A paper cutting device

A paper and rack technology, applied in the field of paper slitting devices, can solve the problems of paper roll falling, affecting the rewinding of base paper, etc., and achieve the effects of smooth winding, lower center of gravity, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

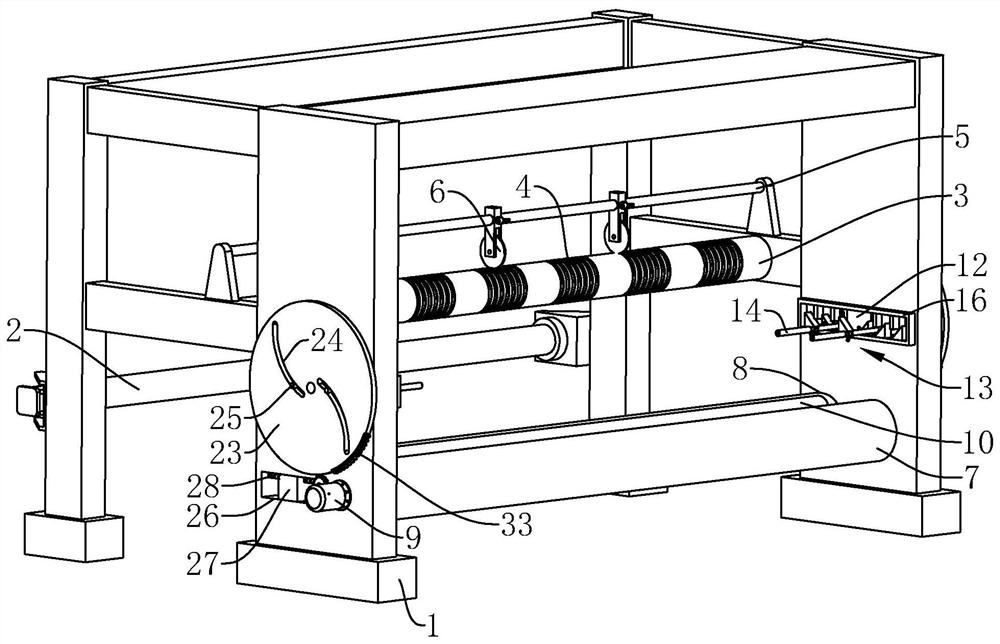

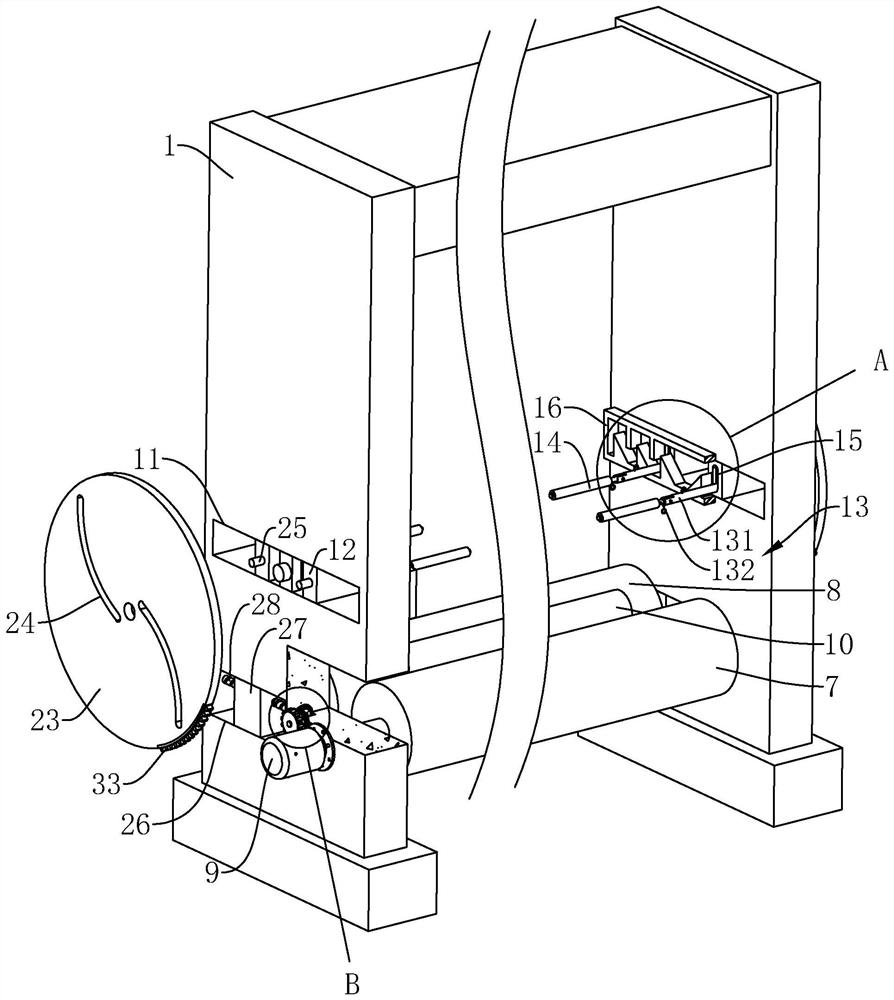

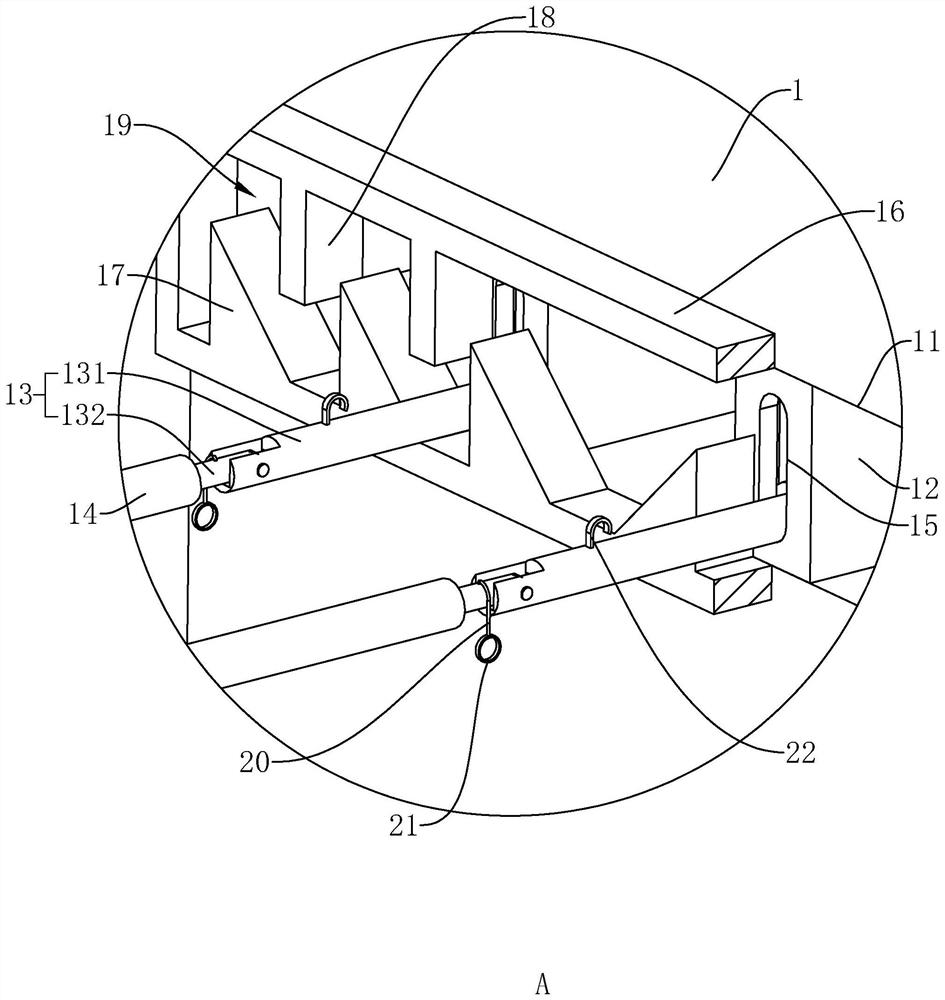

[0037] refer to figure 1 , a paper cutting device, comprising a frame 1, an unwinding roller 2 rotatably connected to the frame 1 and in a horizontal state, a knife roller 3 rotatably connected to the frame 1 and parallel to the unwinding roller 2, an opening The multi-circle knife groove 4 on the knife roller 3, the cross bar 5 installed on the frame 1 and positioned directly above the knife roller 3, the circular knife disc 6 installed on the cross bar 5 and partially embedded in the knife groove 4, The rotation is connected on the frame 1 and is parallel to the main turning roller 7 and the auxiliary turning roller 8 of the unwinding roller 2, is installed on the frame 1 and is used for rotating the motor 9 of the main turning roller 7, and rides on the main turning roller 7 With the wind-up roller 10 between the auxiliary rotating roller 8, the motor 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com