Projection lamp assembly and projection lamp

A projection lamp and component technology, applied in the field of projection lamps, can solve the problems of falling off, expensive parts, damaged and scrapped parts, etc., and achieve the effects of reducing the possibility of debris, improving the imaging effect, and stabilizing the focal length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038]In order to enable those skilled in the art to better understand the present invention and to define the protection scope of the present invention more clearly, the present invention will be described in detail below with respect to some specific embodiments of the present invention. It should be noted that the following are only some specific implementations of the present invention concept, which are only part of the embodiments of the present invention, and the specific and direct descriptions of the relevant structures are only for the convenience of understanding the present invention, and each specific feature is not a matter of course. , directly limit the scope of implementation of the present invention. Routine selections and replacements made by those skilled in the art under the guidance of the concept of the present invention should be considered within the scope of protection of the present invention.

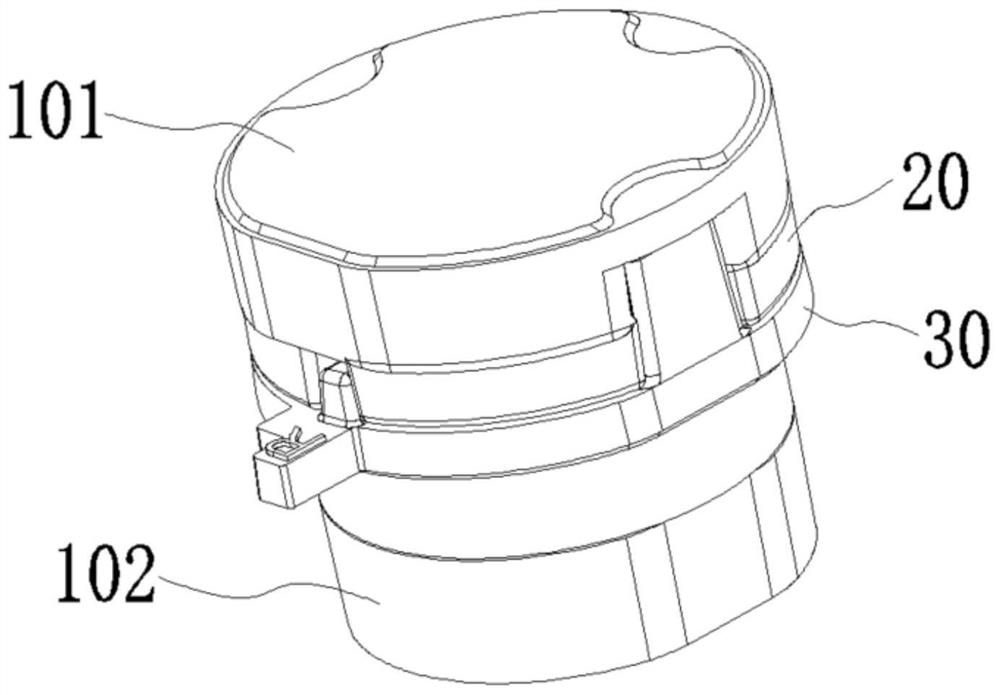

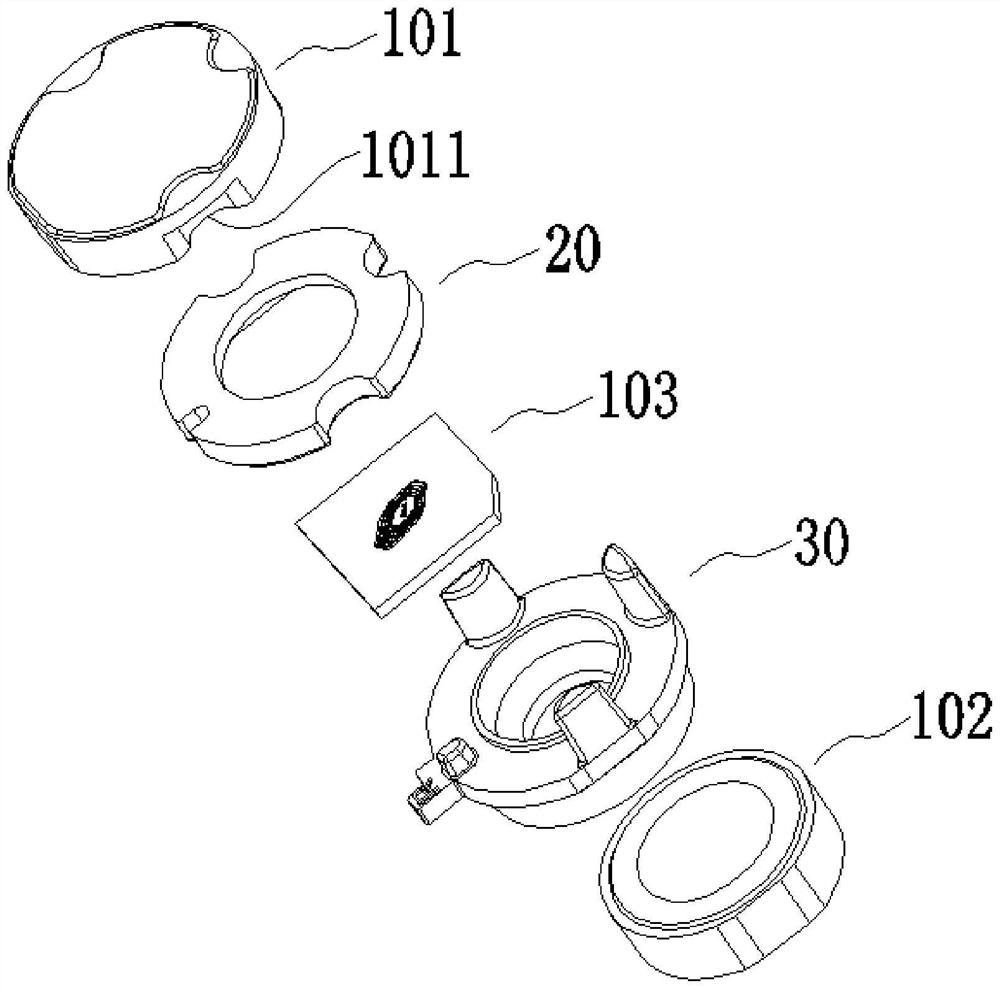

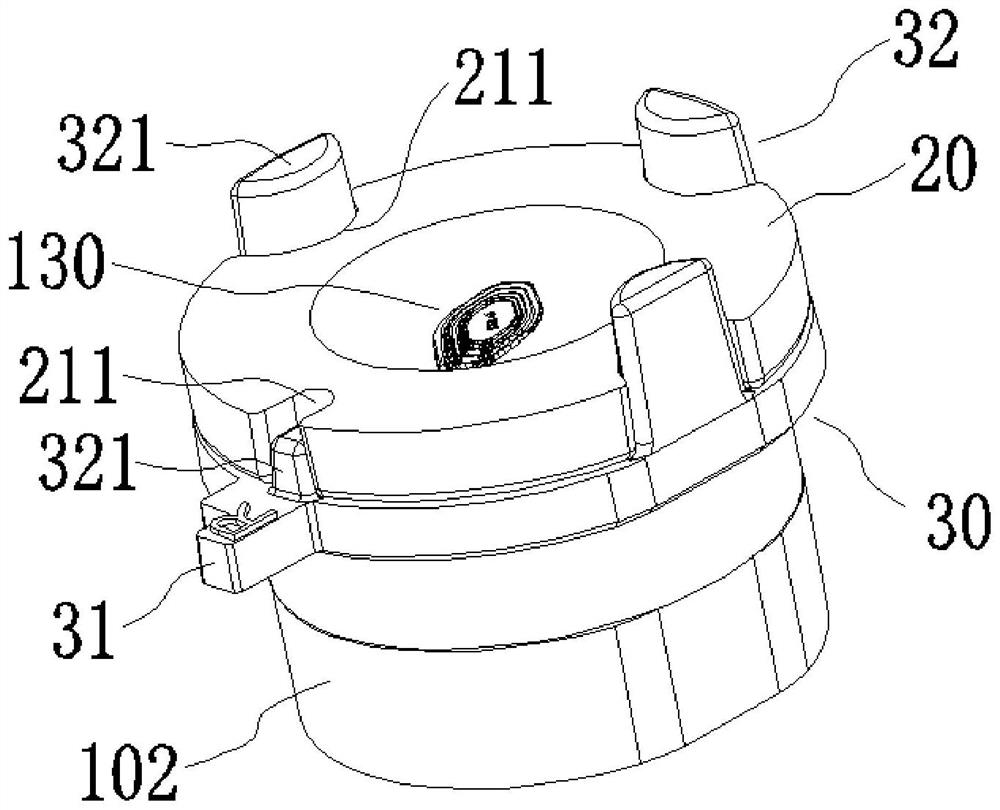

[0039] Such as figure 1 , 2 As shown, a projection la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com