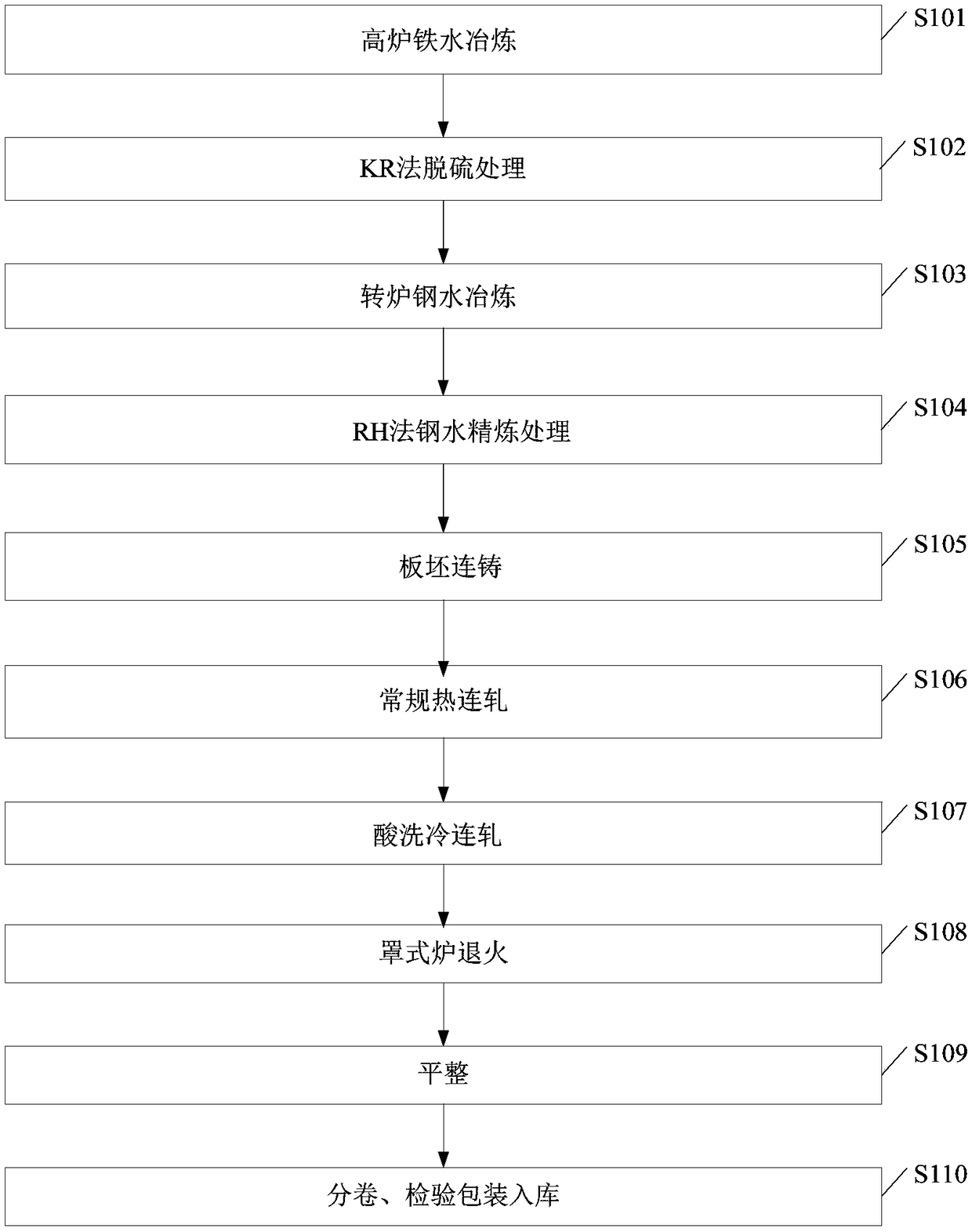

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

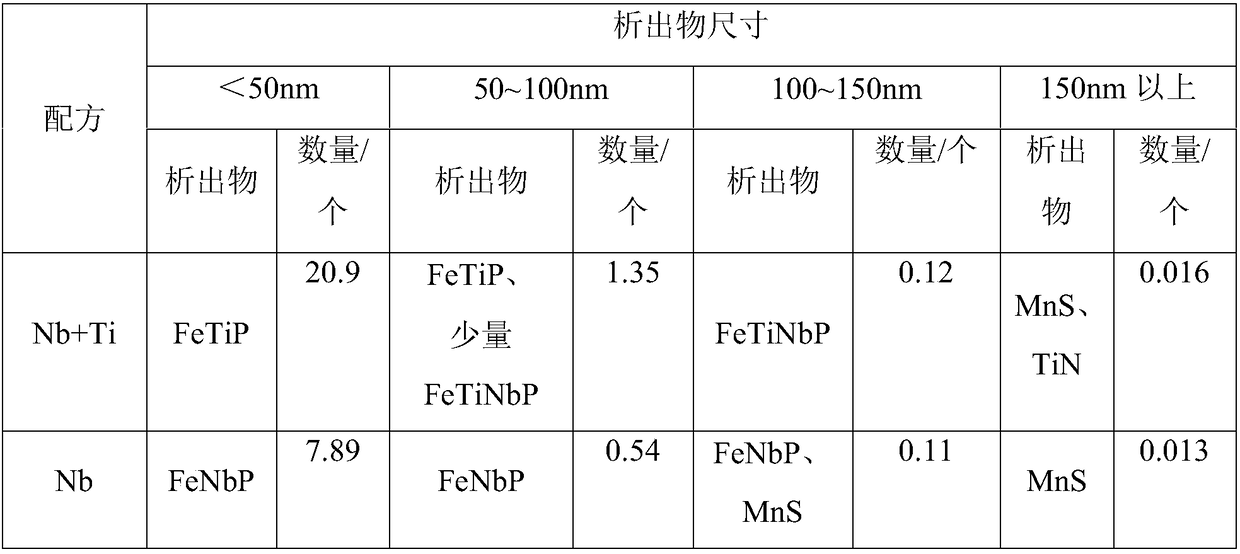

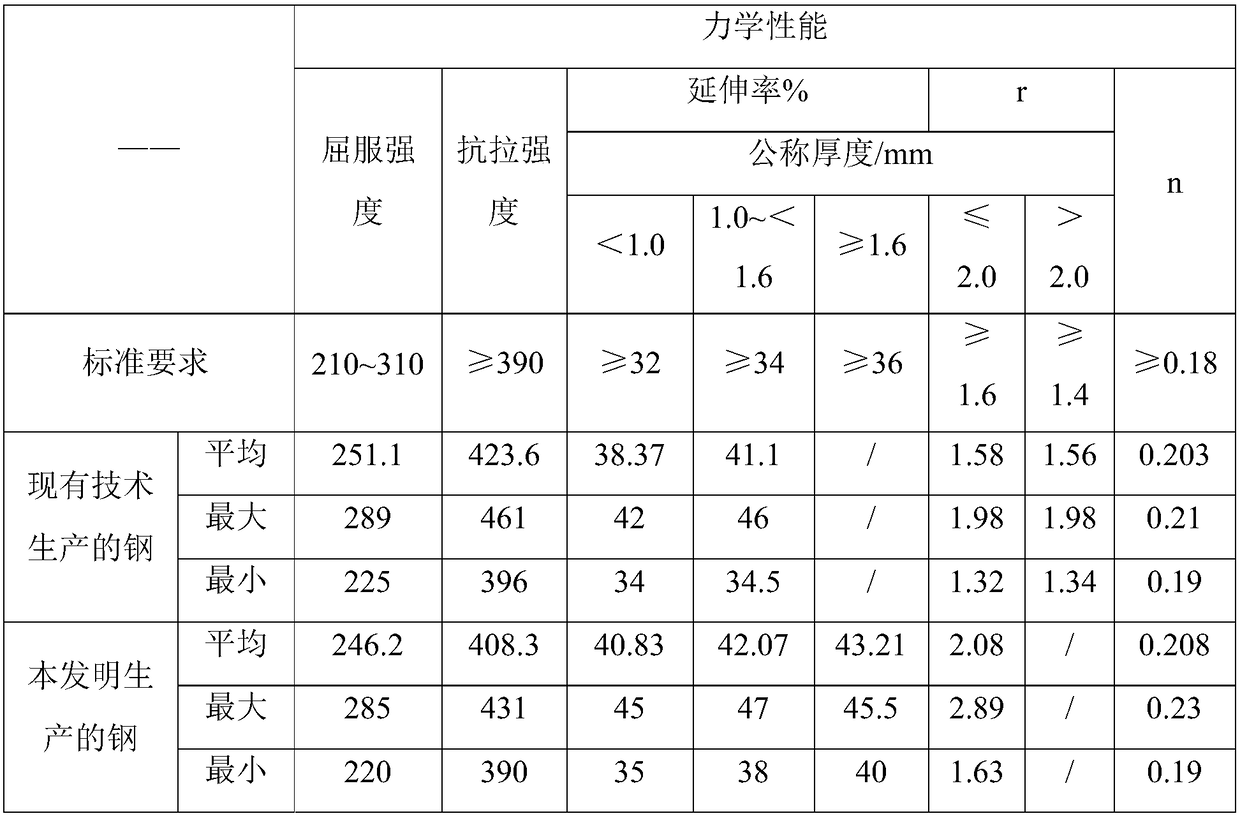

[0024] The embodiment of the present invention discloses a 390MPa grade high-strength IF steel. By only adding micro-alloyed Nb elements, it can avoid a large amount of FeTiP precipitates in the steel from hindering the development of favorable textures, thereby increasing the plastic strain ratio r value.

[0025] The 390MPa high-strength IF steel disclosed in the embodiment of the present invention includes the following chemical components and weight percentages: C: 0.0-0.004%, Si: 0.0-0.030%, Mn: 0.4%-0.6%, P: 0.06%-0.085 %, S: 0.0-0.010%, Al: 0.03%-0.1%, Nb: 0.01%-0.1%, B: 0.00050%-0.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com