Mold pressing molding mold for toothpaste lid

A technology of compression molding and mold molding, which is applied in the field of forming molds for the production of toothpaste caps, can solve the problems of excessive waste, low production efficiency, and damage to the internal threads of toothpaste caps, and achieve the effect of neat and beautiful appearance and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

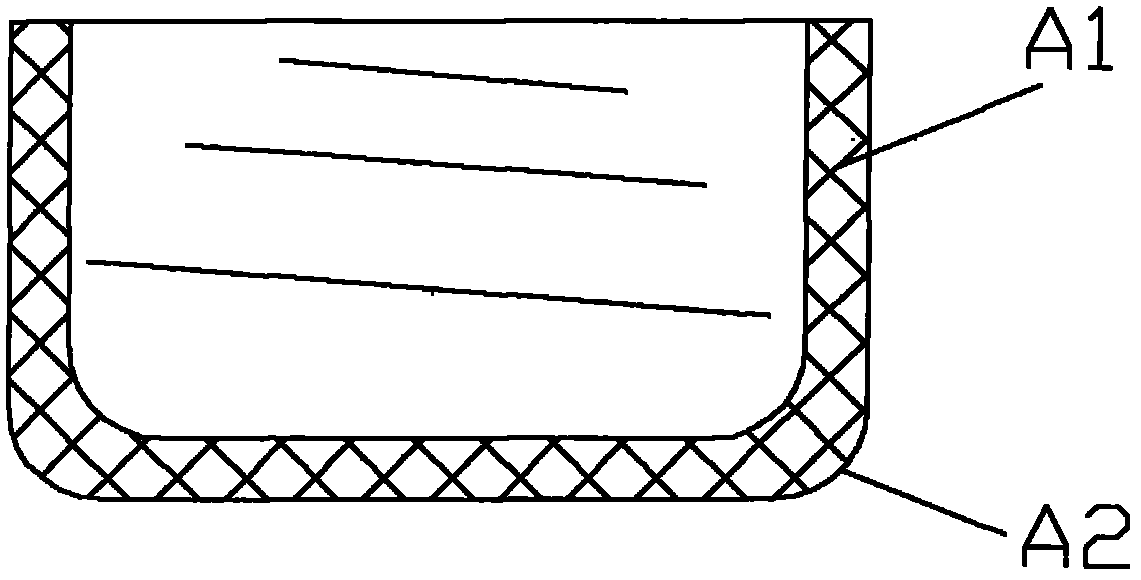

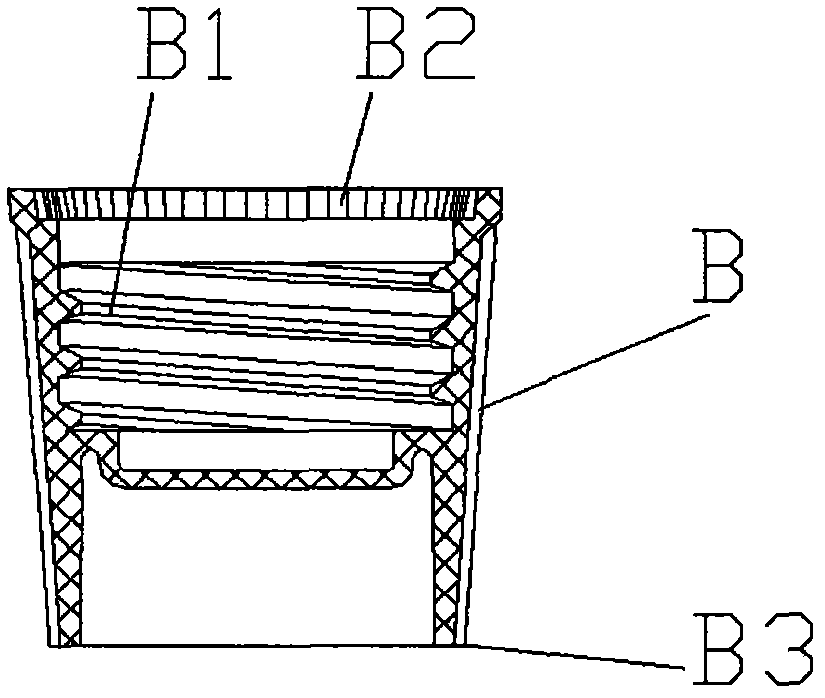

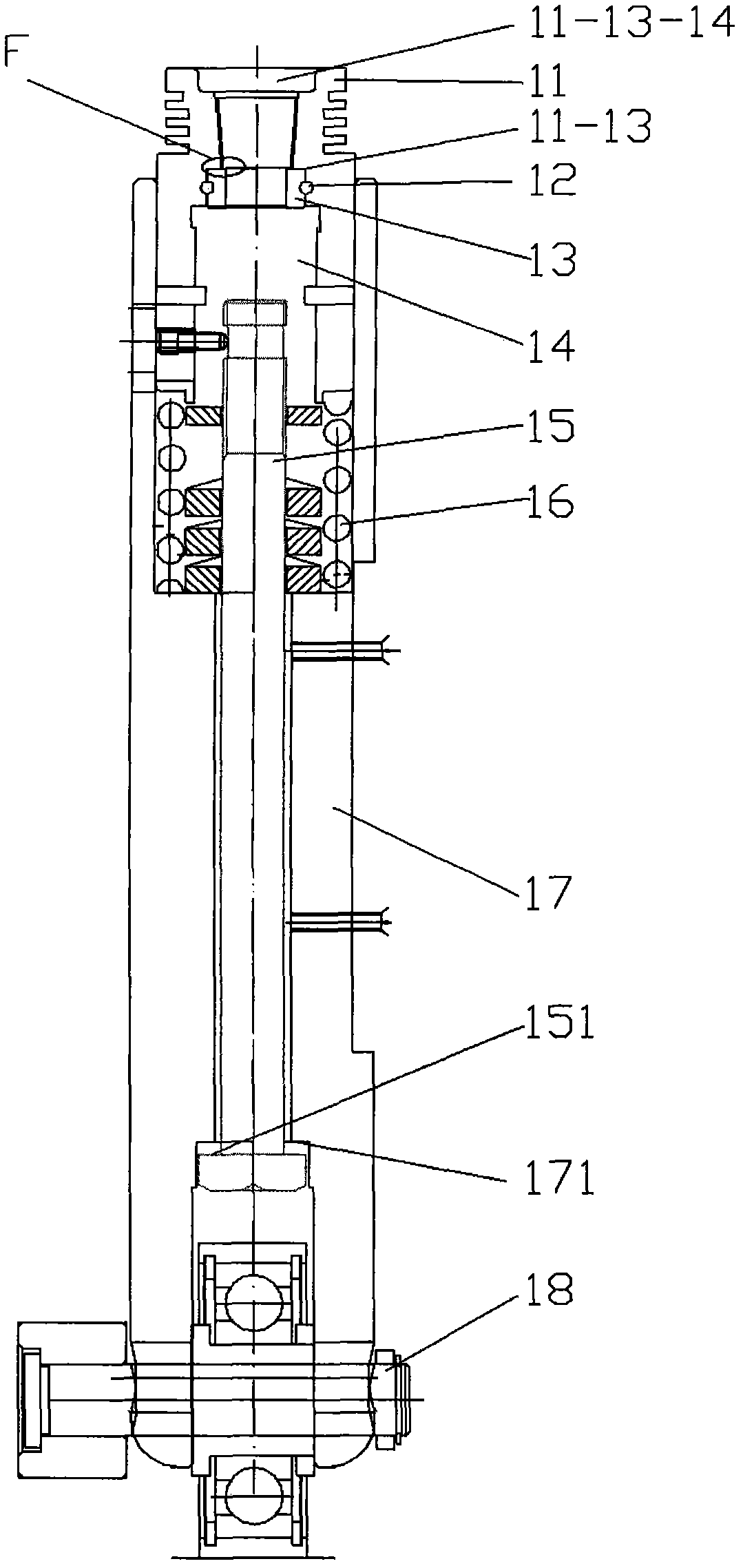

[0019] Example: see Figures 3 to 7 Shown, a kind of toothpaste cover molding mold comprises lower mold 1 and upper mold 2, and lower mold 1 is made of lower mold cavity 11, cylindrical pin 12, lower mold core spacer 13, lower mold core 14, lower mold The pull rod 15, the compression spring 16, the lower mold ejector rod 17 and the roller 18 of the bottle cap machine roller mechanism are composed of the lower mold cavity 11, the lower mold core pad 13 and the lower mold core 14 to form the lower mold molding cavity 11-13-14, the lower mold core pad 13 is inserted into the lower part of the lower mold cavity 11, the lower mold core pad 13 and the lower mold cavity 11 clamp the cylindrical pin 12 for fastening, and the lower mold core 14 The upper part is inserted into the lower mold core pad 13 and extends into the lower mold molding cavity 11-13-14. The lower mold tie rod 15 is screwed and fixed on the lower mold core 14 and inserted into the lower mold ejector rod 17. The low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com