Nickel target blank and manufacturing method of target material

A manufacturing method and nickel target material technology, which is applied in metal material coating process, ion implantation plating, coating, etc., can solve the problems of nickel target blank defects, material waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

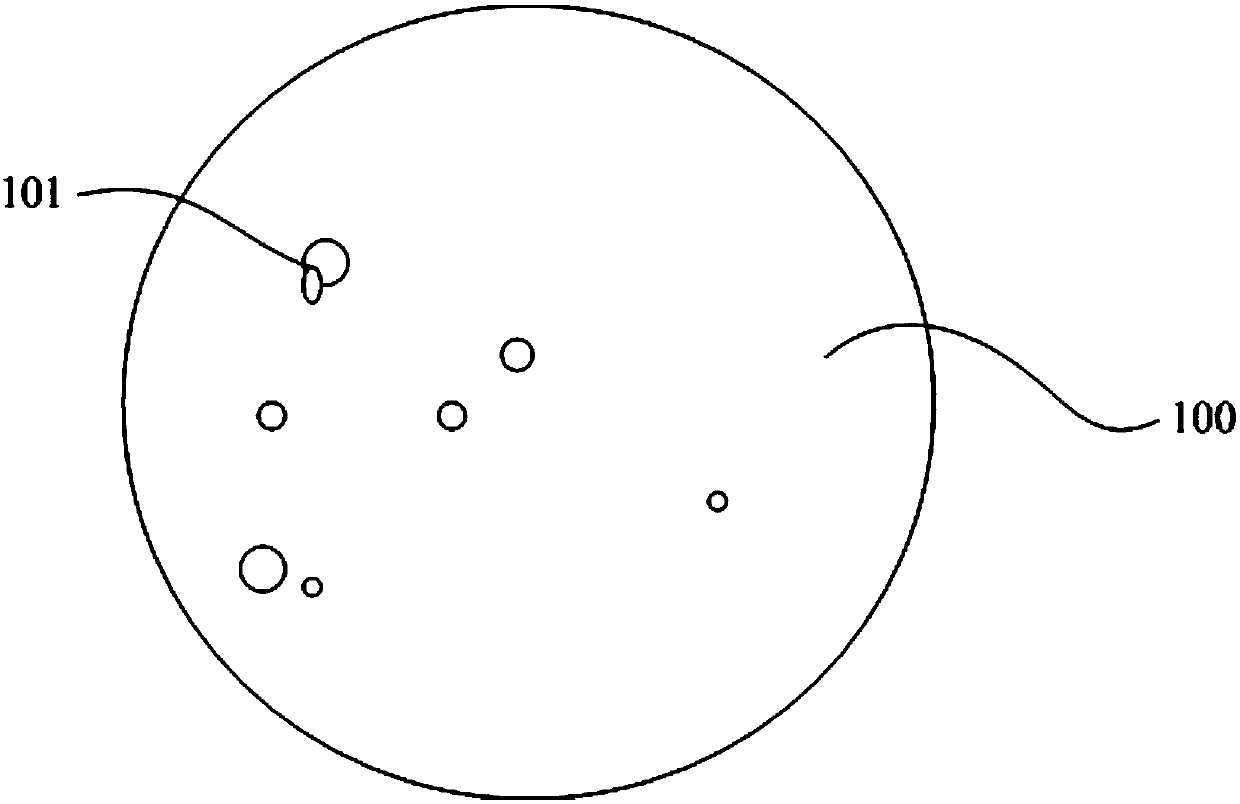

[0027] It can be seen from the background technology that in the prior art, the manufactured nickel target blanks are often easy to get gas and generate inclusions during the manufacturing process, and the formed nickel target blanks have defects, which are not satisfied with the application in the semiconductor industry, resulting in material waste and increased costs.

[0028] Analysis shows that in the prior art, the method to make the manufactured nickel target meet the various parameters in the semiconductor industry is to strictly control the parameters in the annealing process after rolling. However, a large number of facts have proved that However, the defect of the manufactured nickel target blank cannot be completely overcome.

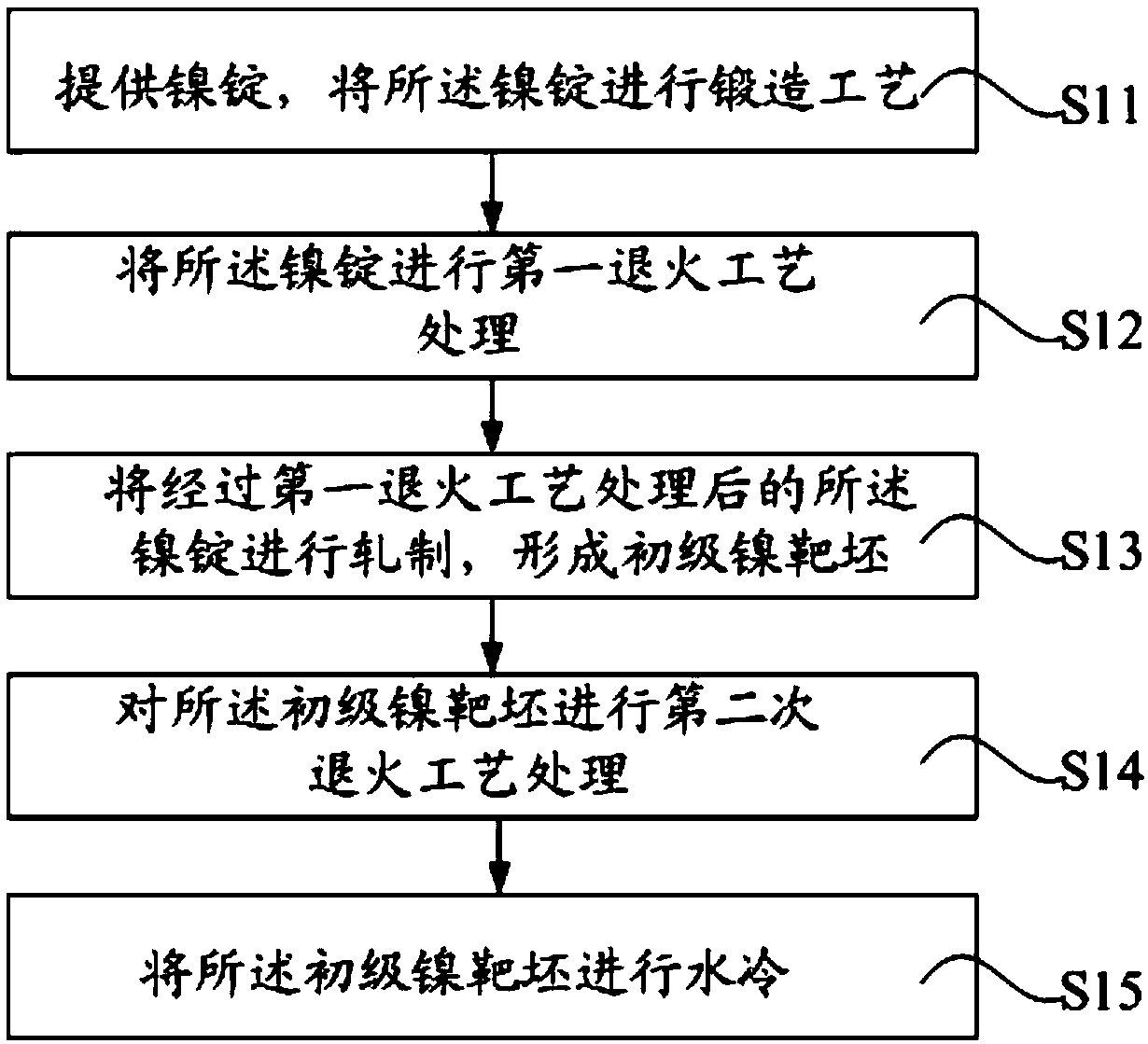

[0029] In order to solve the above problems, the present invention provides a new method, providing nickel ingots; performing the first annealing process on the nickel ingots, the temperature of the first annealing process is 900°C-950°C; Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com