Collimating lens and projection module

A lens and collimation technology, which is applied in the field of camera lenses, can solve problems such as enlarged image points, low yield, and affecting the accuracy of three-dimensional object outline restoration, achieving the effect of stable focal length and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

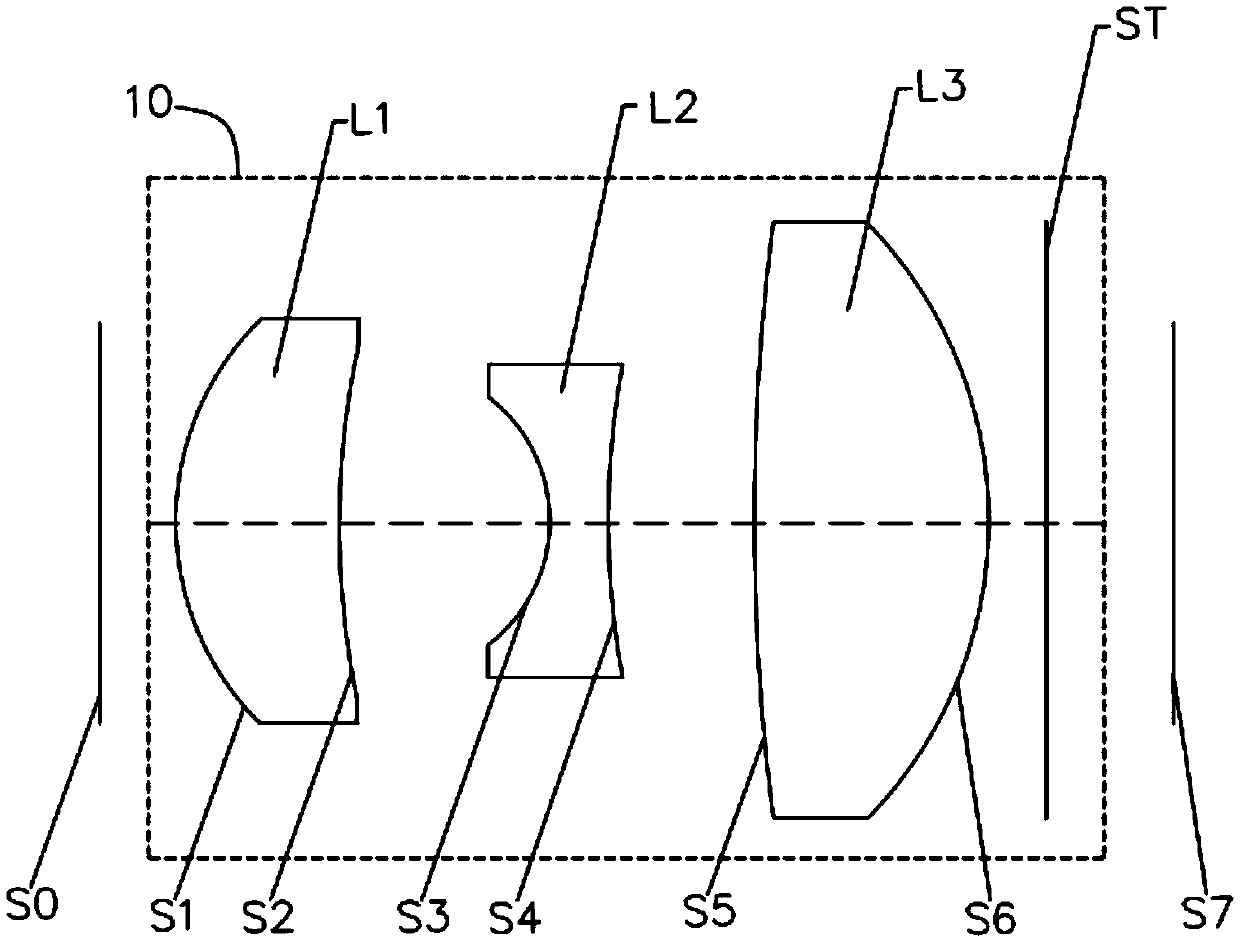

[0087] see figure 1 , a schematic structural diagram of a collimator lens 10 provided in this embodiment, the laser emitter end is set as the object side S0, the measured object end is the image side S7, and the sequence from the object side S0 to the image side S7 includes: the first lens L1, second lens L2, third lens L3 and stop ST.

[0088] The first lens L1 has positive refractive power, the object side S1 of the first lens L1 is a convex surface, and the image side S2 of the first lens L1 is a concave surface.

[0089] The second lens L2 has negative refractive power, and both the object side S3 and the image side S4 of the second lens L2 are concave.

[0090] The third lens L3 has positive refractive power, the object side S5 of the third lens L3 is concave and the image side S6 is convex.

[0091] The stop ST is located between the third lens L3 and the object to be measured. The optical centers of each lens are located on the same straight line, and each lens is ma...

no. 2 example

[0105] The structural representation of the collimating lens 20 of the present embodiment can refer to Figure 5 . This embodiment is roughly similar to the lens structure diagram of the first embodiment, except that the relevant parameters of each lens are different.

[0106] The relevant parameters of each lens in the collimating lens 20 in this embodiment are shown in Table 3.

[0107] table 3

[0108] Surface serial number

r

d

n d

Vd

object plane S0

sphere

—

0.420

S1

first lens

Aspherical

0.646

0.395

1.640

23.529

S2

Aspherical

1.289

0.823

S3

second lens

Aspherical

-0.513

0.266

1.516

57.038

S4

Aspherical

14.889

0.657

S5

third lens

Aspherical

5.288

0.525

1.640

23.529

S6

Aspherical

-1.233

0.350

ST

aperture

sphere

—

300.000...

no. 3 example

[0115] The structural representation of the collimating lens 30 of the present embodiment can refer to Figure 9 , this embodiment is roughly similar to the lens structure diagram of the first embodiment, except that the relevant parameters of each lens are different.

[0116] The relevant parameters of each lens in the collimating lens 30 in this embodiment are shown in Table 5.

[0117] table 5

[0118] Surface serial number

r

d

n d

Vd

object plane S0

sphere

—

0.250

S1

first lens

Aspherical

0.647

0.524

1.640

23.529

S2

Aspherical

1.412

0.592

S3

second lens

Aspherical

-0.726

0.170

1.640

23.529

S4

Aspherical

1.232

0.773

S5

third lens

Aspherical

21.774

0.641

1.640

23.529

S6

Aspherical

-1.054

0.400

ST

aperture

sphere

—

300.000 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical path length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com