Ceramic electric kettle

A technology for electric kettles and ceramics, which is applied to water-boiling utensils, cooking utensils, household appliances, etc. It can solve the problems of affecting the appearance, uncontrollable dimensional accuracy, and lower product grades, so as to reduce the difficulty and cost of the manufacturing process and have a beautiful appearance. Generosity, the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

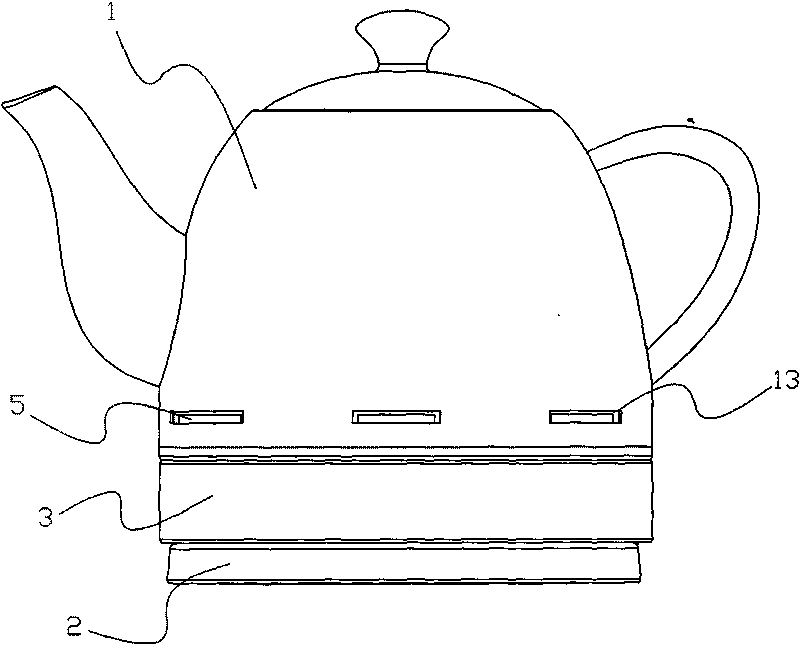

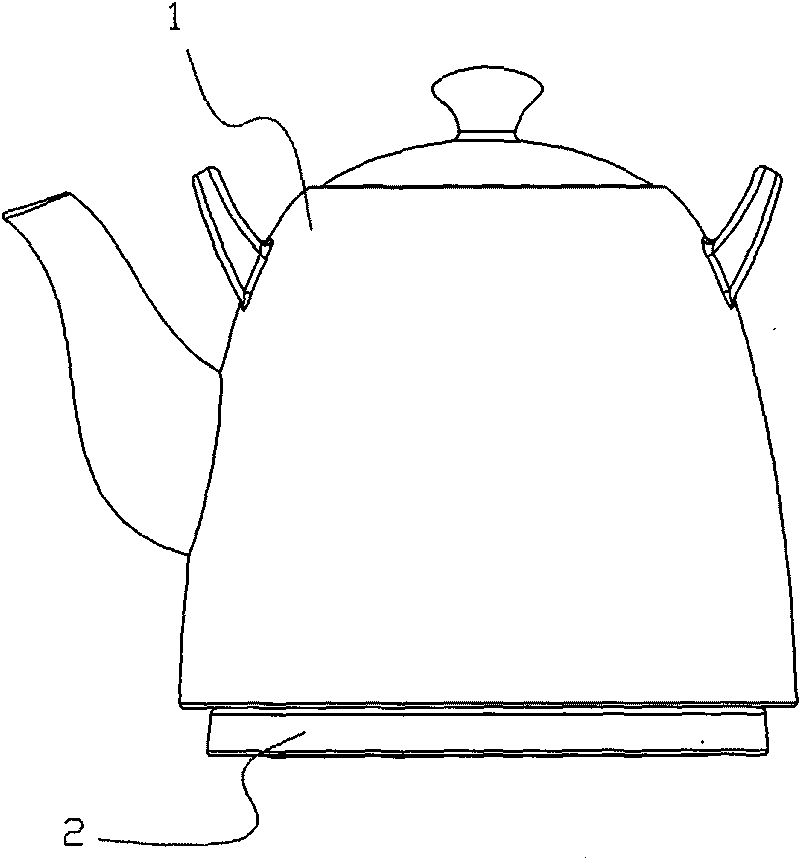

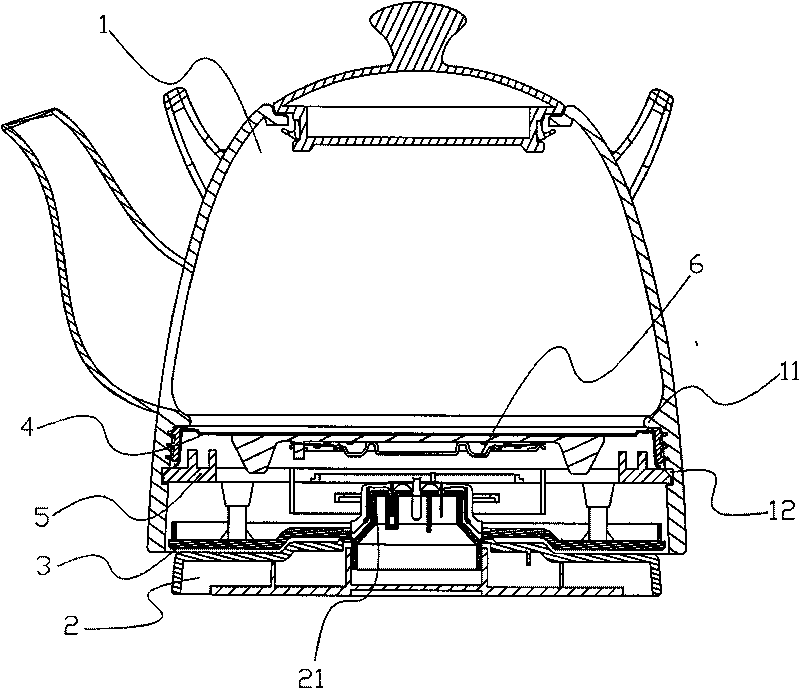

[0018] refer to figure 2 , the ceramic electric kettle provided by the present invention comprises a kettle body 1 and a power base 2, a kettle bottom 3 is provided at the bottom of the kettle body 1, a heating plate 4, a fixing snap ring 5 and a heating plate 4 are arranged between the kettle bottom 3 and the kettle body 1 The thermostat 6 and the heating plate 4 are structures used for electric heating, and its structure is the same as that of common electric kettles. For example, in order to obtain a better sealing effect, sealing silica gel and the inside of the kettle body 1 can be arranged on the outer periphery of the heating plate 4 Contact, after the heating disc 4 is installed in the kettle body 1, it is clamped in the kettle body 1 by the fixing snap ring 5.

[0019] Wherein, the annular slot 12 is arranged on the inner wall of the pot body 1 at 360 degrees, which makes the process simple and ensures a good installation effect at the same time.

[0020] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com