Patents

Literature

265results about "Error compensation/elimination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Probe head for coordinate measuring machines

Owner:CARL ZEISS IND MESSTECHN GMBH

Temperature compensation system for a coordinate measuring machine

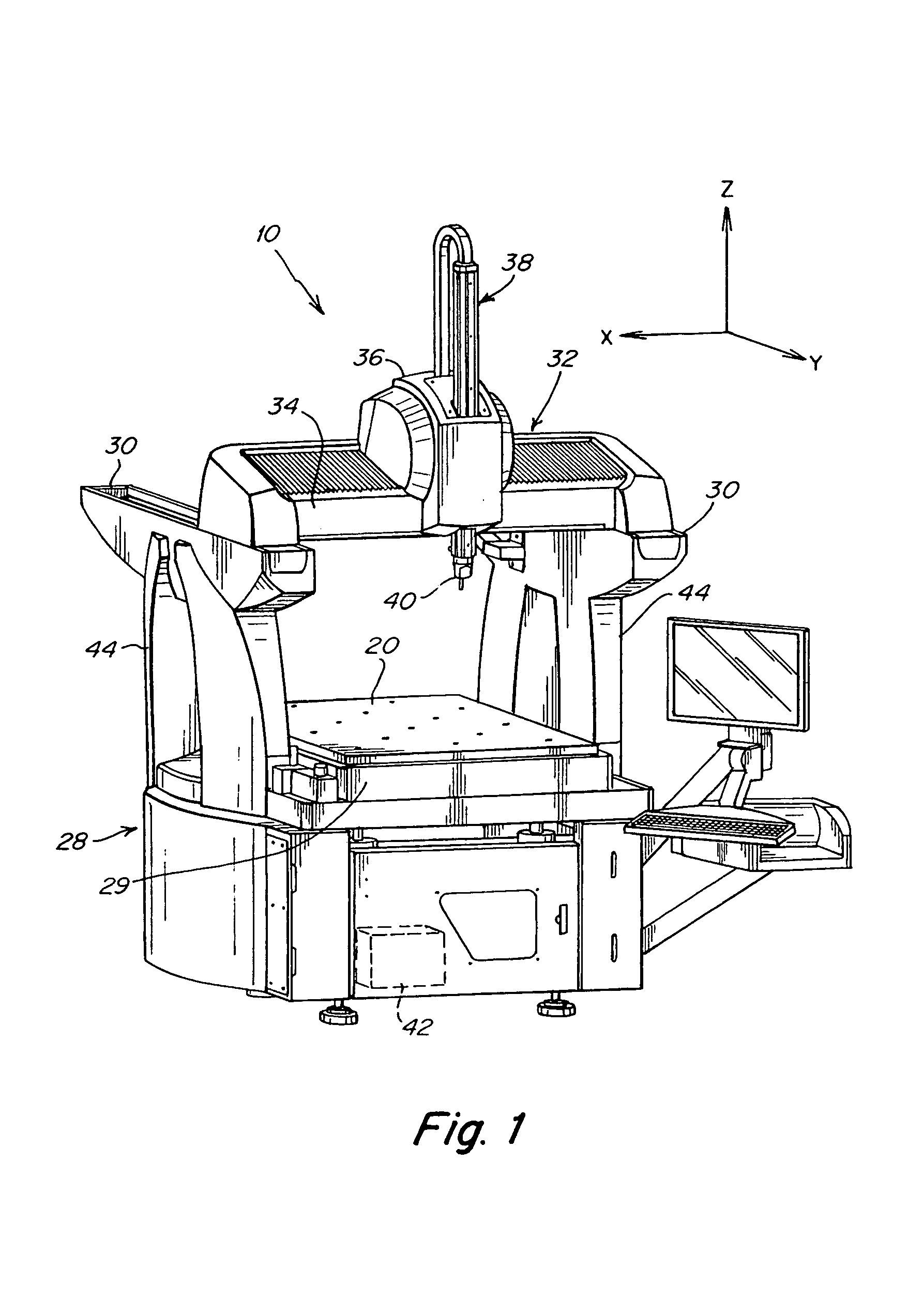

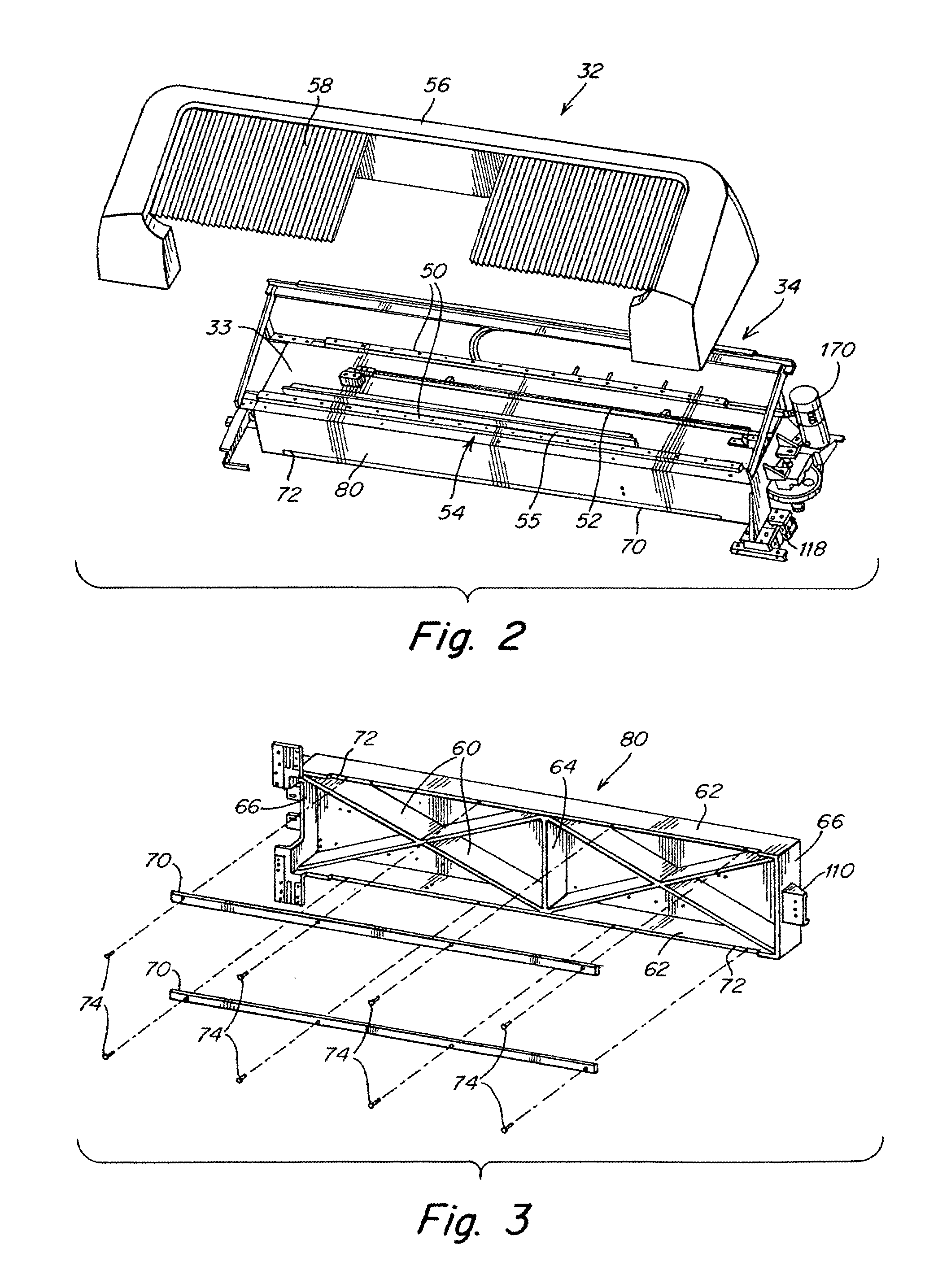

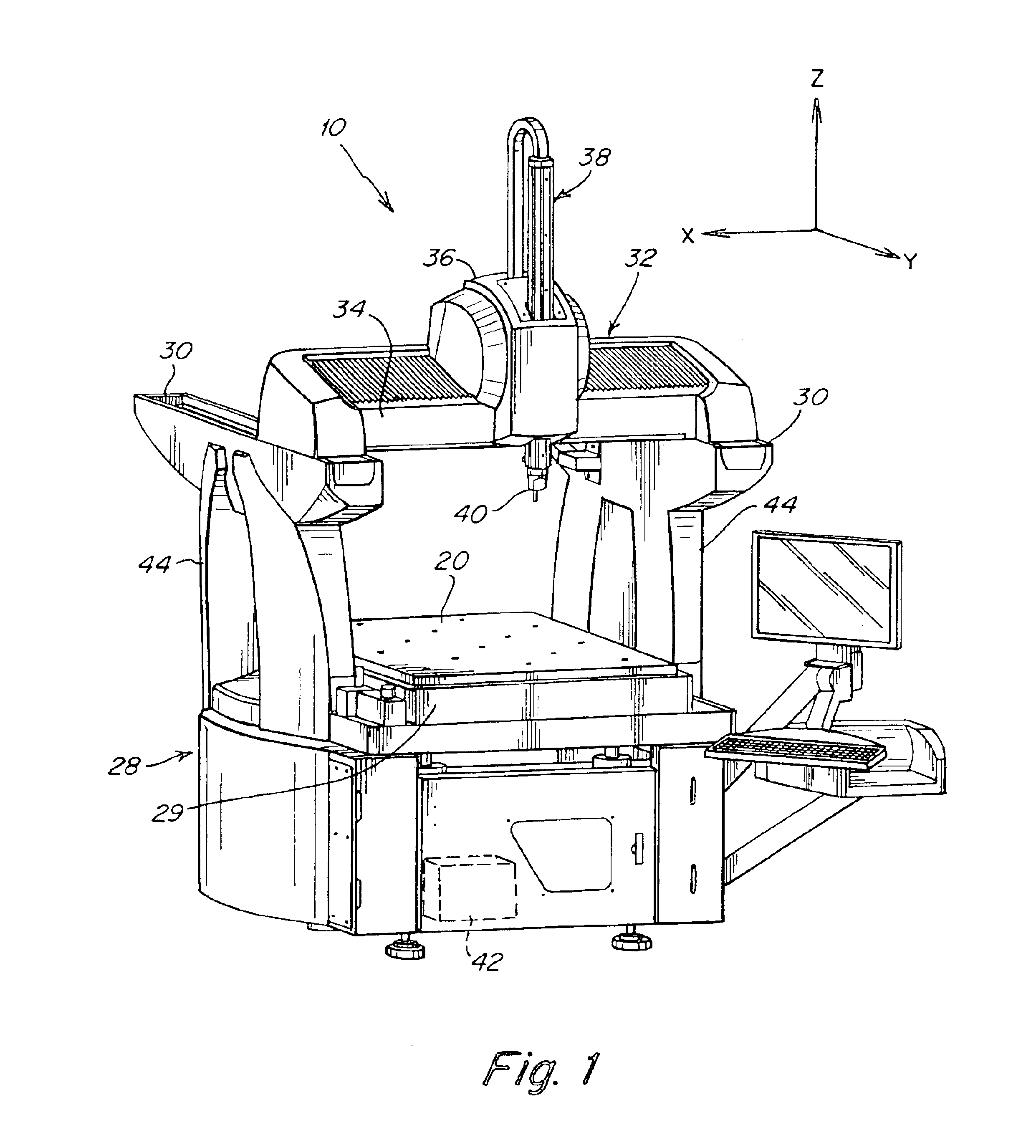

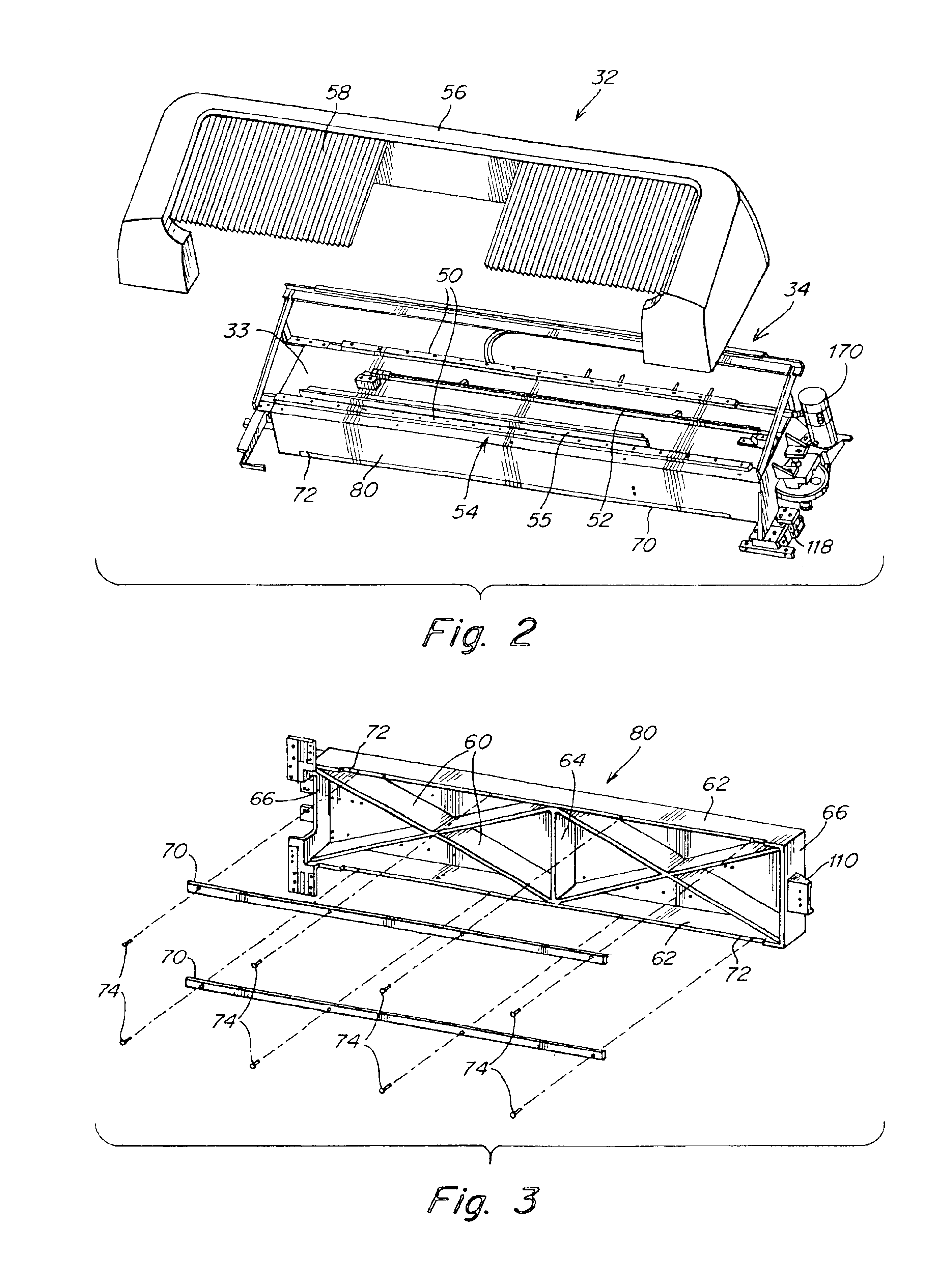

ActiveUS7191541B1Minimize movementWalking sticksMetal working apparatusCouplingCoordinate-measuring machine

A machine, such as a coordinate measuring machine, having a component or element movable with respect to a support structure along rails or guideways, wherein the rails have a coefficient of thermal expansion that is different from that of the support structure to which they are attached. Differential thermal expansion and contraction of the rails with respect to the support structure may be accommodated without binding or distortion of the rails by coupling each guideway to the support structure at two different points. Typically, the coupling at the first point is rigid and prevents any movement of the rail with respect to the support structure. The second coupling includes a flexible component that permits movement of the rail with respect to the support structure in a direction of movement of the element or component. This flexible component may be a leaf spring. In another embodiment, the first coupling may also be flexible. A method is also disclosed for accommodating differential thermal expansion and contraction of the rail with respect to the support structure by providing first and second couplings between the rail and support structure wherein at least the second coupling includes a flexible component that permits movement of the rail with respect to the support structure in a direction generally parallel to the direction of movement of the machine element.

Owner:HEXAGON TECH CENT GMBH

Thermal deformation error compensation method for coordinate measuring machine

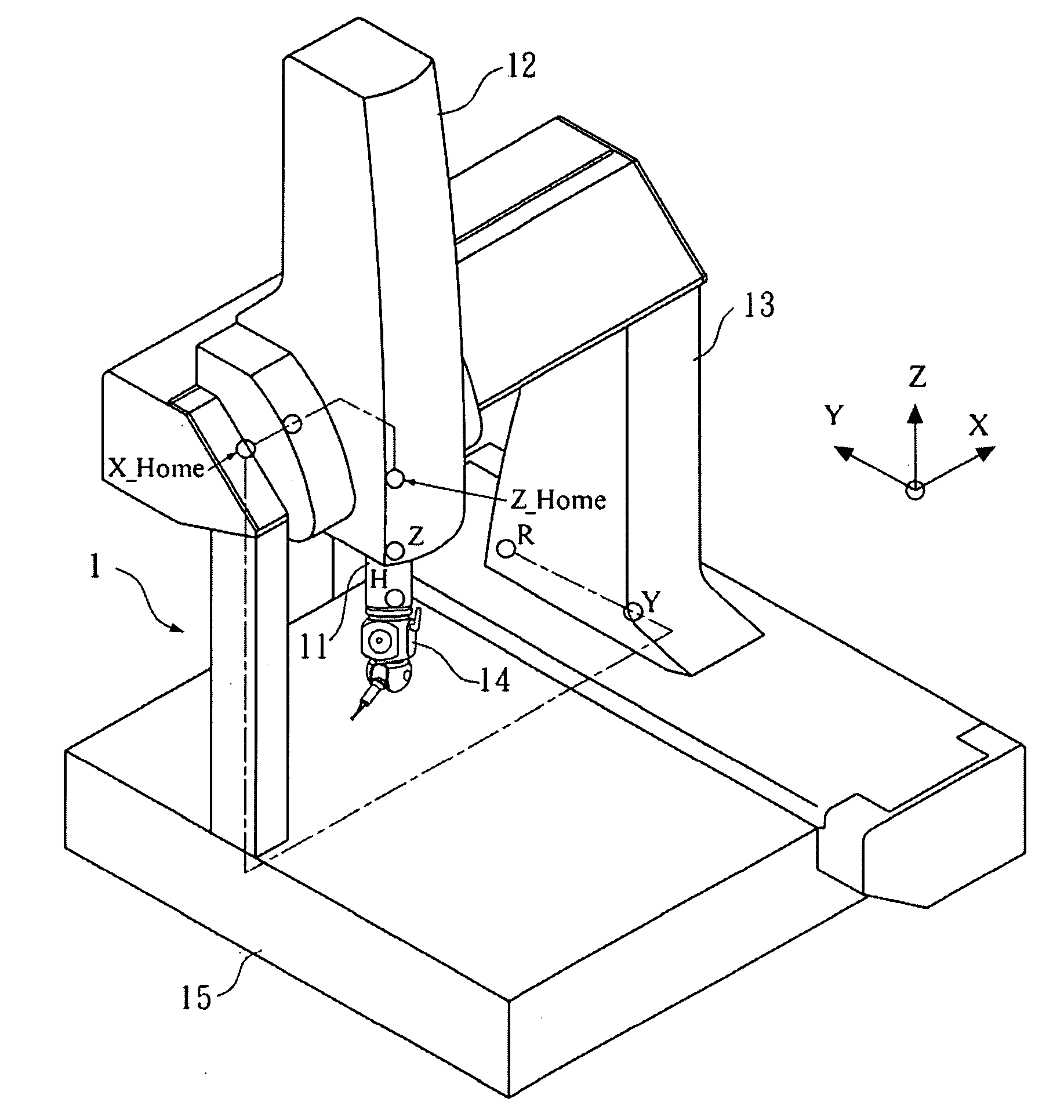

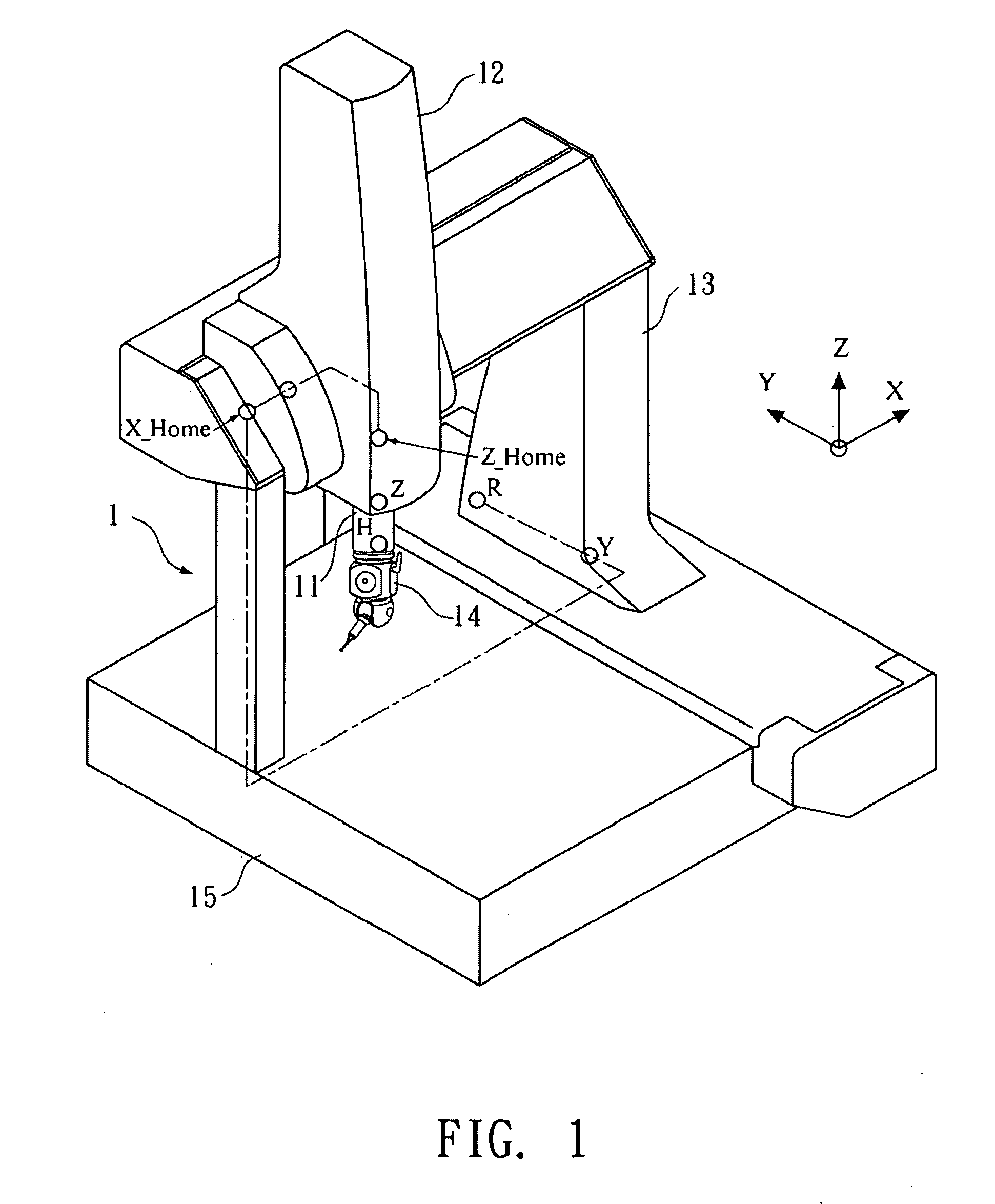

InactiveUS20100299094A1Testing/calibration of speed/acceleration/shock measurement devicesSpecial data processing applicationsGeometric errorMotion parameter

A thermal deformation error compensation method for a coordinate measuring machine creates thermal deformation and geometric error data at different ambient temperatures including temperatures and machine kinematic parameters to obtain a thermal deformation and geometric error model, and inputs the model into central control unit of the coordinate measuring machine, and converts a 3D error compensation to obtain a thermal deformation and geometric error compensation model, and uses the thermal deformation and geometric error compensation model for performing compensations, so as to complete a thermal deformation and geometric error compensation of the coordinate measuring machine.

Owner:CARMAR TECH

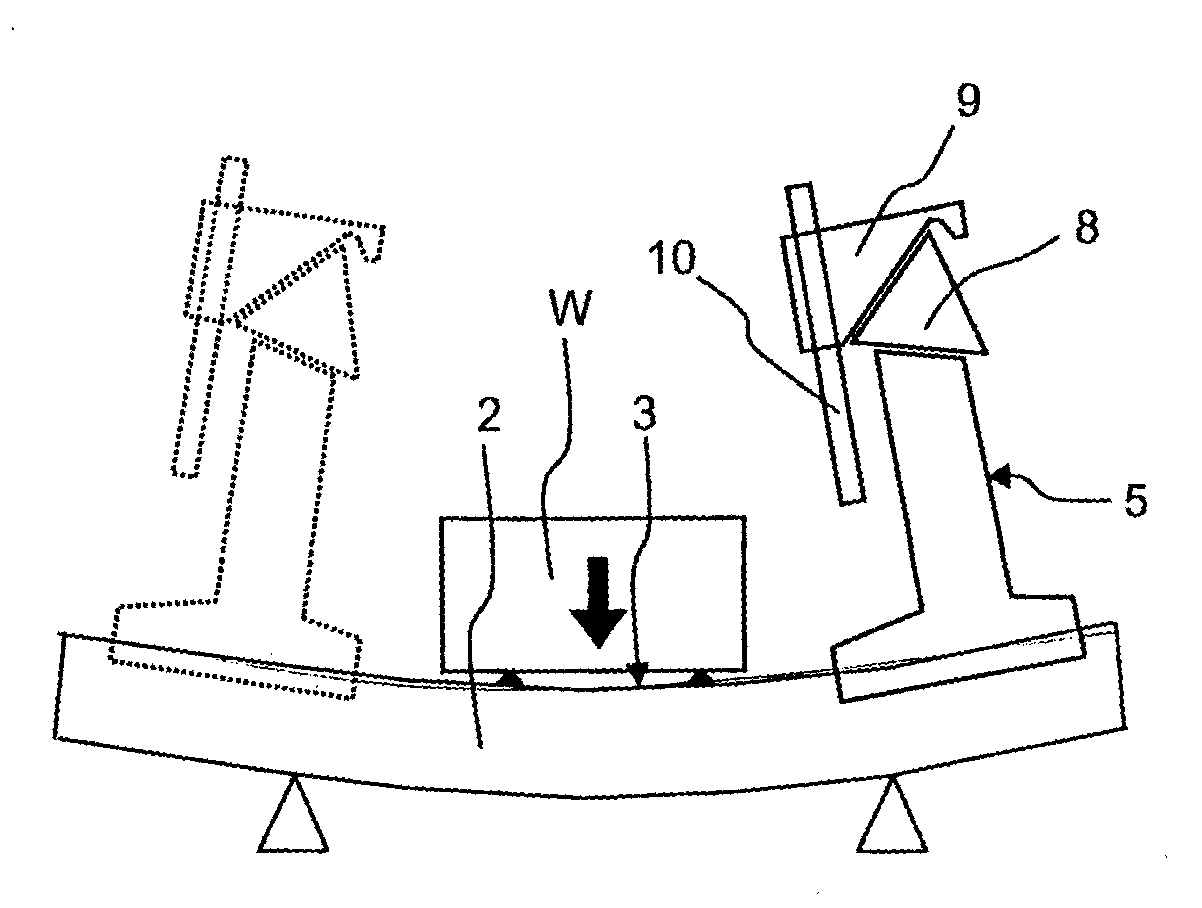

Method for compensating measurement errors caused by deformations of a measuring machine bed under the load of a workpiece and measuring machine operating according to said method

ActiveUS20100286941A1Testing/calibration of speed/acceleration/shock measurement devicesSpecial data processing applicationsObservational errorEngineering

A method of compensating the measurement errors of a measuring machine that derive from the deformations of the machine bed caused by the load exerted by the workpiece to be measured on the machine bed, comprising a first acquisition step in which data regarding the weight of the workpiece and the modes of resting of the workpiece on the machine bed are acquired, and a second calculation step in which correction values depending upon said data are calculated.

Owner:HEXAGON METROLOGY SPA

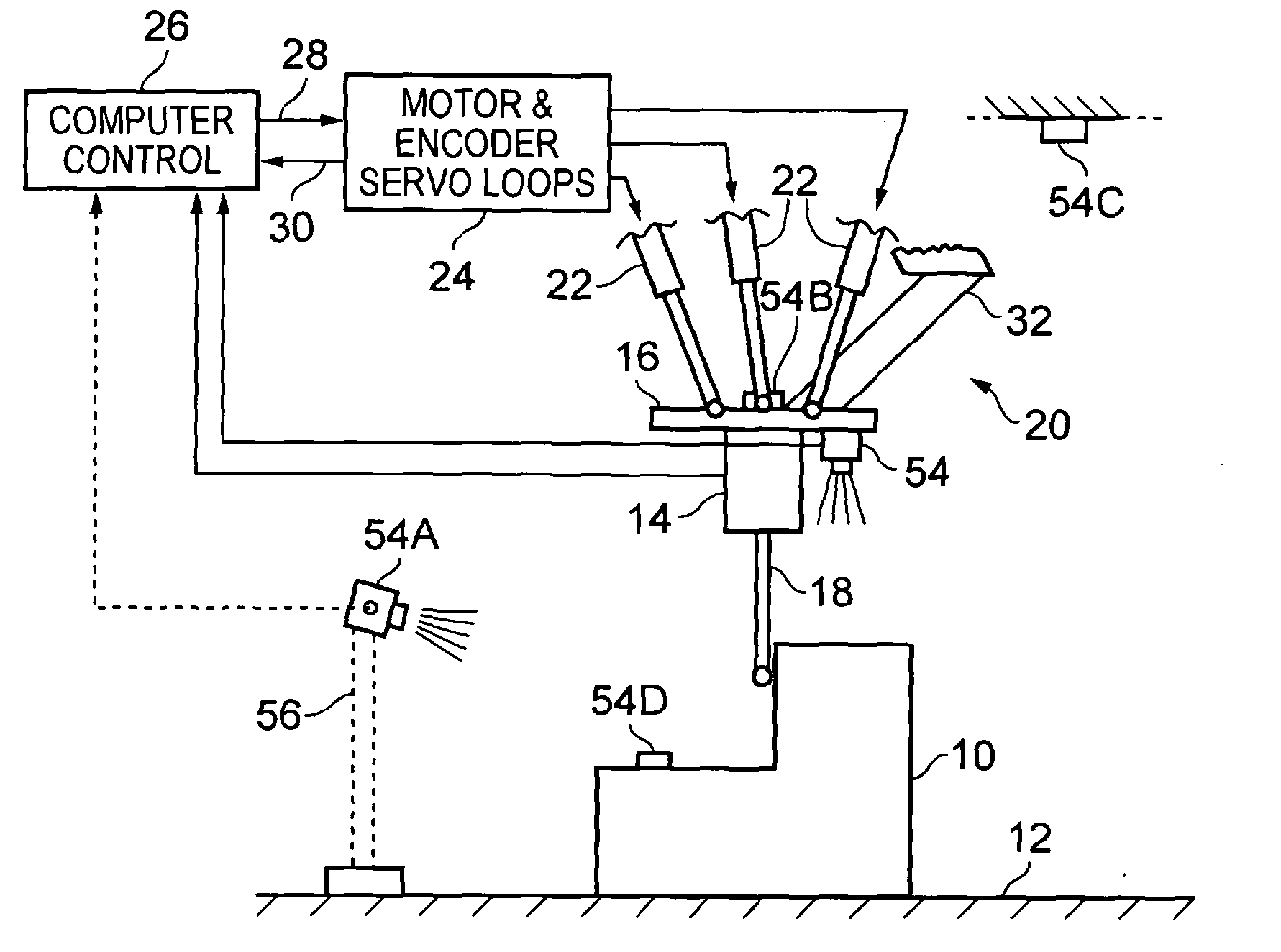

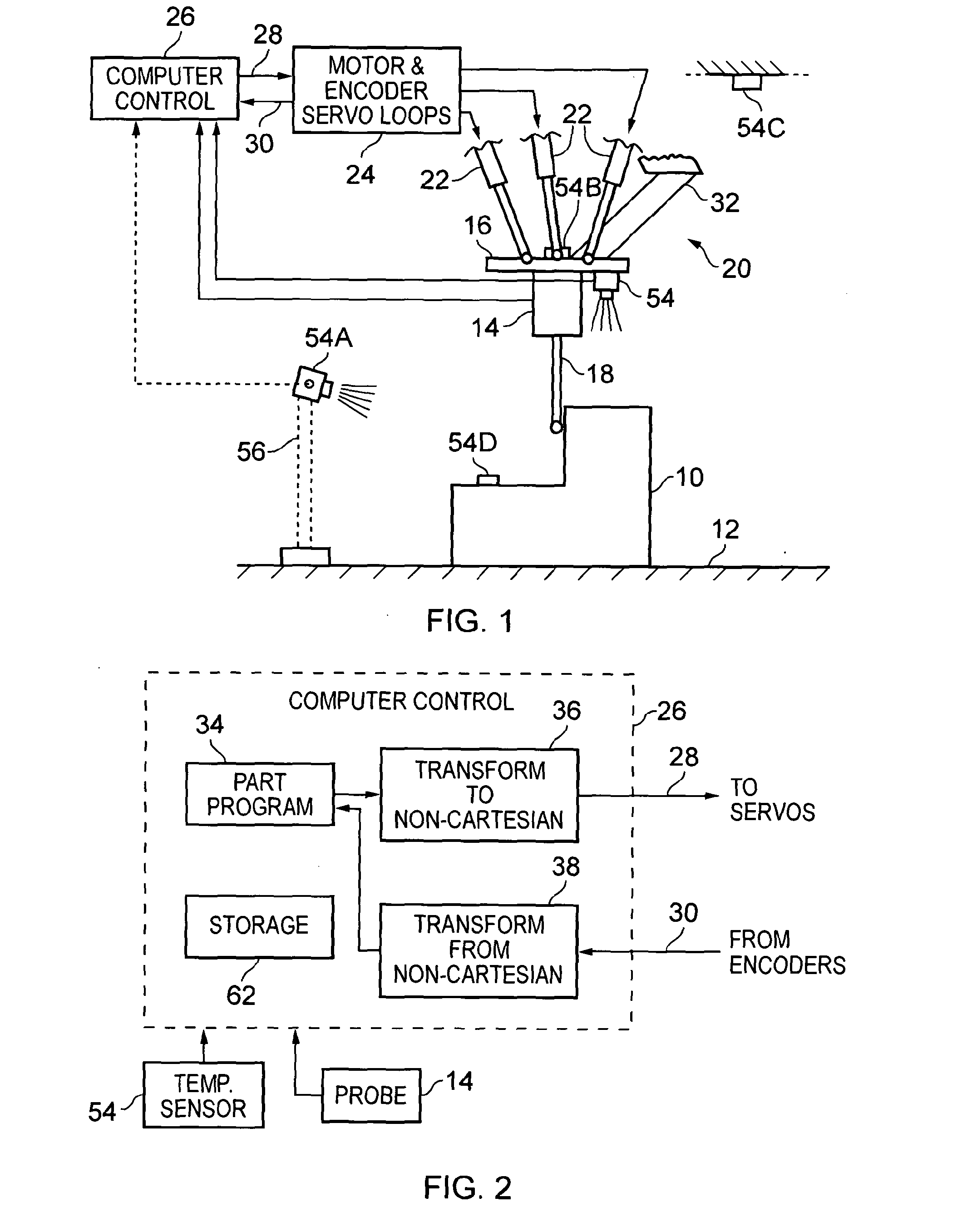

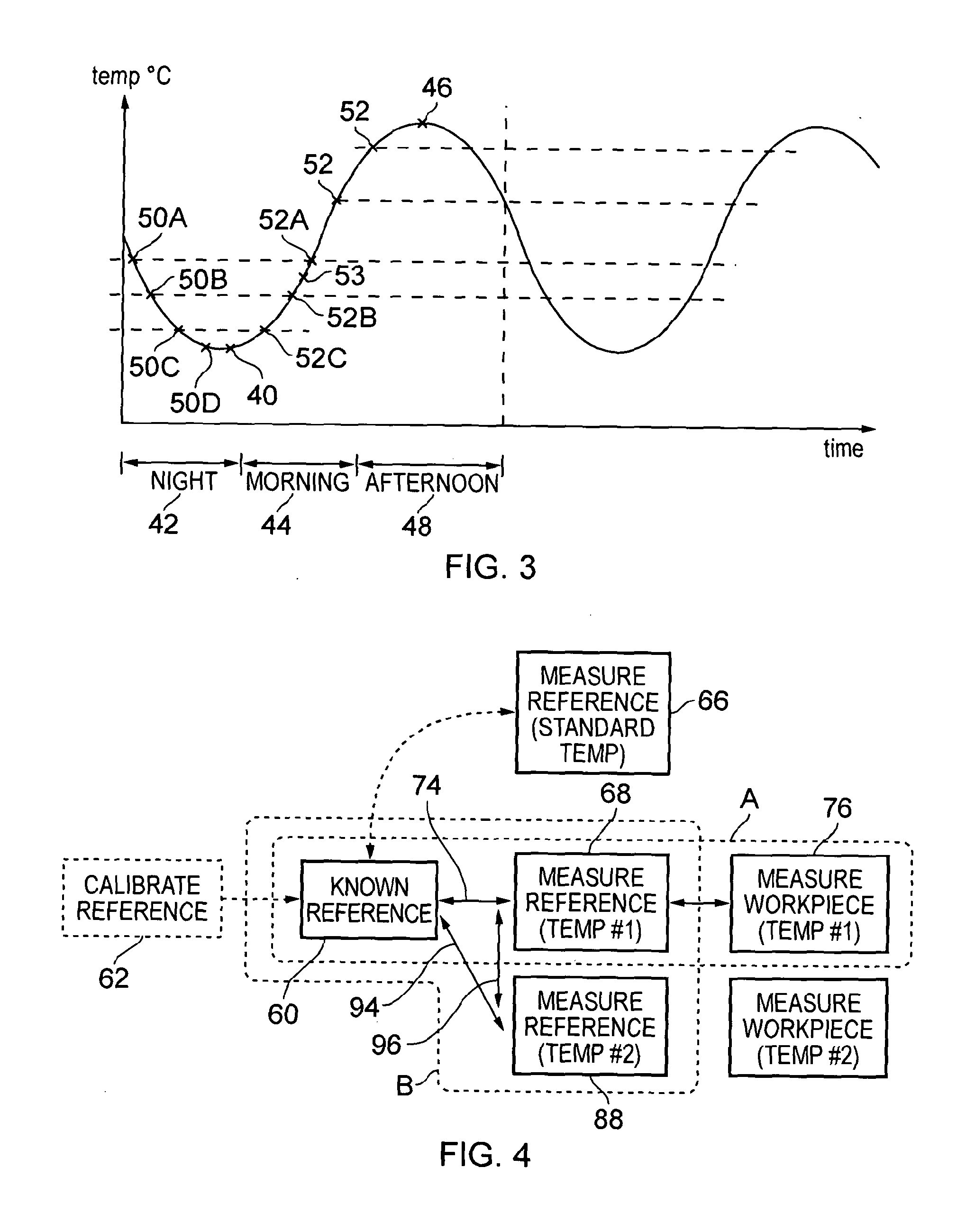

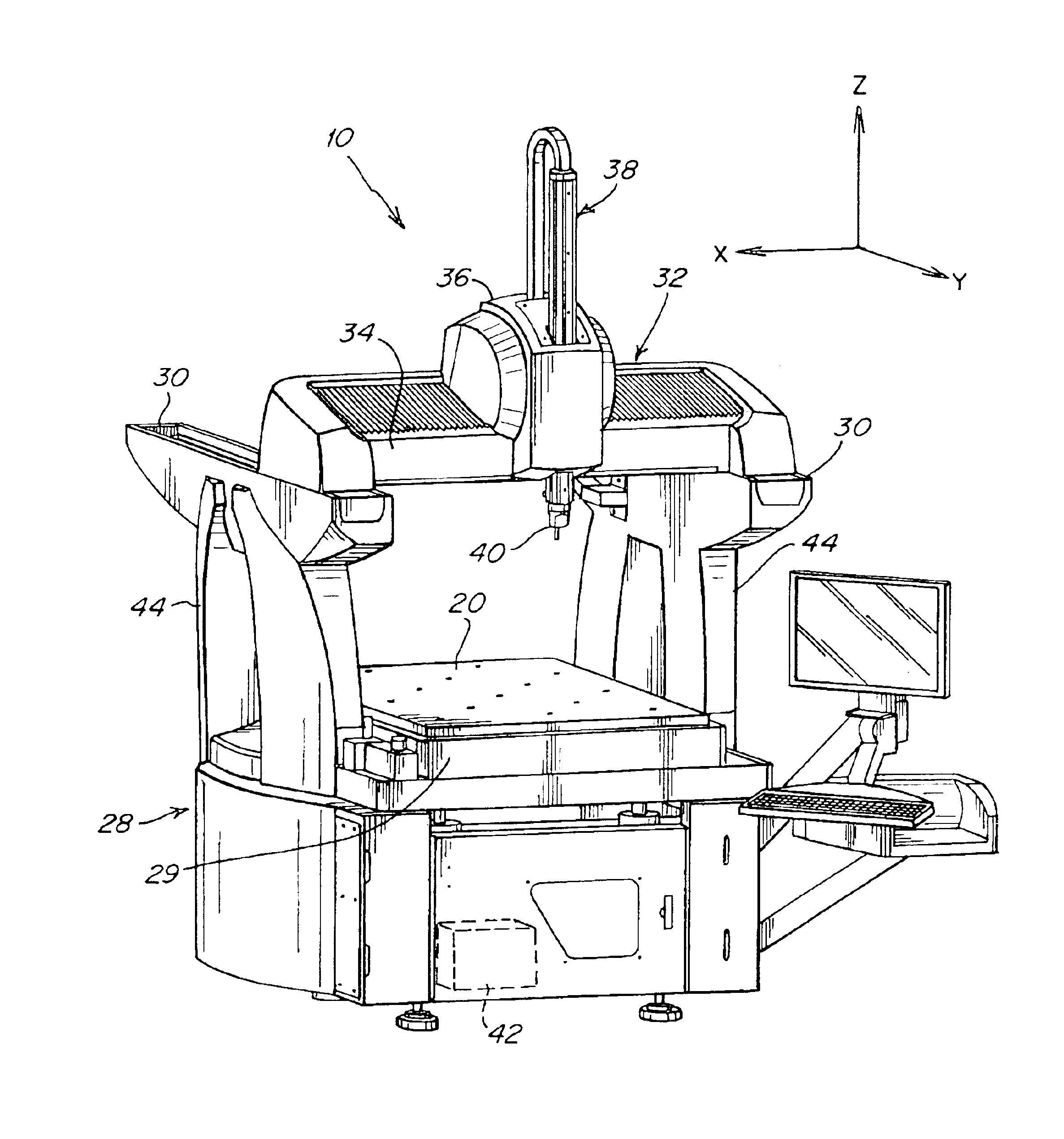

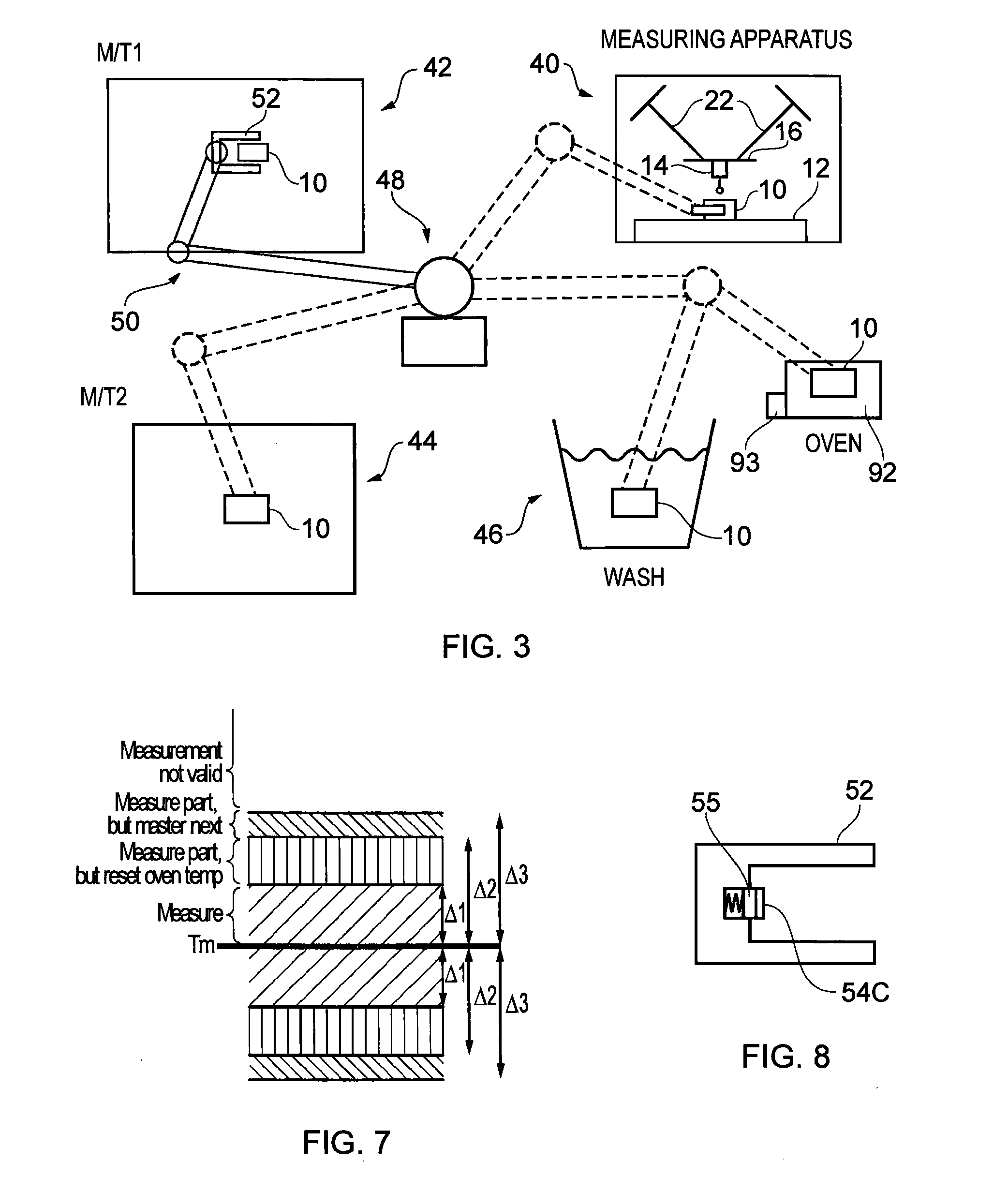

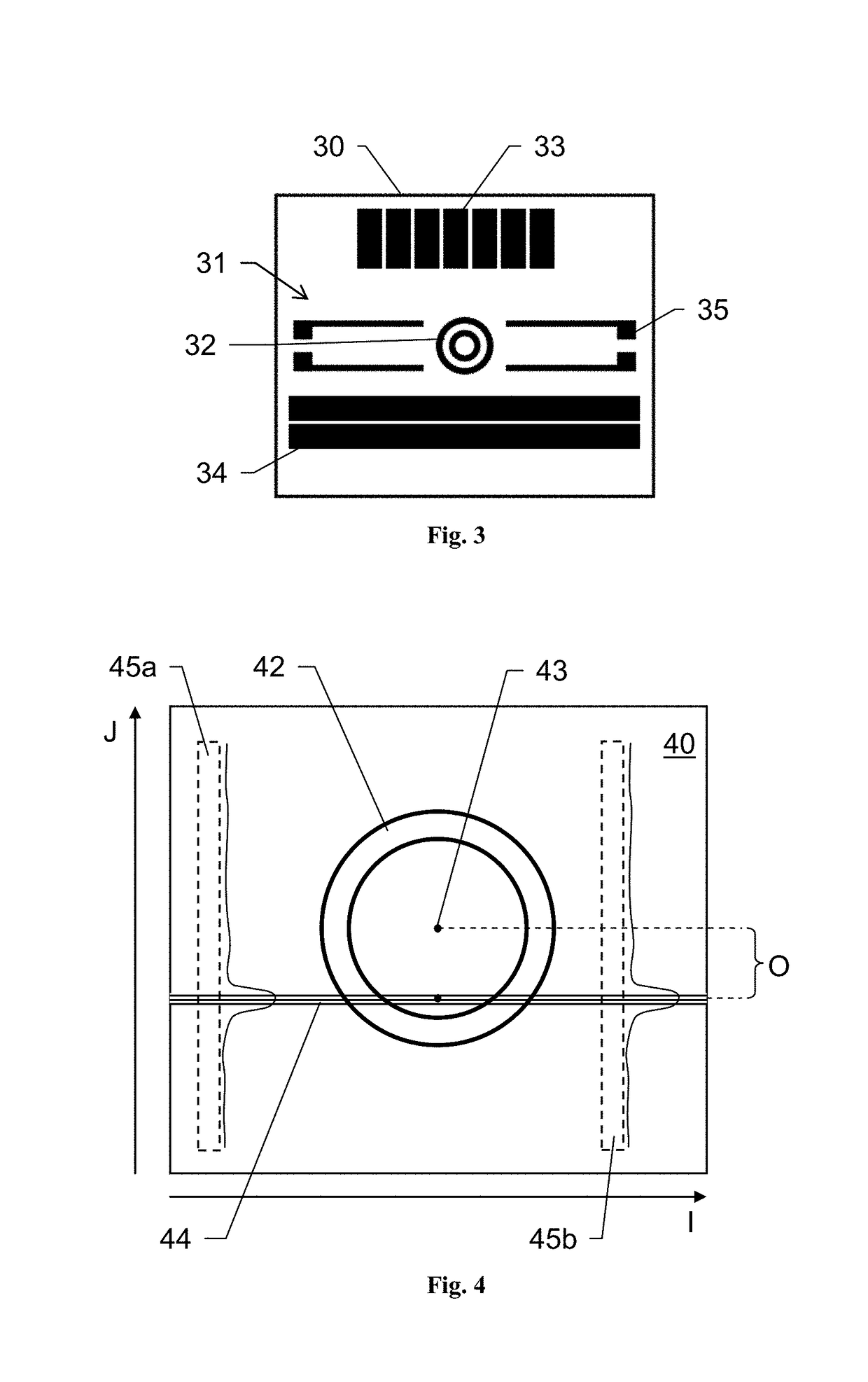

Method and apparatus for inspecting workpieces

ActiveUS20140157861A1Testing/calibration of speed/acceleration/shock measurement devicesError compensation/eliminationElectrical and Electronics engineeringError map

A series of nominally identical production workpieces is measured on a measuring apparatus. To correct for temperature variations, one of the workpieces forms a master artefact, the dimensions of which are known. The artefact is measured on the measuring apparatus at two or more temperatures, producing two or more corresponding sets of measured dimensional values of the master artefact at the respective temperatures. One or more error maps, look-up tables, or functions are generated which relate the measured dimensional values of the artefact to the known dimensions of the artefact. The error map(s), look-up table(s) or function(s) are dependent on the respective temperatures at which the artefact was measured. Correction values derived from the error map(s), look-up table(s) or function(s) are used to correct the measurements of production workpieces in the series. These correction values are determined in dependence upon the temperature at which the workpiece measurements were obtained.

Owner:RENISHAW PLC

Temperature compensation system for a coordinate measuring machine

ActiveUS6829838B1Minimize bendingWalking sticksMetal working apparatusThermal expansionCoordinate-measuring machine

A machine, such as a coordinate measuring machine, having an element and a structure movable with respect to each other along rails, wherein the rails have a different coefficient of thermal expansion than the structure to which they are attached. In one embodiment, a bar is disposed on the structure opposite the rails. This bar has a coefficient of thermal expansion, a stiffness, a spacing from the neutral axis of the structure, and a cross-sectional dimension such that the bar balances any thermal stresses in the structure caused by differential expansion or contraction of the structure and the rails with temperature changes to minimize any bending of the structure. In one embodiment, two rails are disposed on a beam, and a carriage travels on the two rails. For each rail, there is an associated bar disposed on an opposite surface of the beam. In another aspect, a pin extends into an elongated slot on a slide associated with the structure to allow the structure to expand and contact. In yet another aspect, a movable element, such as a carriage, is coupled to an associated slide riding along the rails by a leaf spring to accommodate expansion and contraction of the element.

Owner:HEXAGON TECH CENT GMBH

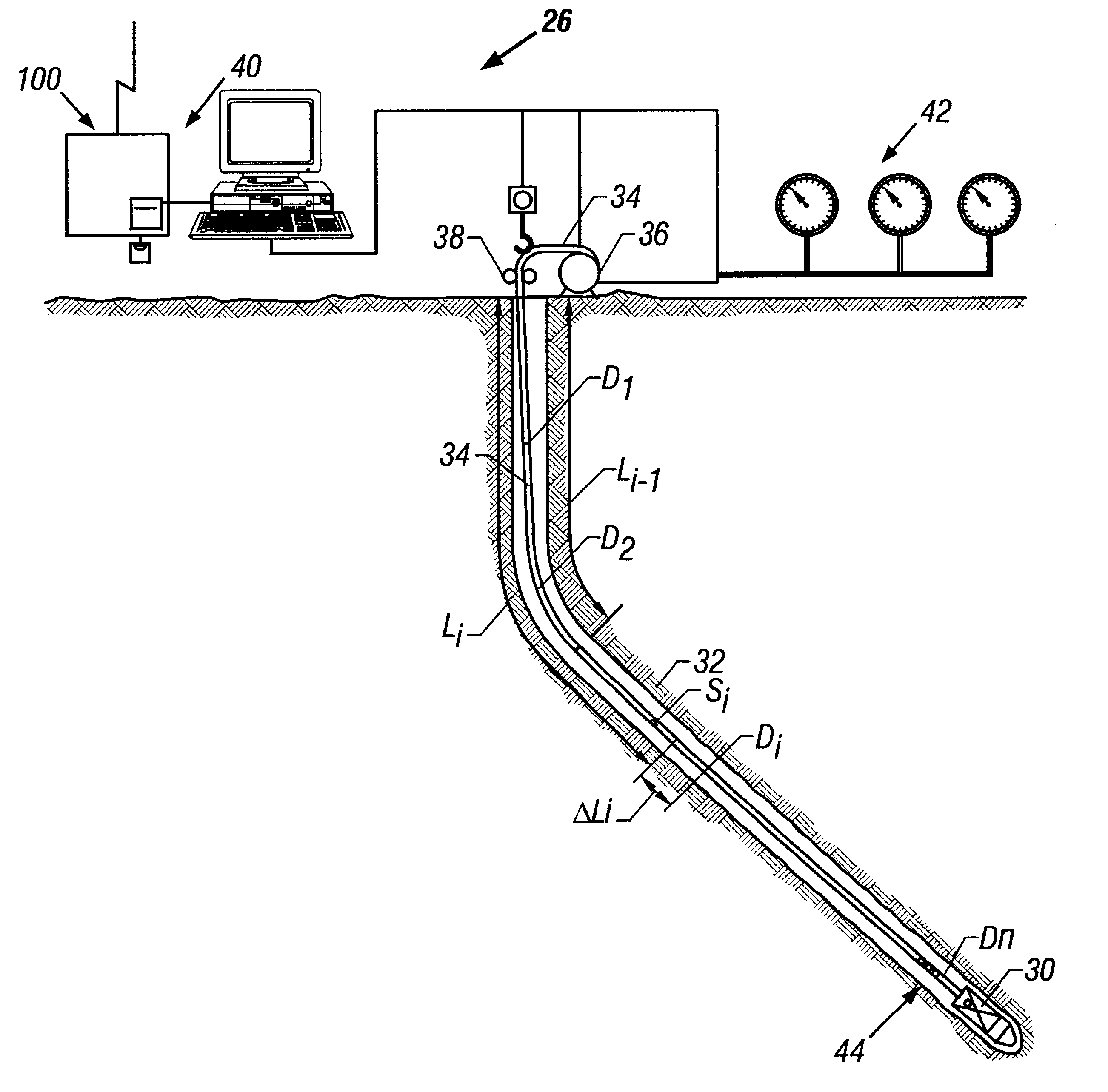

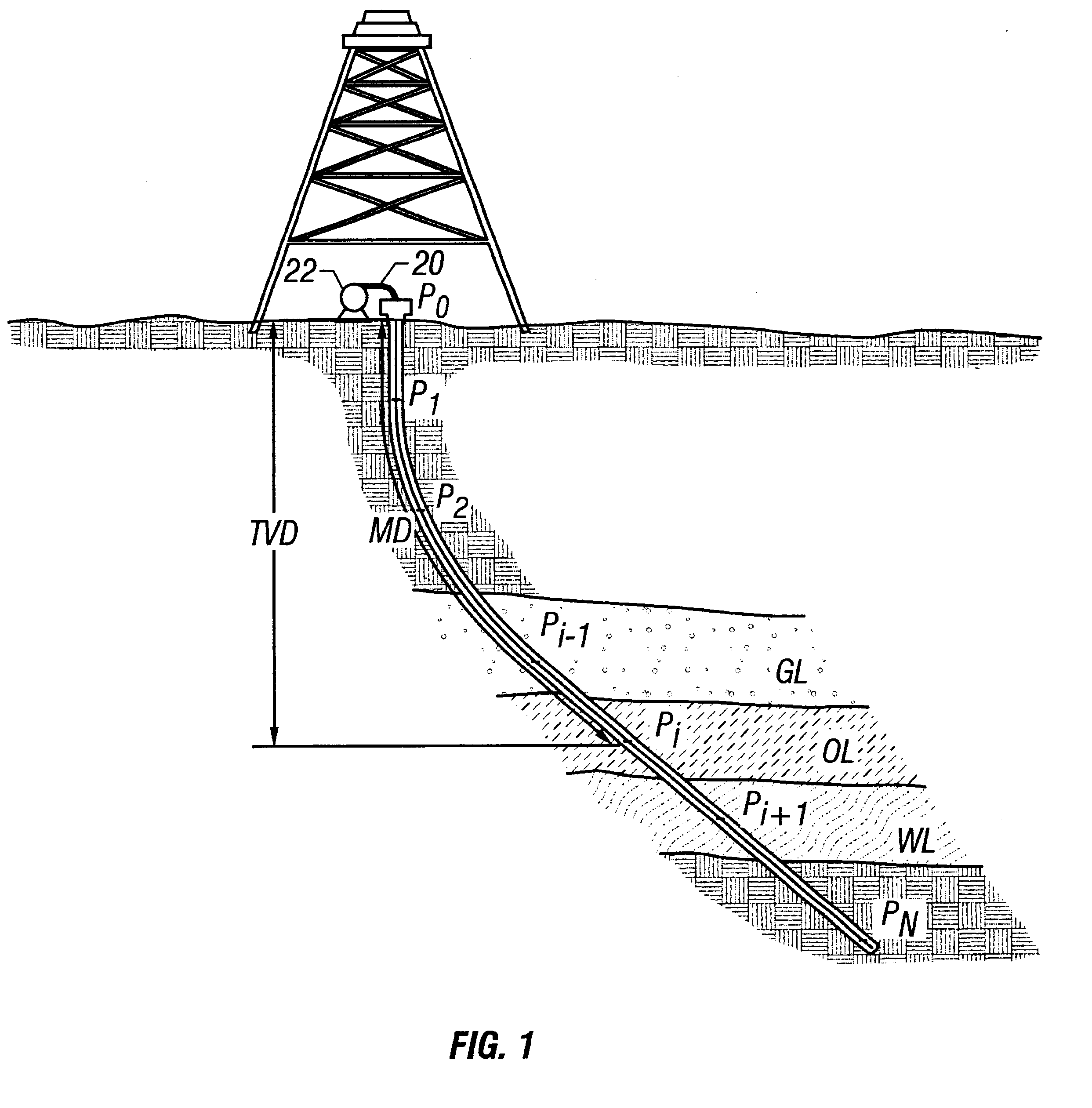

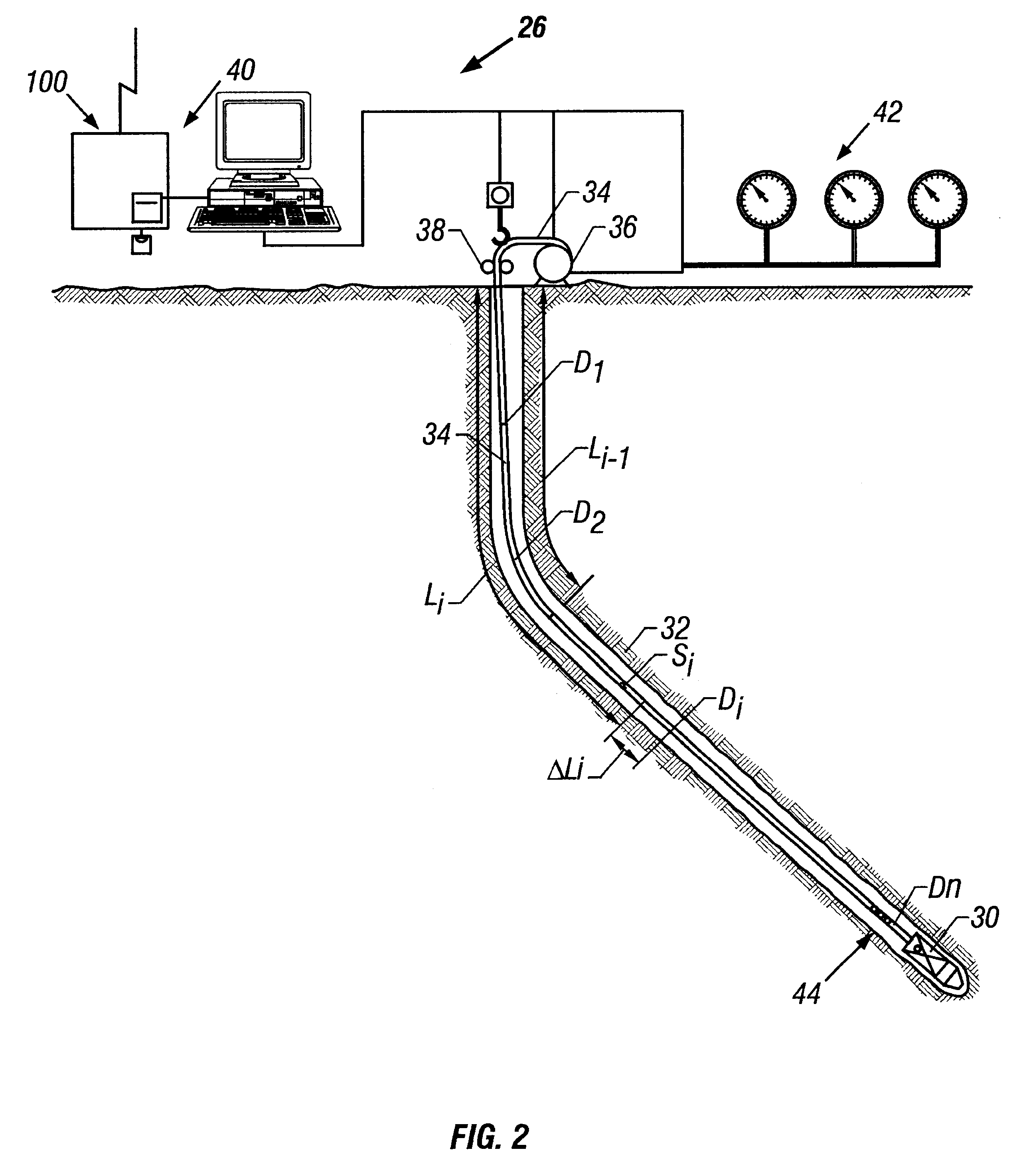

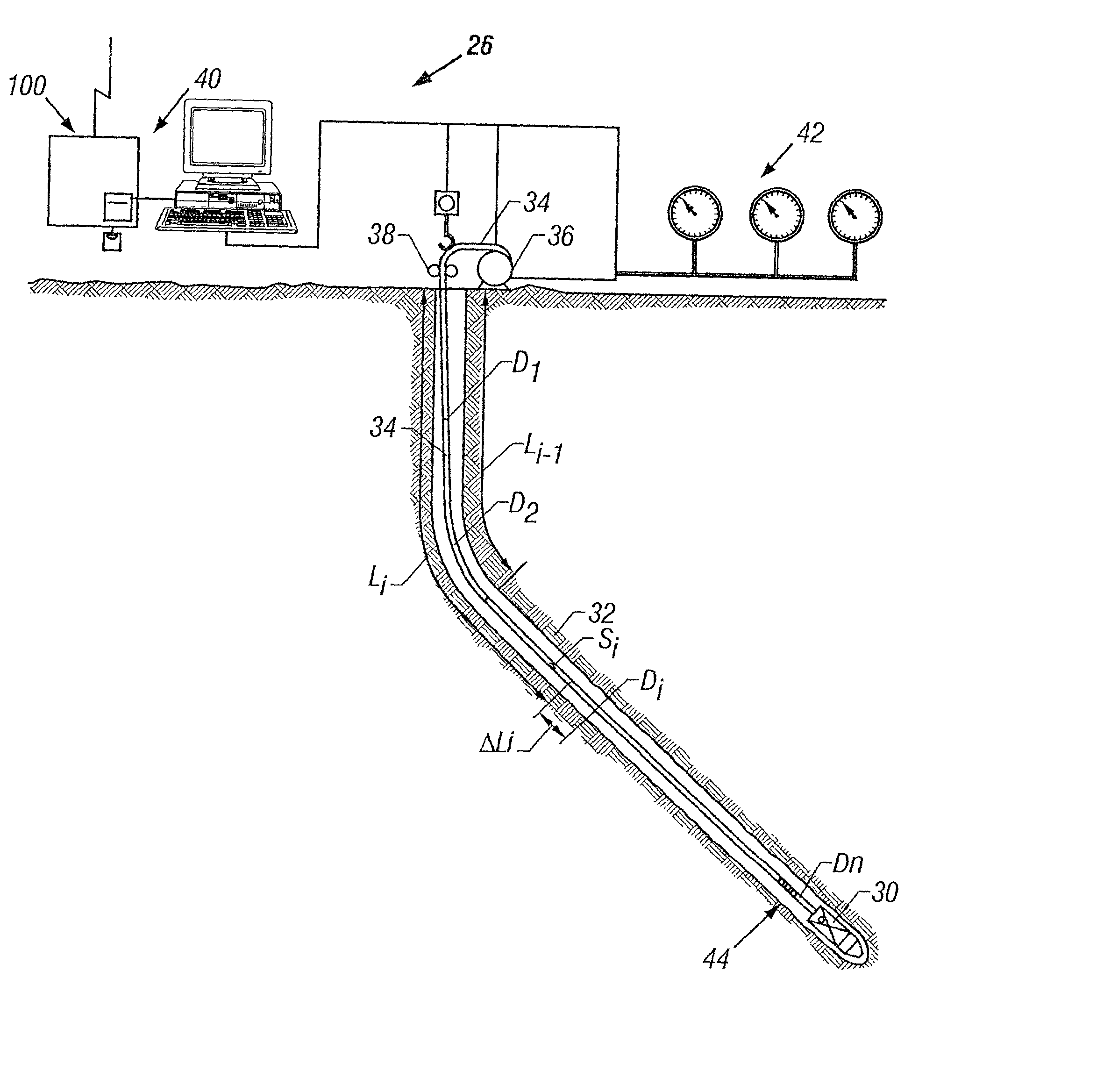

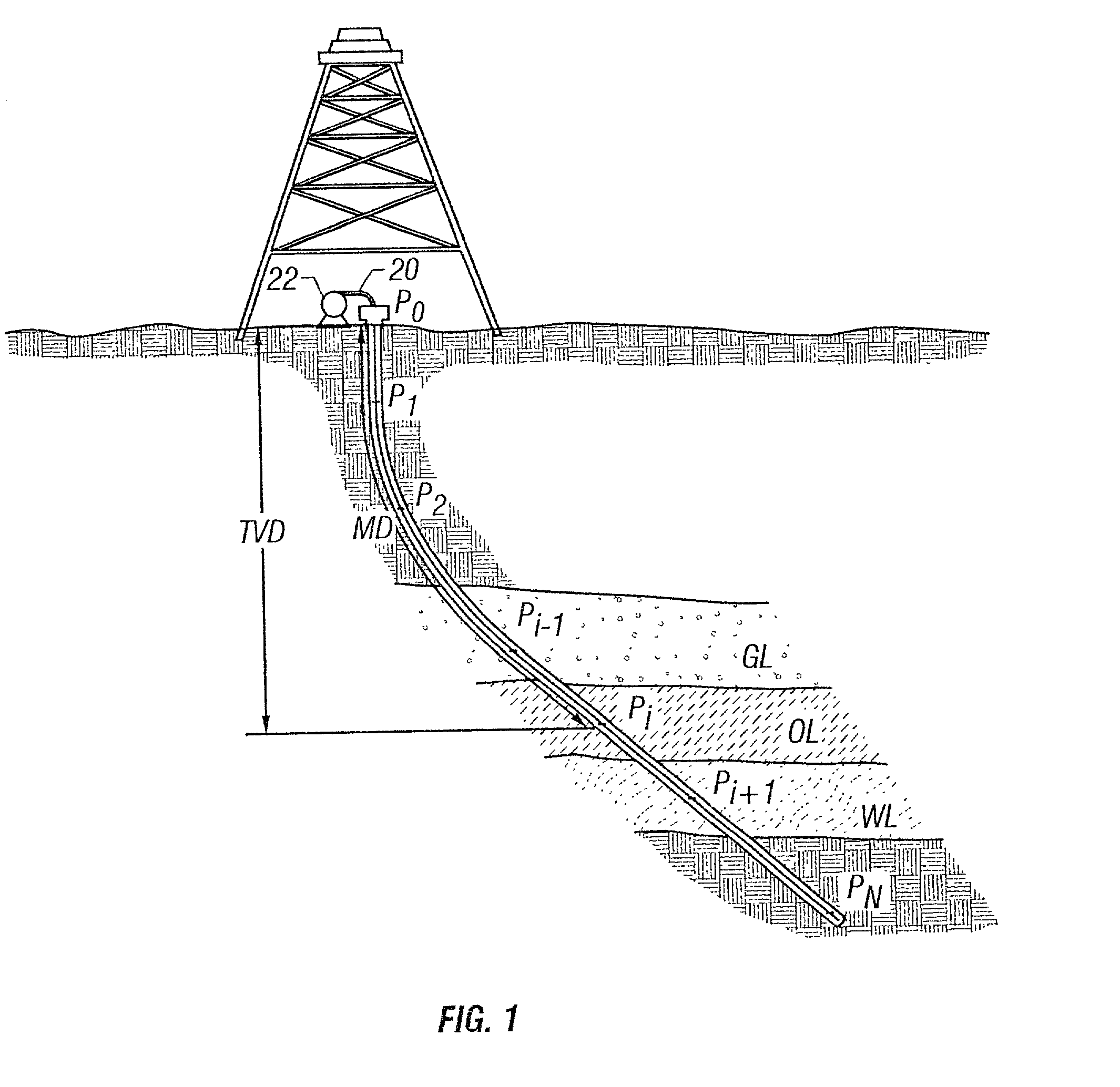

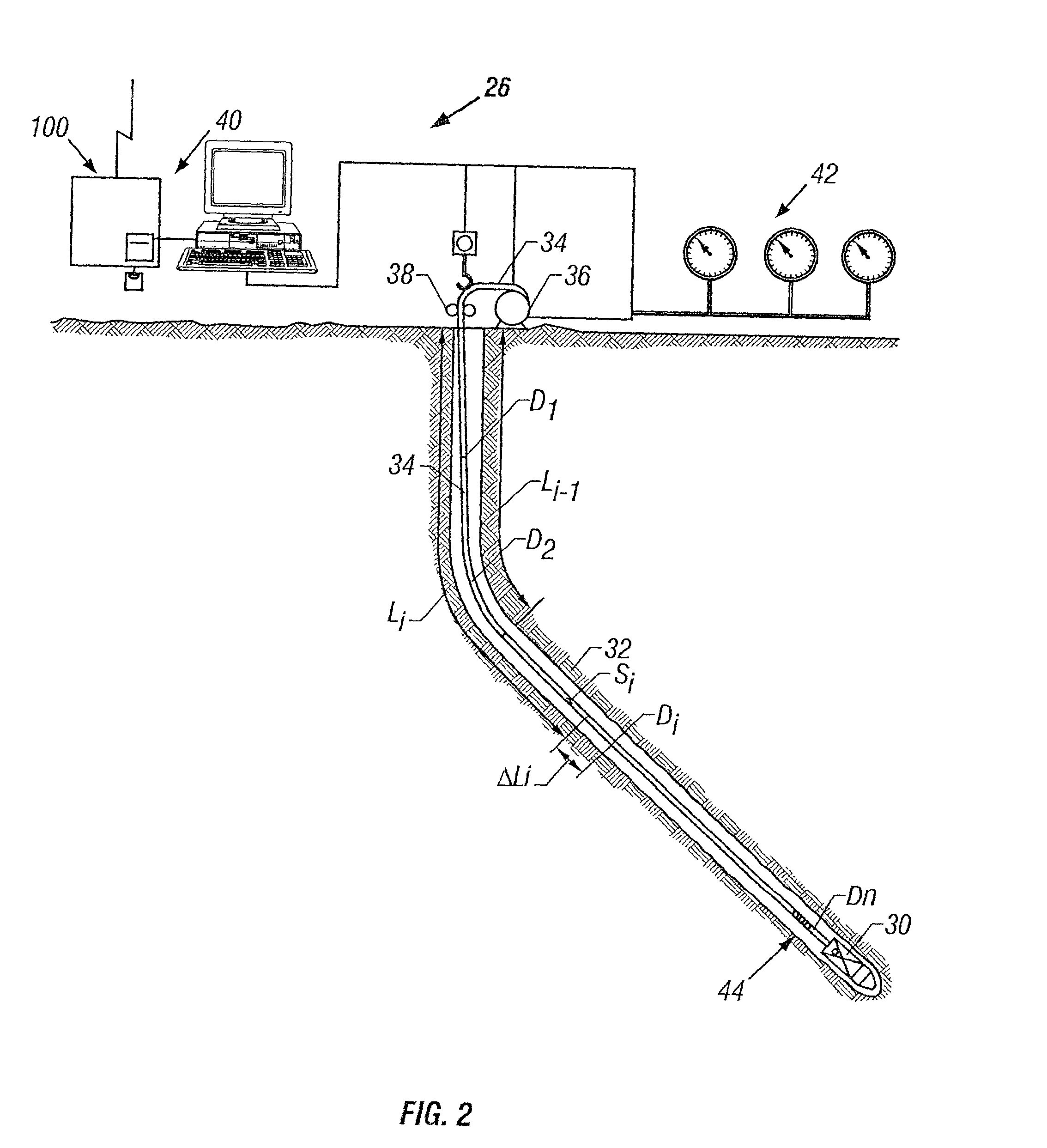

Tubing elongation correction system & methods

A surface processor uses an environmental profile to determine the sub-surface length of tubing disposed in a well bore. Information relating to tubing properties is stored in a memory module of the surface processor. The environmental profile includes data relating to well bore ambient conditions and the operating parameters of well equipment. Surface processor calculates the tubing elongation or length reduction corresponding to the environmental profile. Surface processor may repeat this process to develop a measured depth chart for a well. Logging operations performed in conjunction with the sub-surface length calculations allows formation data to be associated with the measured depth chart.

Owner:HALLIBURTON ENERGY SERVICES INC

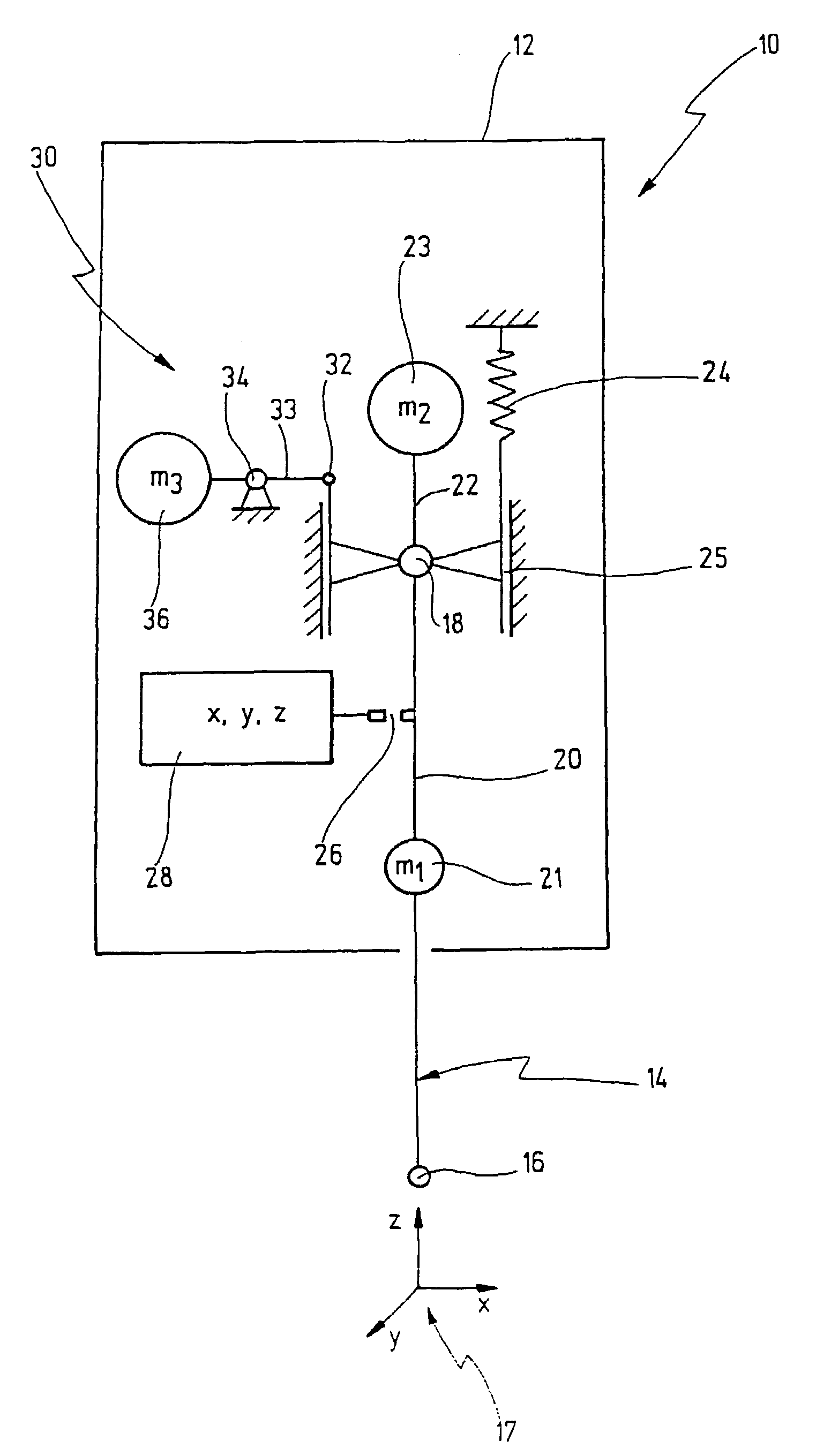

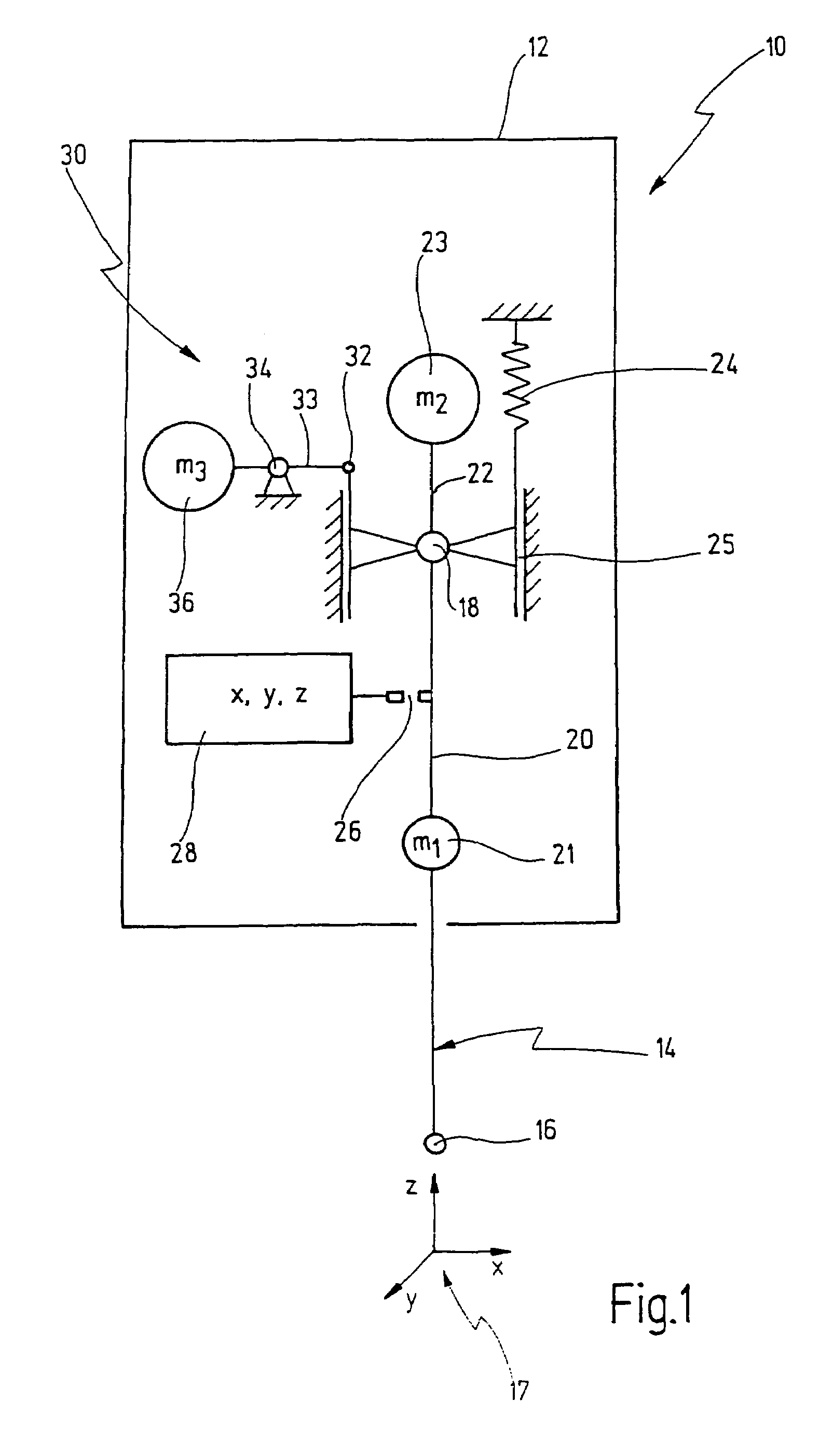

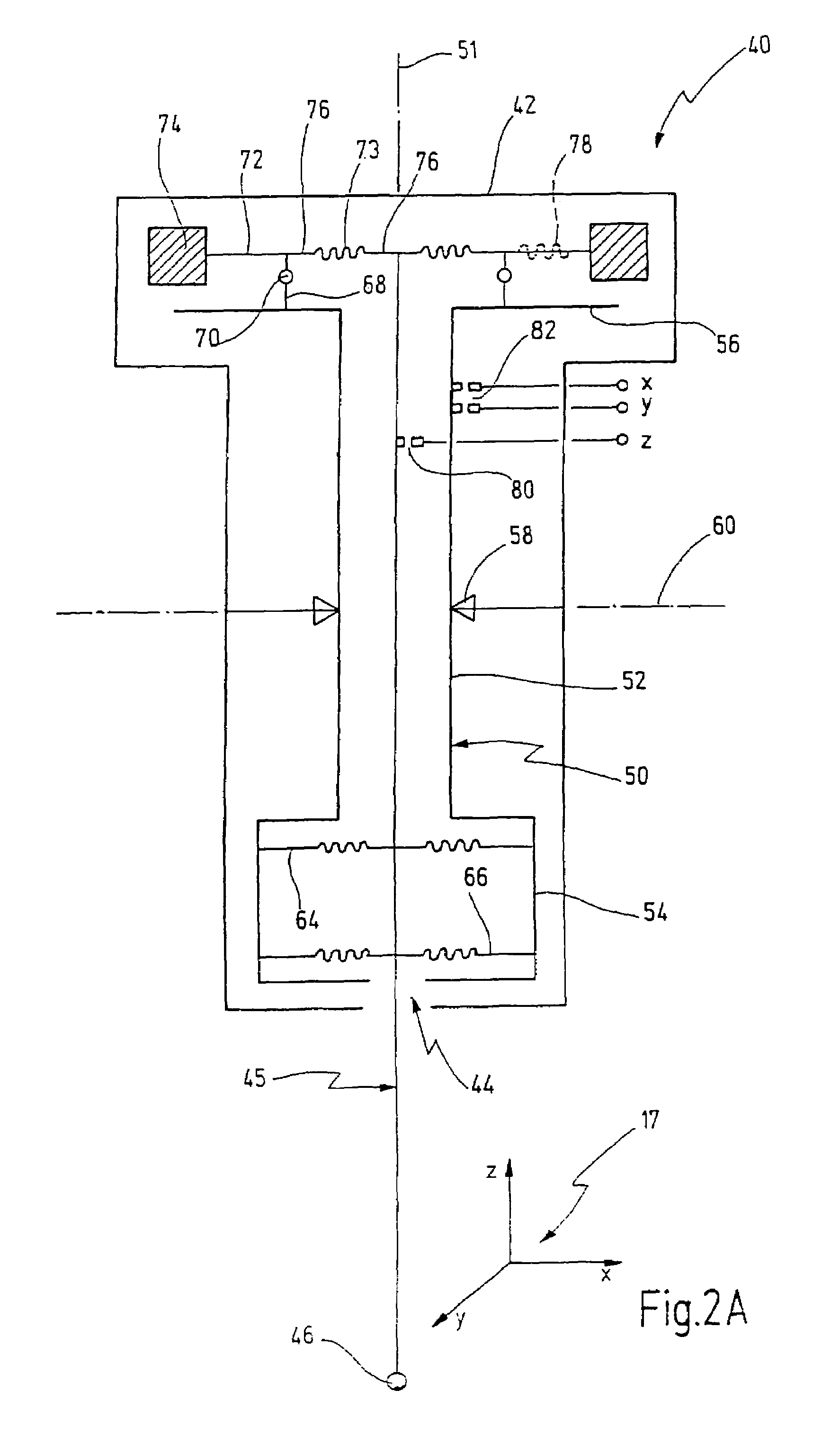

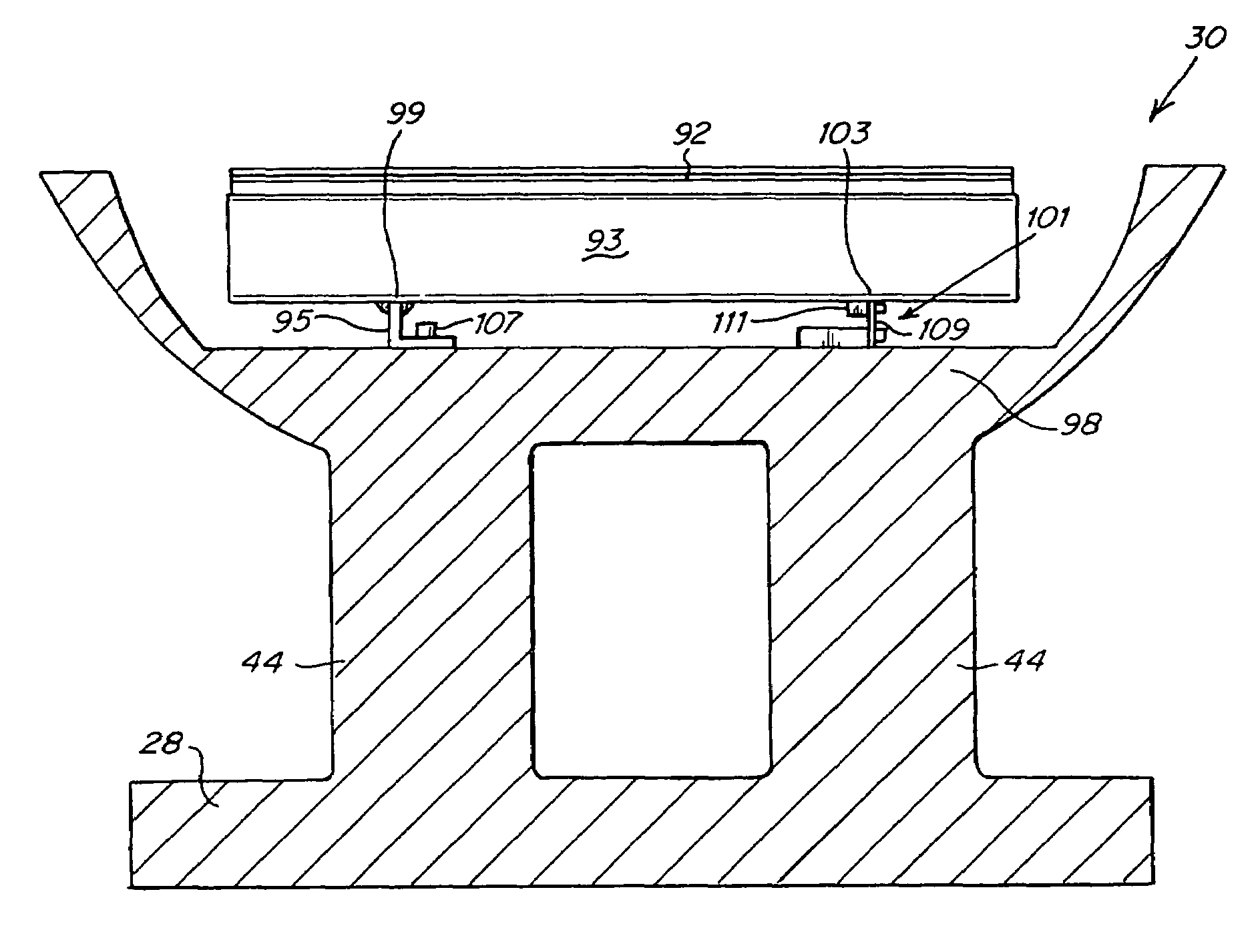

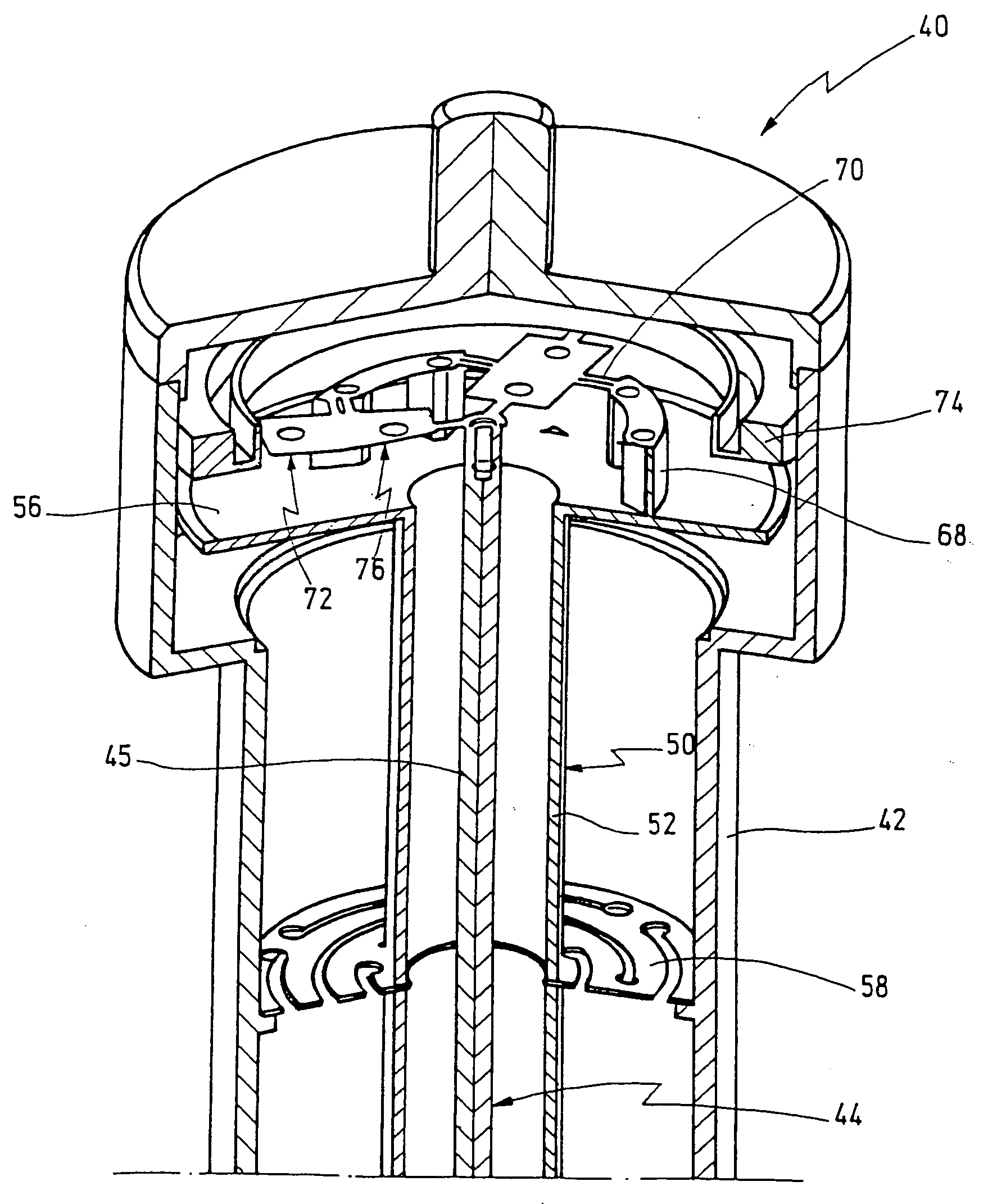

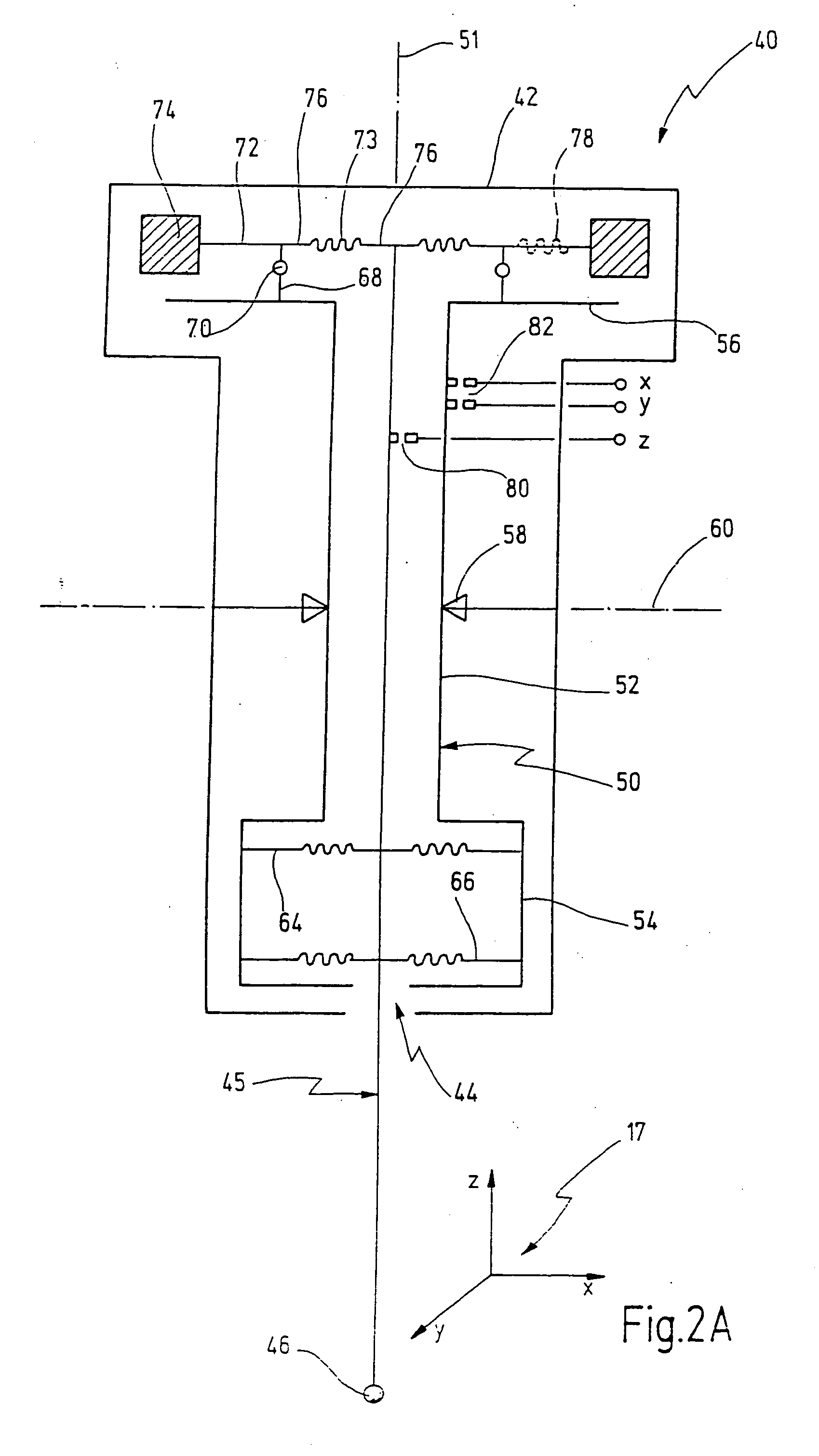

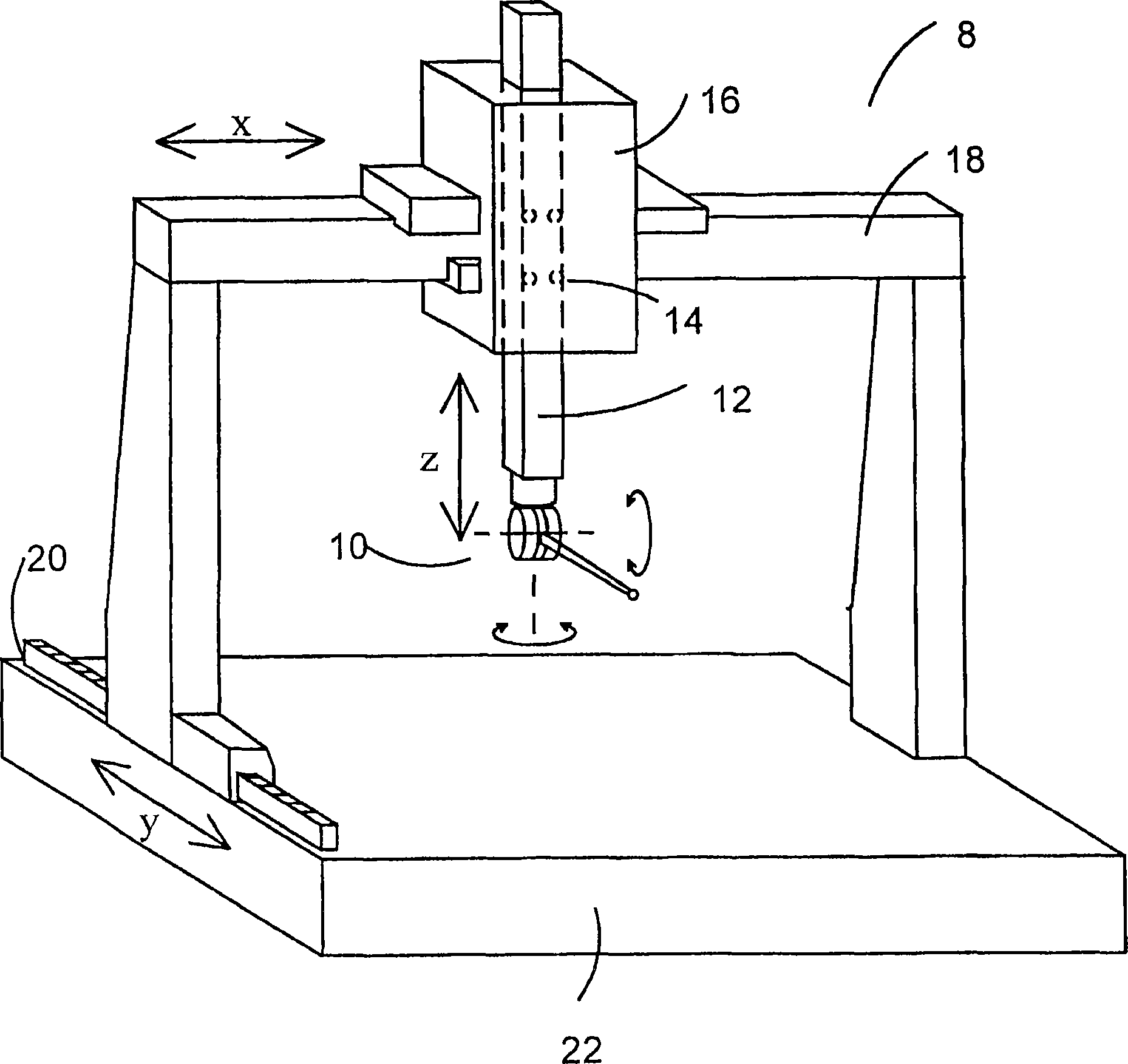

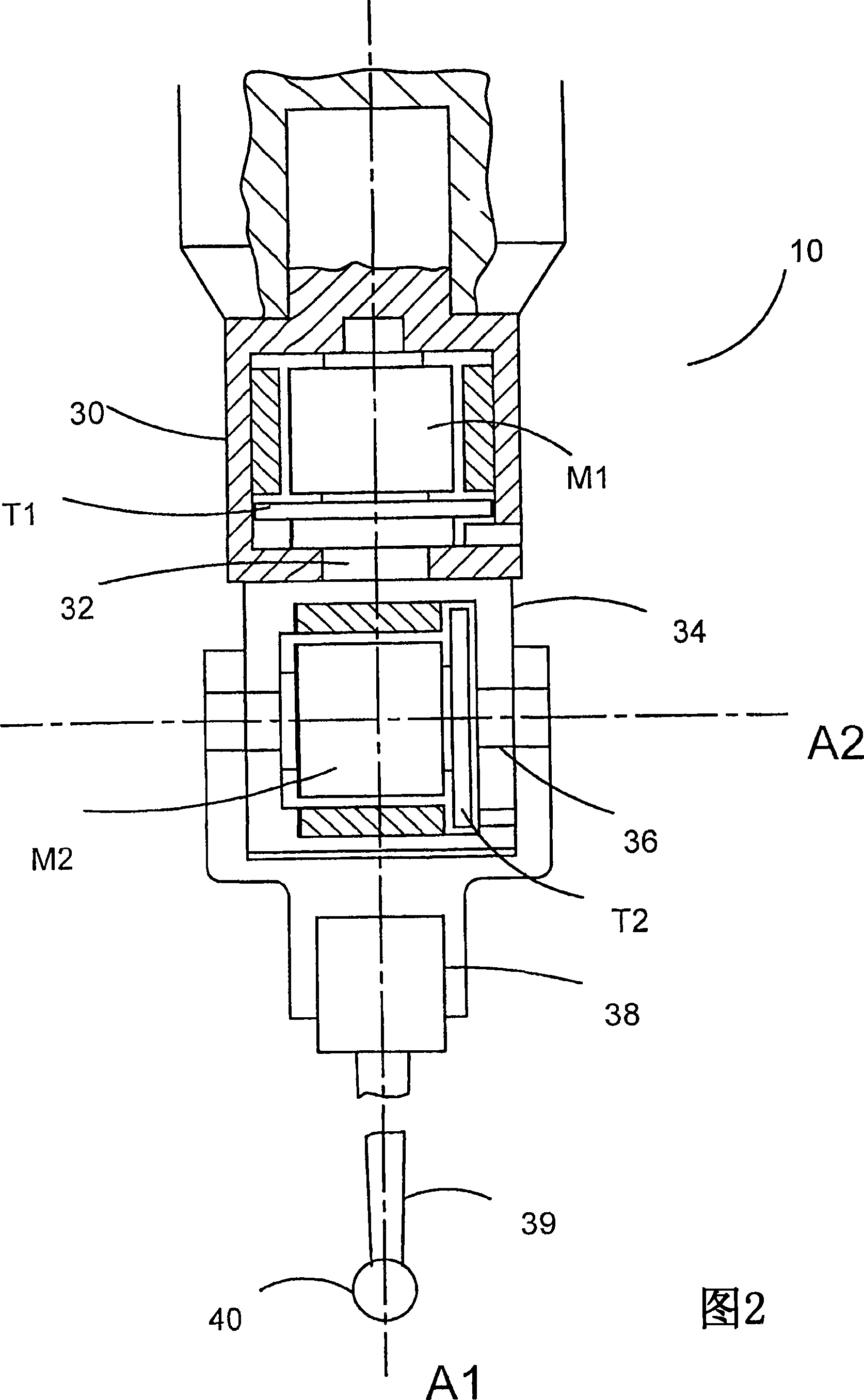

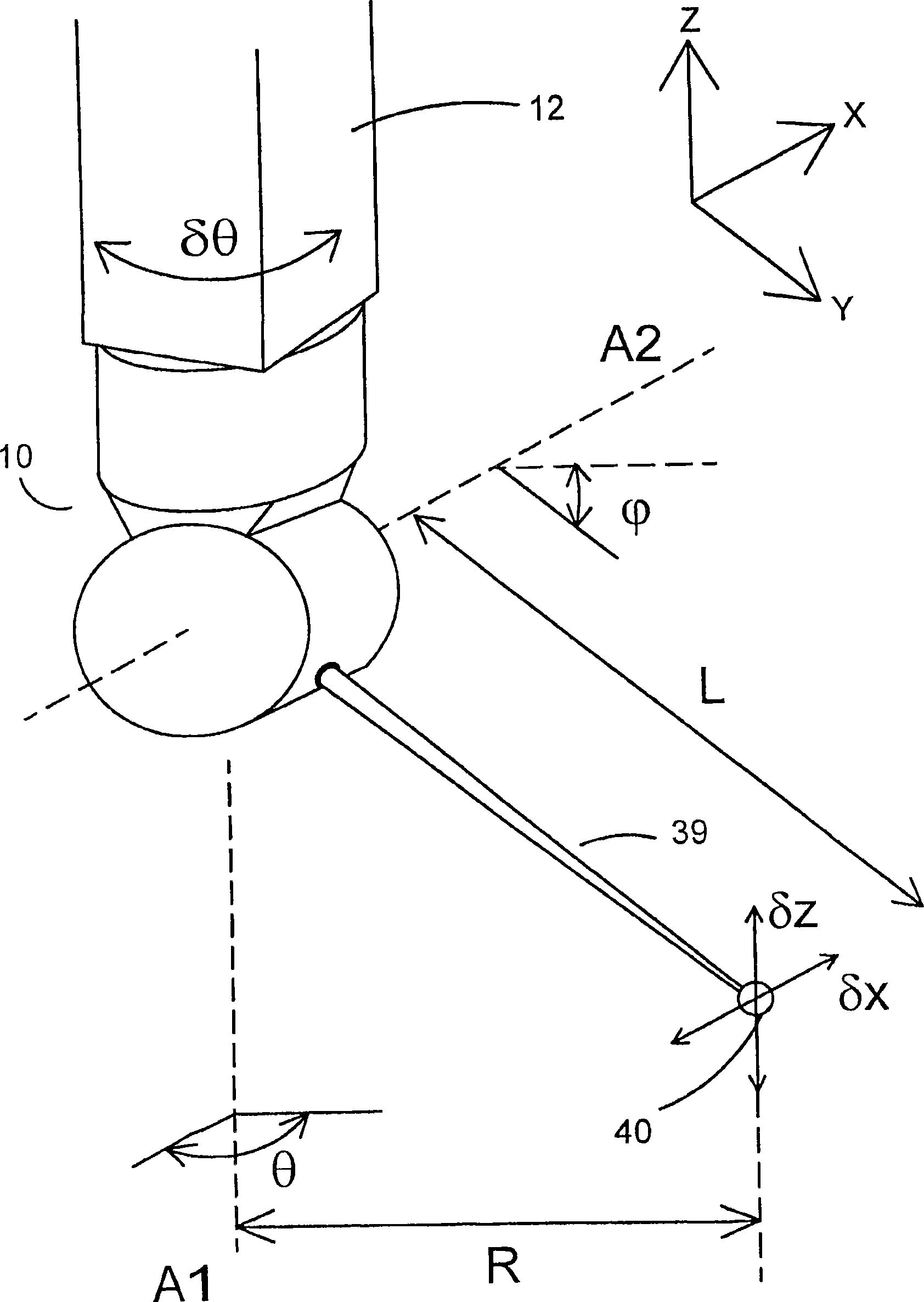

Probe head for coordinate measuring machines

InactiveUS20050055839A1Improve accuracyAvoid disadvantagesGaugesError compensation/eliminationRest positionEngineering

A probe head for a coordinate measuring machine has a feeler device that can be deflected in space. Also provided are balancing element for adjusting a predetermined rest position of the feeler device for any different alignment of the probe head in space. The balancing element are designed as masses. The forces or moments required for balancing the feeler device are produced by the masses.

Owner:CARL ZEISS IND MESSTECHN GMBH

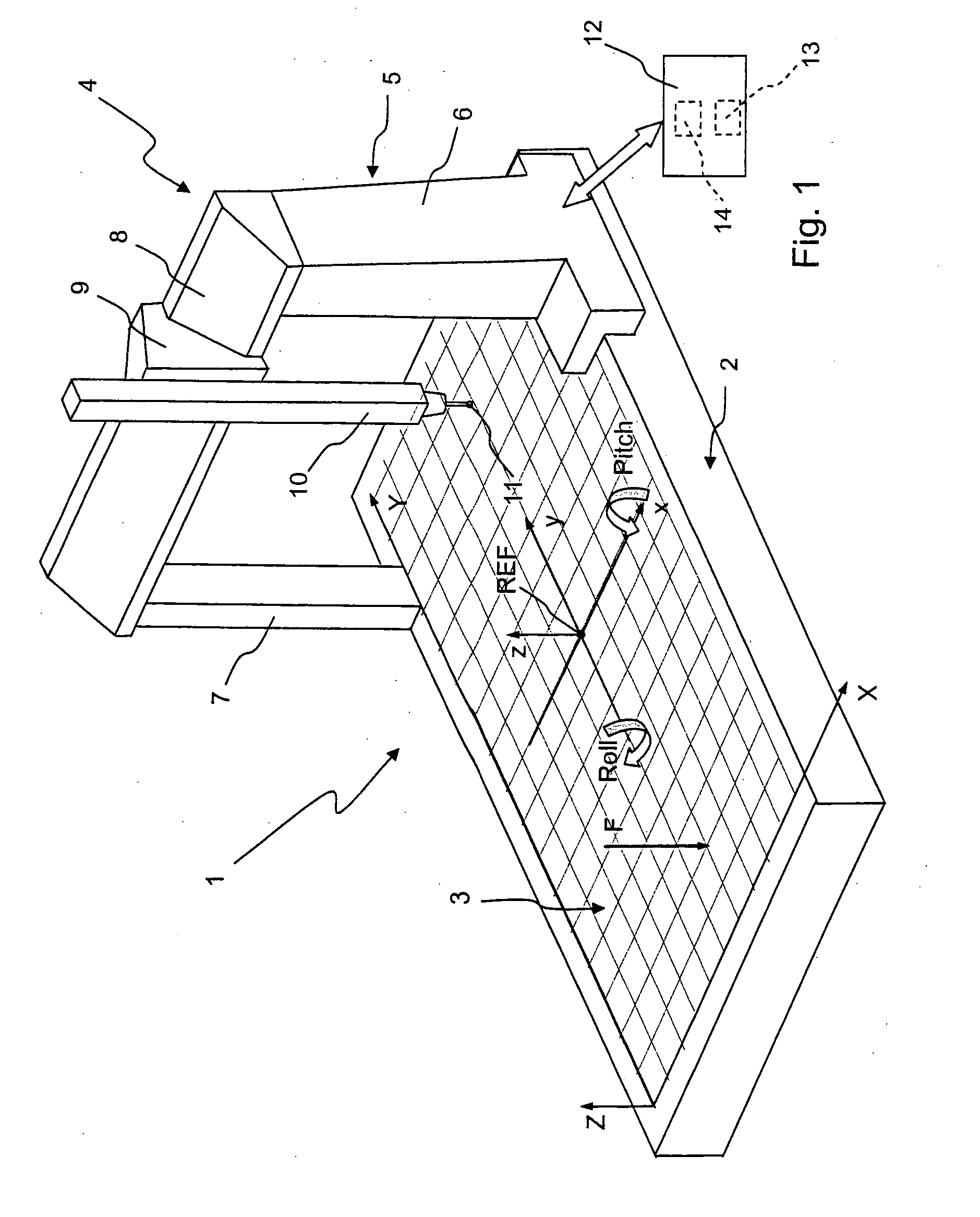

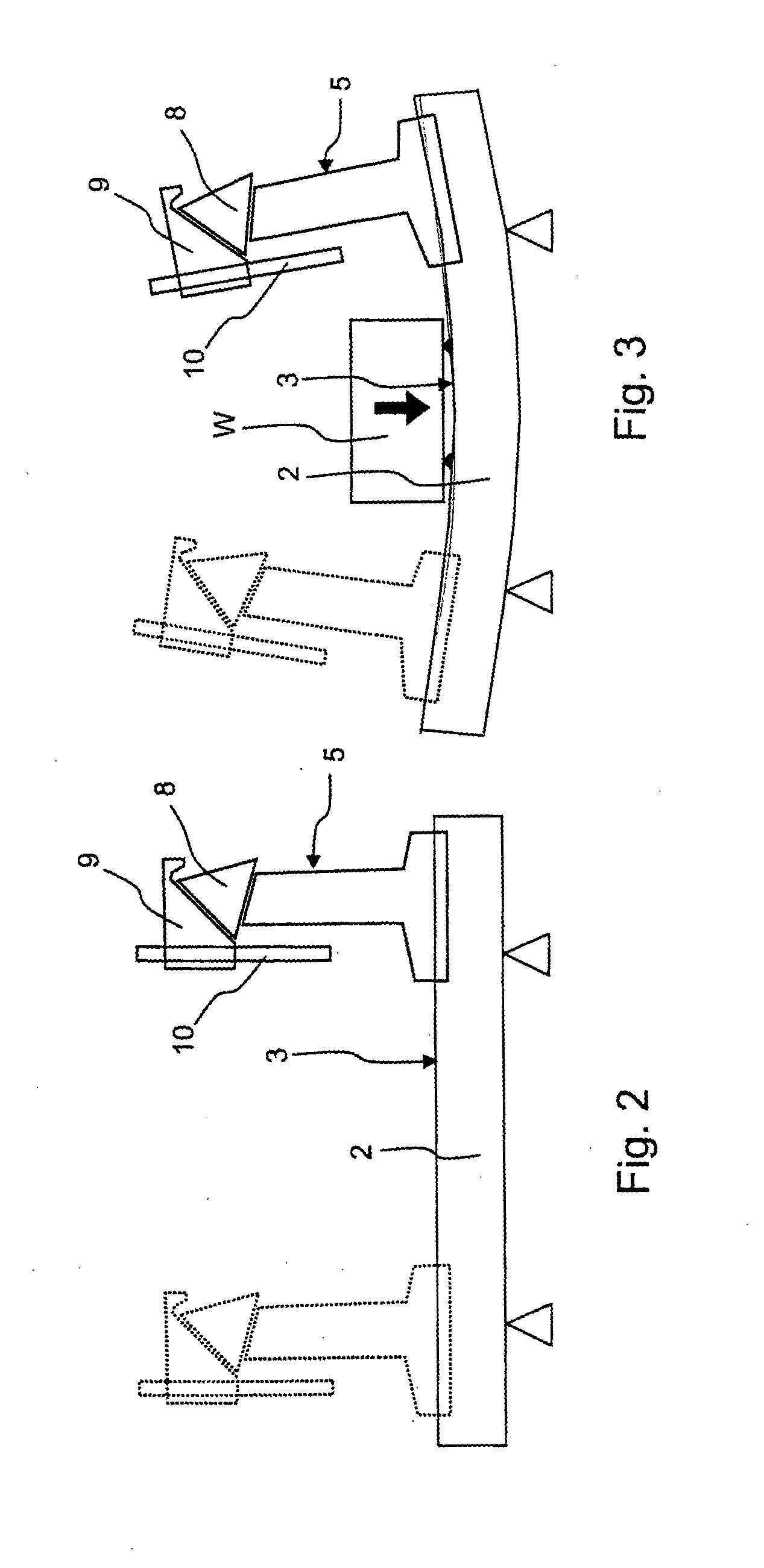

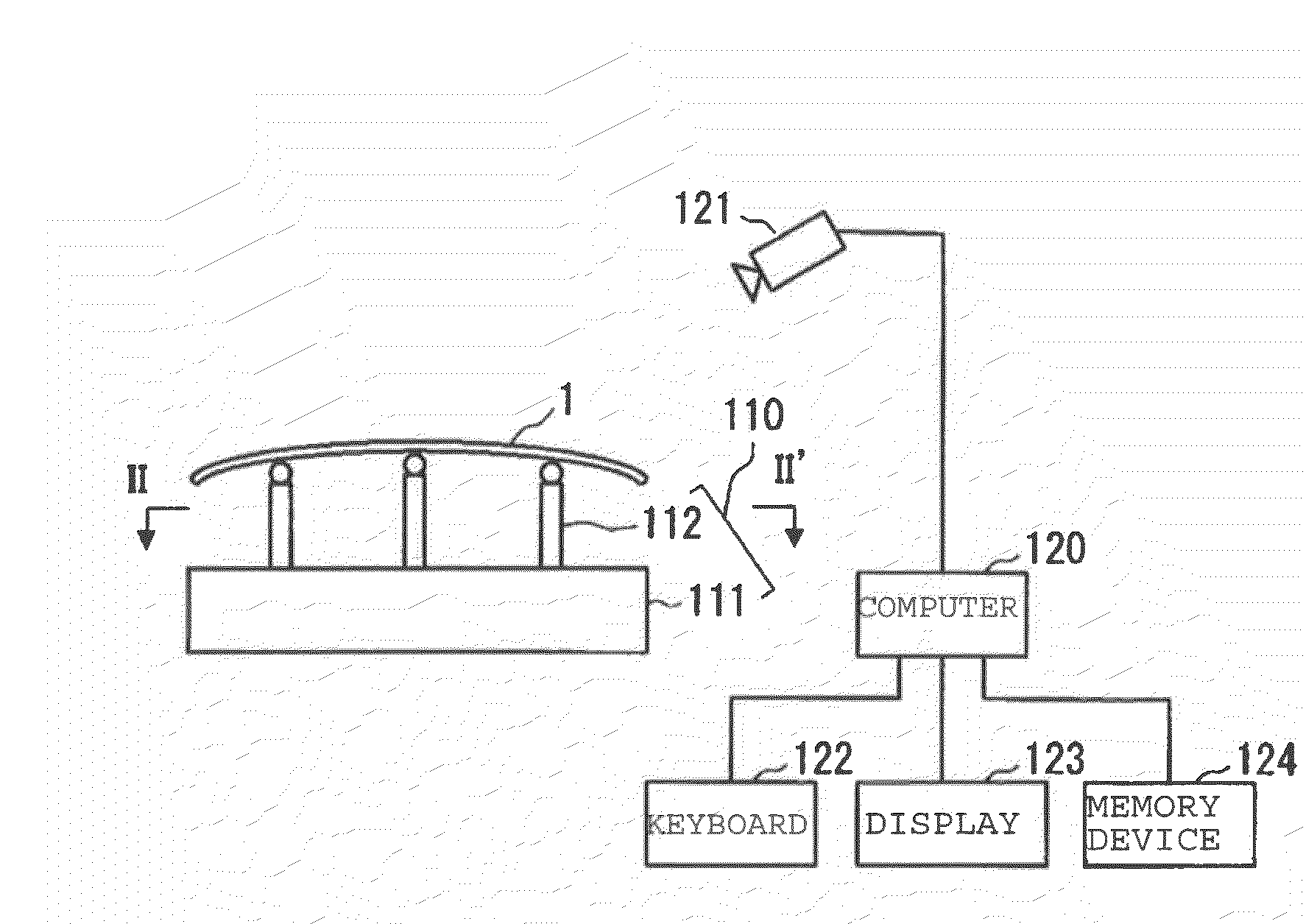

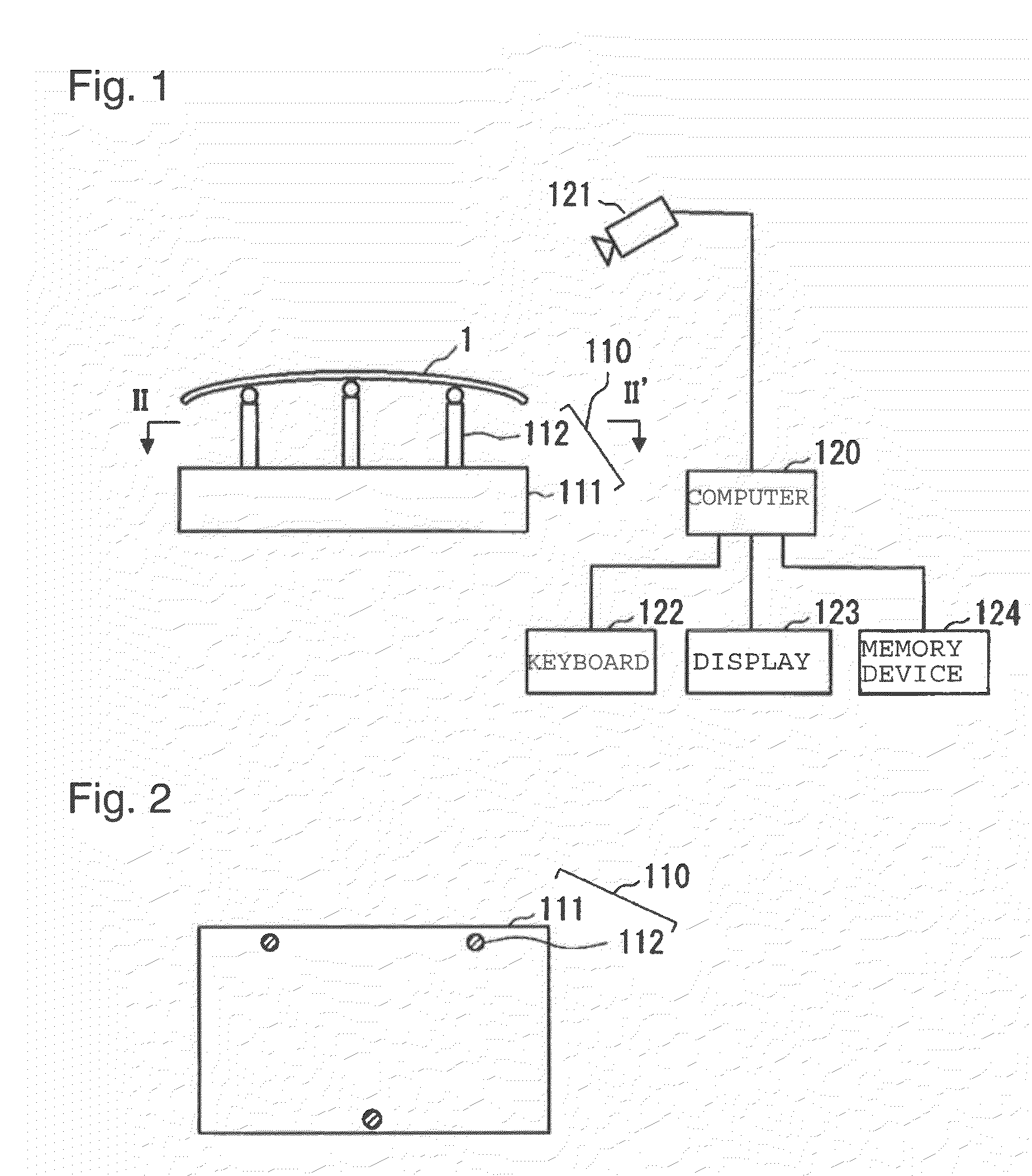

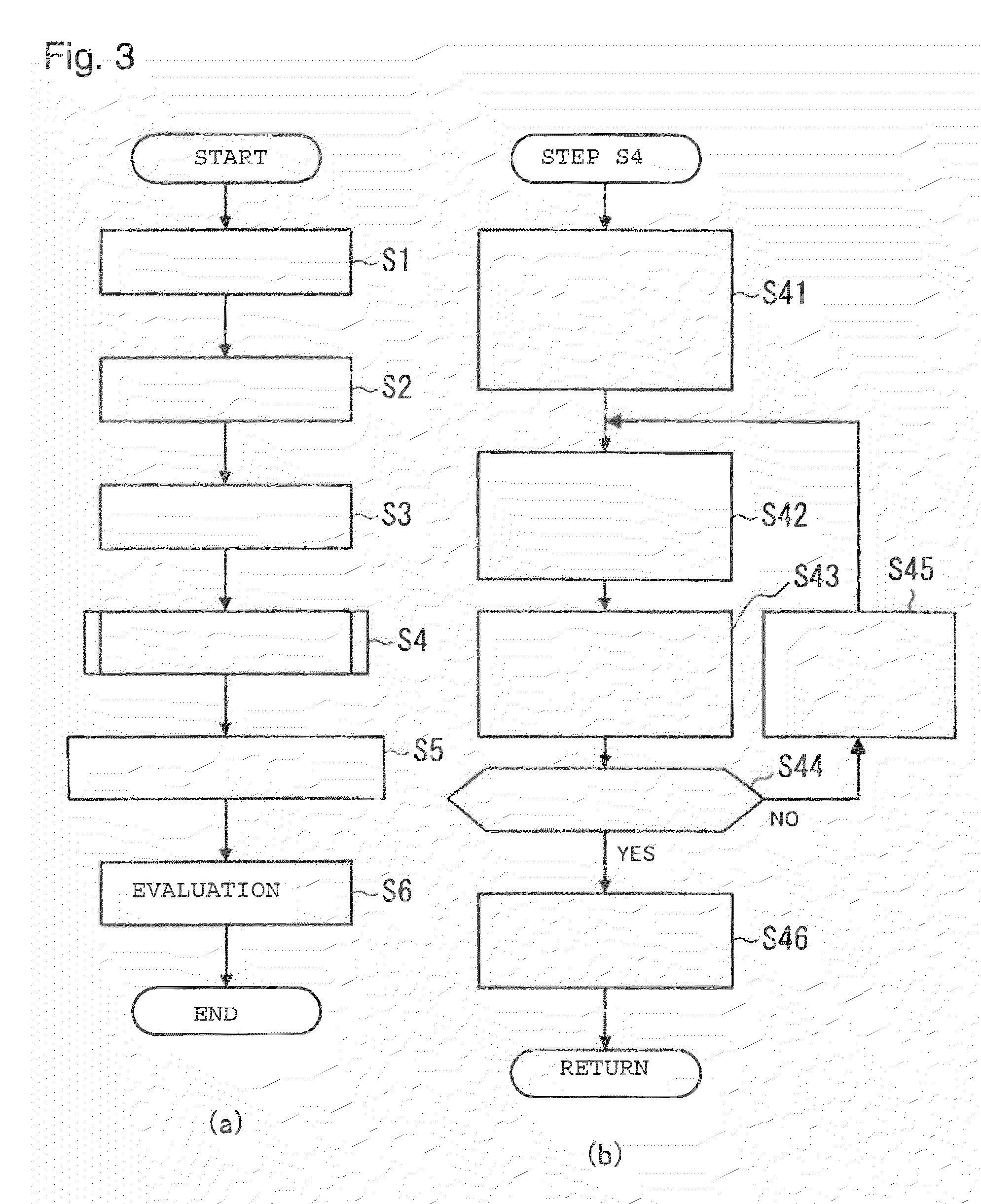

Shape inspection method and apparatus

InactiveUS20080316501A1Judge the shape quality of the objectMaterial analysis by optical meansUsing optical meansObject basedModel Number

Shape inspection is carried out without preparing an inspection apparatus for each model of product.There is provided a shape inspection method comprising a first step of placing an object to be measured on an inspection stand for actual measurement, a second step of obtaining information of the surface shape of the object, a third step of calculating shape data of the object in a weightless state based on the information of the surface shape of the object, and a fourth step of recalculating the shape data of the object in a state that the object is placed on a predetermined inspection stand based on the shape data in the weightless state of the object, and judging the quality of the object based on the recalculated shape data of the object.

Owner:ASAHI GLASS CO LTD

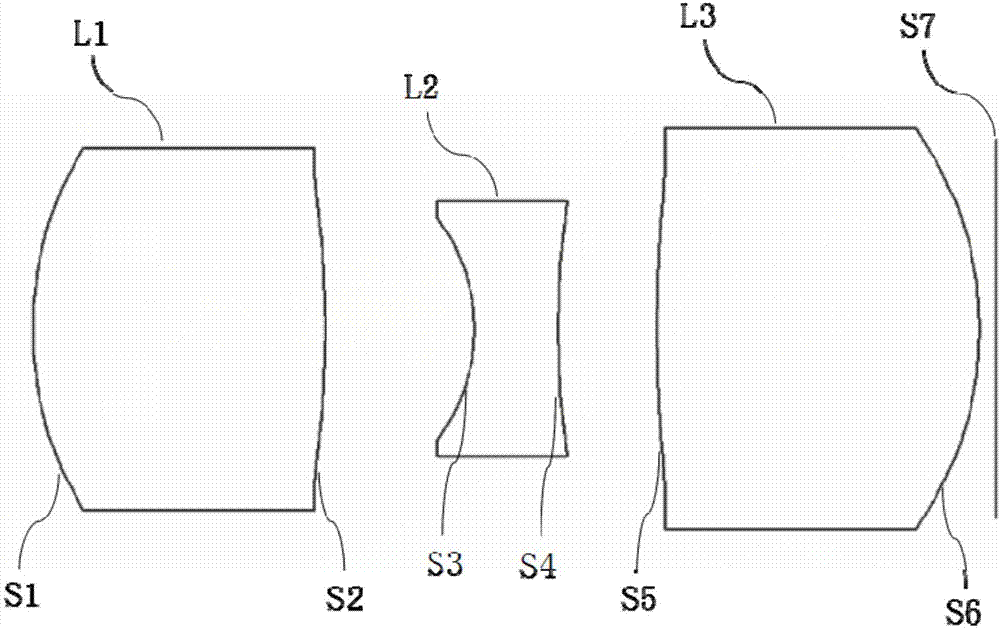

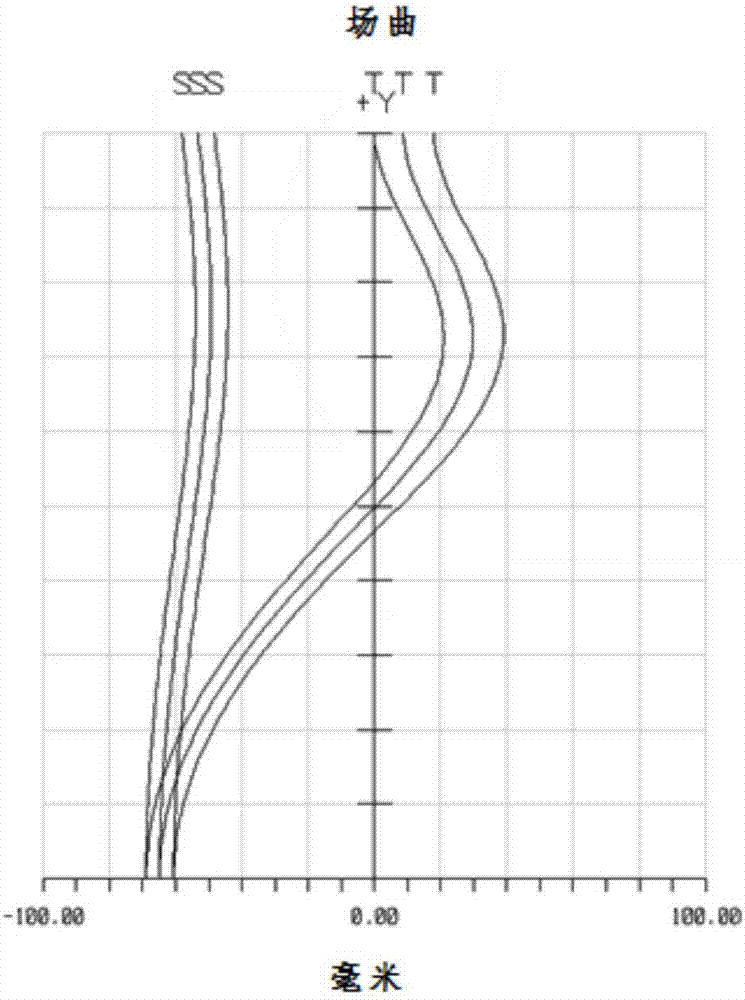

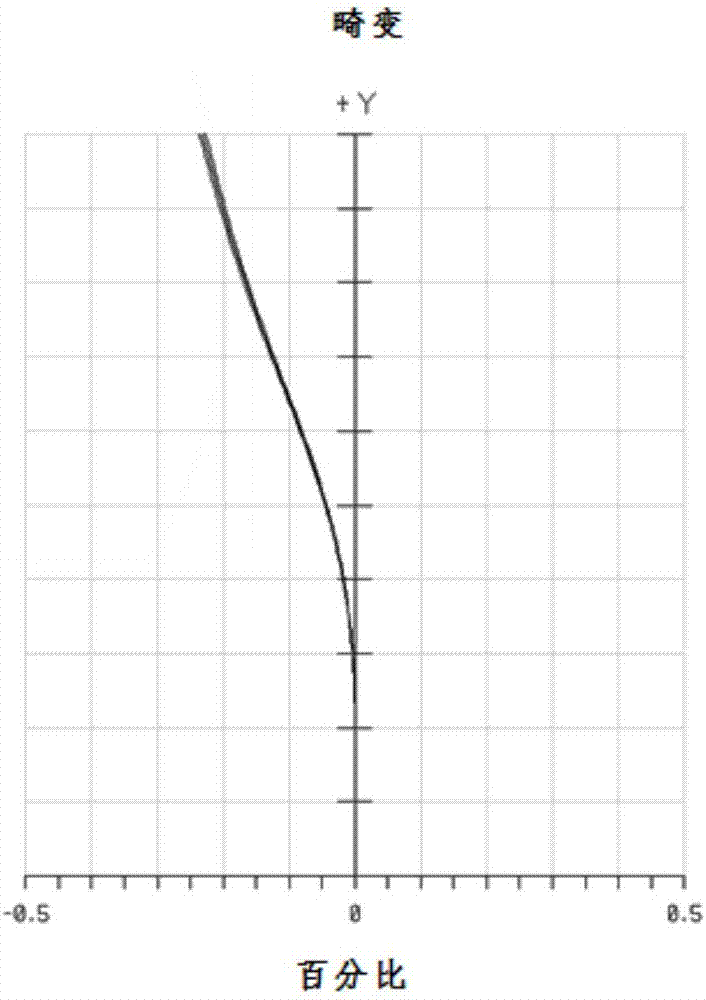

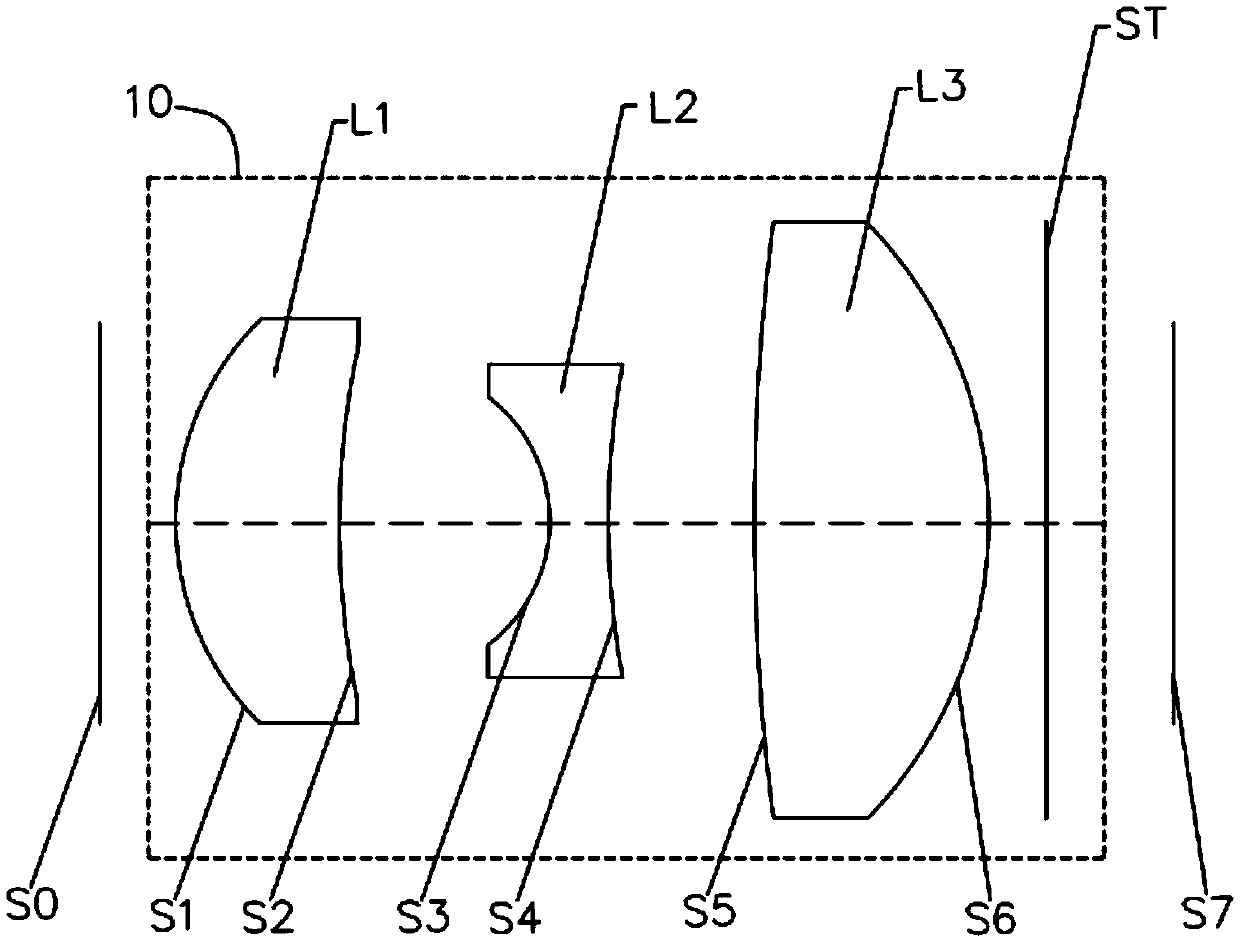

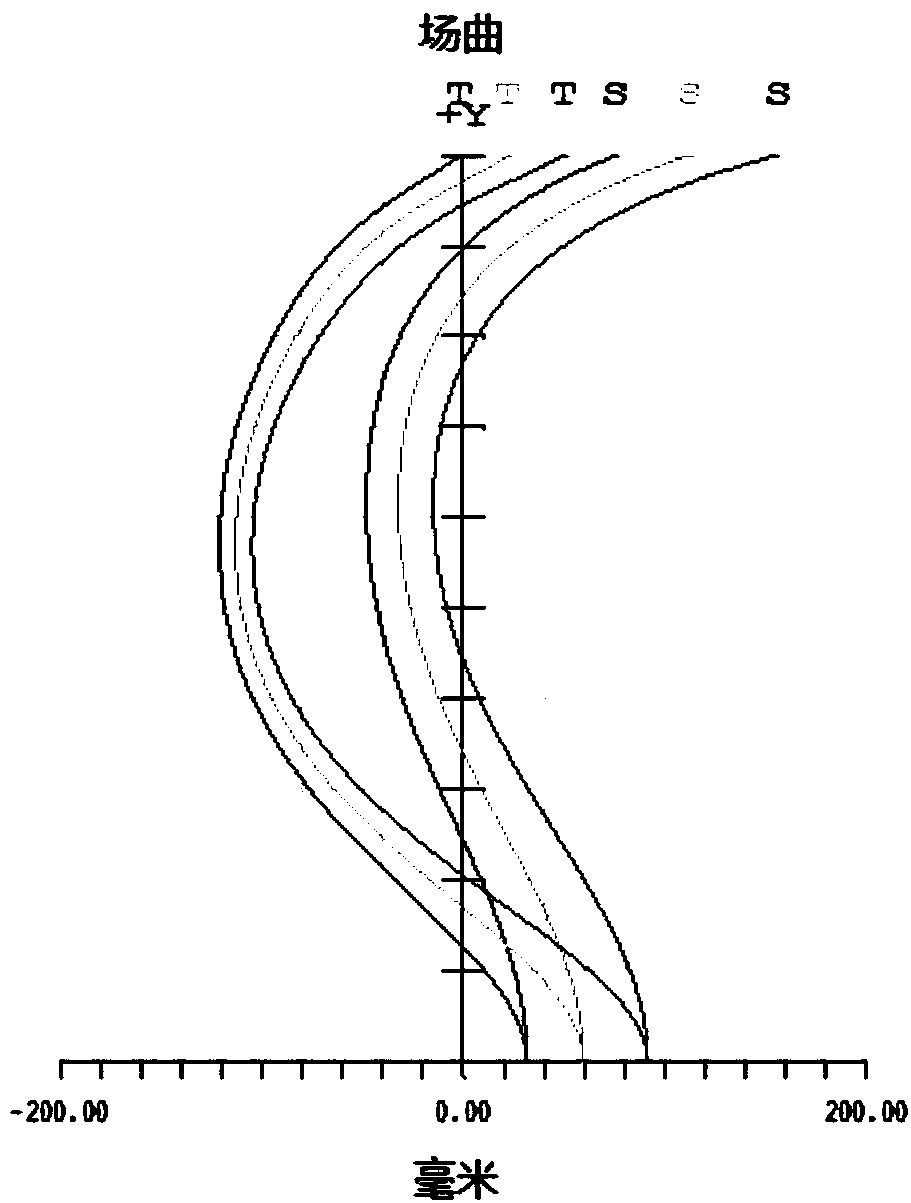

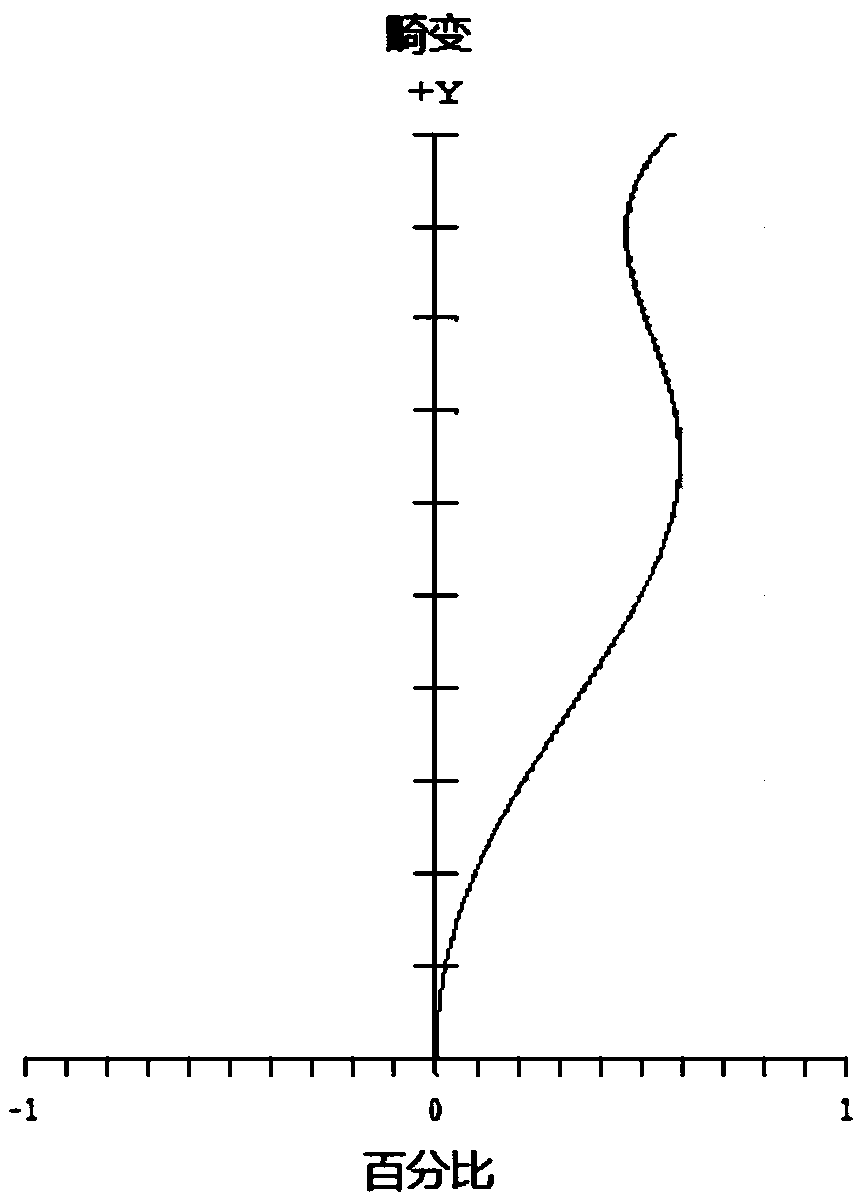

Projection lens system

ActiveCN107505689ASmall change in effective focal lengthFocal length stabilizationUsing optical meansMountingsCamera lensOptical axis

The invention discloses a projection lens system. The projection lens system sequentially comprises a first lens with positive focal power, a second lens with negative focal power, a third lens with positive focal power and a diaphragm from an object side to an image side along an optical axis, and is characterized in that an object-side surface of the first lens is a convex surface; an image-side surface of the third lens is a convex surface; and the optical centers of the lenses are located at the same straight line. The projection lens system satisfies the following conditions: f12>f3, (dn / dt)1<-50*10<-6> / DEG C, (dn / dt)2<-50*10<-6> / DEG C, and (dn / dt)3>-10*10<-6> / DEG C, wherein f12 represents the combined focal length of the first lens and the second lens, f3 represents the focal length of the third lens, and (dn / dt)1, (dn / dt)2 and (dn / dt)3 respectively represent changes rates of refractive indexes of the first lens, the second lens and the third lens along with the temperature. The projection lens system can cancel out influences imposed on the focal length by thermal expansion brought about by the lenses and structural members due to reasonable distribution of the change rate of the refractive index of each lens along with the temperature, thereby being capable of realizing stable focal length and being applicable to different temperature occasions.

Owner:JIANGXI LIANCHUANG ELECTRONICS CO LTD

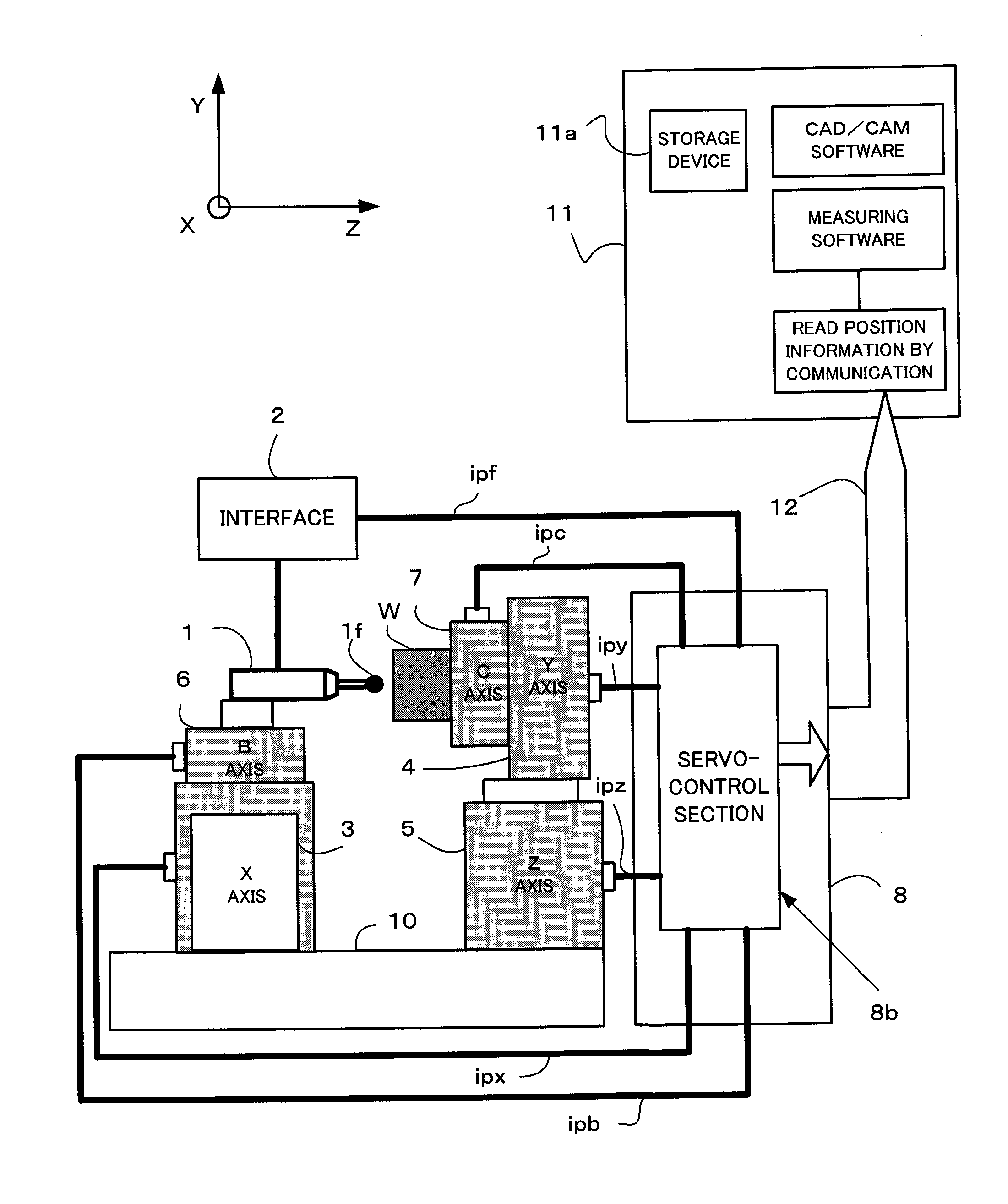

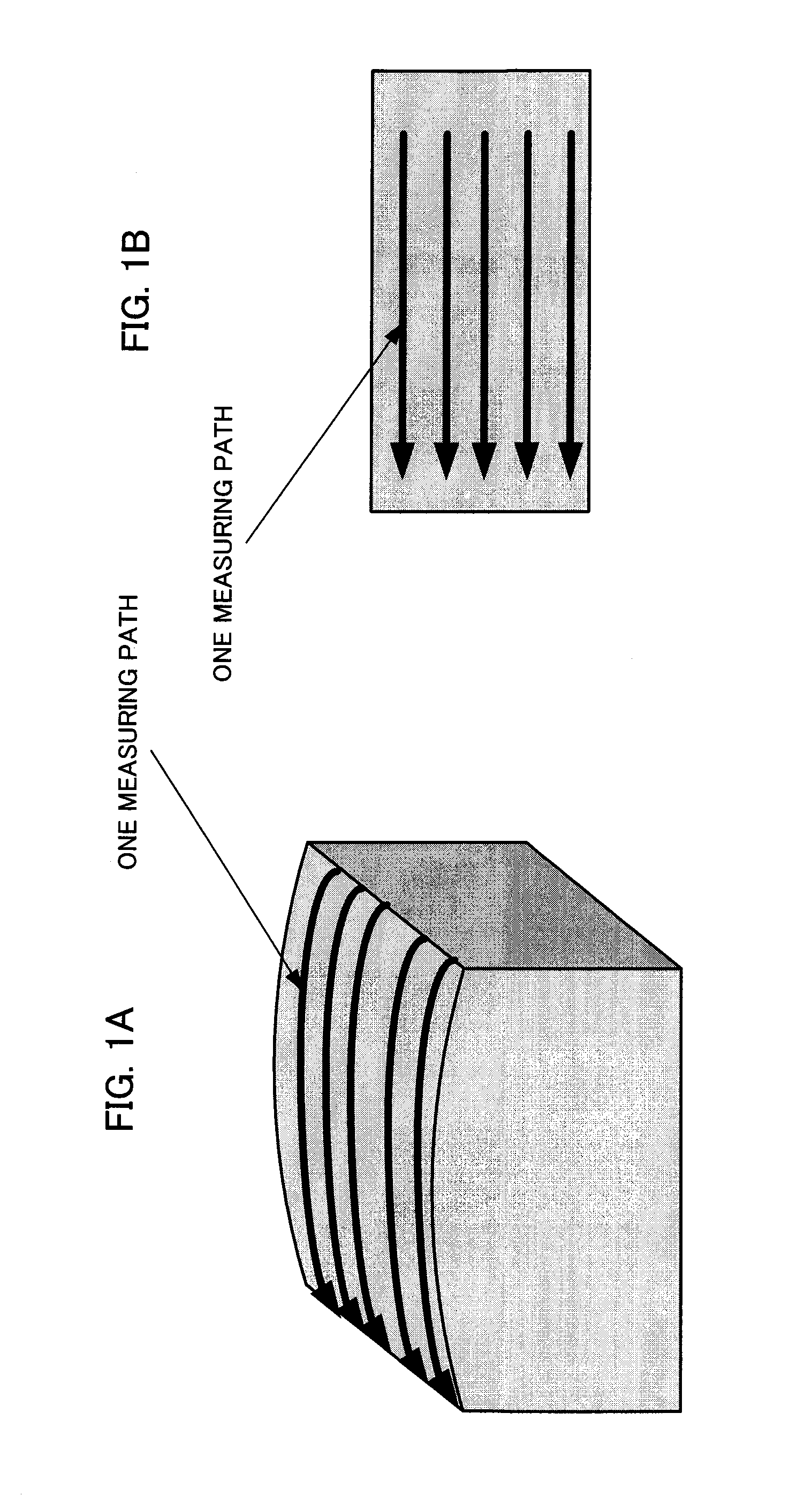

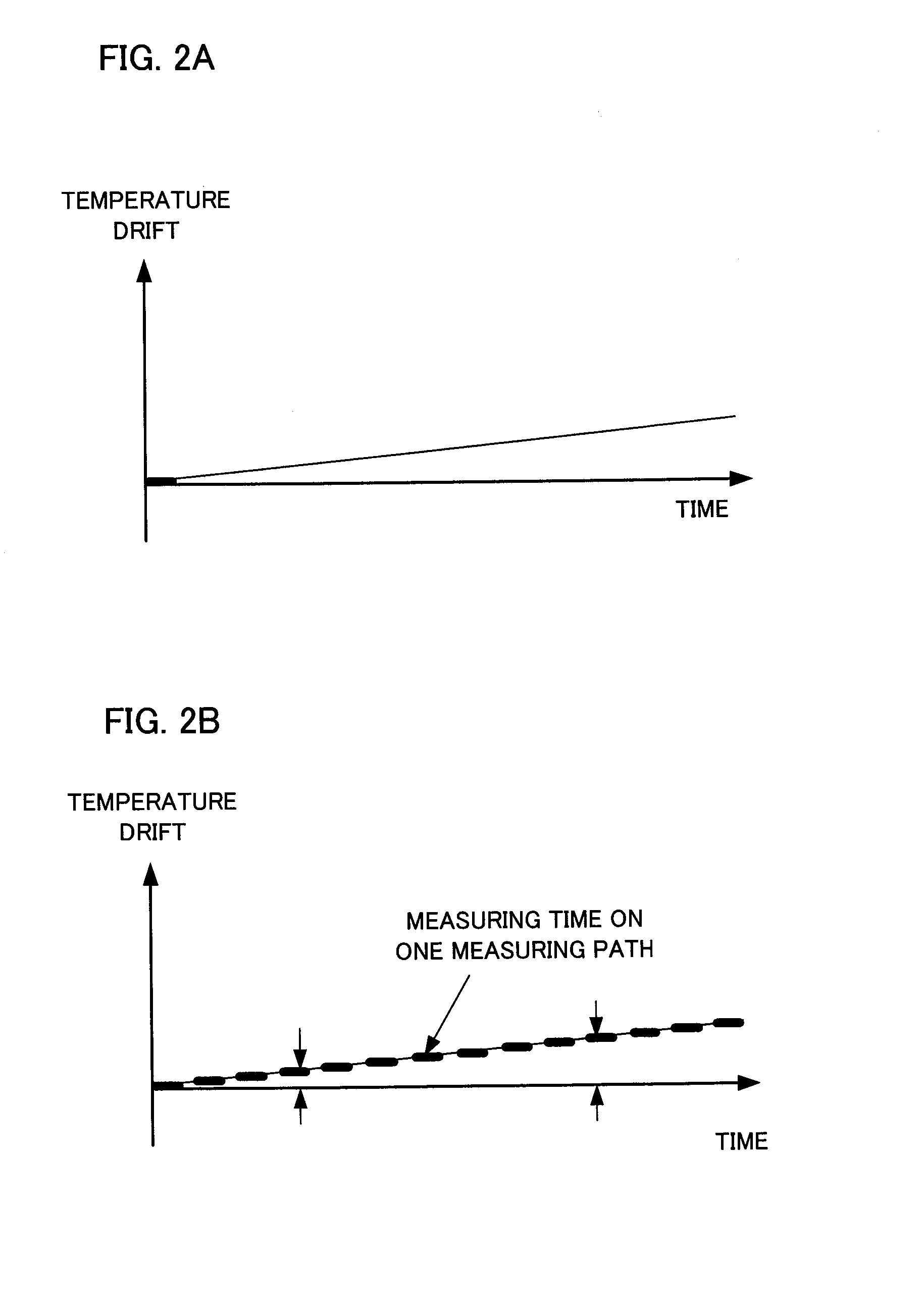

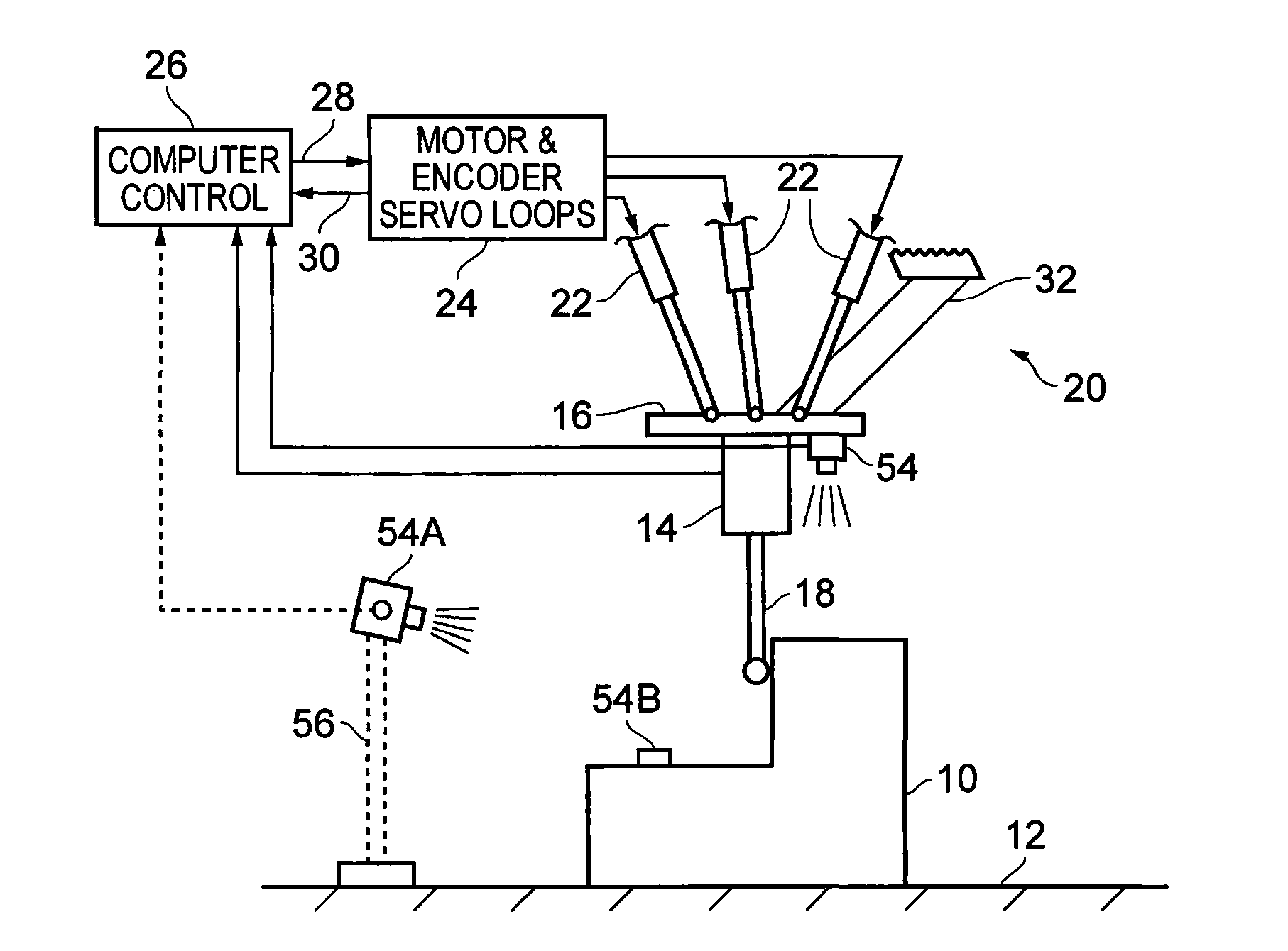

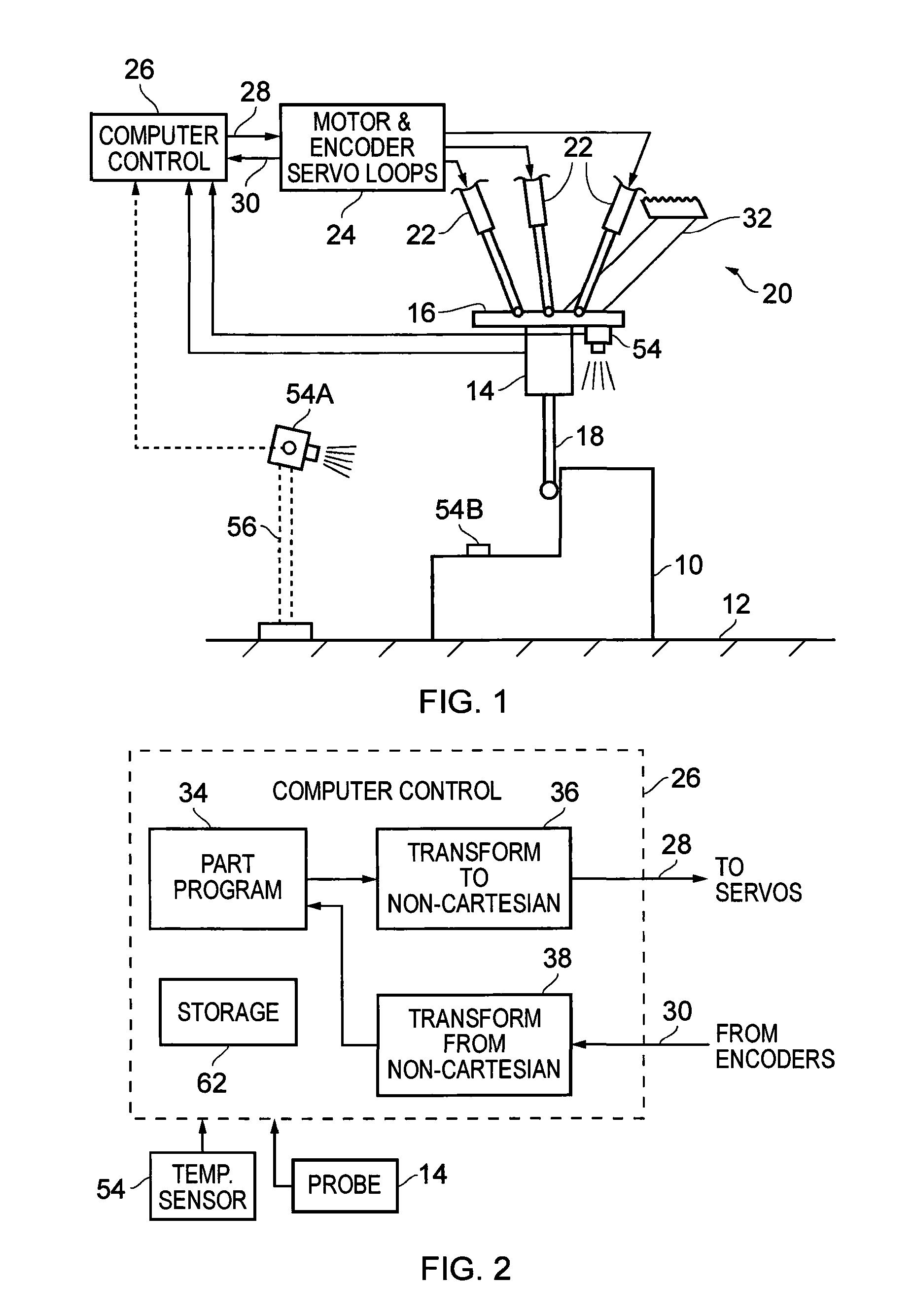

Method of measuring shape of workpiece by using on-board measuring machine for carrying out temperature drift correction and machine tool having on-board measuring machine

ActiveUS20100101105A1Programme controlMechanical counters/curvatures measurementsOn boardEngineering

In a machine tool having an on-board measuring machine and controlled by a numerical controller, a method of measuring a shape of a workpiece presets a reference point for temperature drift correction on the workpiece, moves a probe to the reference point, resets a coordinate system of the probe to correct a temperature drift of the probe, and carries out shape measurement of the workpiece along a first measuring path. Next, the method moves the probe to the reference point again, resets the coordinate system of the probe to correct a temperature drift of the probe again, and carries out shape measurement of the workpiece along a second measuring path. Thereafter, similar temperature drift correction is carried out for each measuring path until the shape measurement of the workpiece is carried out along the last measuring path.

Owner:FANUC LTD

Method and apparatus for inspecting workpieces

ActiveUS20160146589A1Improve validityCalibration accuracyError compensation/eliminationError mapEngineering

A series of nominally identical workpieces is received from a manufacturing process and measured on a measuring apparatus. They are received at a non-ambient temperature because of heat introduced during the manufacturing process, but they are placed on the measuring apparatus in a repeatable manner, e.g. by a robot, such that their non-ambient temperatures when measured are repeatable. One of the workpieces is measured as a reference workpiece at the non-ambient temperature, and these measurements are compared to calibrated values obtained from an external source, in order to generate an error map or error function. The error map or error function is used to correct measurements of subsequent workpieces of the series which are measured at the repeatable non-ambient temperature.

Owner:RENISHAW PLC

Tubing elongation correction system & methods

A surface processor uses an environmental profile to determine the sub-surface length of tubing disposed in a well bore. Information relating to tubing properties is stored in a memory module of the surface processor. The environmental profile includes data relating to well bore ambient conditions and the operating parameters of well equipment. Surface processor calculates the tubing elongation or length reduction corresponding to the environmental profile. Surface processor may repeat this process to develop a measured depth chart for a well. Logging operations performed in conjunction with the sub-surface length calculations allows formation data to be associated with the measured depth chart.

Owner:HALLIBURTON ENERGY SERVICES INC

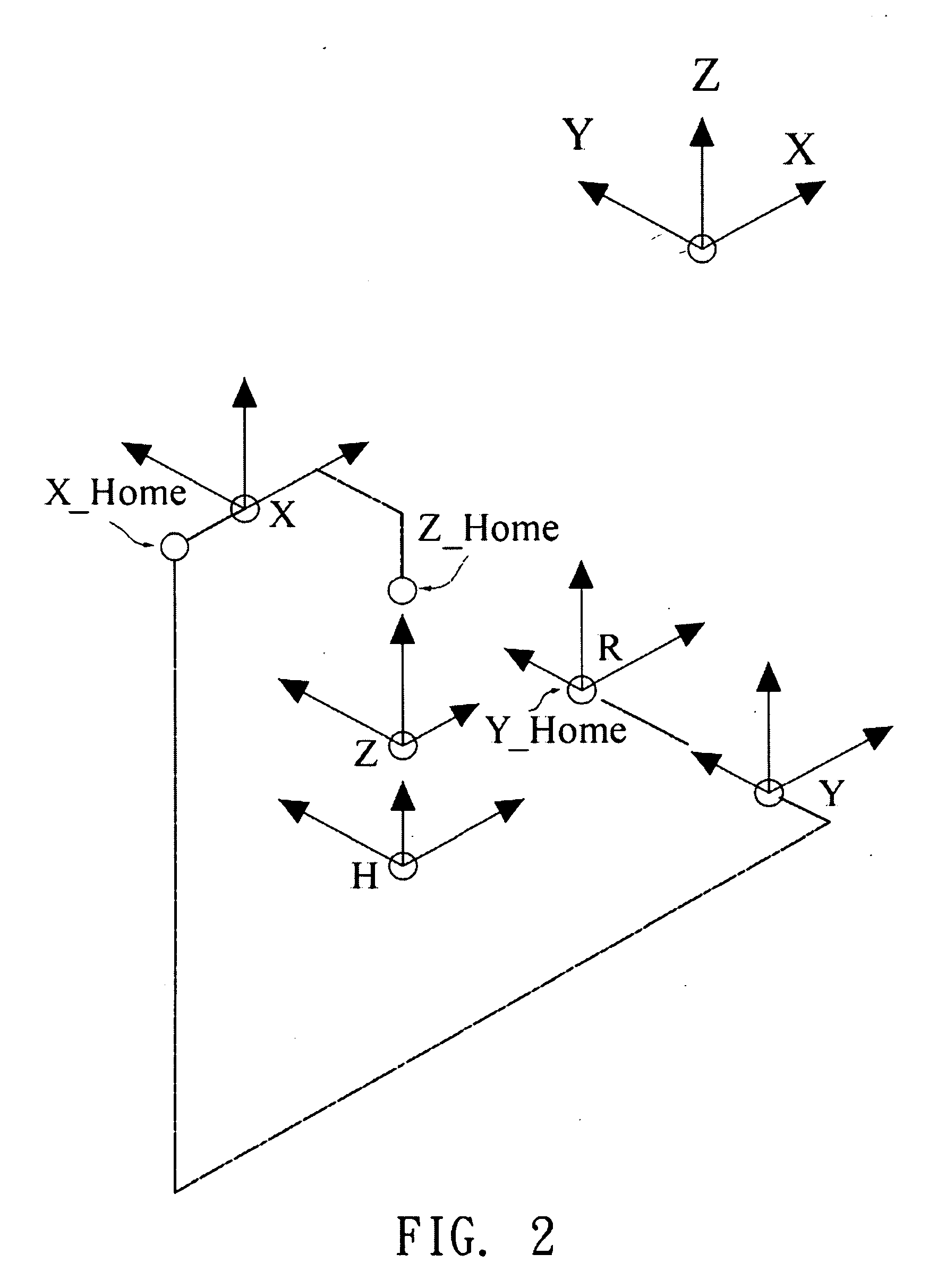

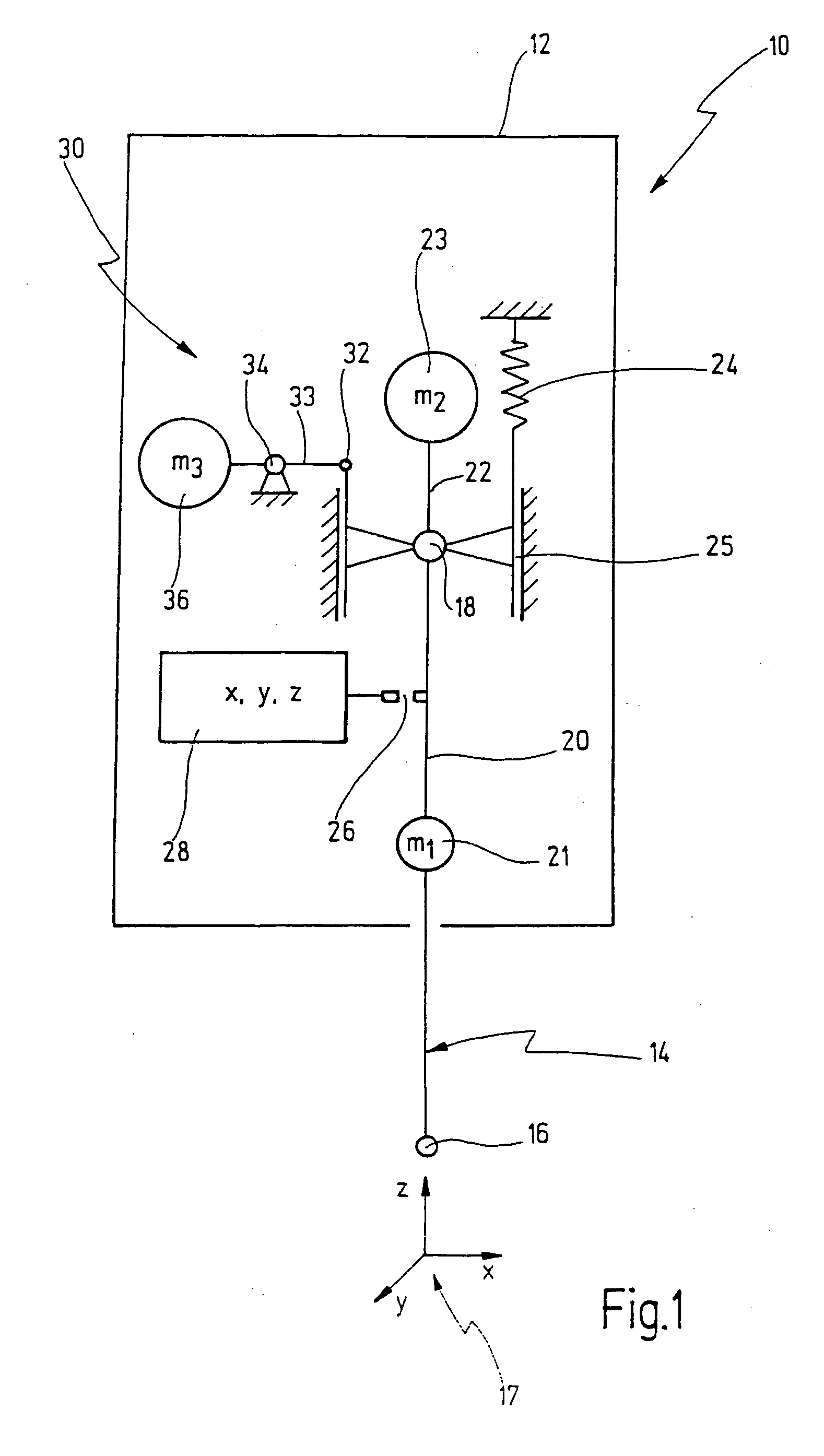

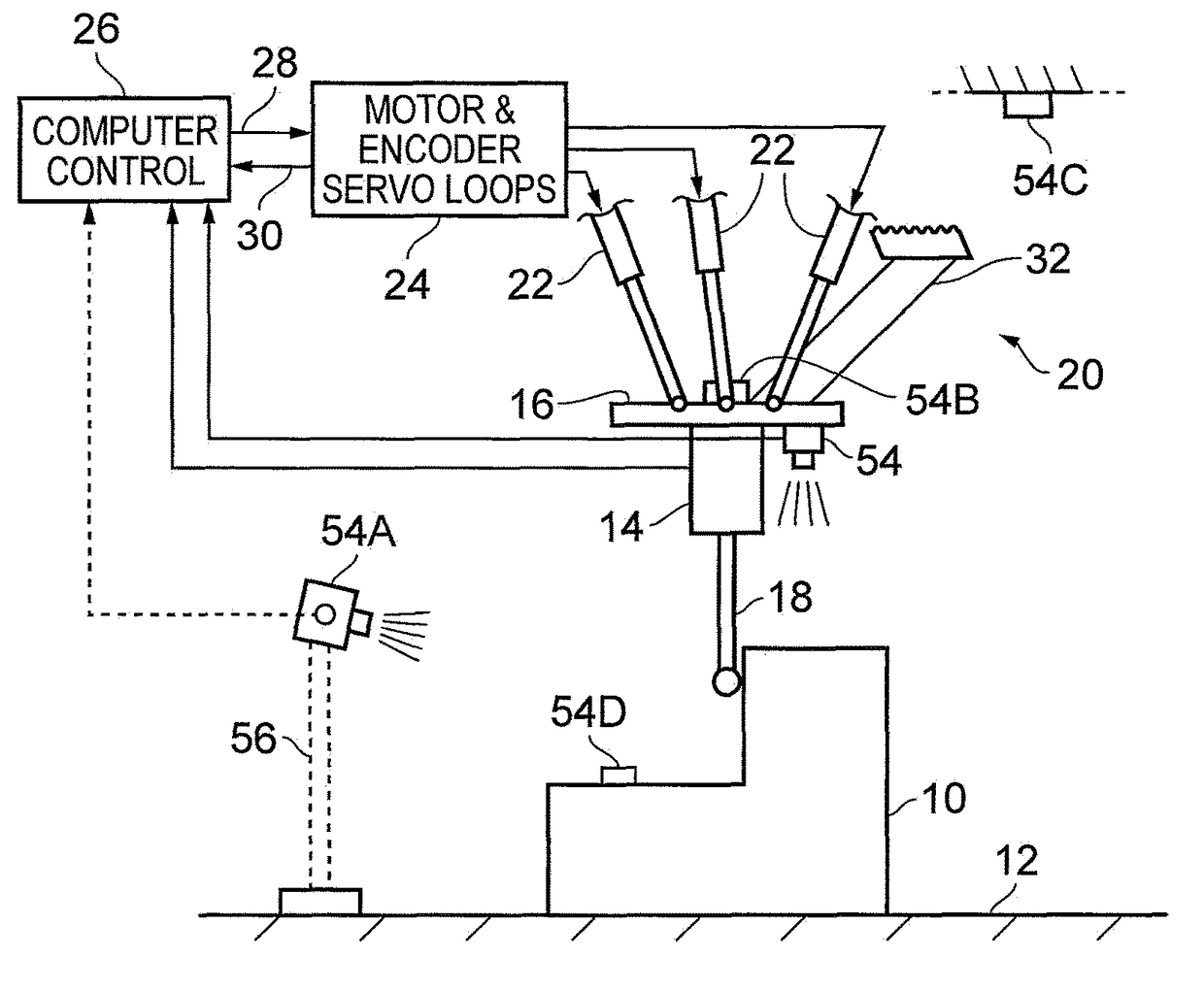

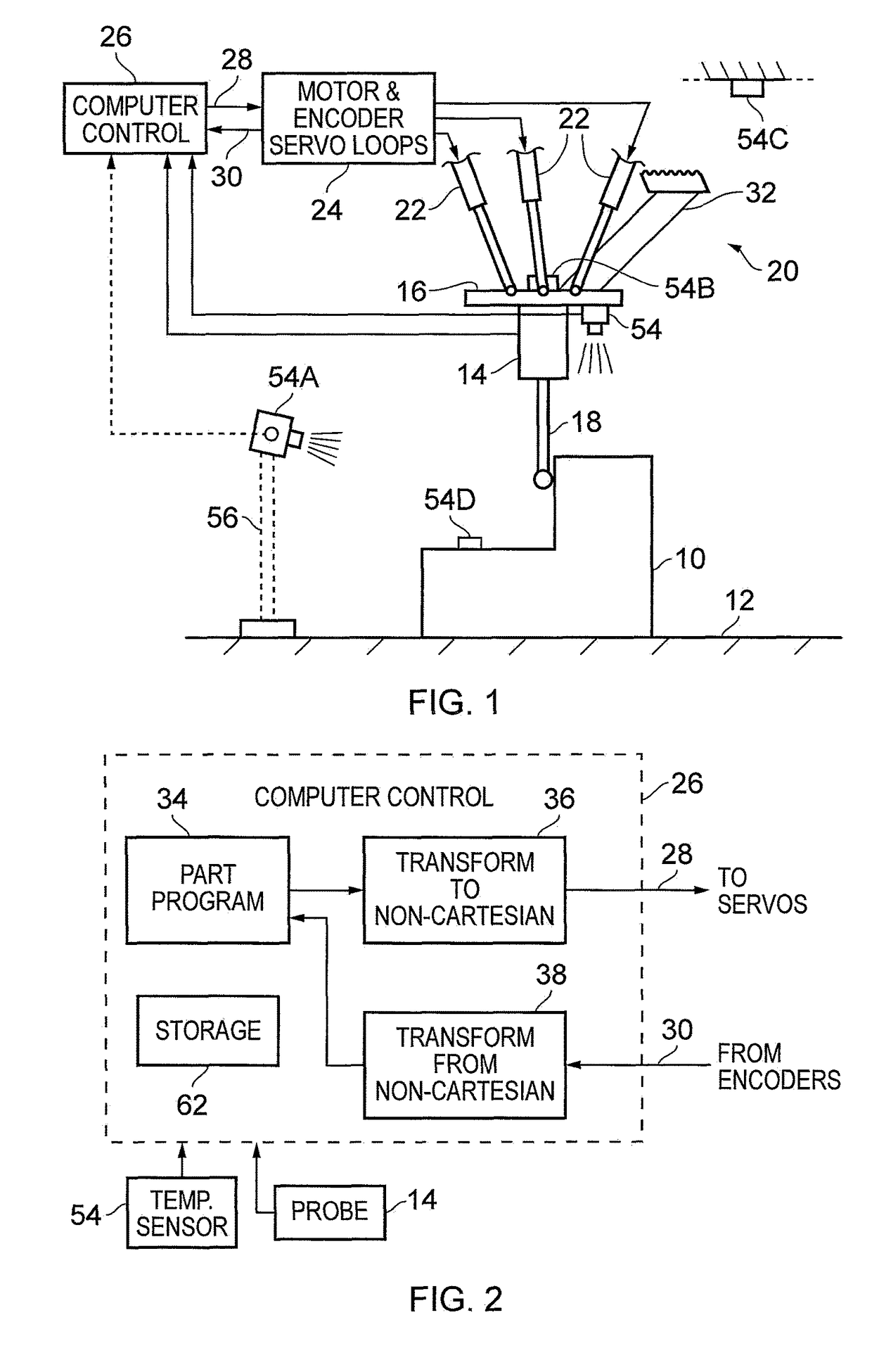

Method of error compensation in a coordinate measuring machine with an articulating probe head

Owner:RENISHAW PLC

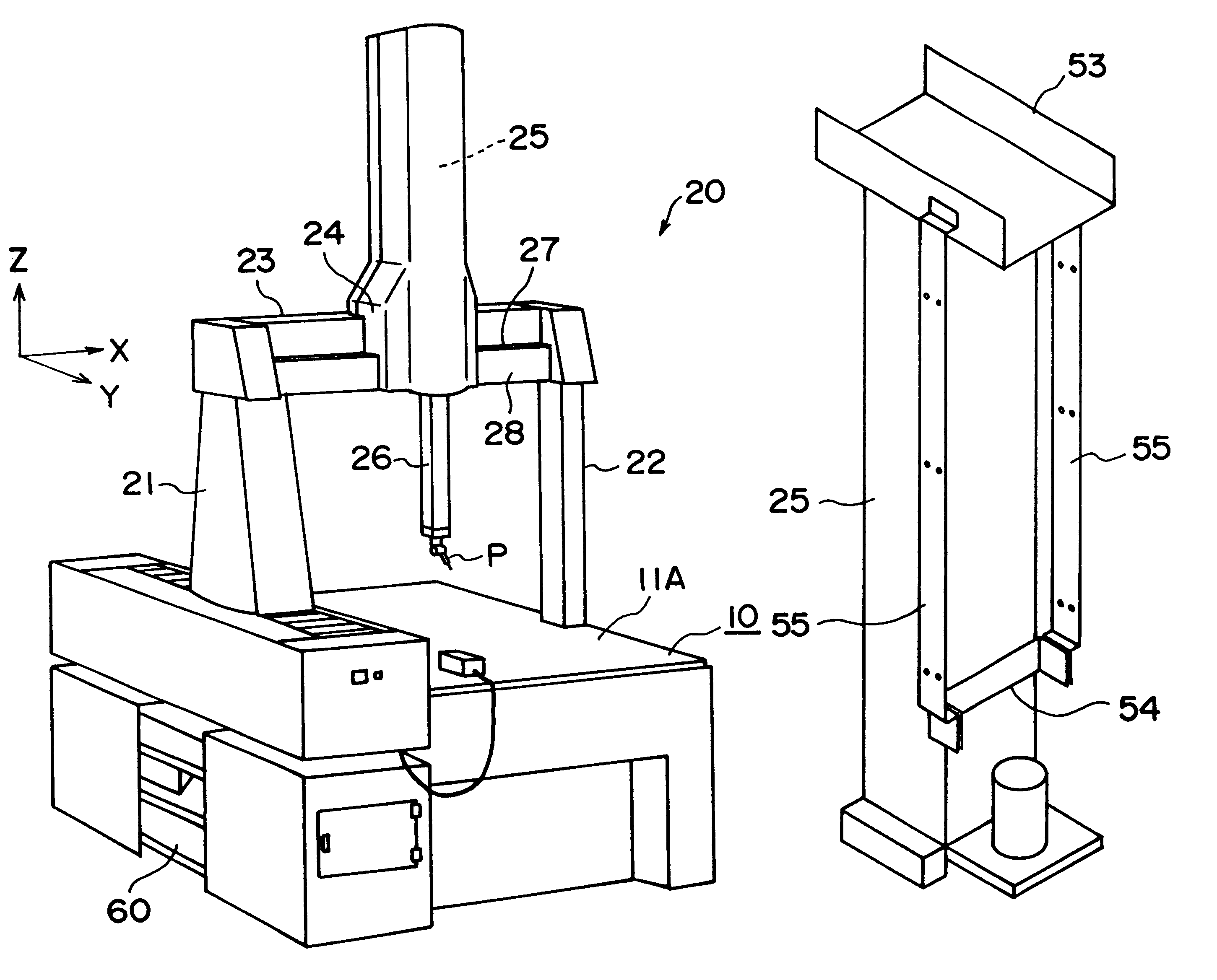

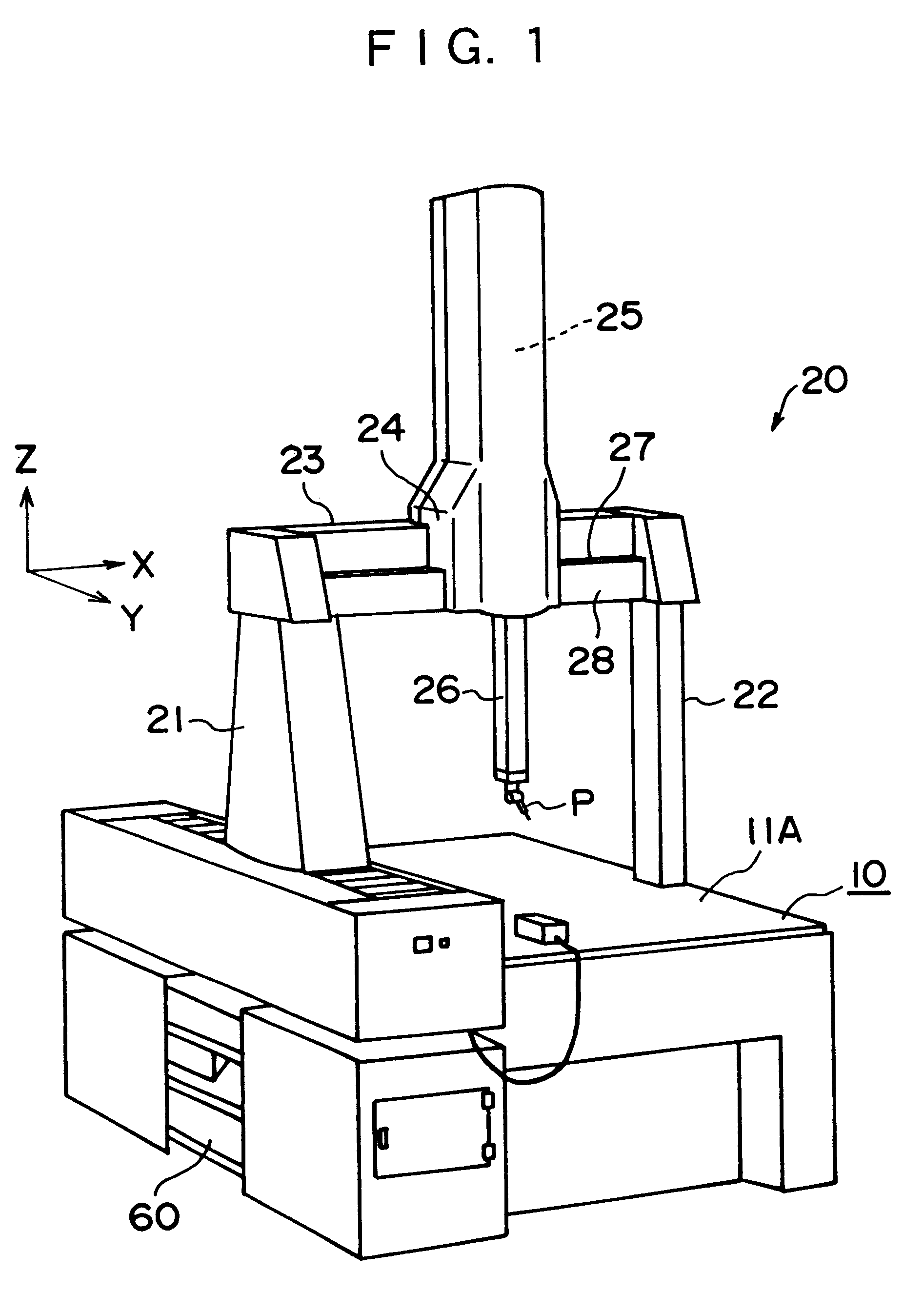

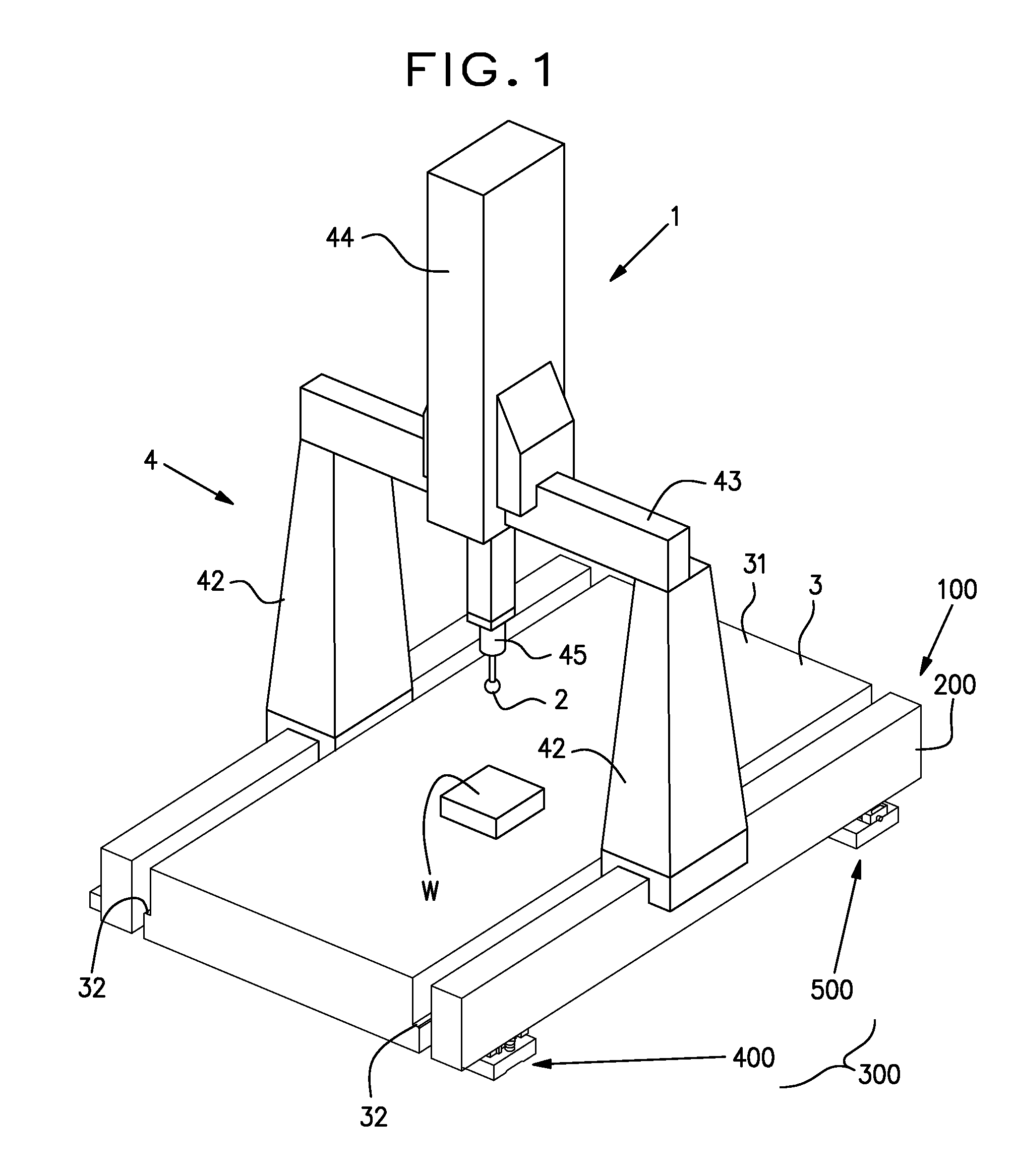

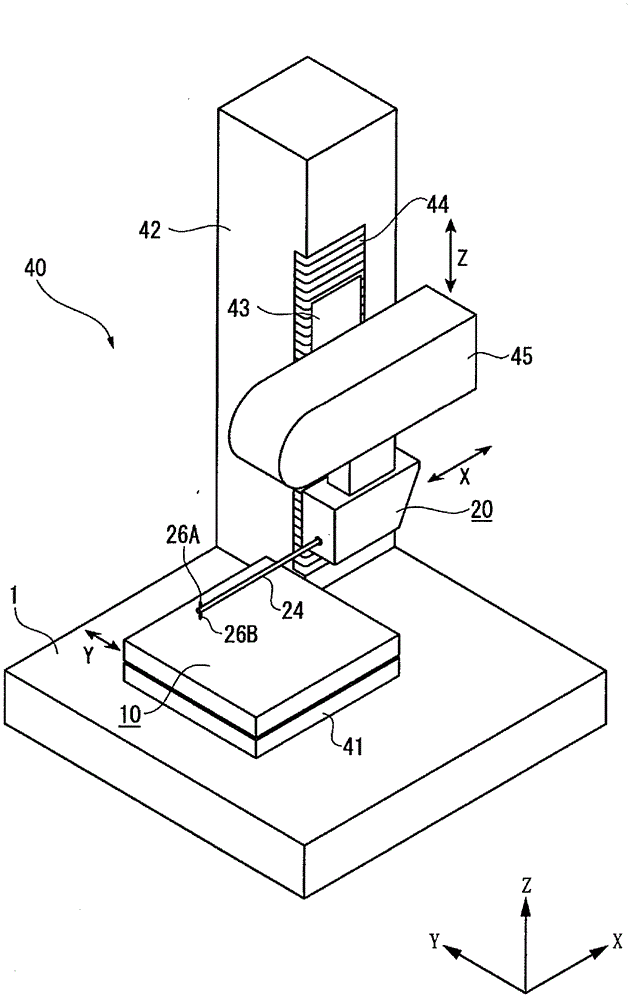

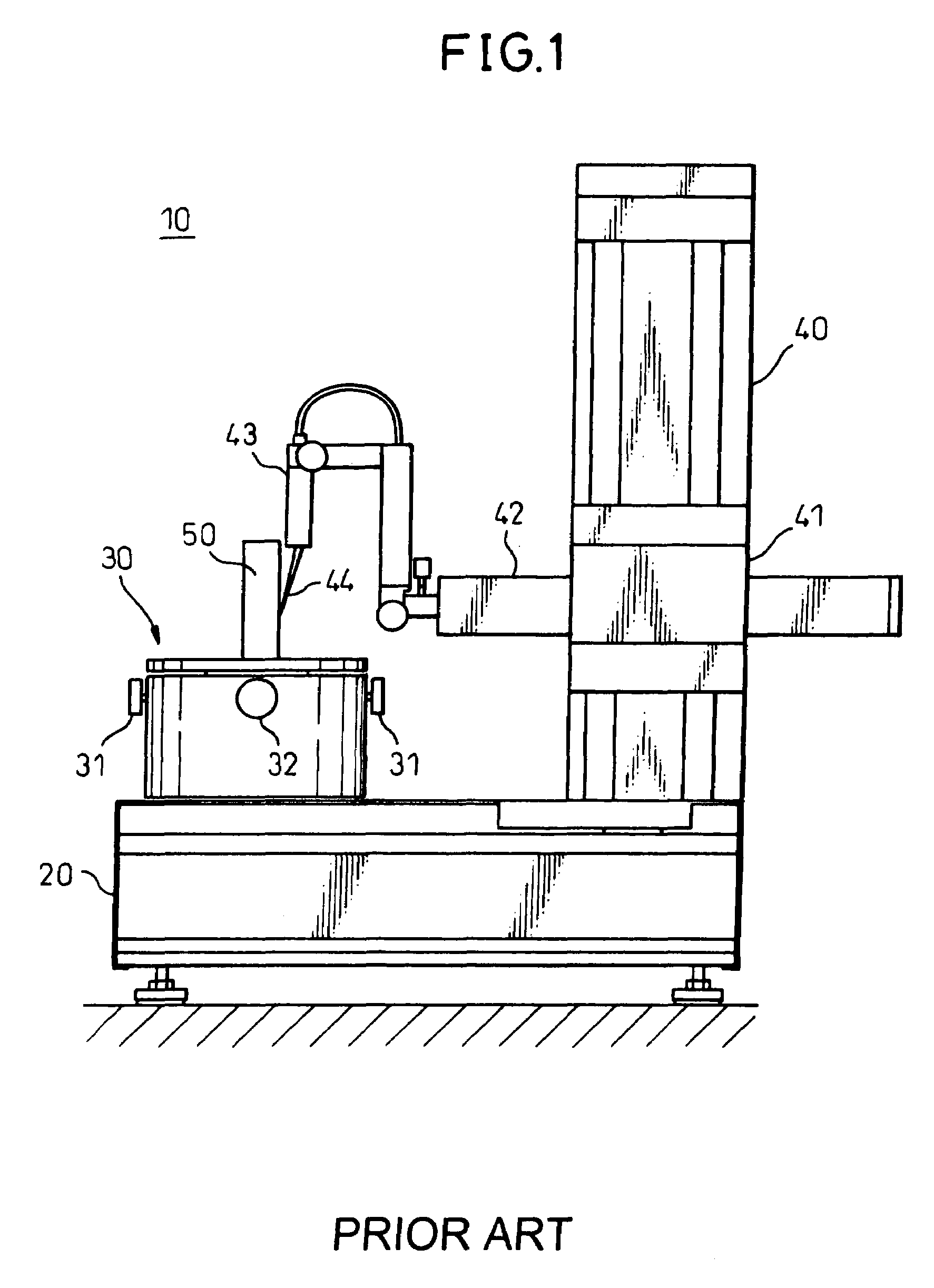

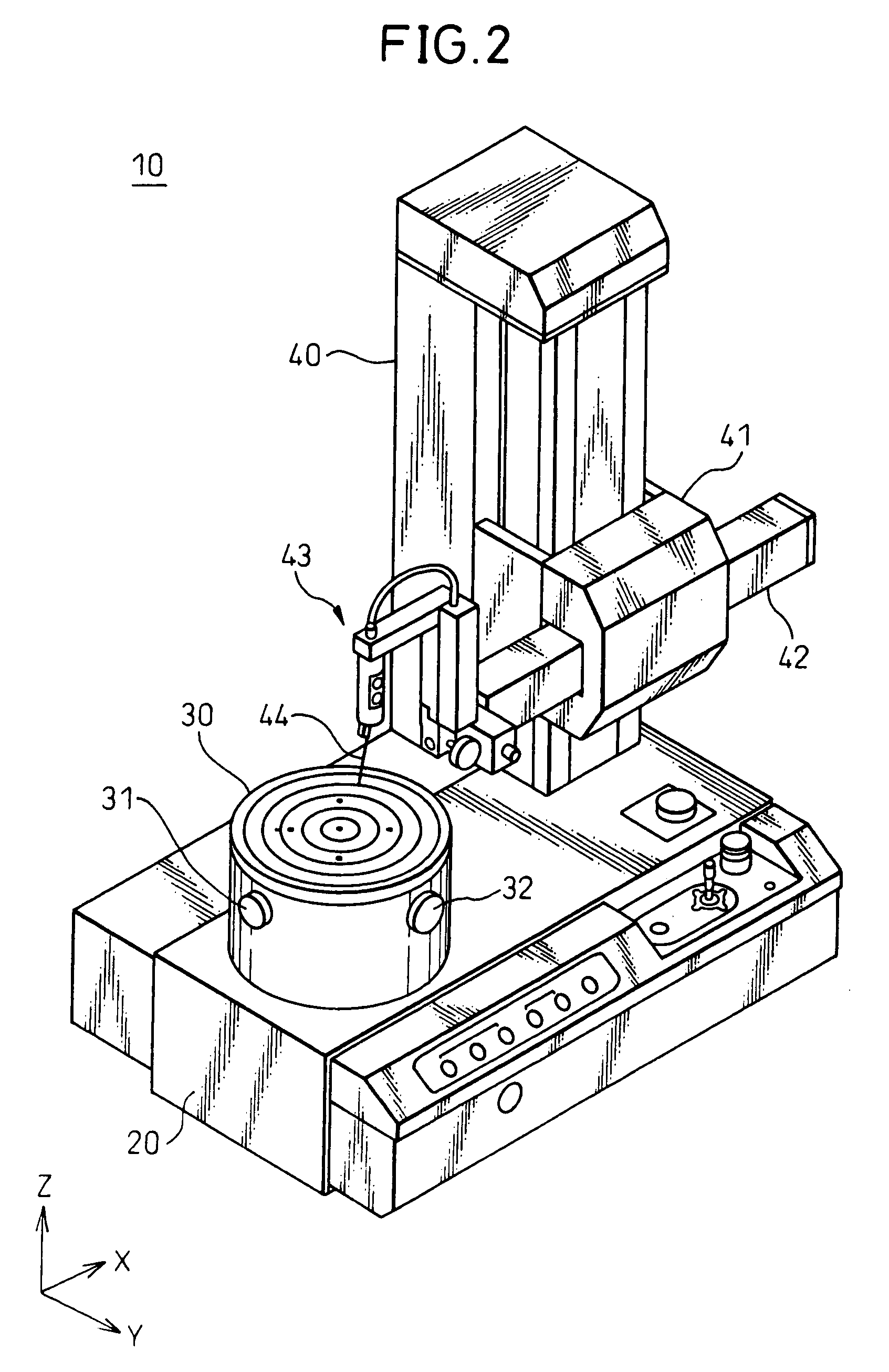

Measuring machine

InactiveUS6370787B1Uniform temperature distributionLarge thermal conductivityUsing electrical meansElectric/magnetic contours/curvatures measurementsEngineeringAlloy

A measuring machine having a base (10), a touch signal probe (P), a moving mechanism (20) for retaining the touch signal probe (P) movably in three-dimensional directions, and a controller (60) for controlling a movement of the moving mechanism (20) and for acquiring coordinates value of respective axes based on a contact signal from the touch signal probe (P) to measure a dimension etc. of a workpiece based on the coordinates value is provided. Main structural members structuring the moving mechanism (20), more specifically, a column (21), a supporter (22), a X-beam (23), a Z-axis structure (25) and a Z-axis spindle (26) are made of aluminum or aluminum alloy including aluminum as main component, which has large thermal conductivity, thereby making temperature distribution uniform to improve geometrical accuracy.

Owner:MITUTOYO CORP

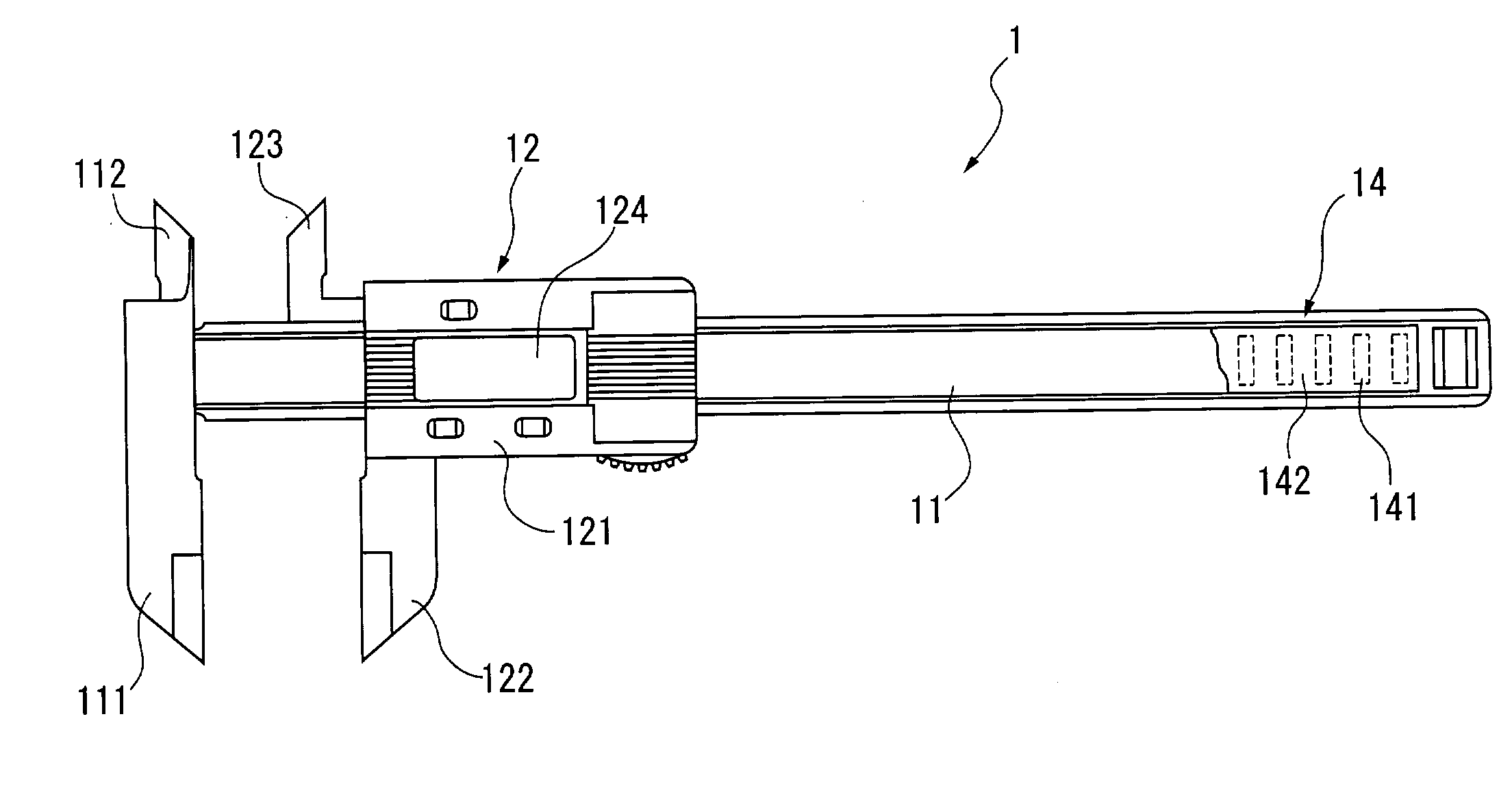

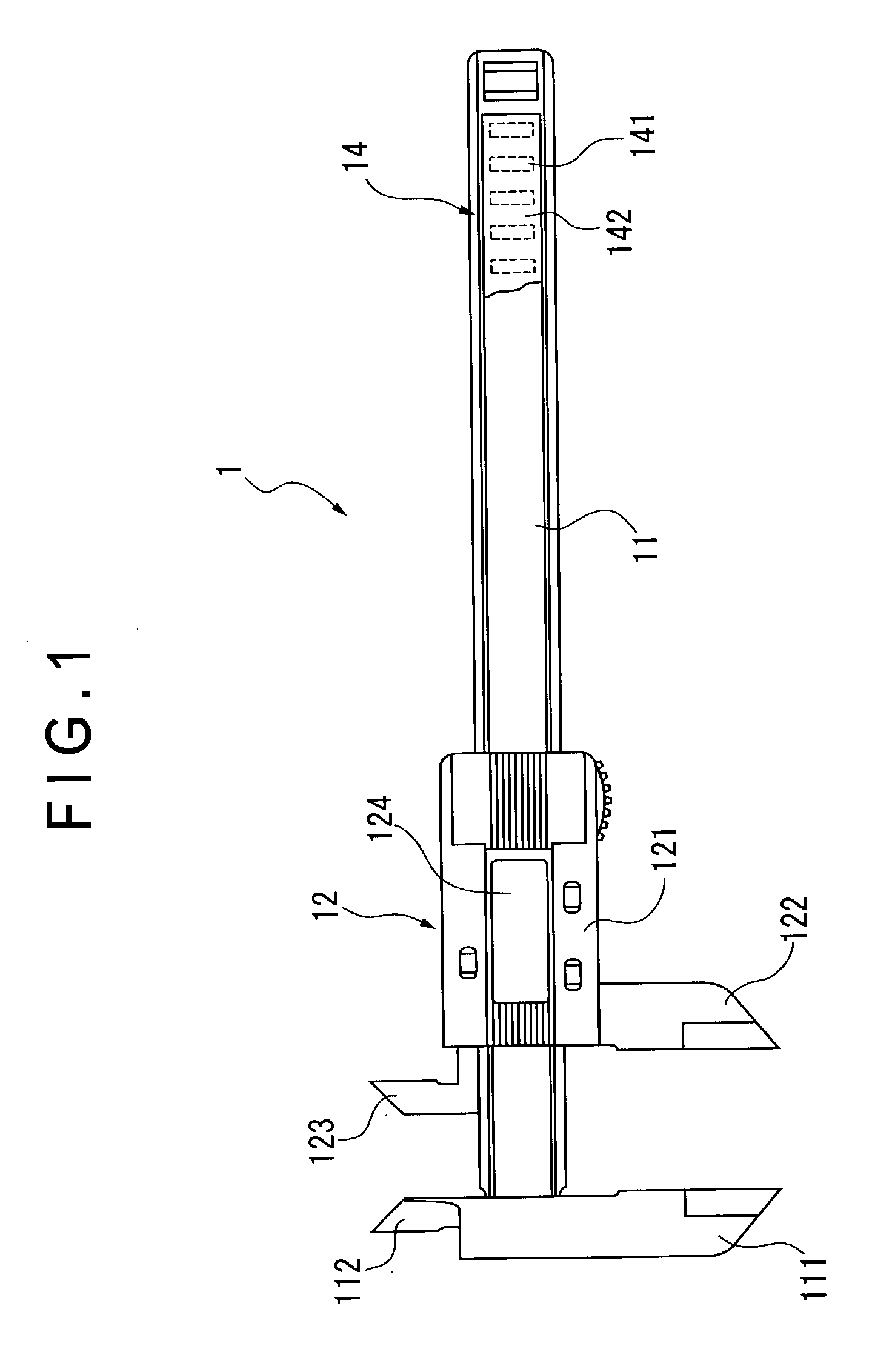

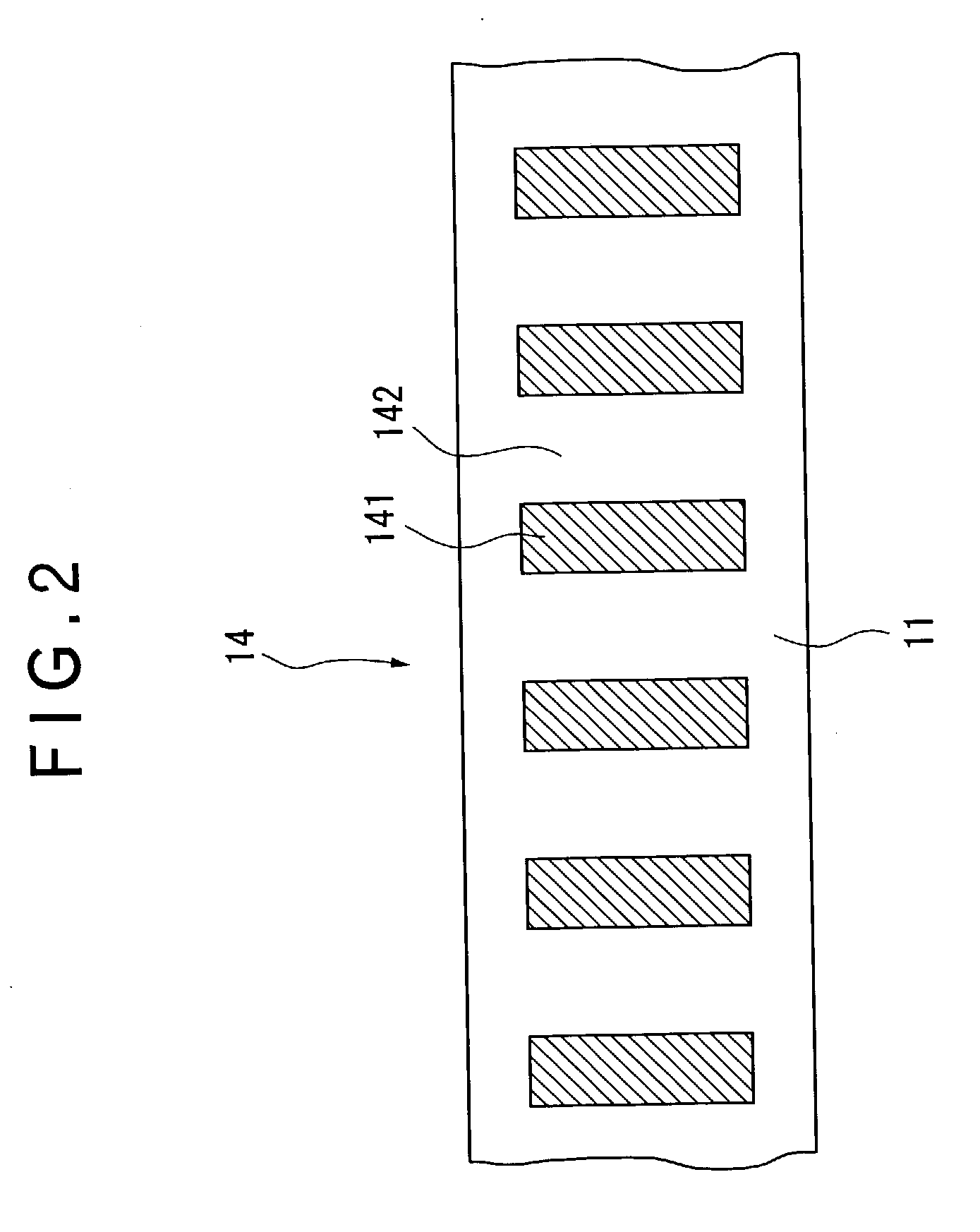

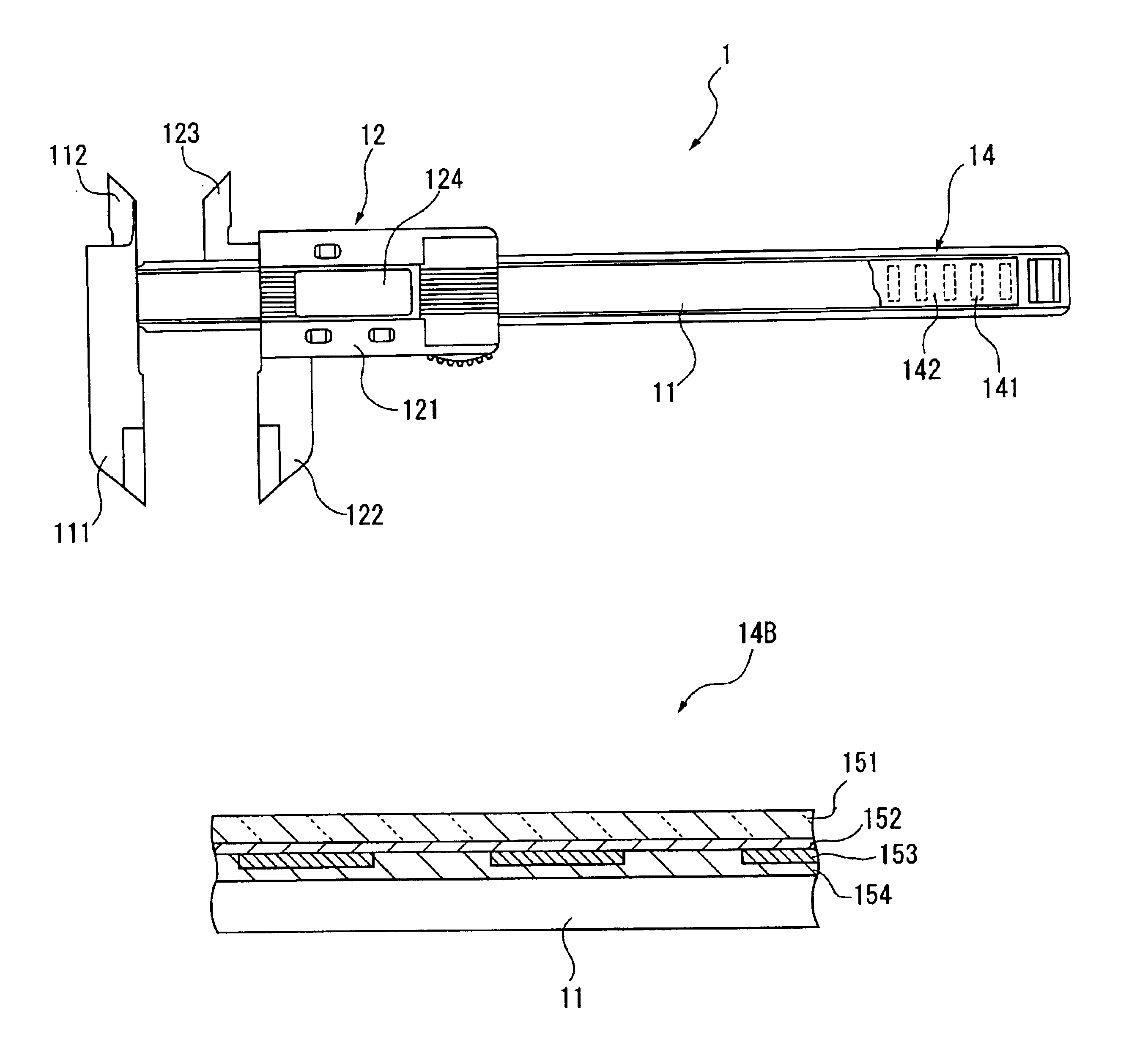

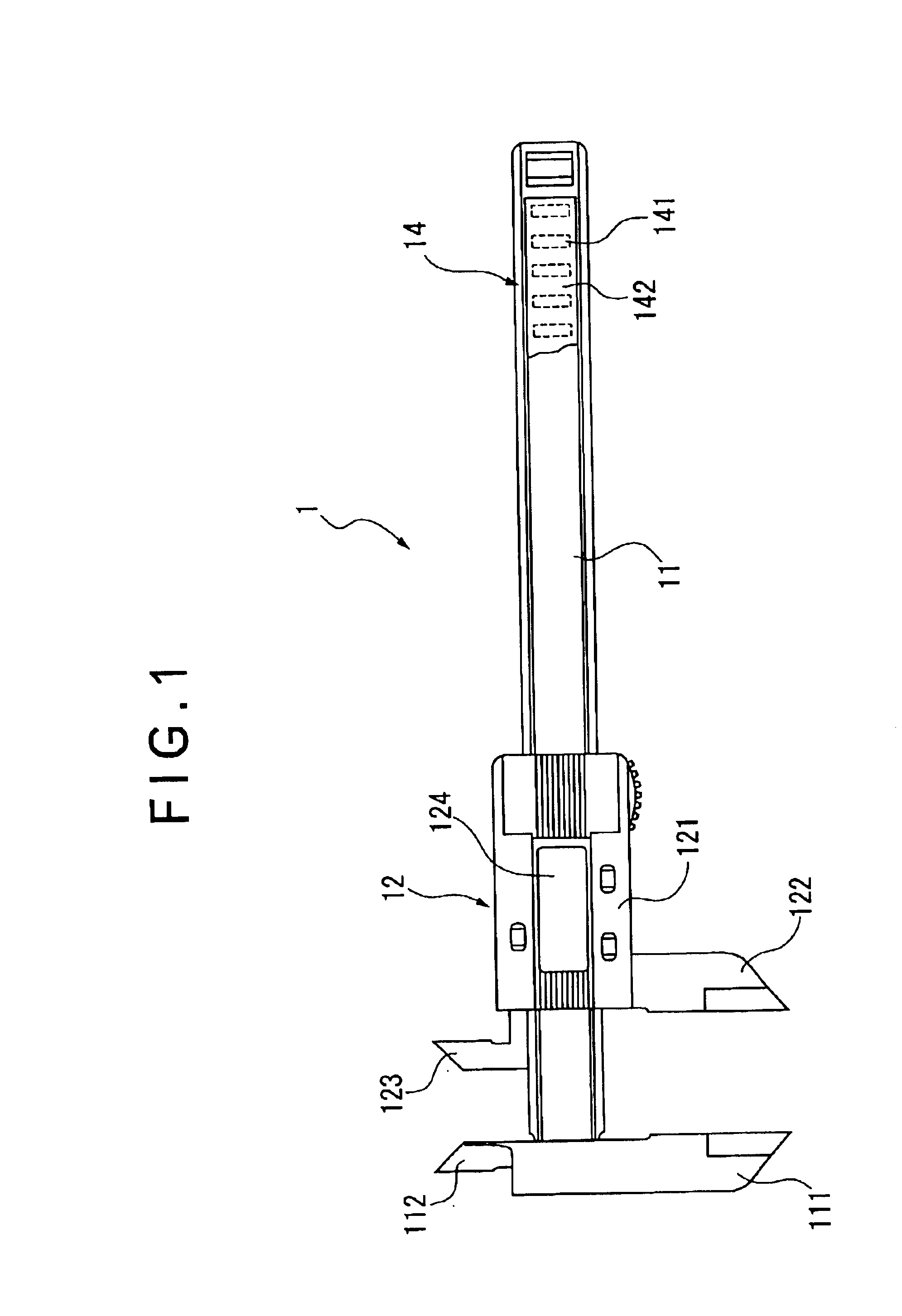

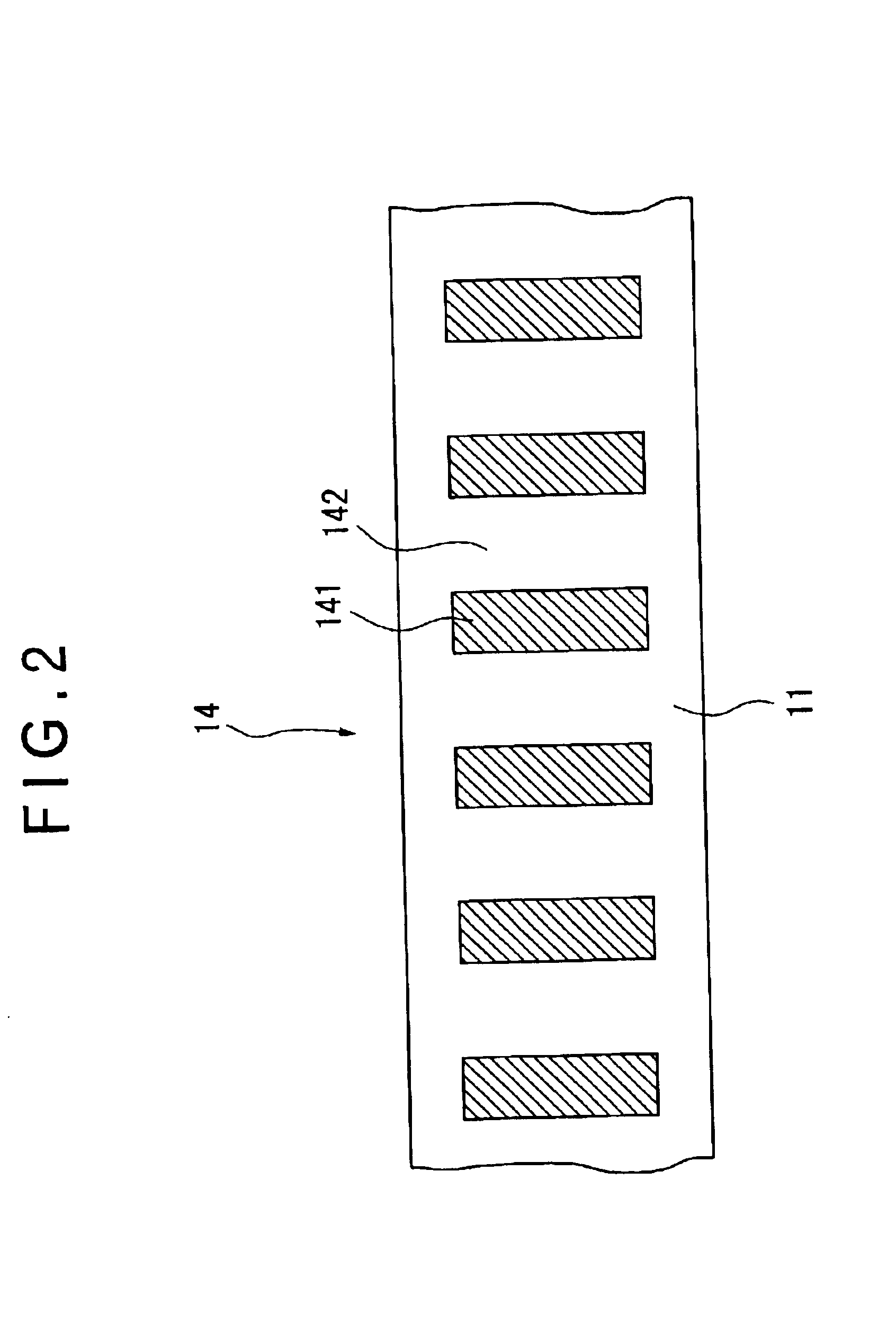

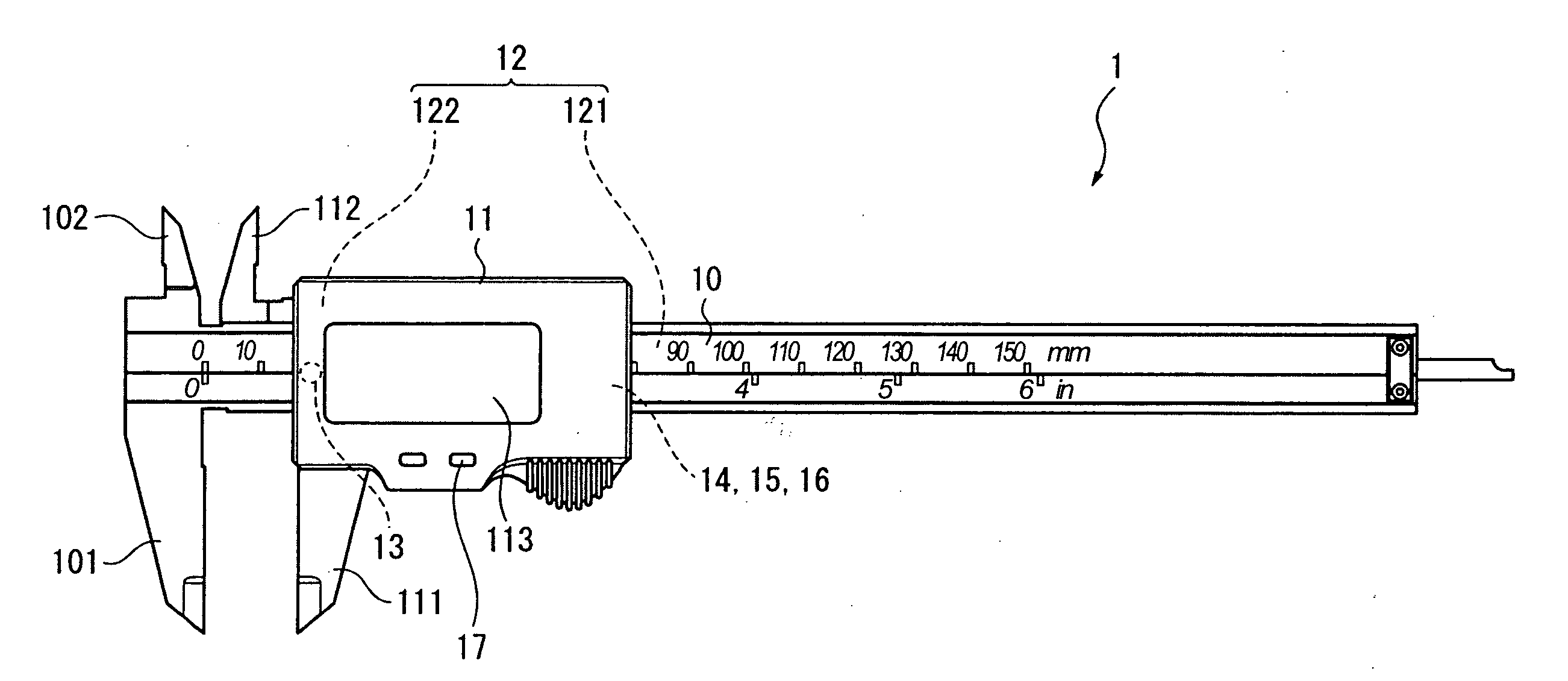

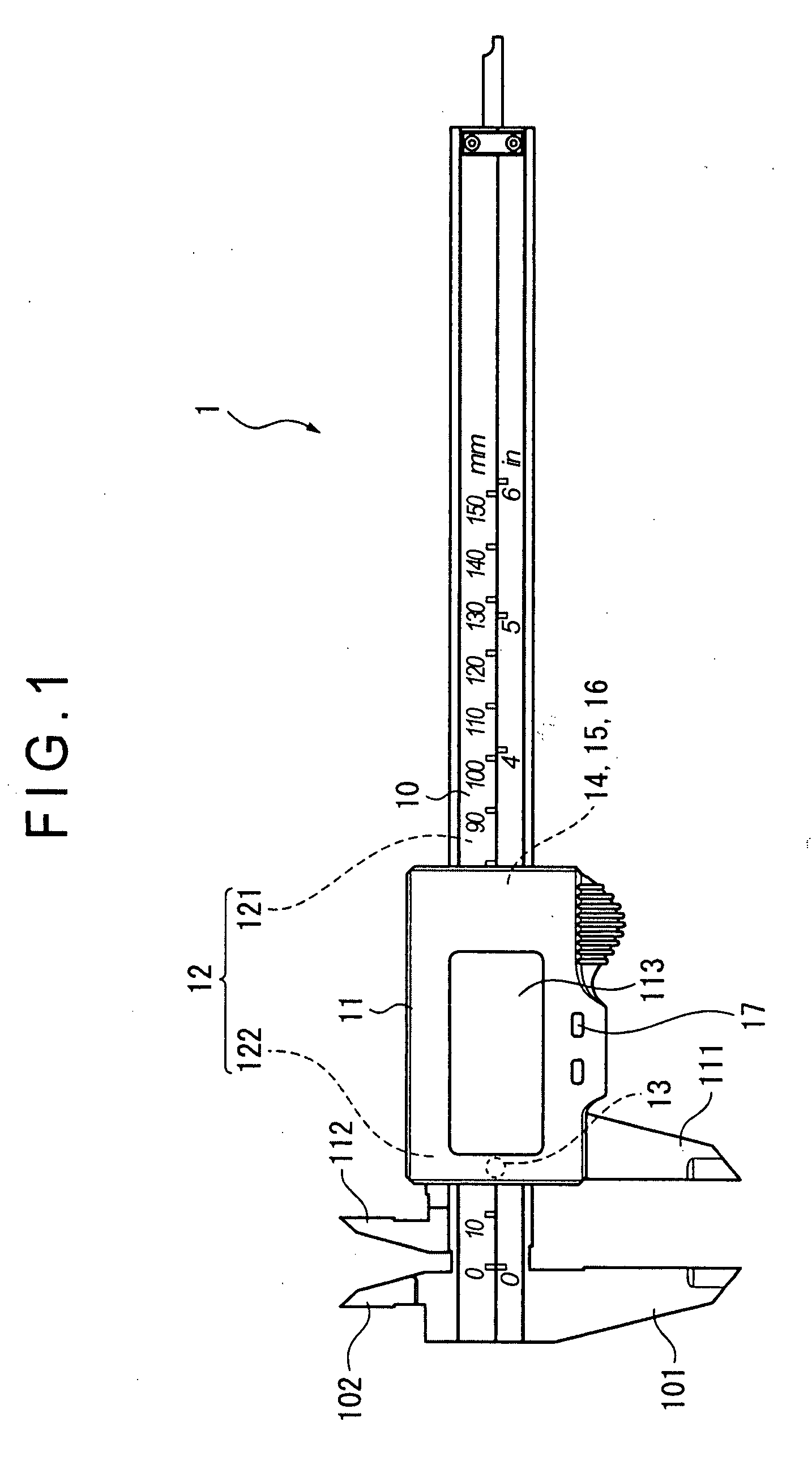

Measuring tool, encoder and producing method of encoder

Components of a measuring tool such as a main beam (11) and a slider (12) of a caliper gauge (1) are formed by a synthetic resin containing carbon nanofiber and an electro-conductive electrode (15) is formed on the surface of the main beam (11) at a predetermined pitch, so that a production process can be simplified, rigidity of the components can be enhanced, linear expansion coefficient can be reduced, and anti-frictional properties can be improved, thus enhancing durability while improving measurement accuracy.

Owner:MITUTOYO CORP

Measuring tool, encoder and producing method of encoder

Owner:MITUTOYO CORP

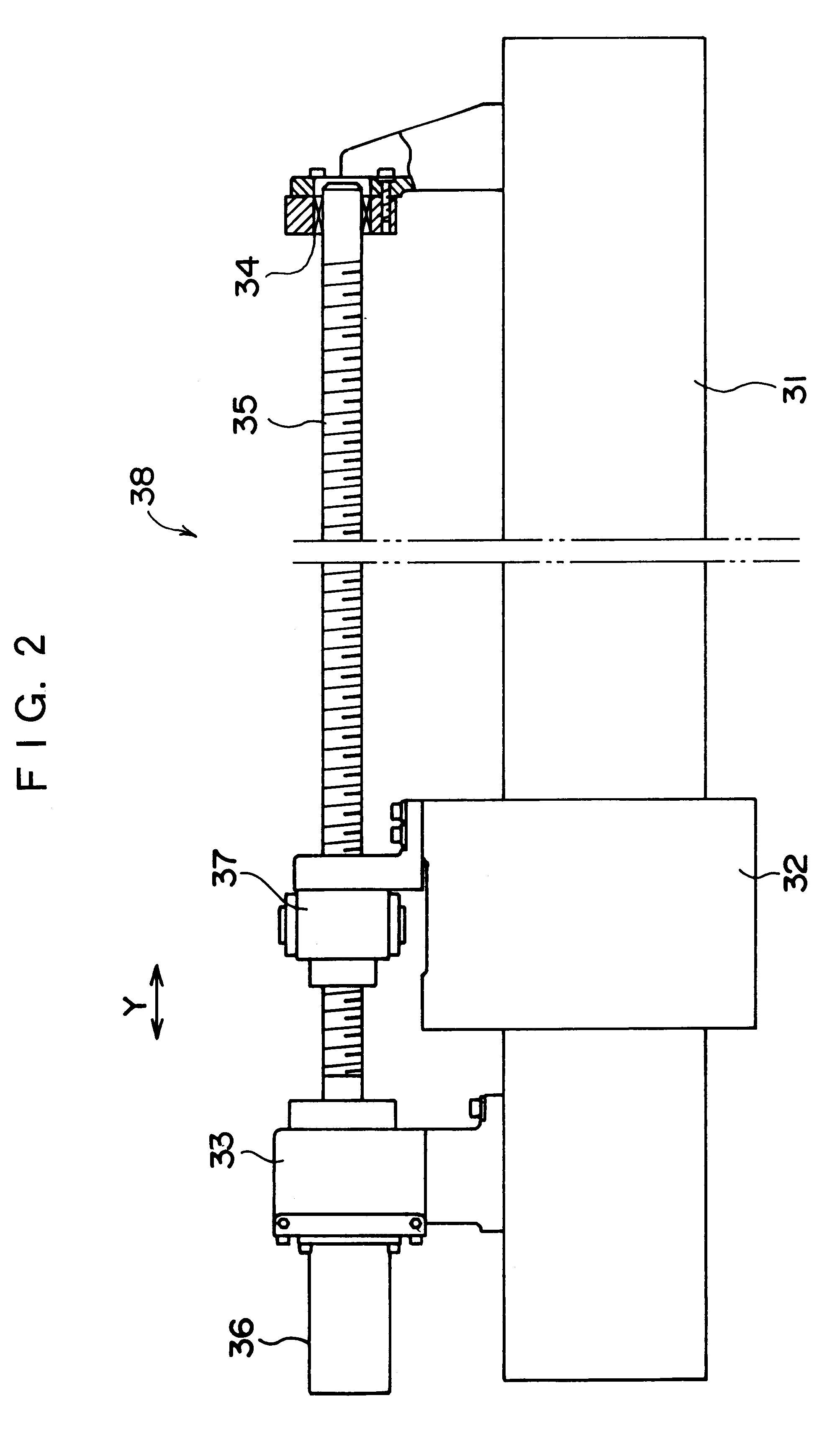

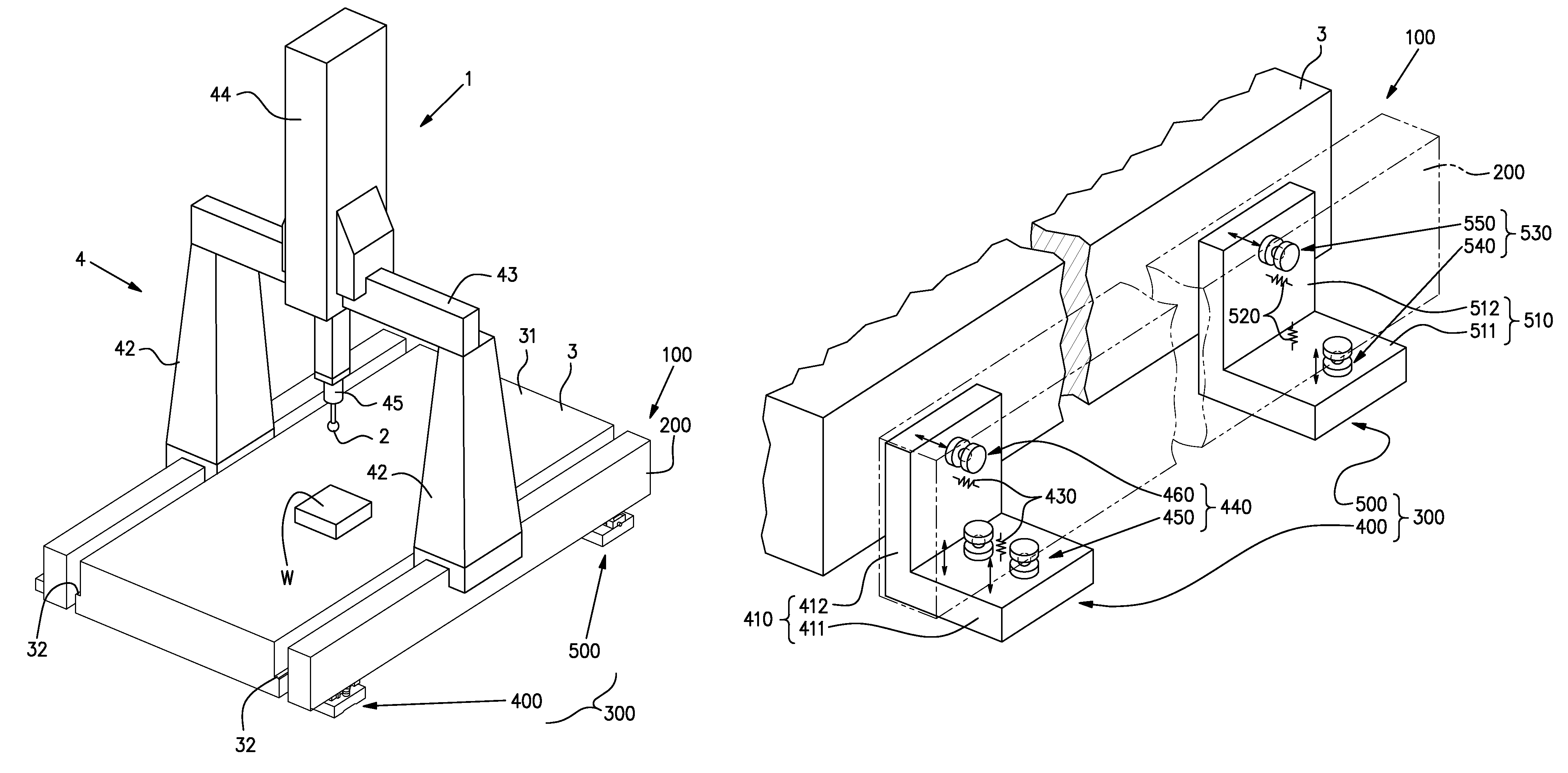

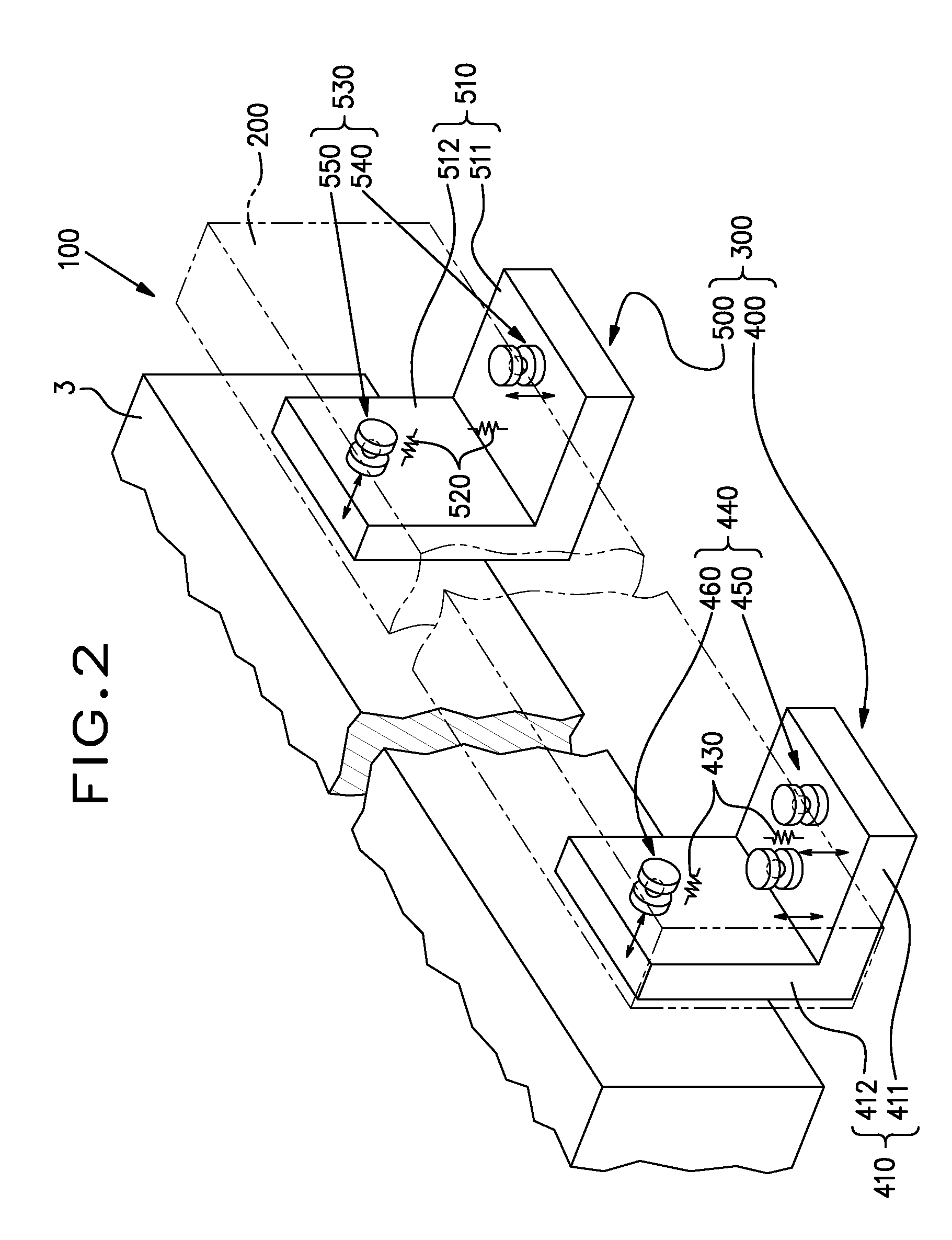

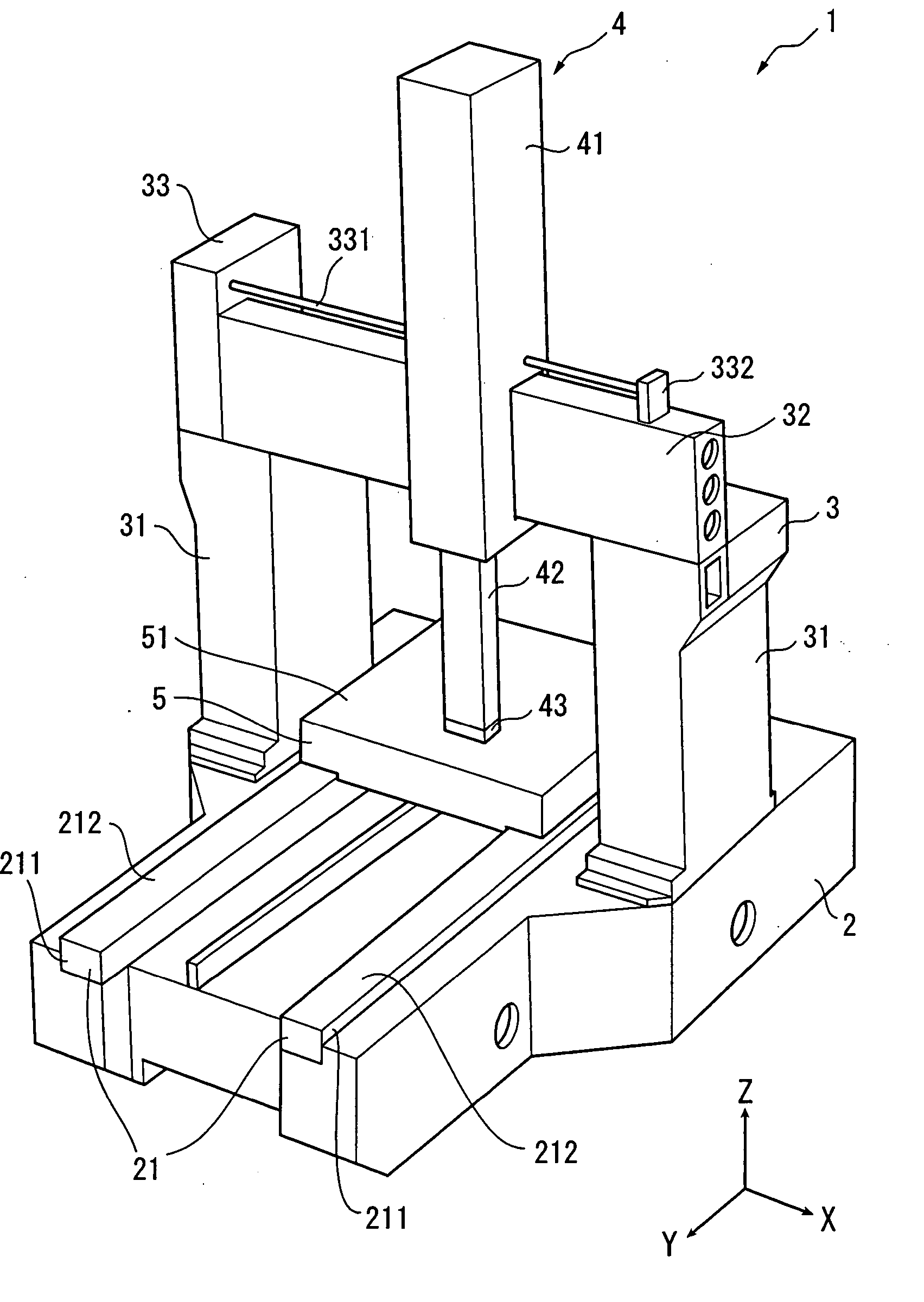

Driving device and measuring instrument

ActiveUS7222434B2Improve rigidityReduce thicknessLinear bearingsUsing electrical meansRelative displacementMeasuring instrument

A supporting device (300) for supporting a guide rail (200) for guiding a movable member subjected to relative displacement in relation to the base table (3). The supporting device includes, base bodies (410, 510) engaged onto the base table (3) and carrying the guide rail (200), and holding section (440, 530) for holding the guide rail (200) intervening between the guide rail (200) in the state where the guide rail is carried by the base bodies (410, 510). The holding section (440, 530) supports the guide rail (200) in the state where it can move swingingly. A change in the posture or position of the base bodies (410, 510) is offset with a swinging movement by the holding section, and does not affect the guide rail. As a result, excessive force is not applied on the guide rail, so that the form of the guide rail is maintained.

Owner:MITUTOYO CORP

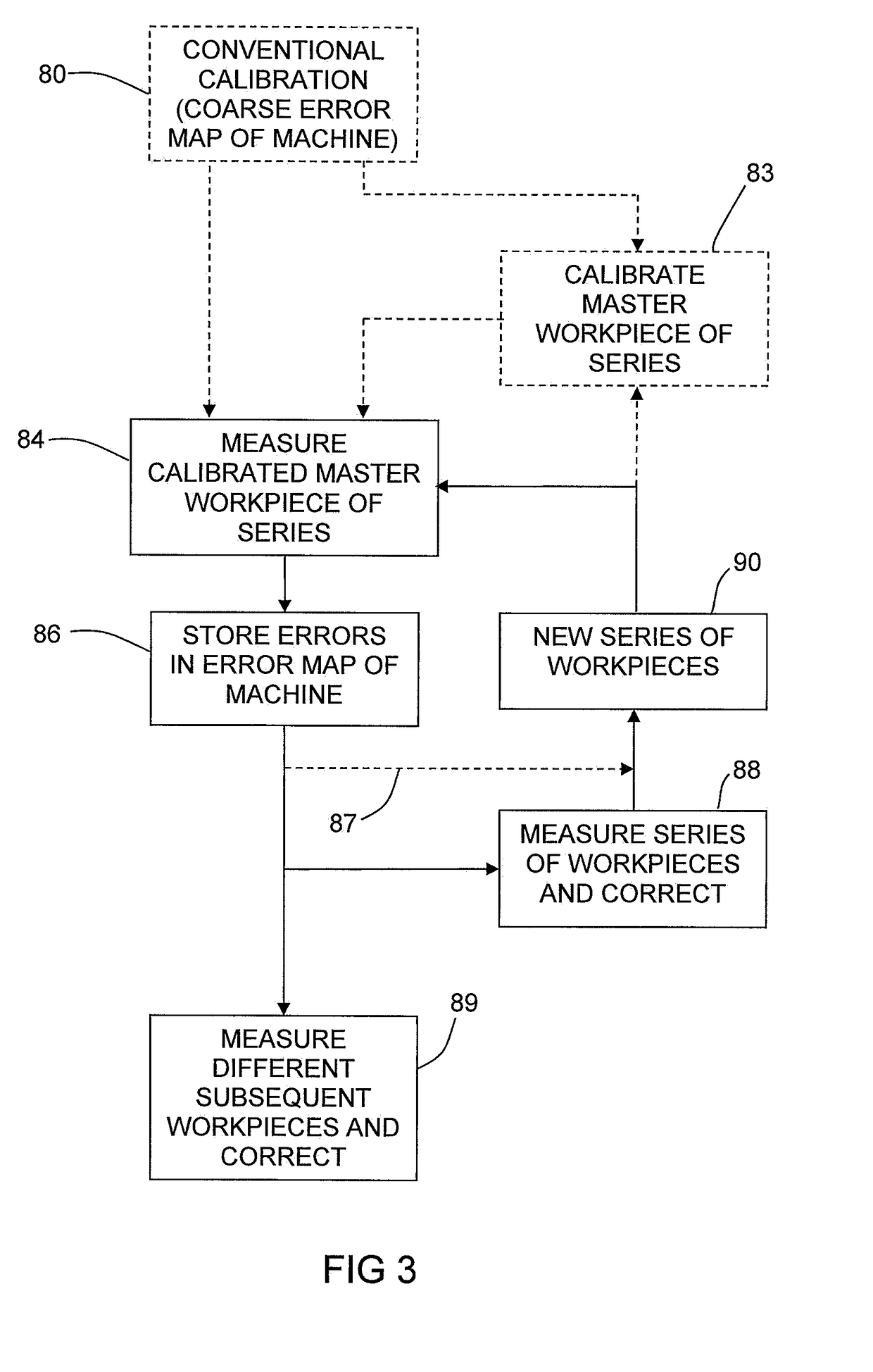

Method and apparatus for inspecting workpieces

Methods are described for measuring series of nominally identical production workpieces on a dimensional measuring apparatus such as a coordinate measuring machine. One master workpiece of the series is calibrated, to provide correction values which are used to build an error map of the measuring apparatus. This map is used to correct measurements not only of subsequent nominally identical workpieces of the same series, but also of multiple different subsequent series of different workpieces. Each subsequent series also has a master workpiece which is calibrated and used to further build the error map. As this process is repeated over time, the error map becomes more and more densely populated. In due course, it becomes possible to dispense with the use of a calibrated master workpiece, because measurements can be corrected using error values which already exist in the error map.

Owner:RENISHAW PLC

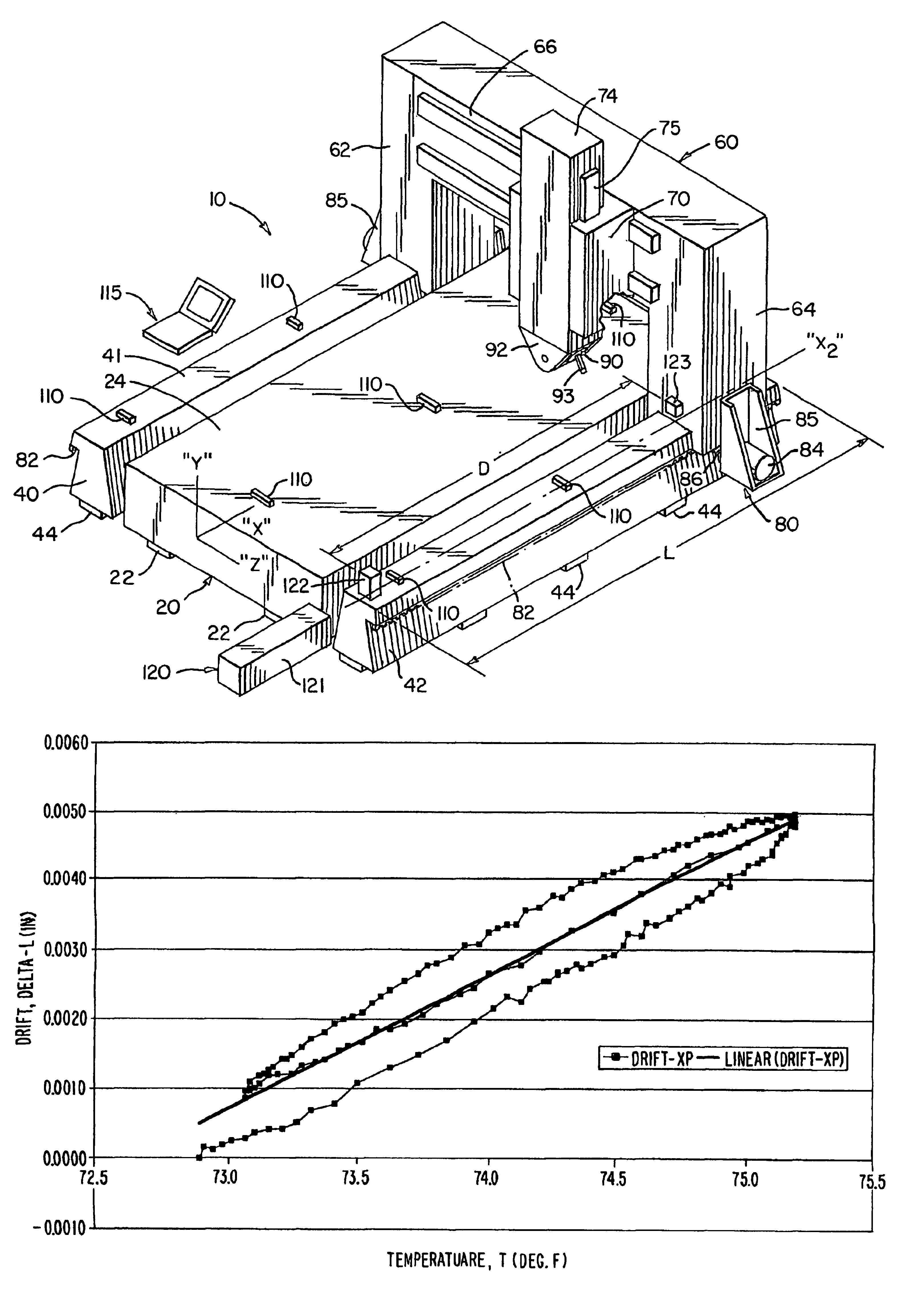

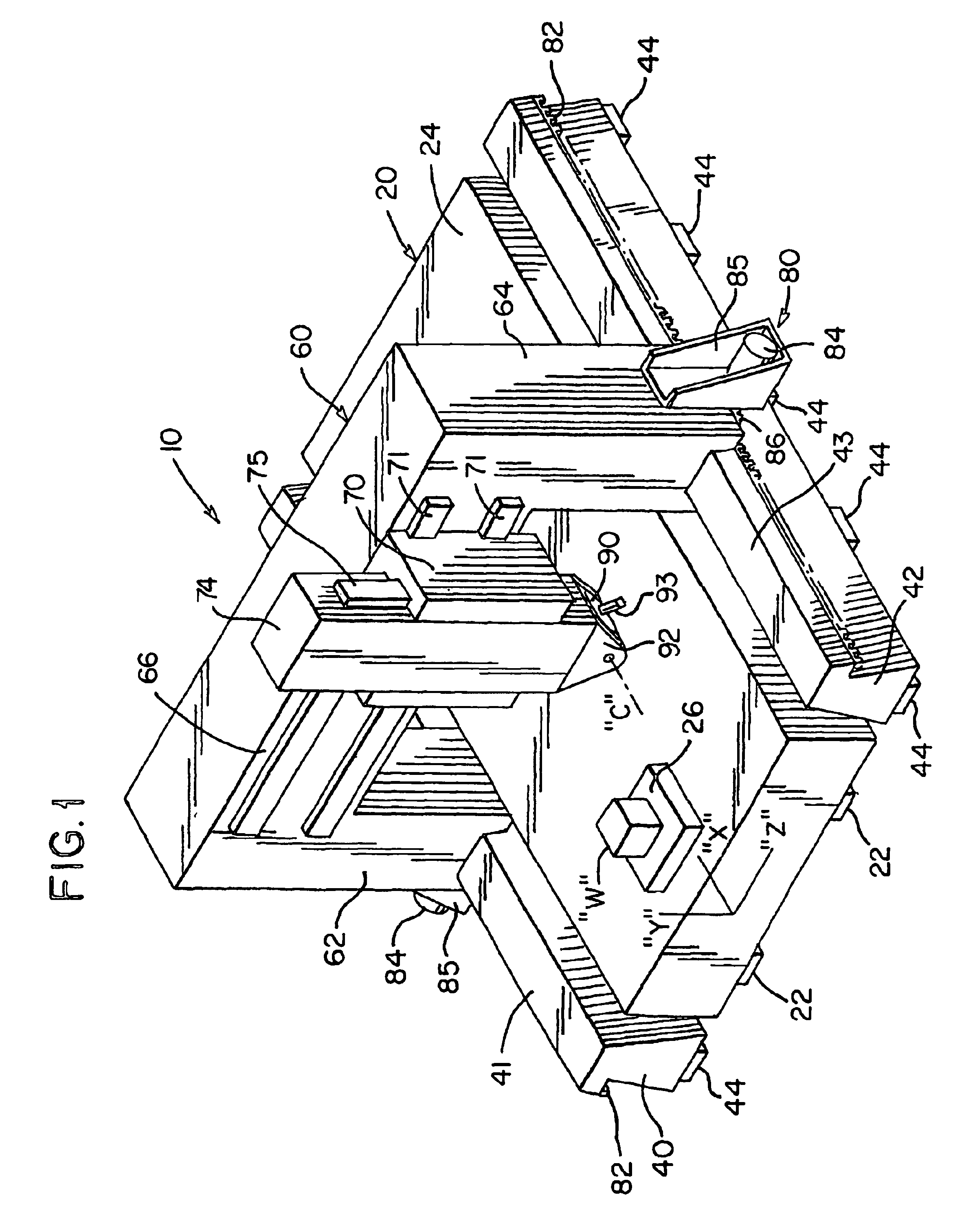

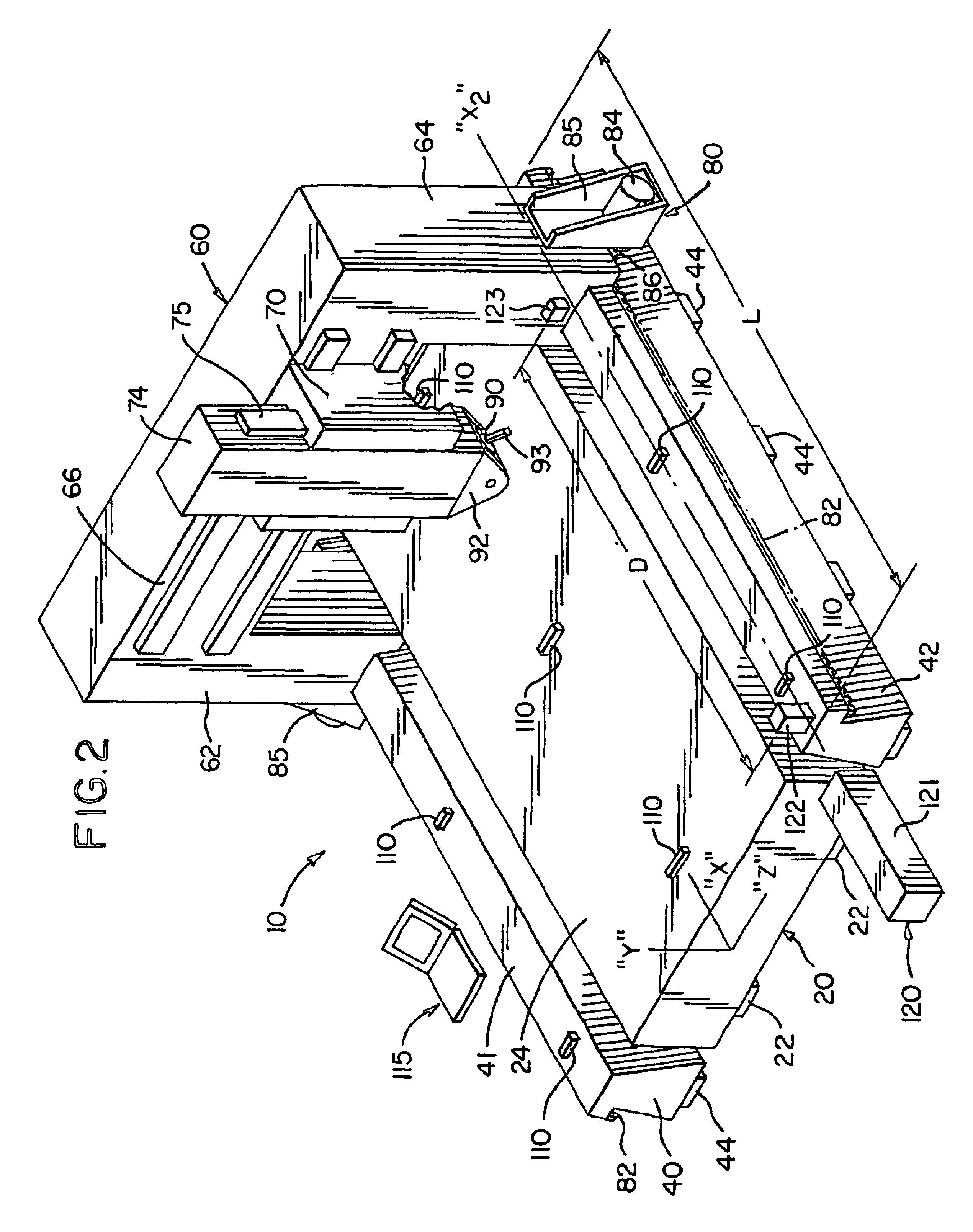

Method for determining effective coefficient of thermal expansion

A method for determining an “effective” thermal coefficient of a machine comprises the steps of installing one or more temperature sensors (110) at various locations on the machine, positioning a first machine member (60) at a “known” reference location, relative to a second machine member (42), installing a linear position measuring device (120) to detect changes in position of the first machine member (60) relative to the second machine member (42) along a first axis of movement, periodically acquiring readings from each of the temperature sensors (110) and from the linear position measuring device (120) during a test cycle and compiling the temperature and linear position data into a table. A statistical correlation analysis is performed to determine which of the temperature sensors (110) experiencing changes in temperature are most linearly related to changes in the linear position of the first machine member (60) relative to the second machine member (42) and an “effective” coefficient of thermal expansion is thereafter determined as the rate of change of position, i.e. length, relative to change in temperature. The present method includes using the machine's “effective” thermal coefficient the calibrate the motion of the machine to compensate for the thermal characteristics thereof.

Owner:FIVES MACHINING SYST +1

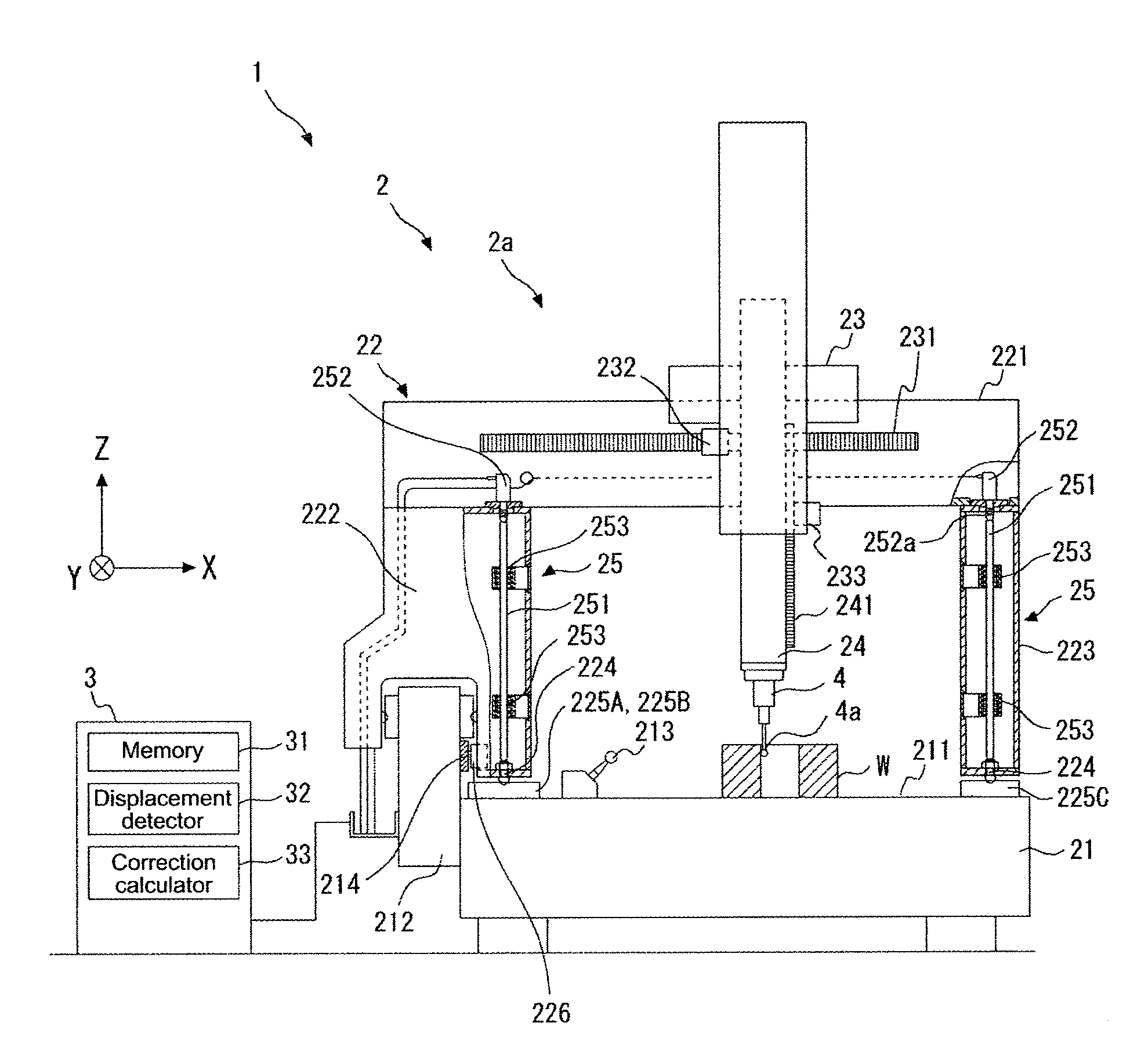

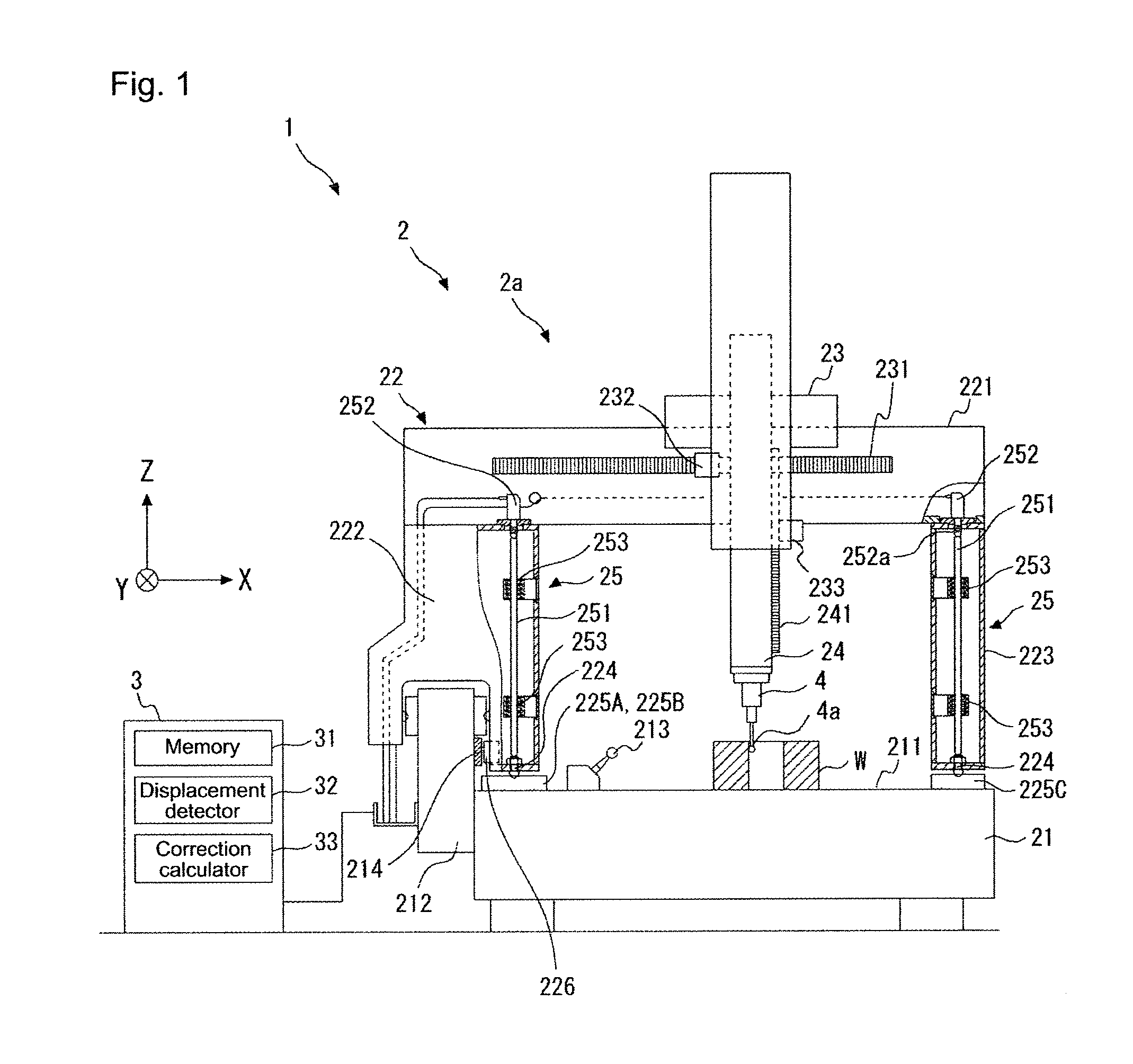

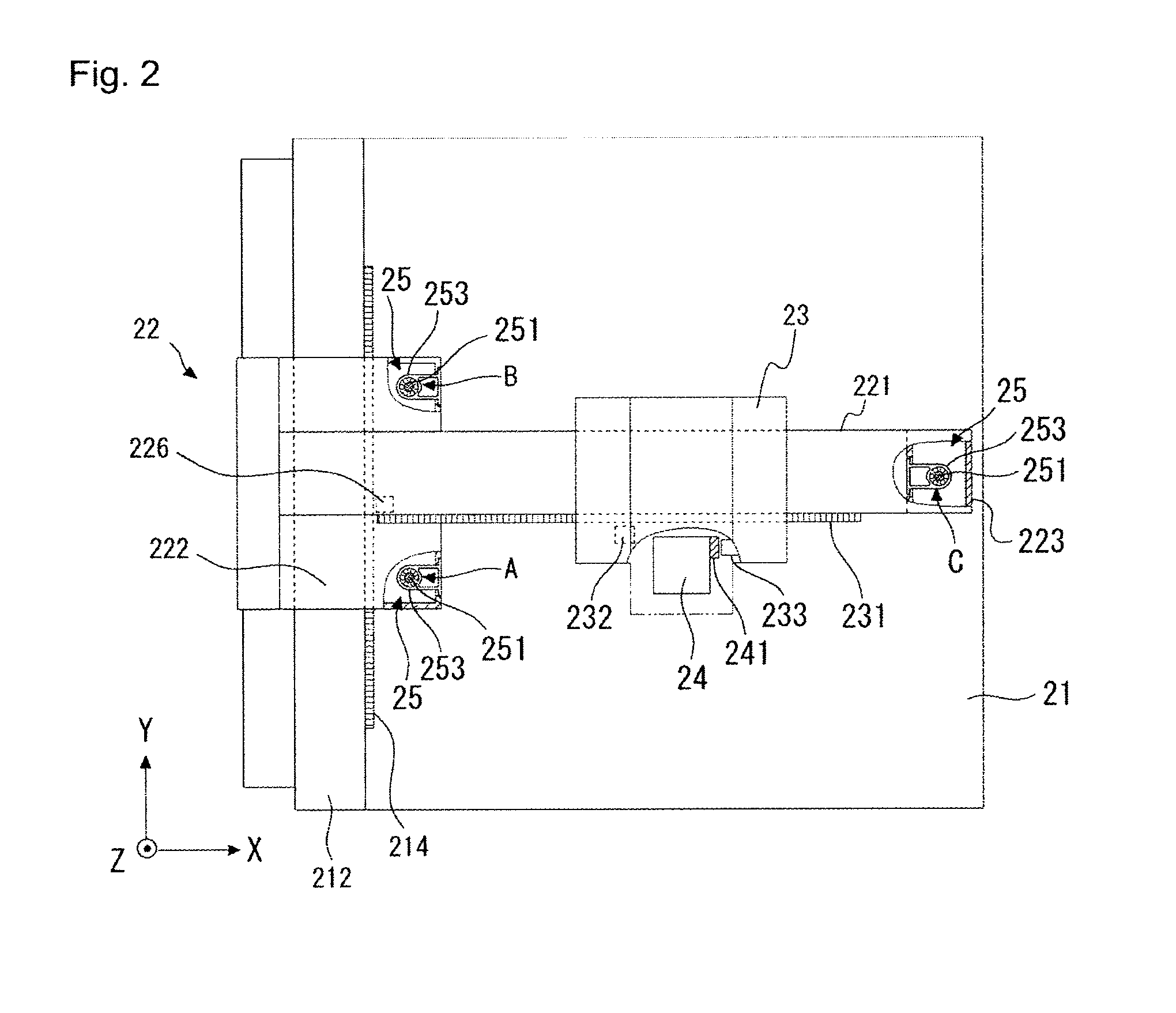

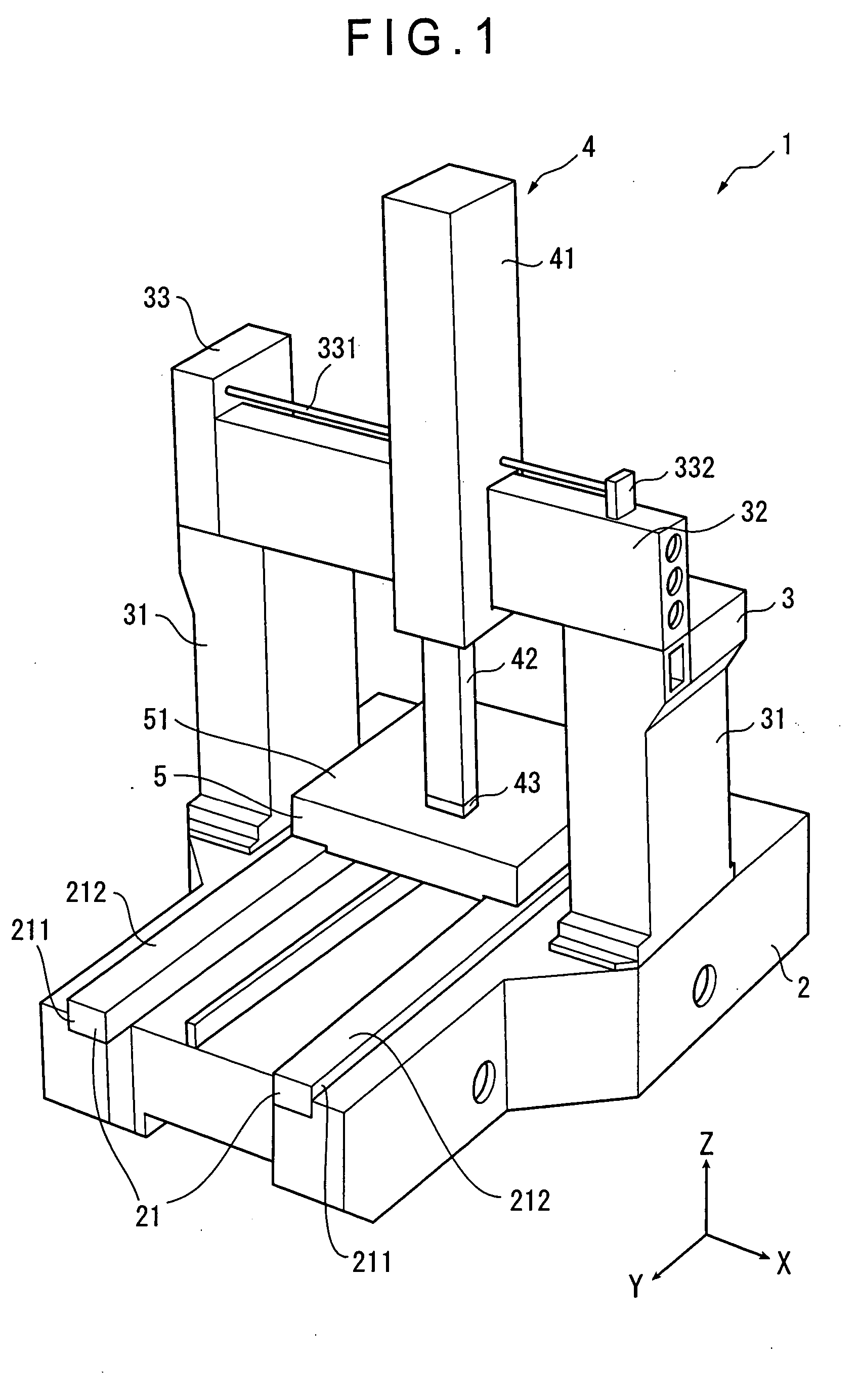

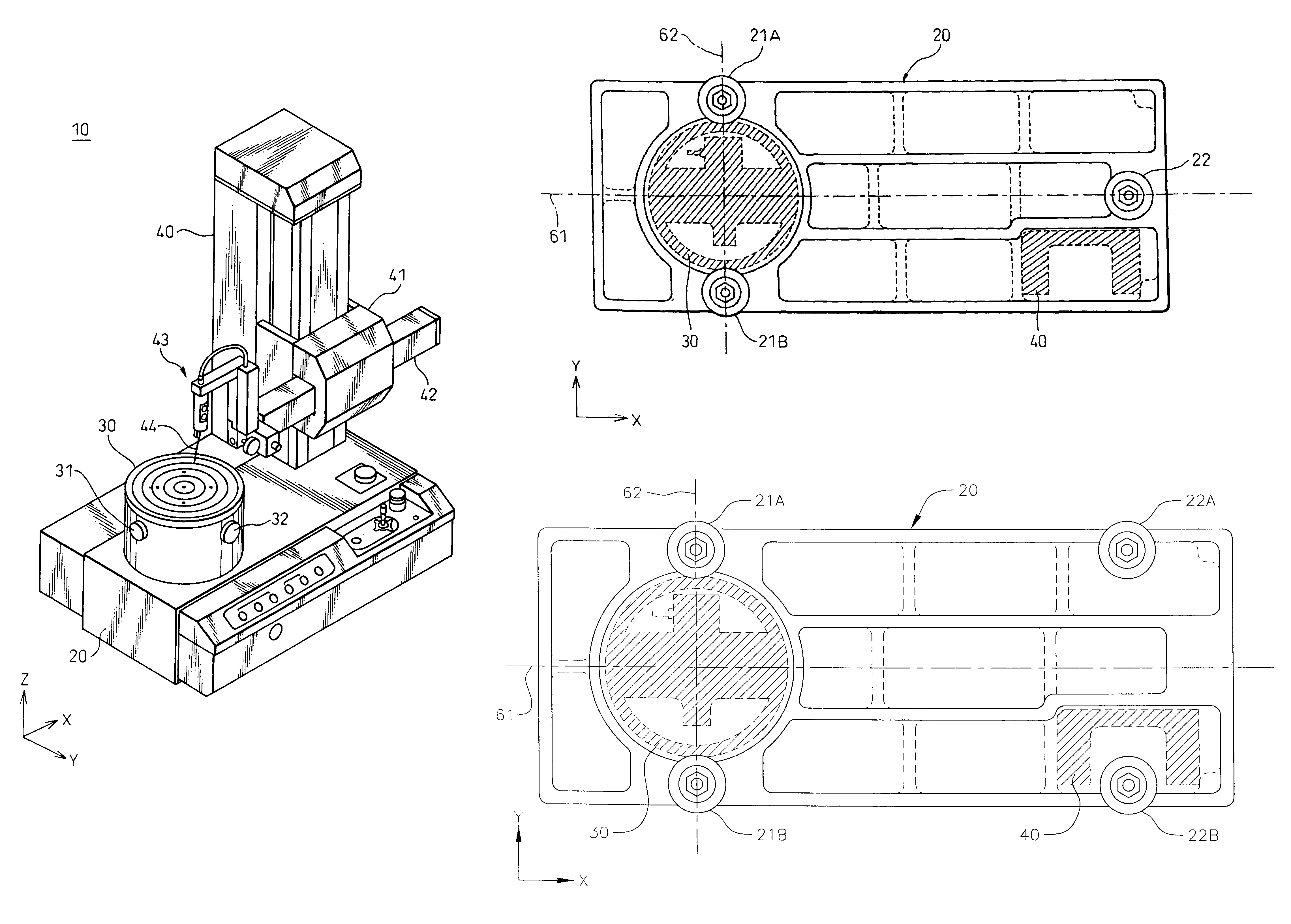

Industrial machine and method for measuring amount of expansion/contraction of industrial machine

ActiveUS20150131697A1Accurate measurementMaterial thermal coefficient of expansionUsing electrical meansEngineeringIndustrial machine

An industrial machine includes a moving mechanism moving one of a probe and a tool relative to a work piece, using three displacement axes parallel to each of three orthogonal axis directions; a low thermal expansion member formed with a material having a smaller thermal expansion coefficient than a material forming a structural element of the moving mechanism; and an expansion / contraction measurer measuring, using the low thermal expansion member as a reference, an amount of expansion / contraction of the structural element in one of the three orthogonal axis directions, the expansion / contraction occurring due to a change in temperature.

Owner:MITUTOYO CORP

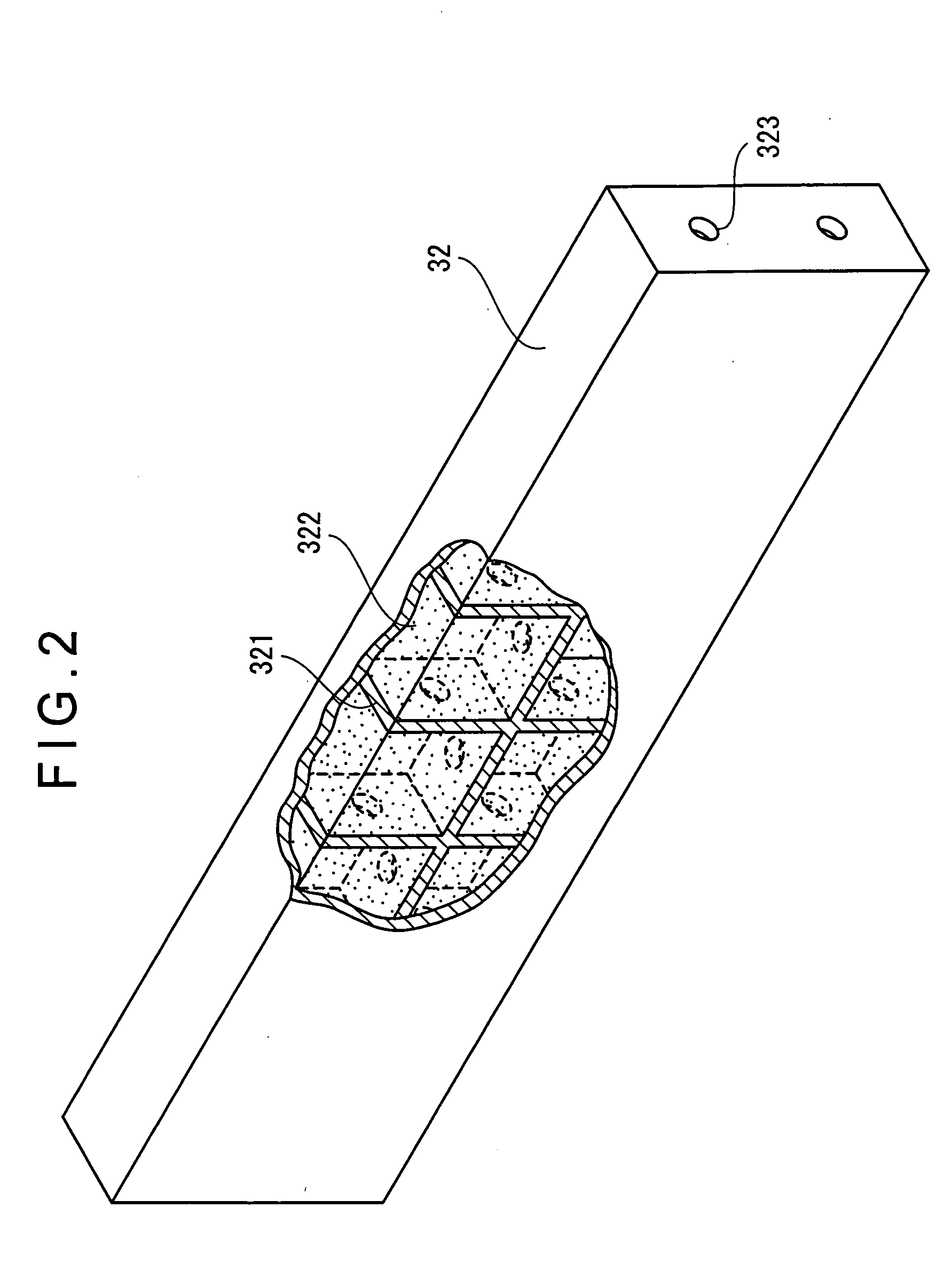

Measuring instrument

ActiveUS20040250434A1Improve rigidityIncrease vibrationNon-rotating vibration suppressionError compensation/eliminationResidual vibrationMeasuring instrument

At least one assembly of a movable member or a guide member (32) that guides the movement of the movable member out of a plurality of assemblies of a measuring instrument contains a sealed space (322). A filler is filled in the sealed space (322). According to this arrangement, rigidity of the movable member or the guide member (32) can be enhanced. Further, residual vibration generated along with the movement of the movable body can efficiently be attenuated.

Owner:MITUTOYO CORP

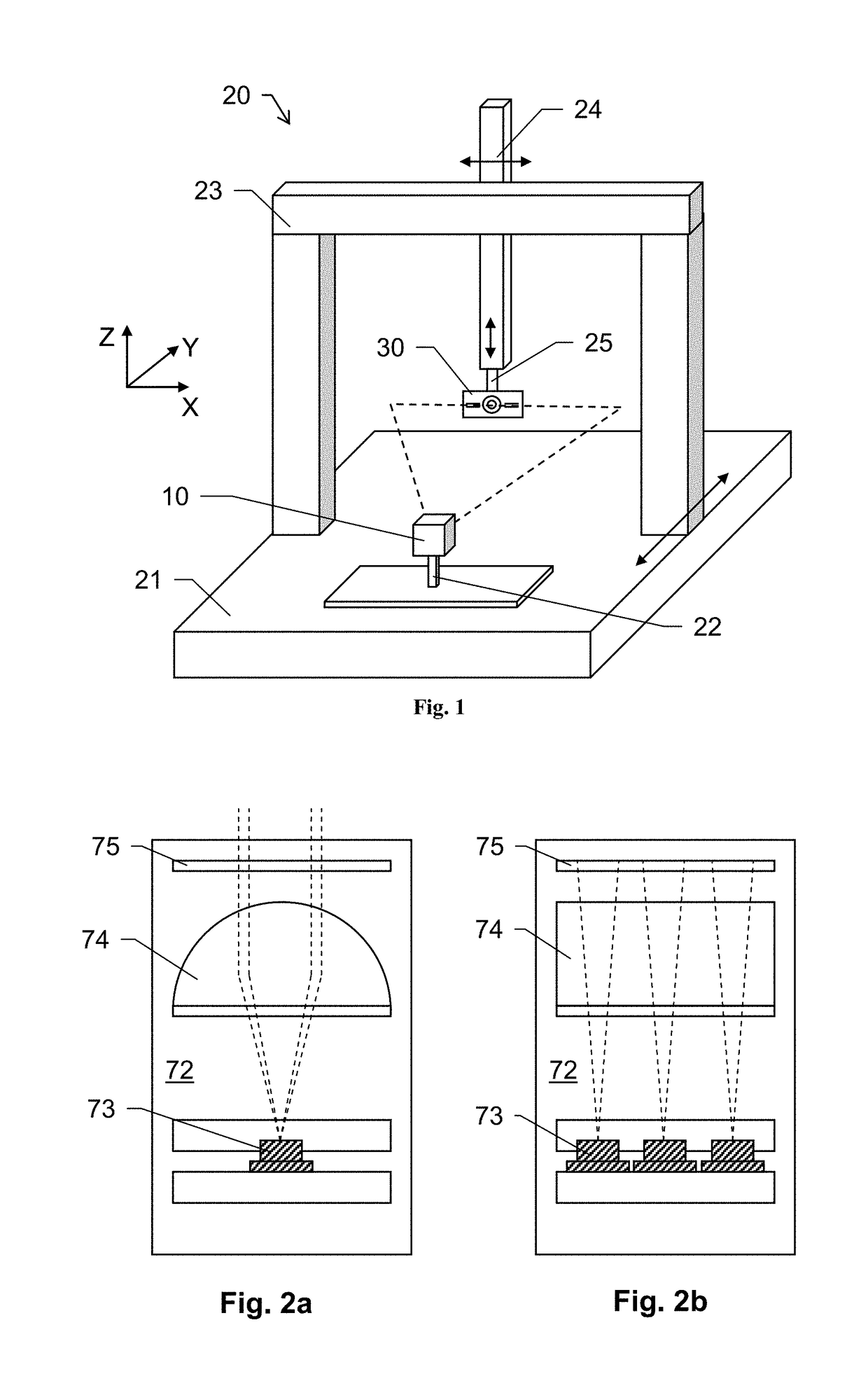

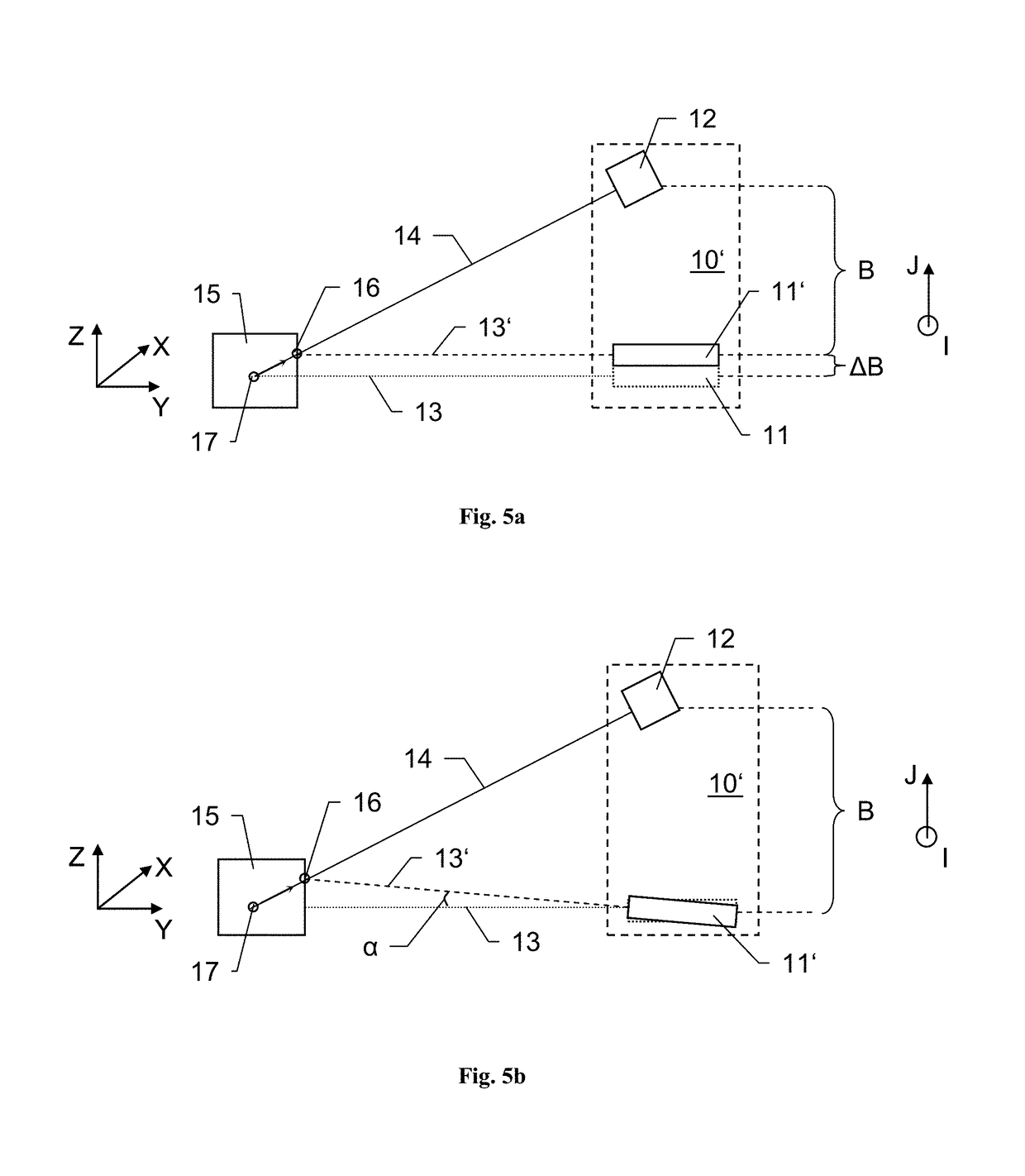

Calibration of a triangulation sensor

ActiveUS20180372481A1High calibrationEasy to getUsing optical meansError compensation/eliminationTriangulationOptics

A method for calibrating a triangulation sensor including a light emitting unit for emitting measuring light and a light receiving unit. The light emitting unit is arranged with known position and orientation relative to the light receiving unit and the triangulation sensor which is adapted to provide triangulation-based position measurements. A calibration setup which comprises the triangulation sensor and a calibration target providing a defined calibration pattern, and a calibration measurement is performed with reference to the calibration target by means of the triangulation sensor. An image of the calibration target is captured by means of the light receiving unit, and the captured image is processed with deriving a pattern image position with reference to the inner sensor image coordinate system and deriving a light image position with reference to the inner sensor image coordinate system.

Owner:HEXAGON TECH CENT GMBH

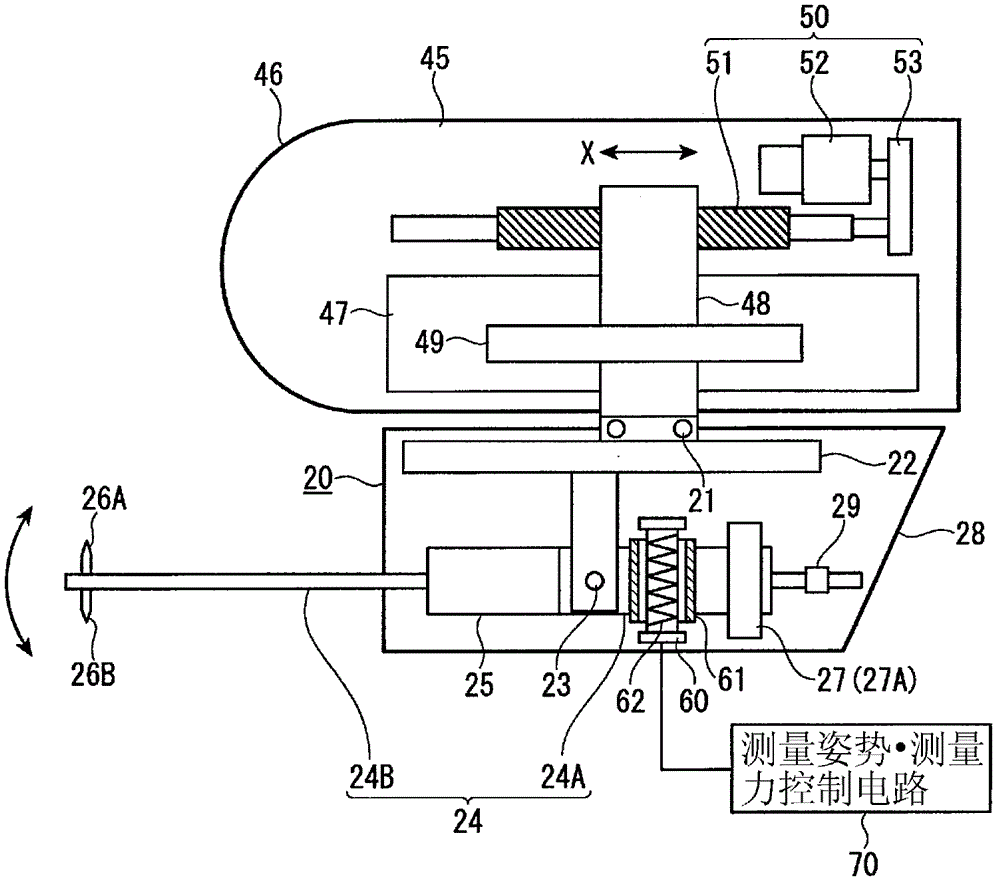

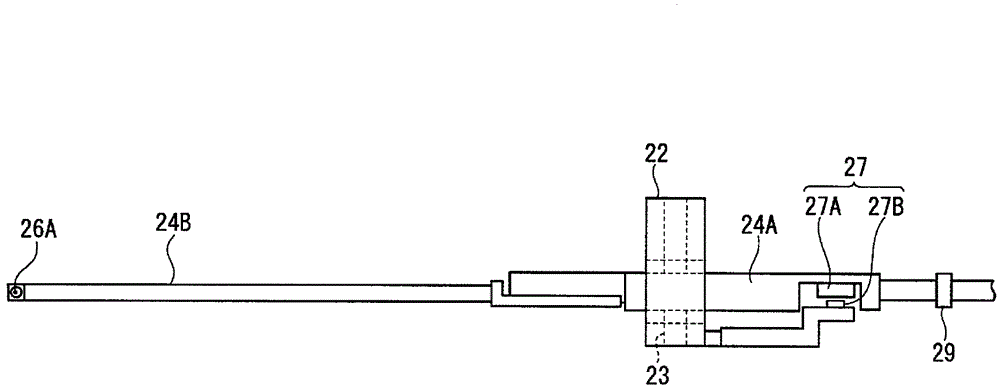

Surface texture measuring instrument

ActiveCN102749058AAvoid damageShock suppressionError compensation/eliminationMechanical roughness/irregularity measurementsMeasuring instrumentEngineering

The invention provides a surface texture measuring instrument. In the surface texture measuring instrument, a measurement arm (24) includes: a first measurement arm (24A) that is supported by a bracket (22) around a support shaft (23) movably in a circular movement in a casing (28); and a second measurement arm (24B) having styluses (26A, 26B) that are attachably and detachably provided to an end of the first measurement arm (24A) via an attachment-detachment mechanism (25), the attachment-detachment mechanism (25) being arranged in the casing. A displacement detector (27) includes: a scale (27A) provided to the measurement arm; and a detection head provided to the bracket (22) to face the scale. A detecting surface of the scale is on an axis of the measurement arm and on a plane of the circular movement of the measurement arm.

Owner:MITUTOYO CORP

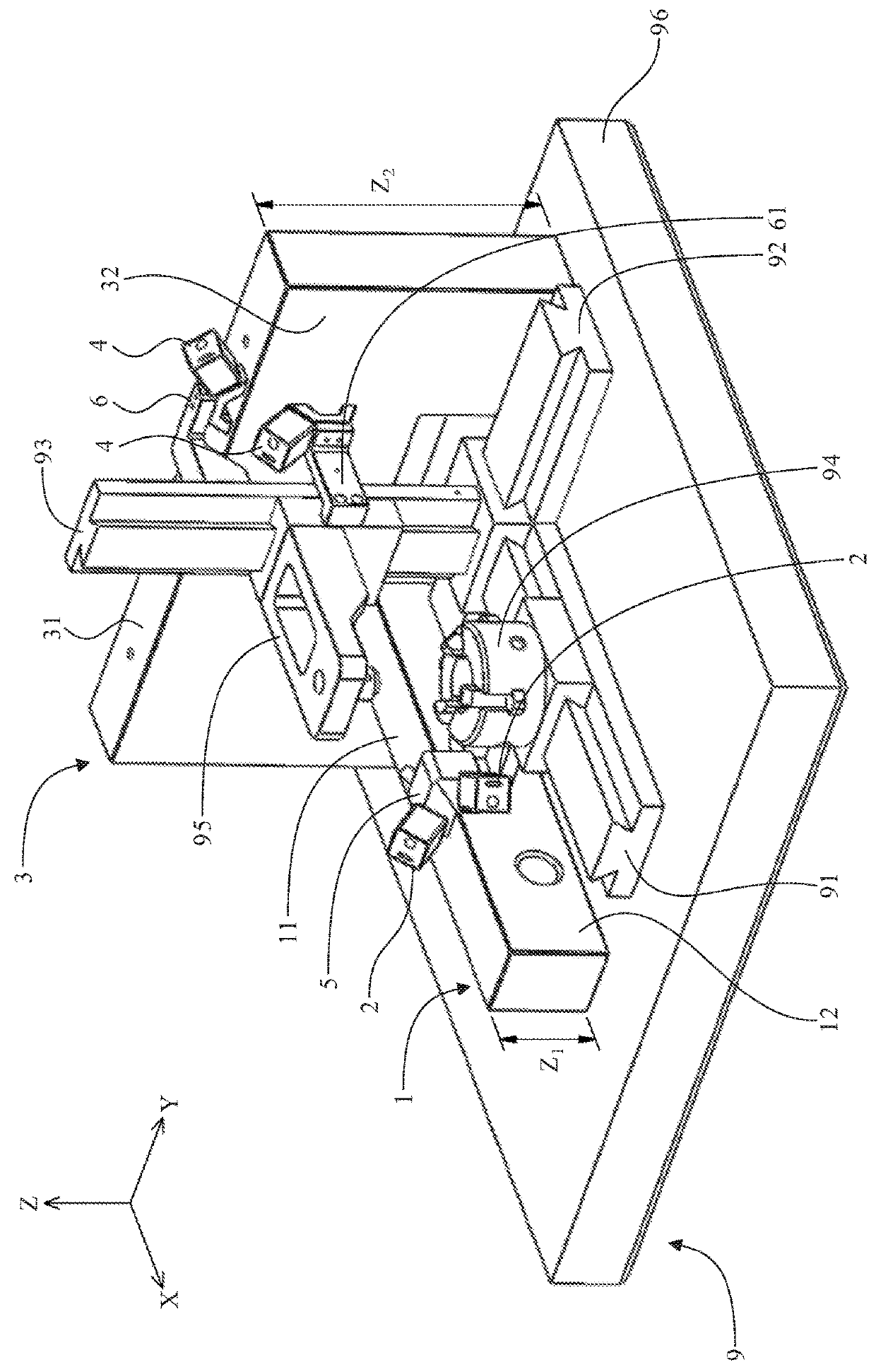

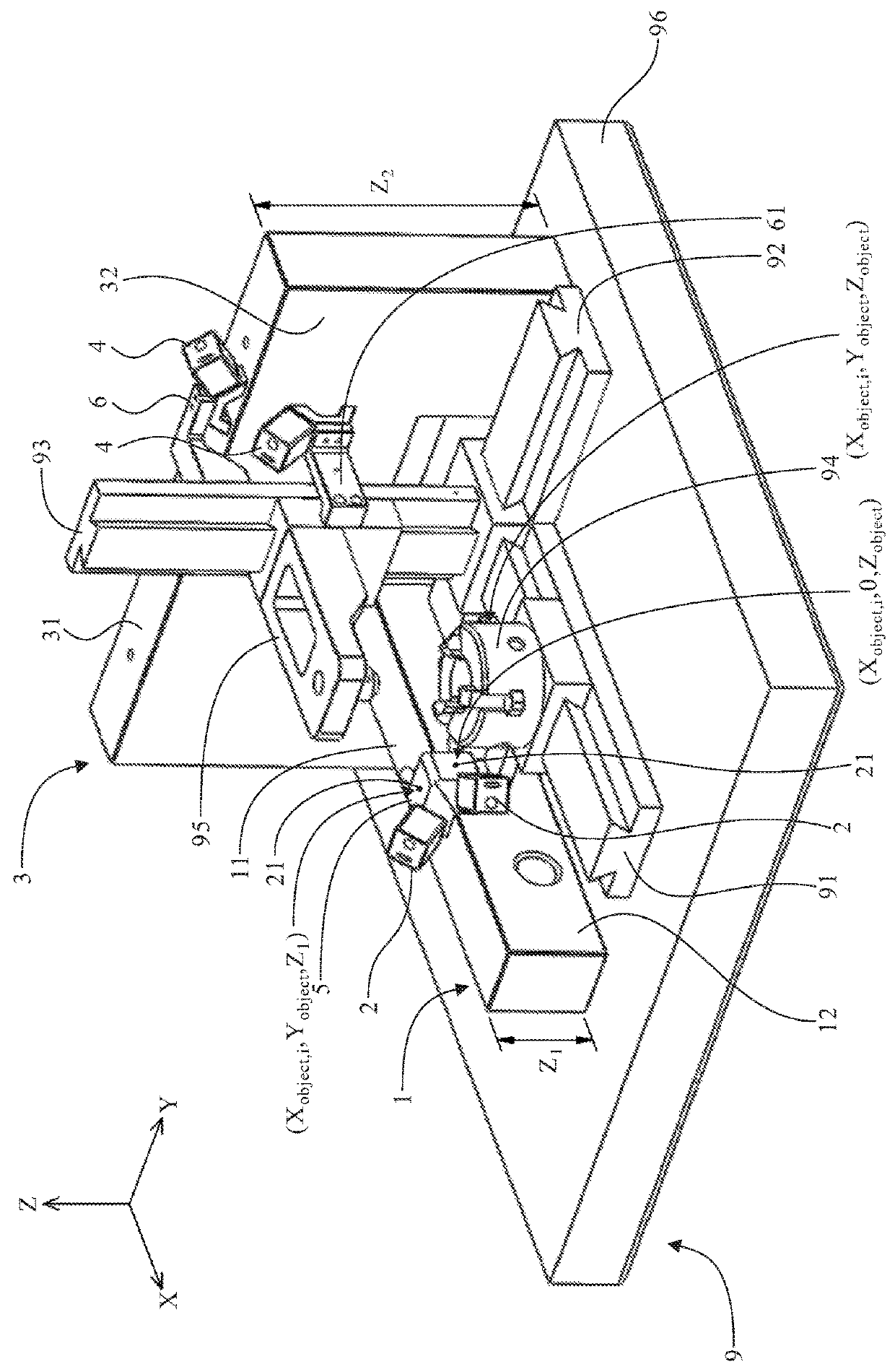

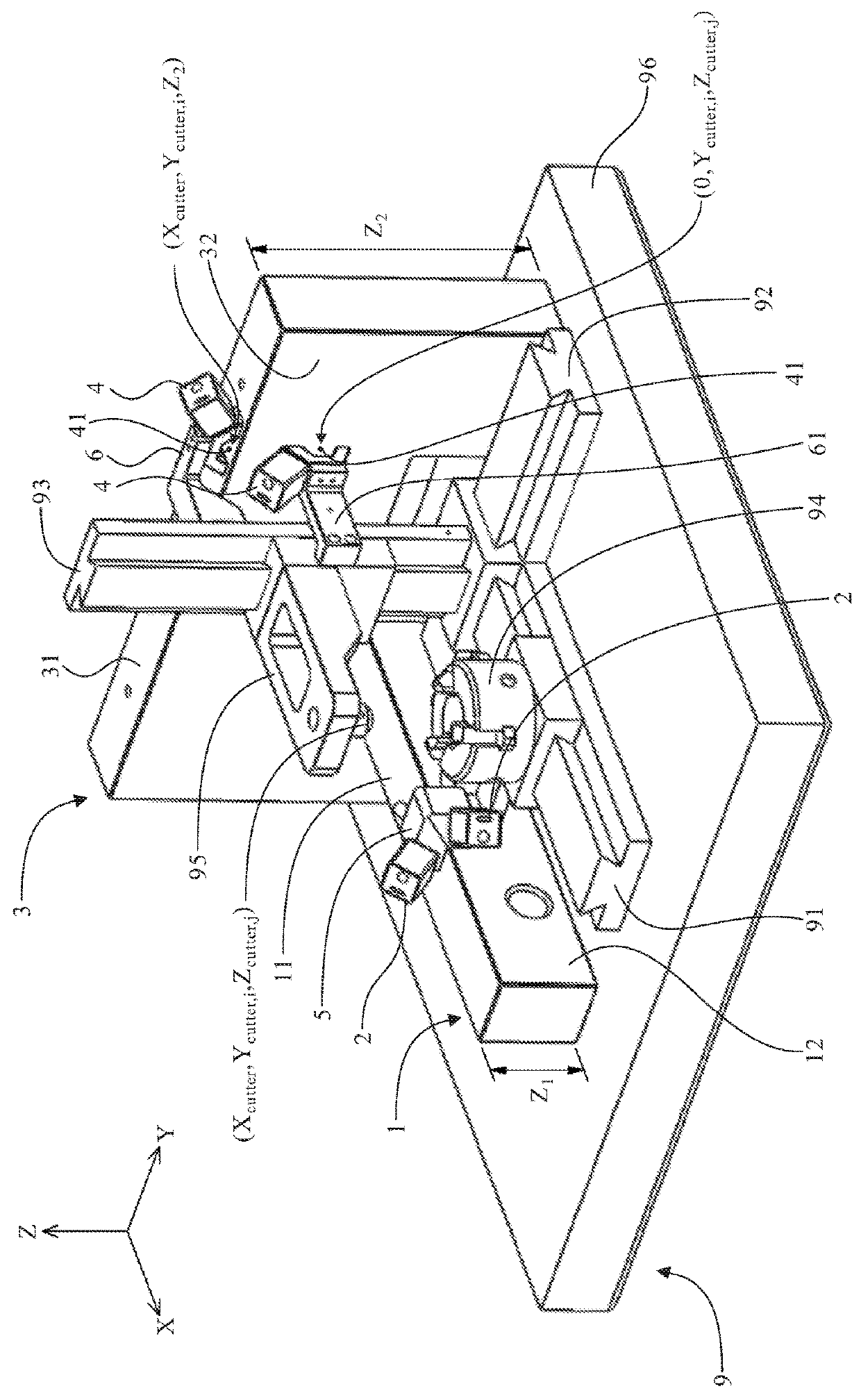

Measurement, calibration and compensation system and method for machine tool

ActiveUS20180178339A1Good thermal deformation calibration accuracyHigh positioning accuracyProgramme controlComputer controlEngineeringThermal expansion

A measurement, calibration and compensation system for machine tool includes a first positioning base; two first speckle image sensors for sensing speckle positions of an object holding unit at a first XY plane and a first XZ plane of the first positioning base before and after the machine tool is started for machining; a second positioning base; two second speckle image sensors for sensing speckle positions of a cutter holding unit at a second XY plane and a second YZ plane of the second positioning base before and after the machine tool is started for machining. Thus, the thermal expansion at all axes of the machine tool can be measured in a simplified and low-cost way, and the absolute positioning coordinates of all axes of the machine tool can be calibrated in real time to avoid reduced positioning accuracy due to the thermal expansion of the multi-axis machine tool.

Owner:NAT CHUNG SHAN INST SCI & TECH

Device for measuring circularity and cylindrical shape

InactiveUS7290348B2Minimize deflectionReduce weightPrecision positioning equipmentMechanical counters/curvatures measurementsRotary stageObservational error

Owner:TOKYO SEIMITSU

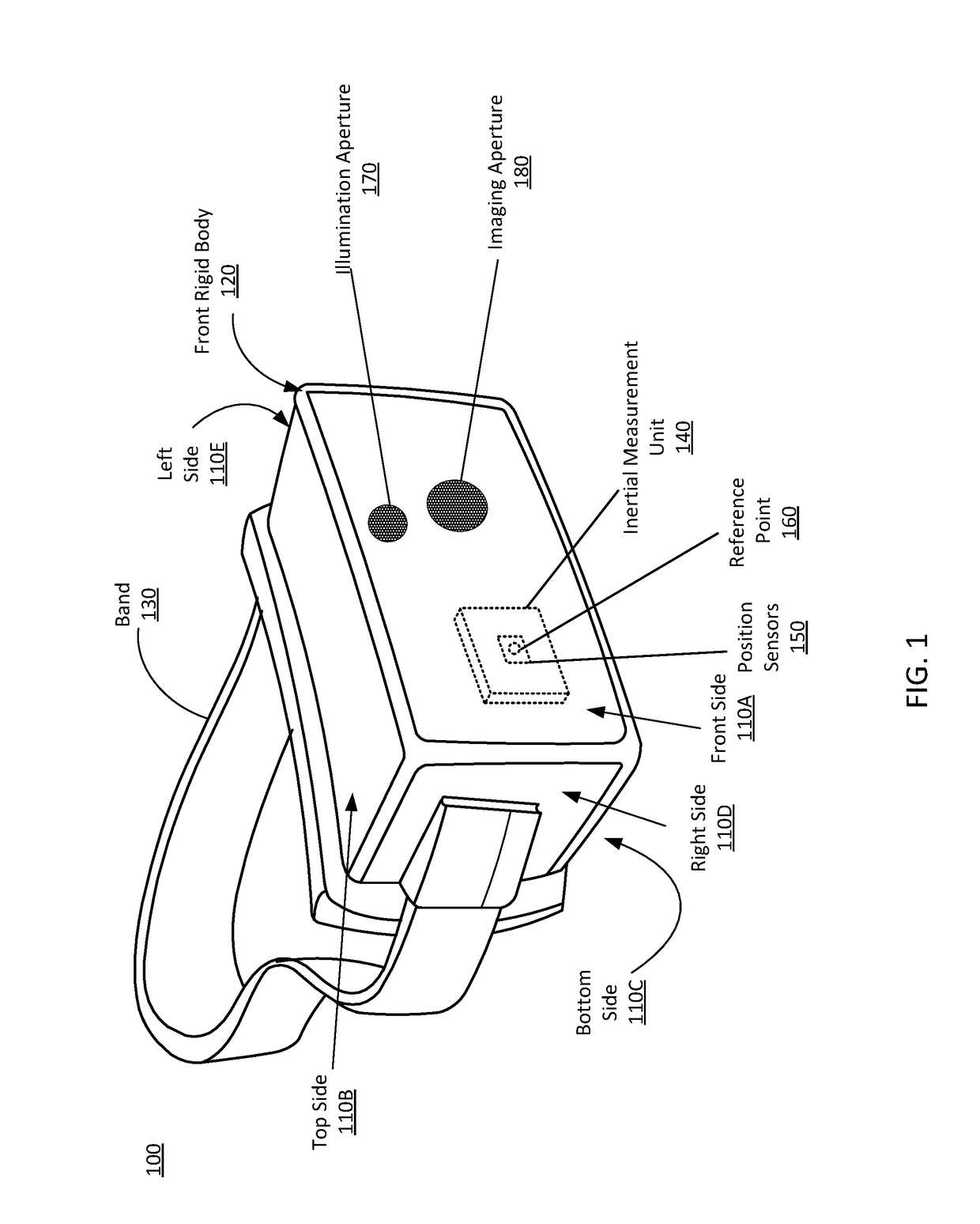

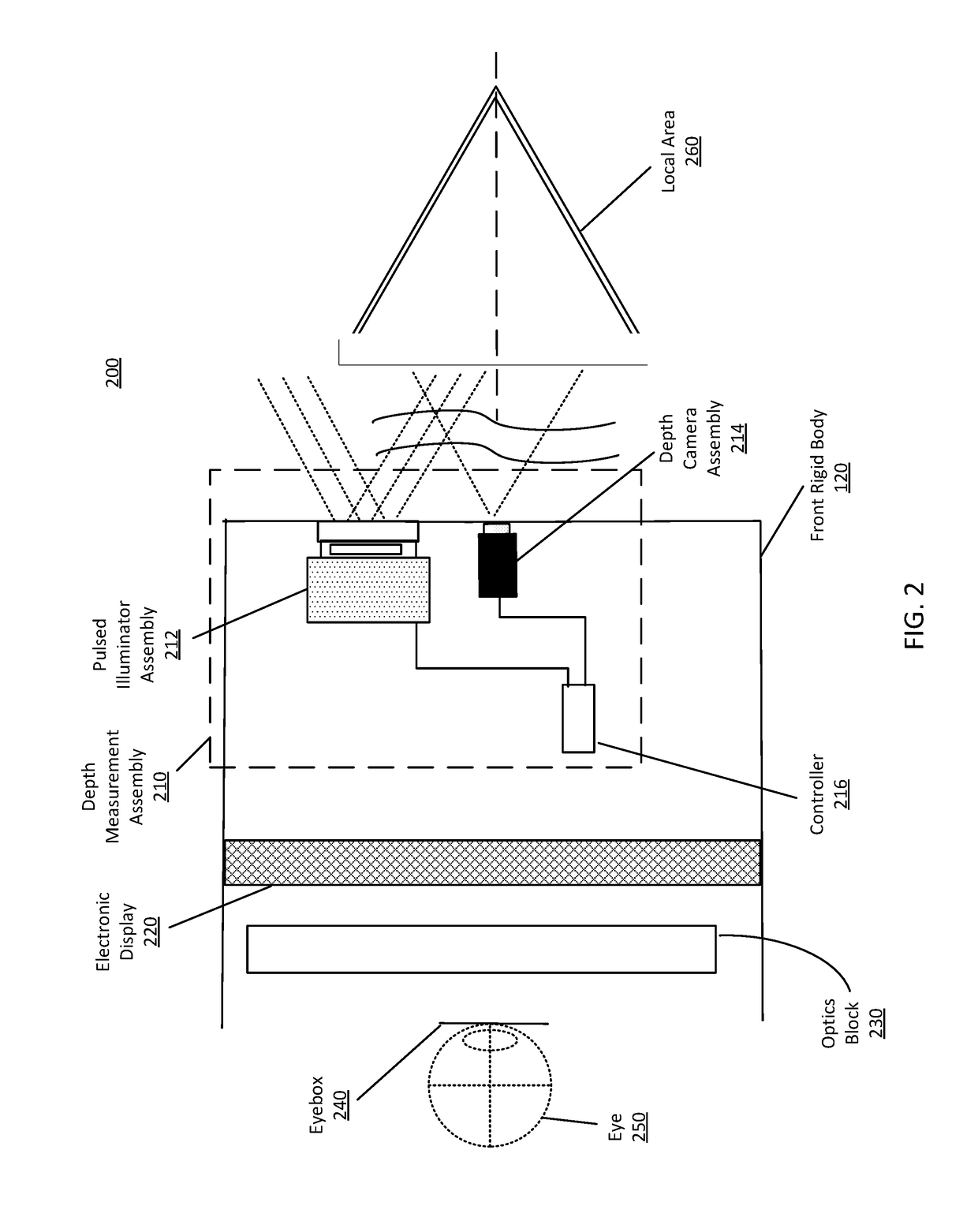

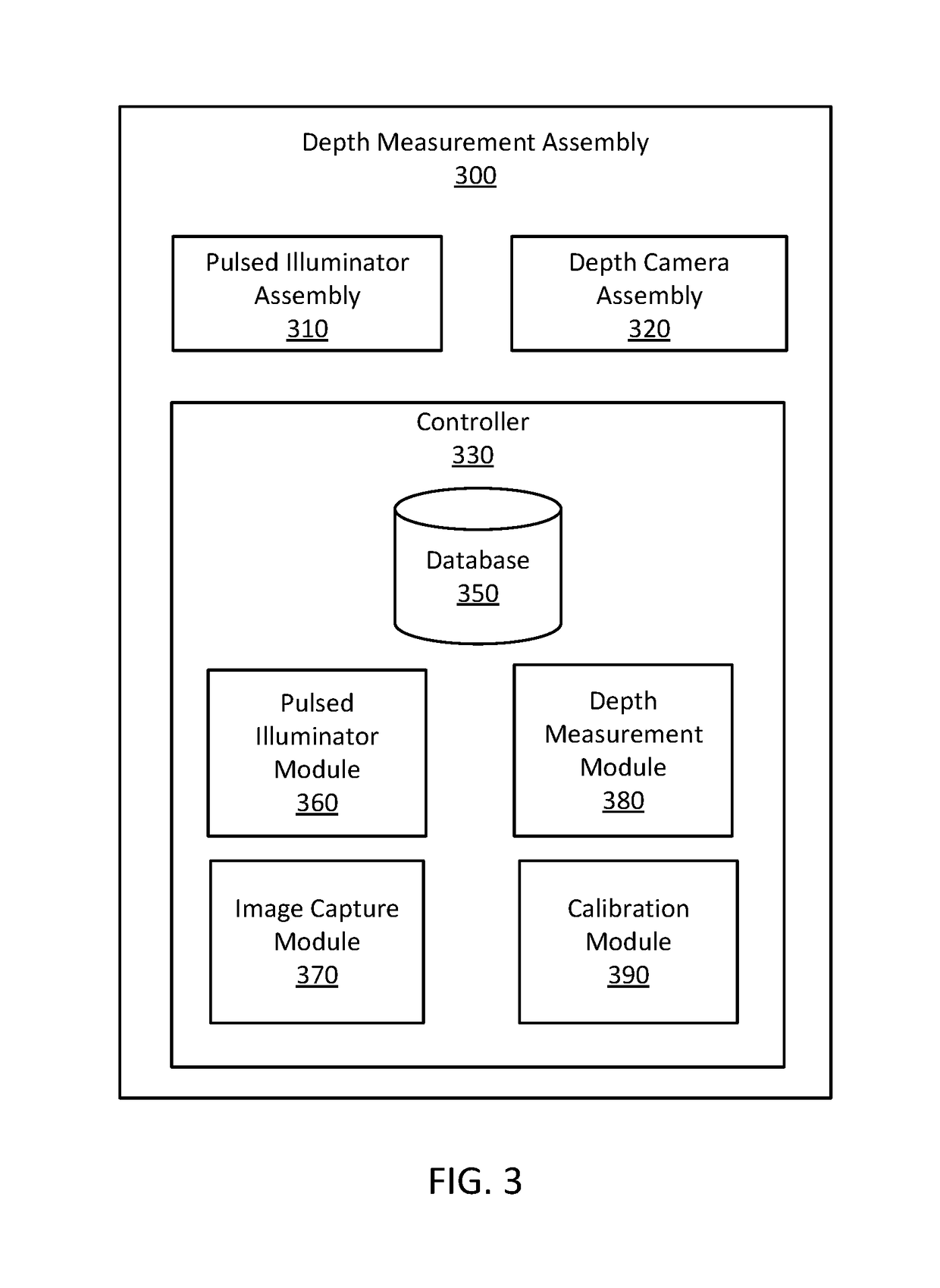

Depth measurement using multiple pulsed structured light projectors

InactiveUS20190072771A1Improve signal-to-noise ratioImage analysisUsing optical meansObject basedPulse rate

A depth measurement assembly (DMA) includes a pulsed illuminator assembly, a depth camera assembly, and a controller. The pulsed illuminator assembly has a structured light projector that projects pulses of structured light at a pulse rate into a local area. The depth camera assembly captures images data of an object in the local area illuminated with the pulses of structured light. An exposure interval of the depth camera assembly is pulsed and synchronized to the pulses projected by the pulsed illuminator assembly. The controller controls the pulsed illuminator assembly and the depth camera assembly so that they are synchronized. The controller also determine depth and / or tracking information of the object based on the captured image data. In some embodiments, the pulsed illuminator assembly have a plurality of structured light projectors that projects pulses of structured light at different times.

Owner:META PLATFORMS TECH LLC

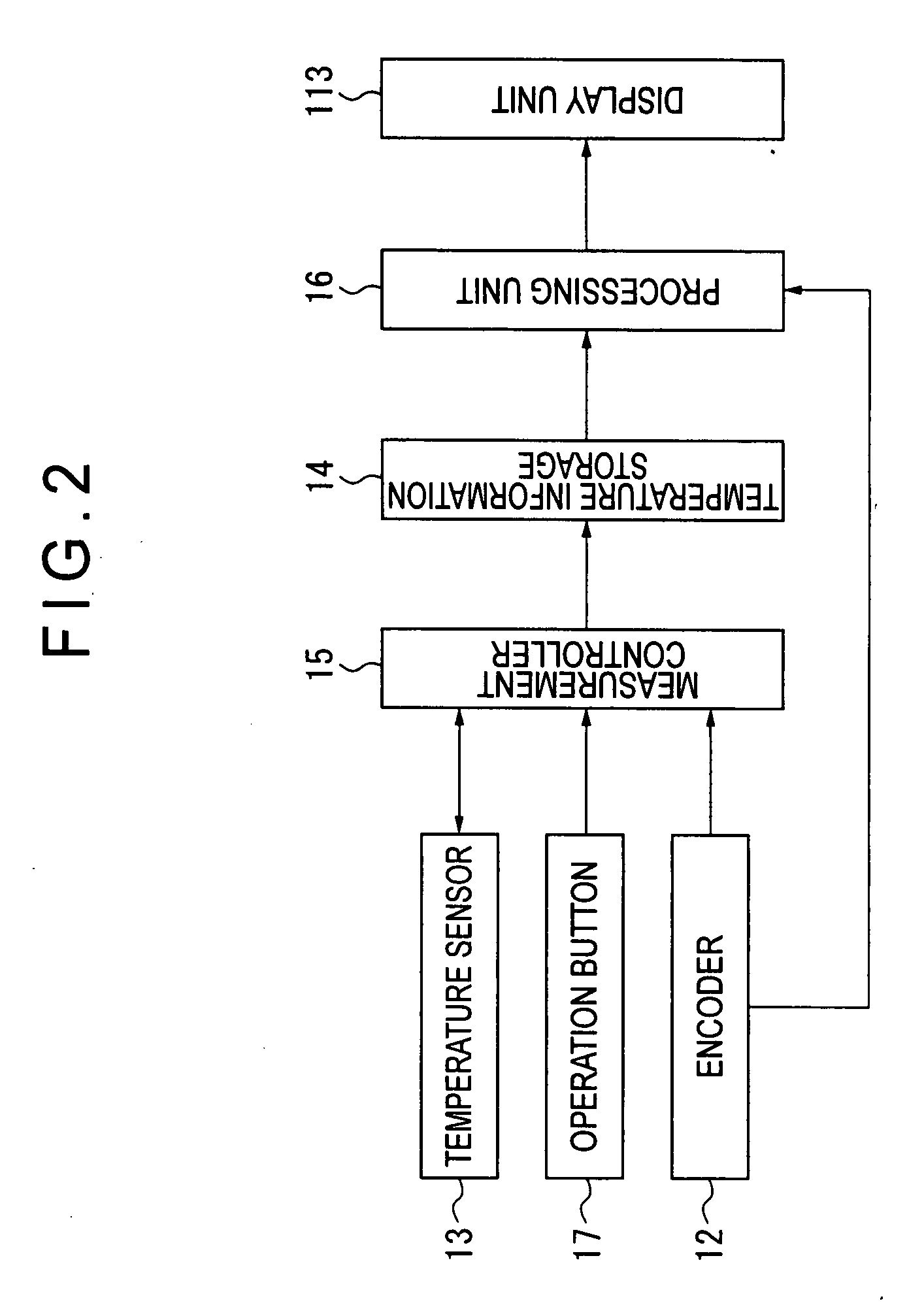

Caliper gauge

InactiveUS20080052942A1Easy to correctEasily errorWalking sticksSlide gaugesEngineeringThermal expansion

A caliper gauge (1) includes: a temperature sensor (13) that is provided on a slider (11) and detects a temperature of a main beam (10); a temperature information storage (14) that stores the temperature of the main beam (10) detected by the temperature sensor (13) and a displacement of the slider (11) relative to the main beam (10) that an encoder (12) detects concurrently with the temperature detection as temperature information of the main beam (10); and a processing unit (16) that calculates a thermal expansion amount of the main beam (10) based on the temperature information of the main beam (10) stored in the temperature information storage (14) to compensate the displacement of the slider (11) relative to the main beam (10) detected by the encoder (12) based on the calculated thermal expansion amount.

Owner:MITUTOYO CORP

Collimating lens and projection module

ActiveCN109557650AFocal length stabilizationLow costColor television detailsUsing optical meansCamera lensLaser transmitter

The invention provides a collimating lens and a projection module. A laser emitter side is set as an object side and a measured object end is set as an image side. A first lens having the positive focal power, a second lens having the negative focal power, a third lens having the positive focal power, and a diaphragm are arranged successively along the optical axis from the object side to the image side. The object side surface of the first lens is a convex surface; the object side surface of the second lens is a concave surface; the object side surface of the third lens is a convex surface ora near plane and the image side surface is a convex surface. The diaphragm is arranged between the third lens and a measured object. The first lens, the second lens and the third lens are all made ofplastic materials. The collimating lens meets the following conditional expression: (dn / dt) 1 is less than -30*10<-6> / DEG C, (dn / dt) 2 is less than -30*10<-6> / DEG C, and (dn / dt)3 is less than -30*10<-6> / DEG C. According to the invention, the changing rates of refractive indexes of the three lenses with the temperature are defined clearly and thus reasonable matching of the thermal expansion characteristics of the lenses is realized, so that the stable focal length is realized. The collimating lens and the projection module are suitable for different temperature applications.

Owner:JIANGXI LIANYI OPTICS CO LTD

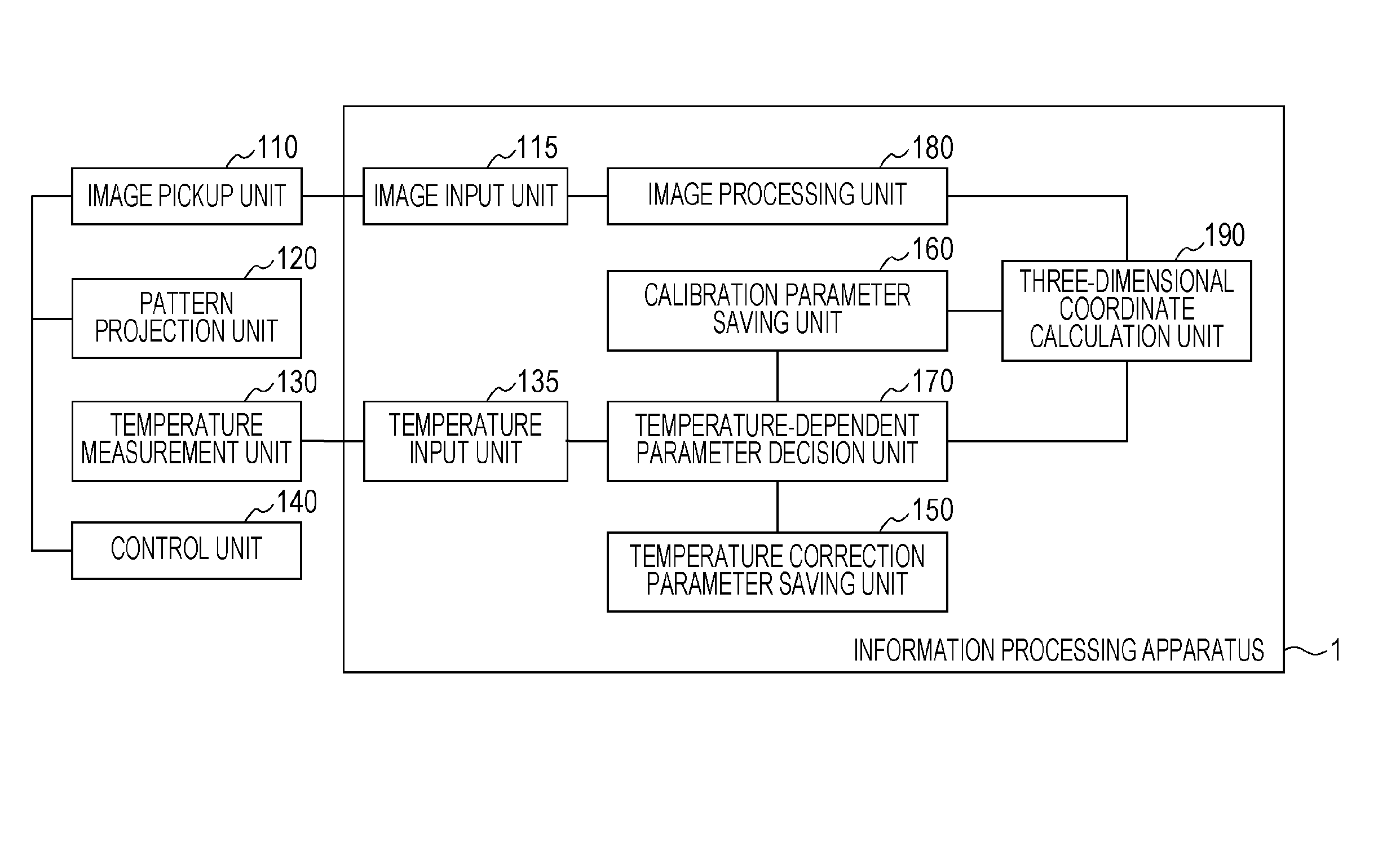

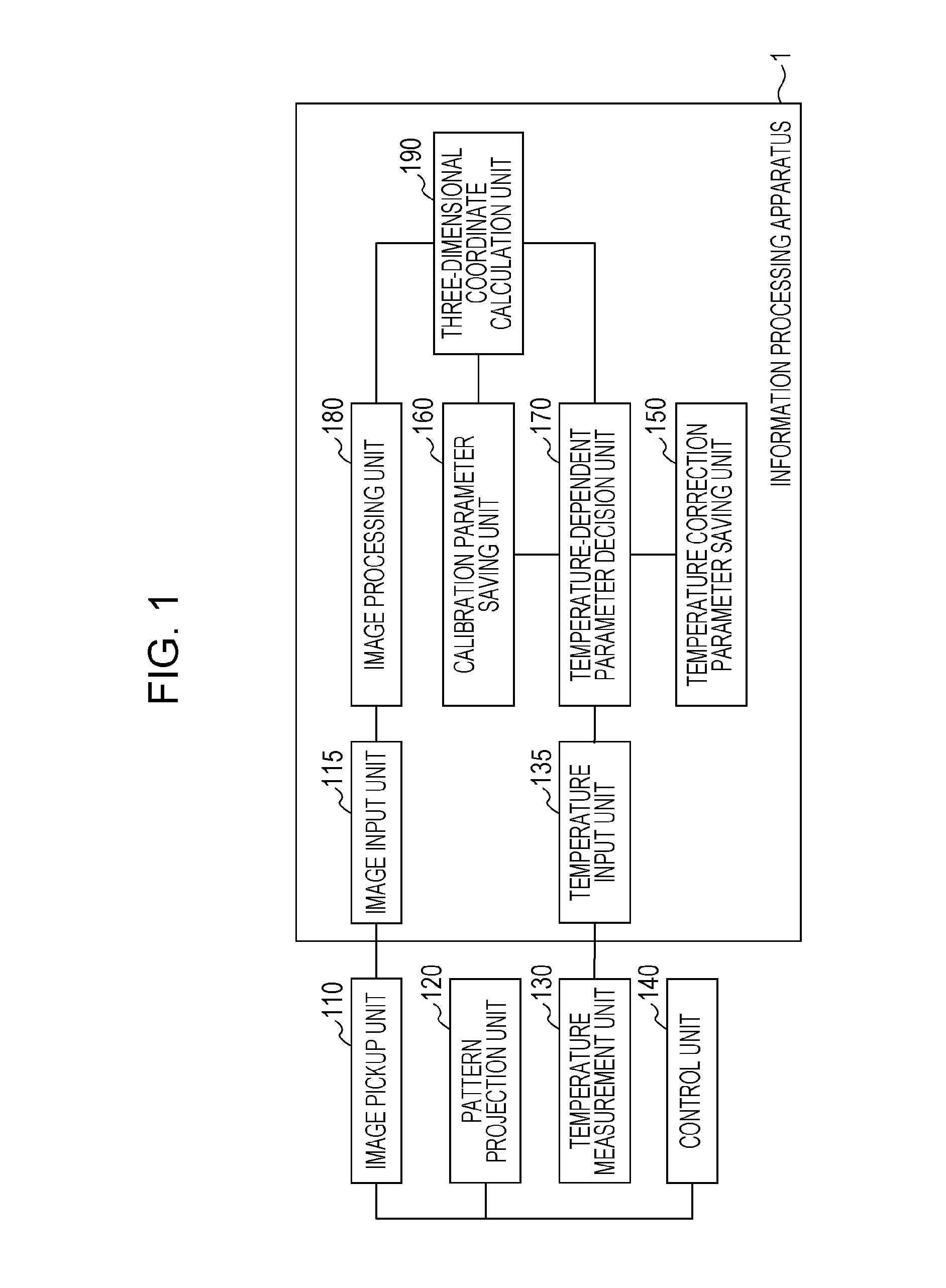

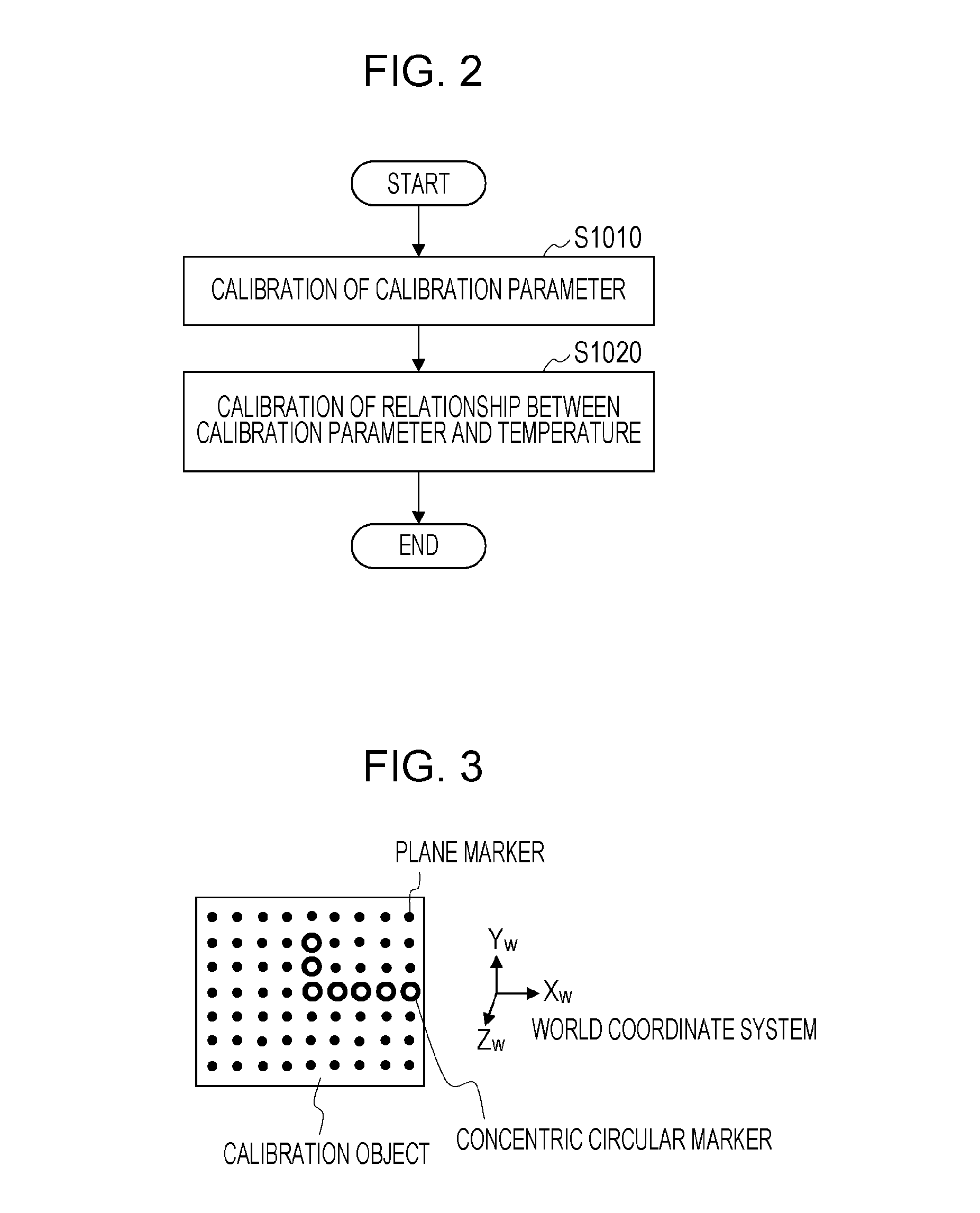

Information processing apparatus, method, and storage medium

ActiveUS20150124055A1Using optical meansSteroscopic systemsInformation processingControl engineering

To perform a high-accuracy three-dimensional measurement by performing an appropriate calibration in accordance with various temperature changes, an information processing apparatus that decides a temperature-dependent parameter of a projection apparatus configured to project a pattern onto a measurement target object to perform a three-dimensional measurement includes a holding unit configured to hold a relationship in which the temperature-dependent parameter of the projection apparatus is set as a temperature function, a temperature input unit configured to input a temperature of the projection apparatus, and a temperature-dependent parameter decision unit configured to decide the temperature-dependent parameter of the projection apparatus based on the temperature of the projection apparatus which is input by the temperature input unit and the relationship.

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com