Rivet Mounting Collet

A collet and rivet technology, which is applied in the field of rivet installation machines, can solve the problems of cracked rivet joints, easy rivets falling off, slow processing speed, etc., and achieve the effect of fast stamping, convenient installation and high pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

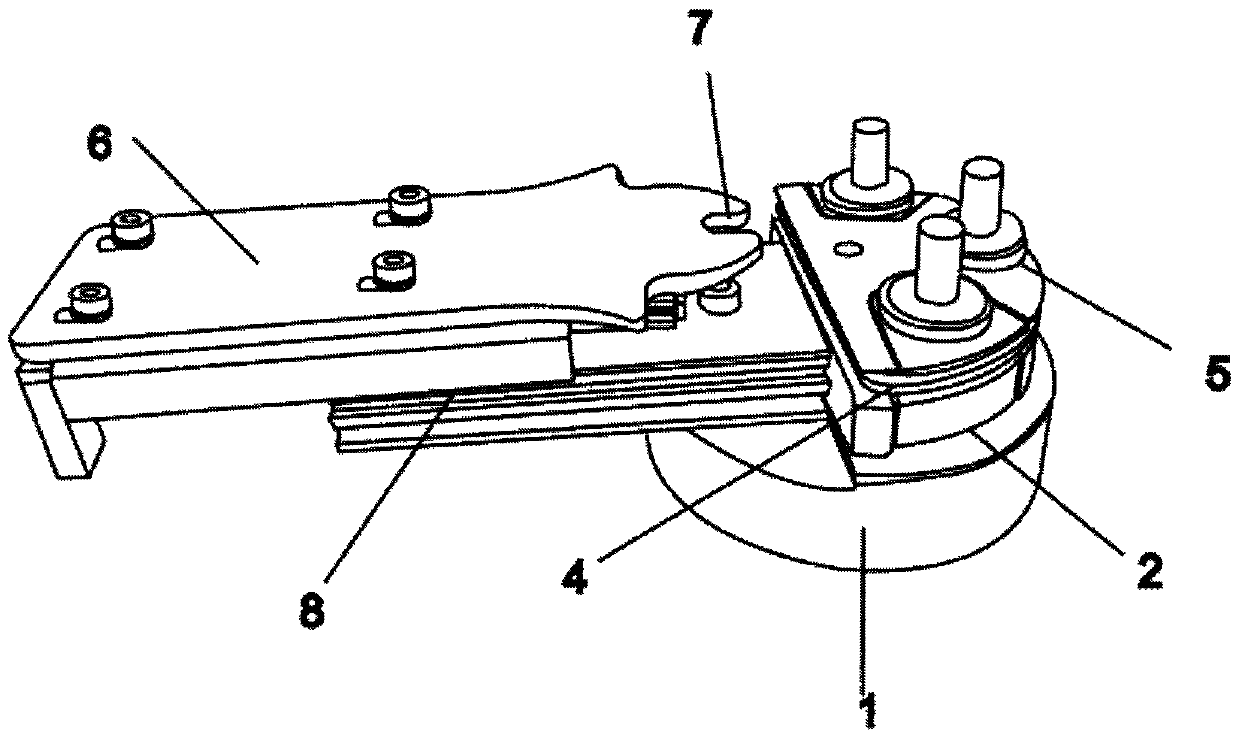

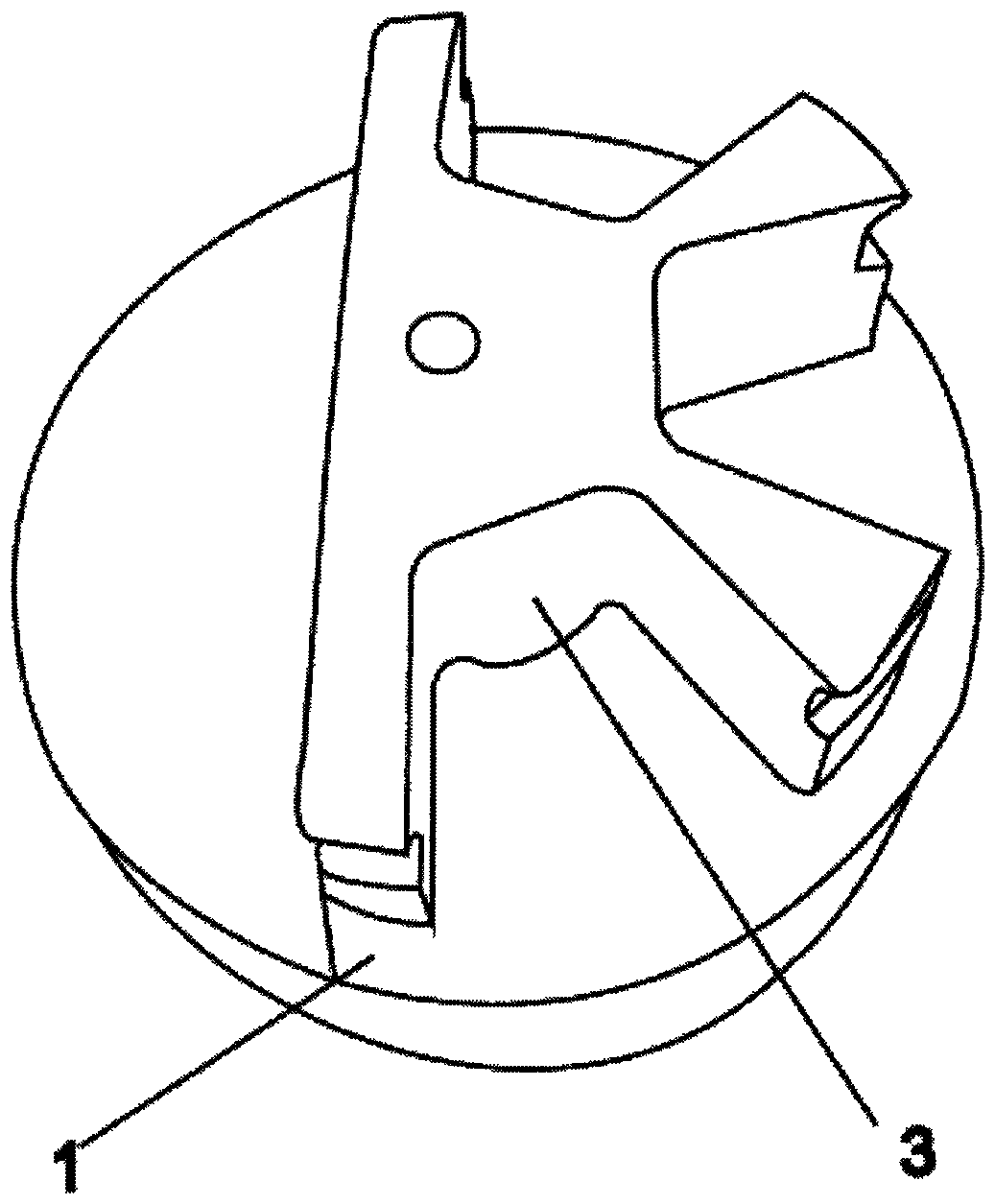

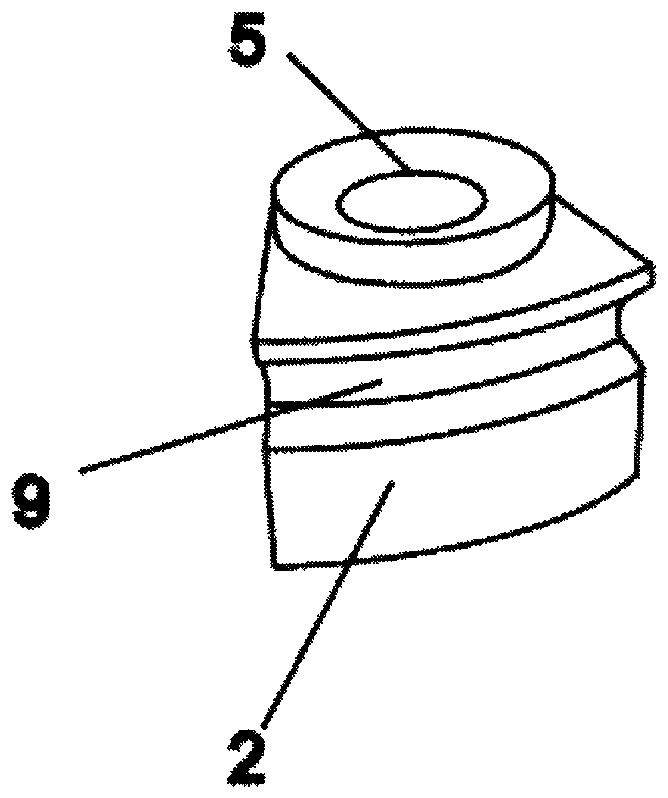

[0021] figure 1 The rivet installation chuck according to the present invention includes a chuck body 1 and three rivet fixing bodies 2 placed in the chuck body 1. In order to facilitate the placement of the fixing body 2, as figure 2 As shown, there are three evenly distributed accommodation grooves 3 on the chuck body 1, and the ways of fixing the fixed body 2 can be various, preferably springs and elastic rings 4, taking the elastic ring 4 as an example, the fixing method is: by The rivet fixing body 2 and the chuck body 1 are provided with a card slot 9 on the vertical surface, that is, on the side, and the elastic ring 4 is set in the card slot 9 to realize fixing. Stamping, and there will be no waste products. It should also be explained here that the punch of the punching machine also needs three heads, and the length of the three heads needs to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com