Patents

Literature

60results about How to "Block fall" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

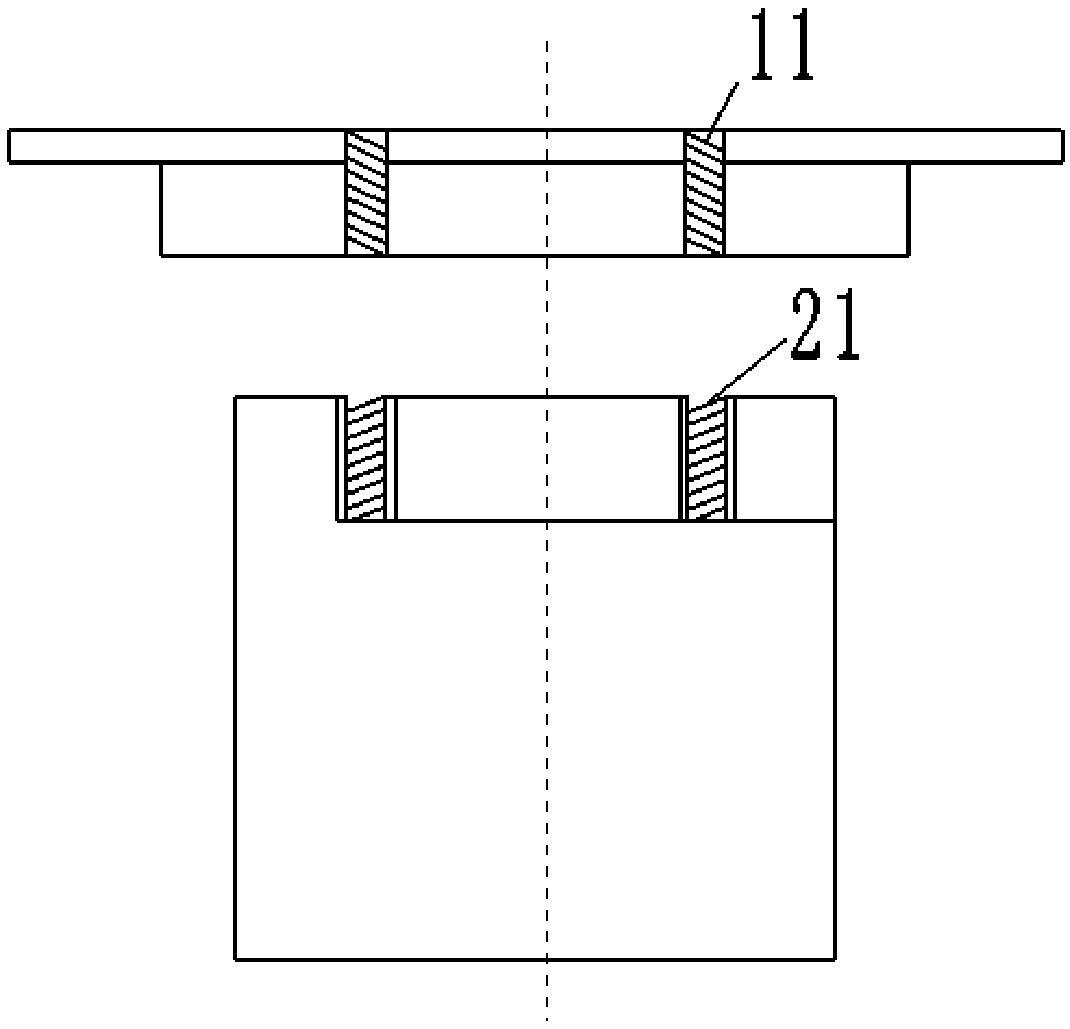

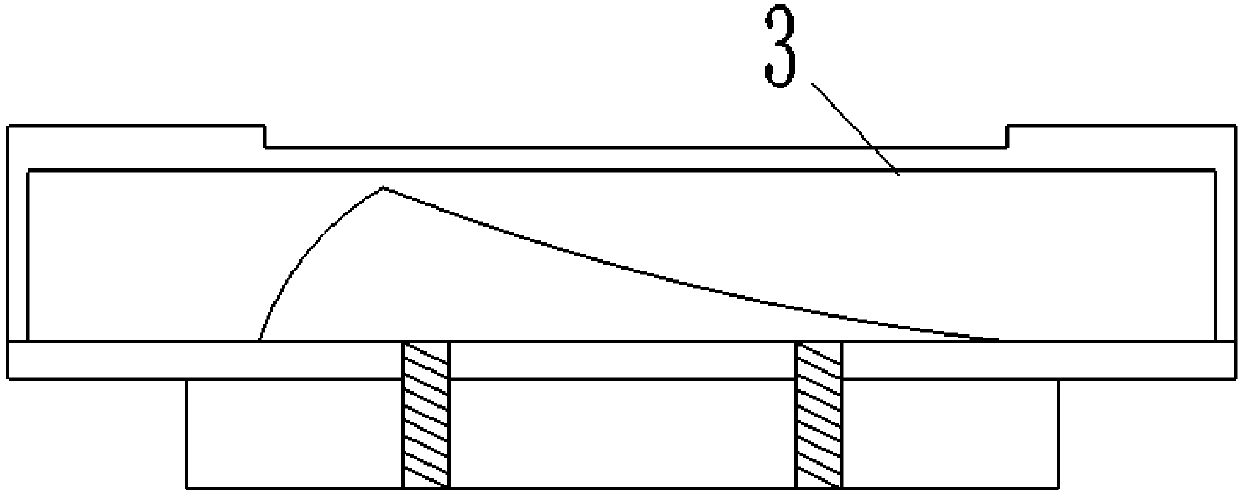

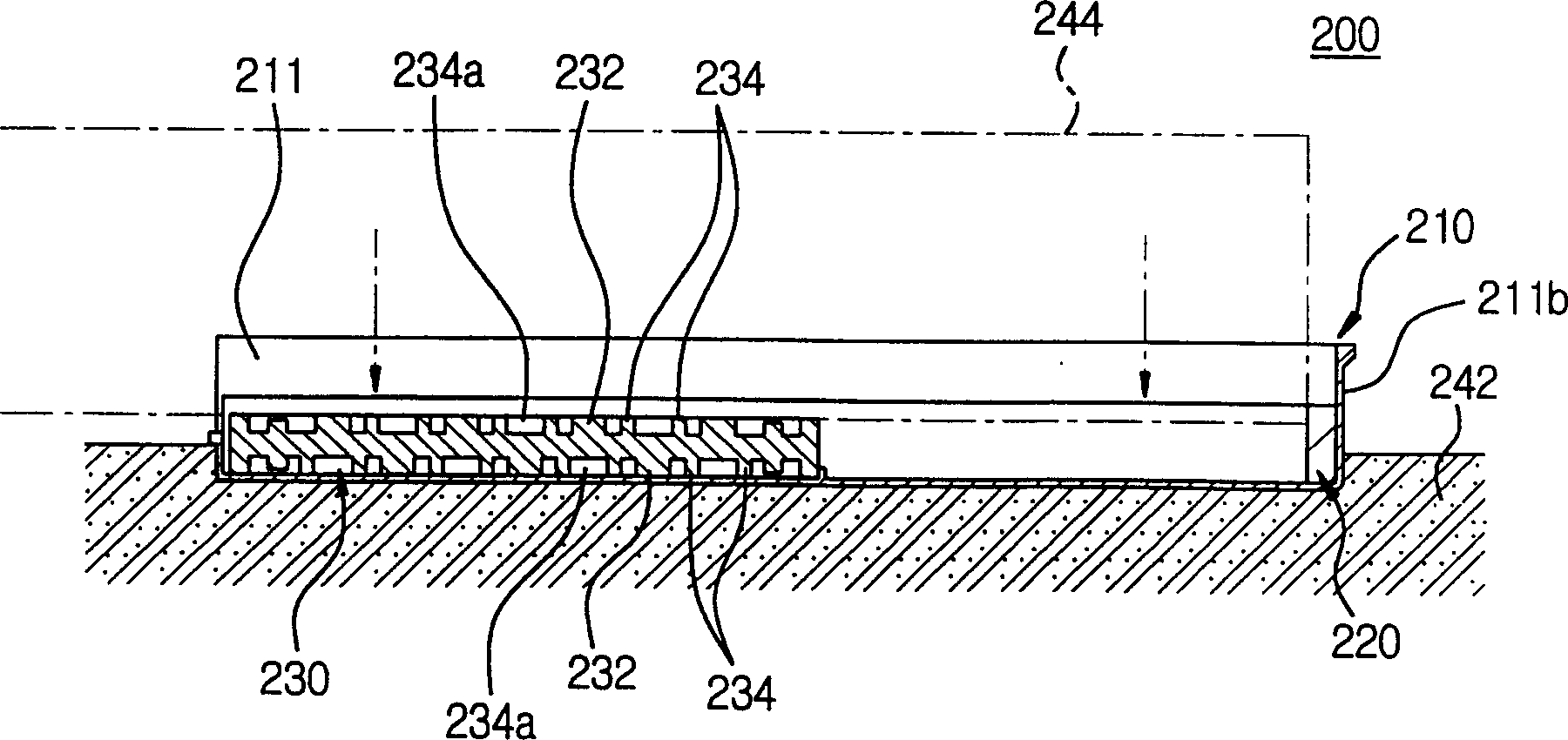

Processing technology of protective plate of PCB (Printed Circuit Board) testing device

InactiveCN101793913AEffective protectionBlock fallElectrical measurement instrument detailsElectrical testingPrinted circuit boardMaximum diameter

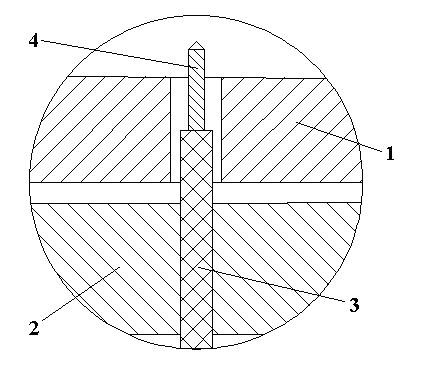

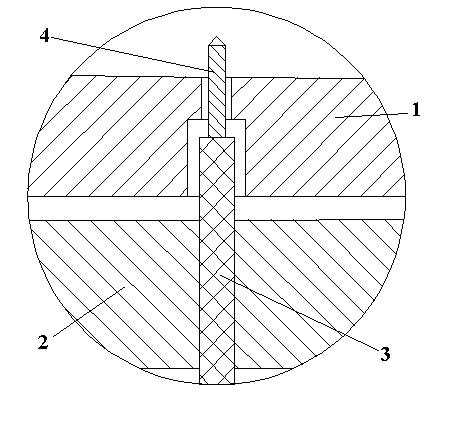

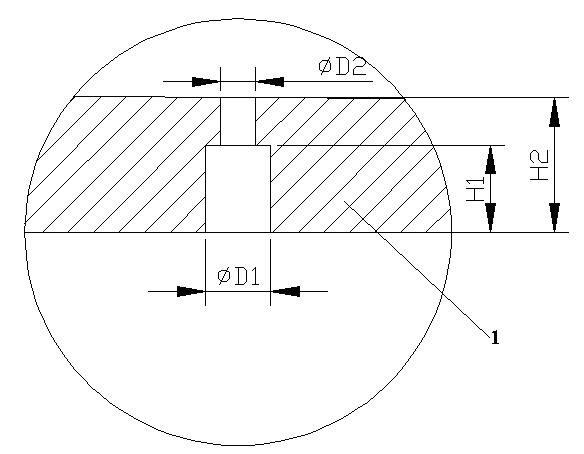

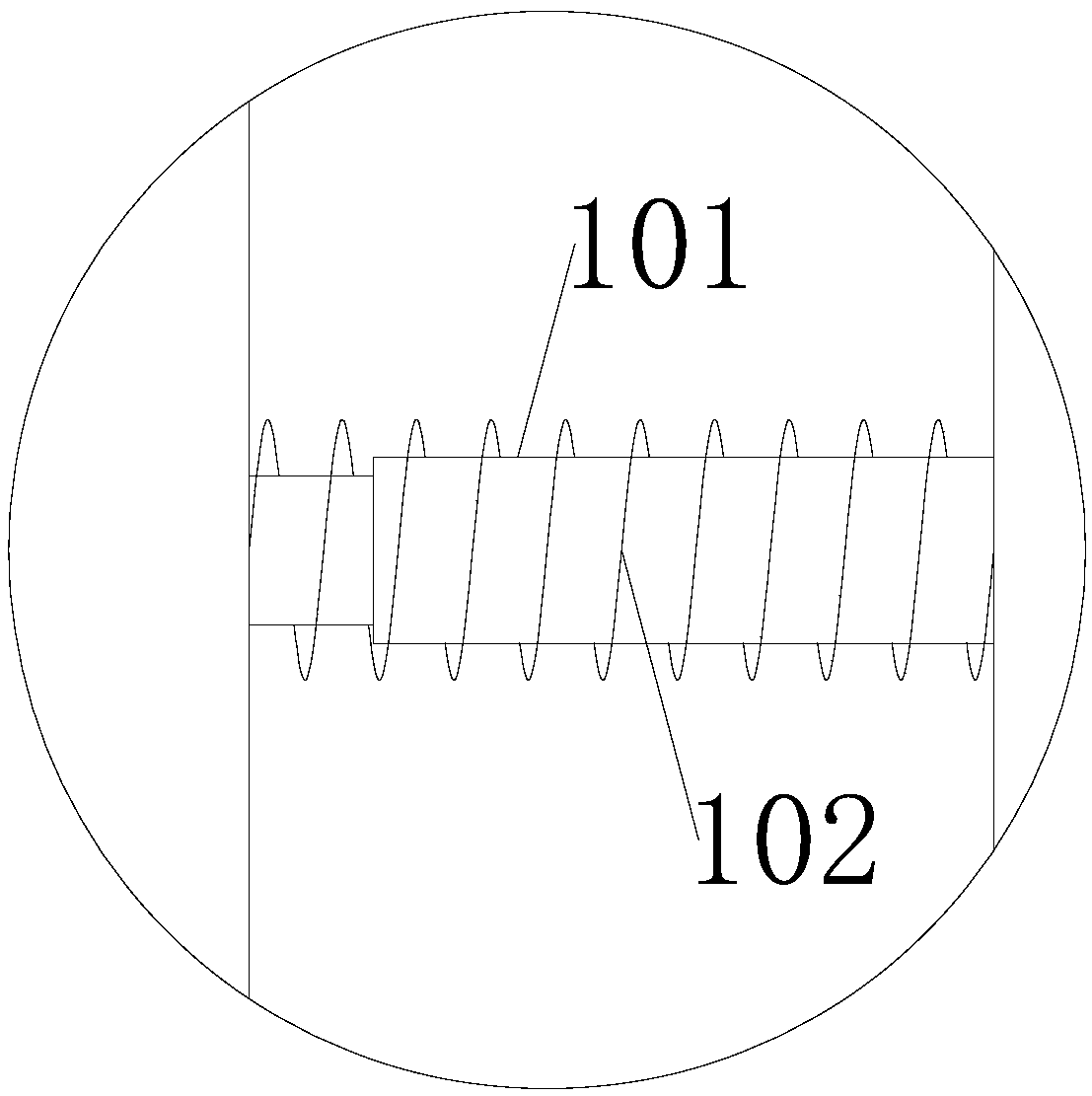

The invention relates to a processing technology of a protective plate of a PCB (Printed Circuit Board) testing device, which comprises the following steps of: a, arranging a blind hole with a diameter of D1 and a depth of H1 on a protective plate surface facing one side of a needle placing plate relative to the position of a testing needle, wherein D1>d1 and h1<H1<h2, d1 is the diameter of a needle sheath of the testing needle, h2 is the depth of the protective plate and h1 is the installation height of the needle sheath of the testing needle; and b, arranging a through hole in the reverse position of the protective plate with the processed blind hole, wherein the diameter of the through hole is D2, the depth of the through hole is equal to that of the blind hole, D1>D2>d2, and d2 is the maximum diameter of a needle rod of the testing needle. The invention meets different hole diameter requirements for the needle sheath and the needle rod of the testing needle for the protective plate, and enables the protective plate to effectively protect the testing needle, lead and correct the positioning of the testing needle, and effectively obstruct impurities such as tin balls, flux and the like from dropping on the needle sheath of the testing needle and the needle placing plate of the PCB testing device.

Owner:TPV ELECTRONICS (FUJIAN) CO LTD

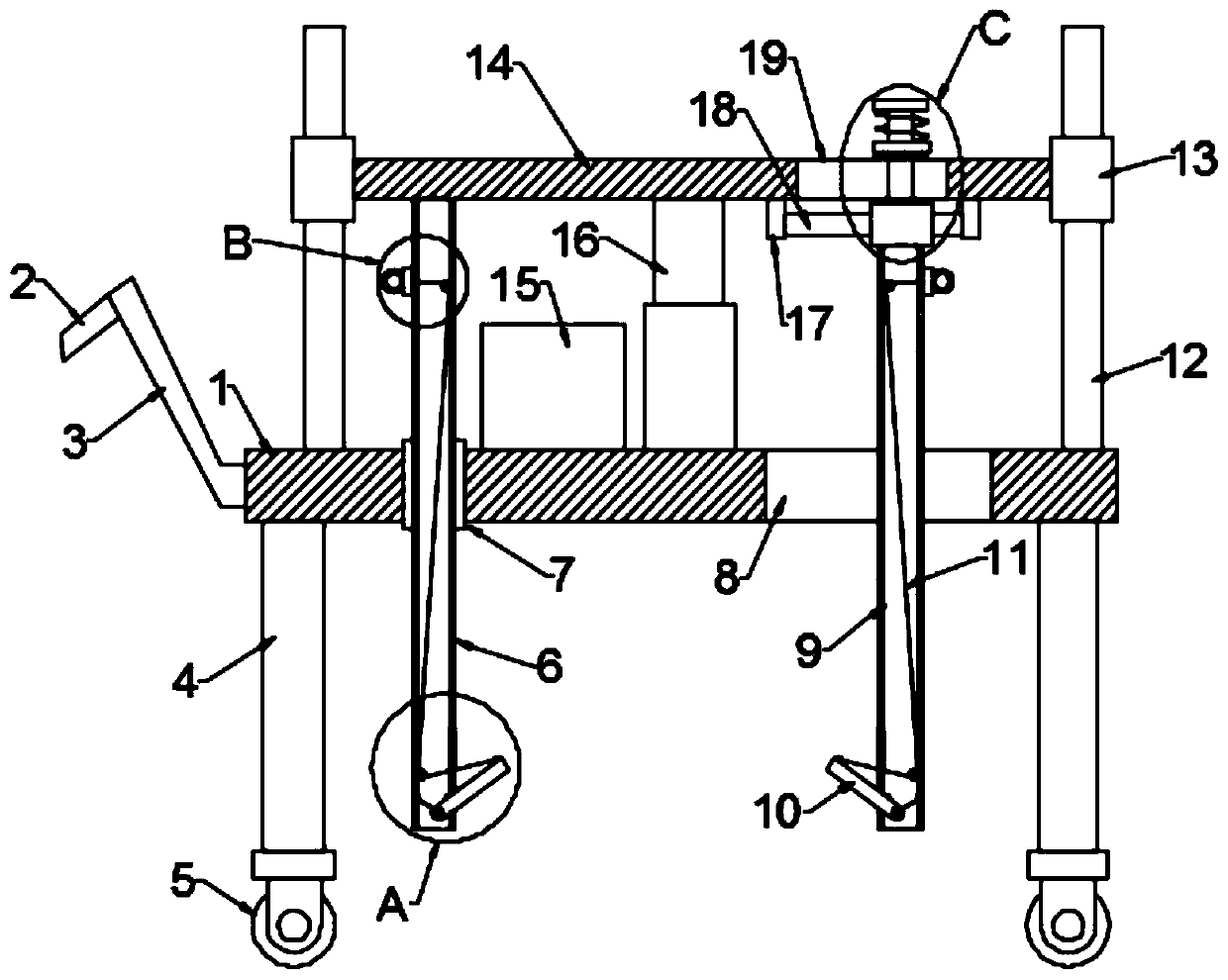

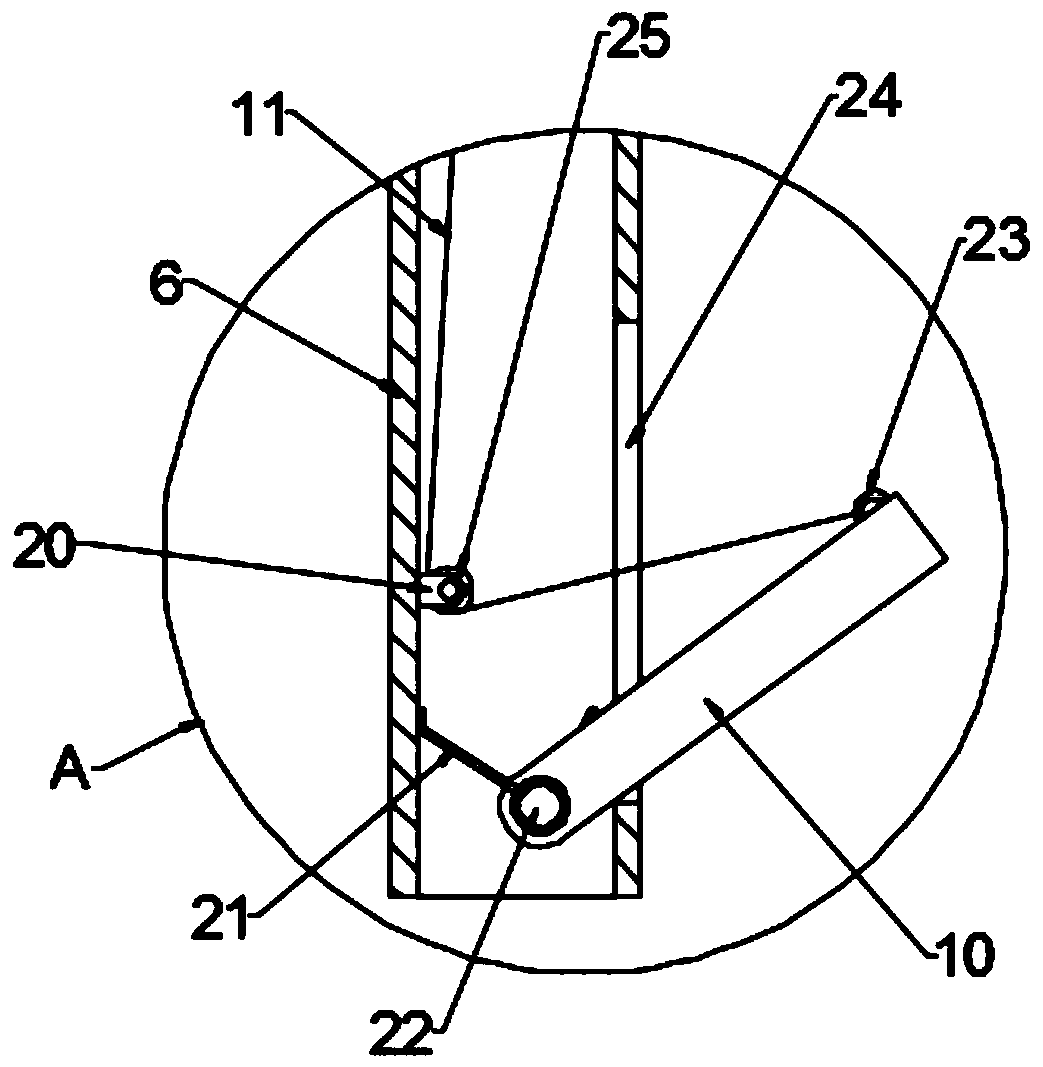

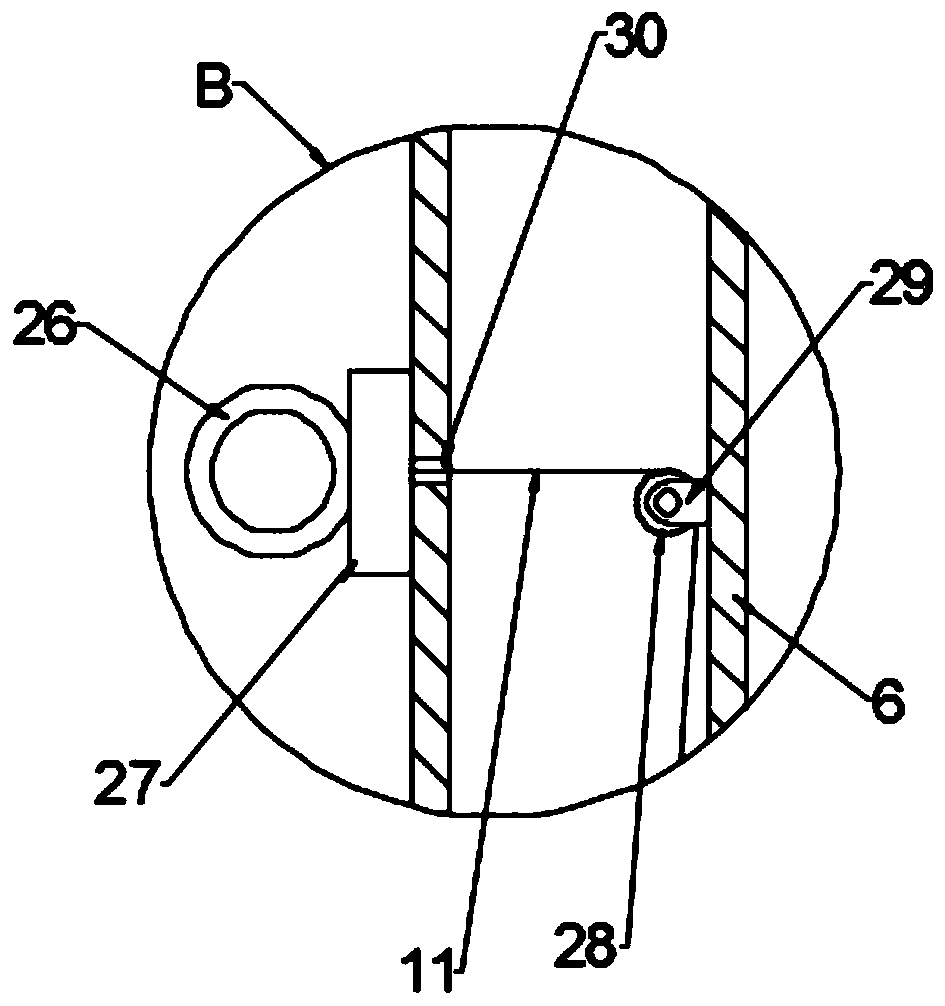

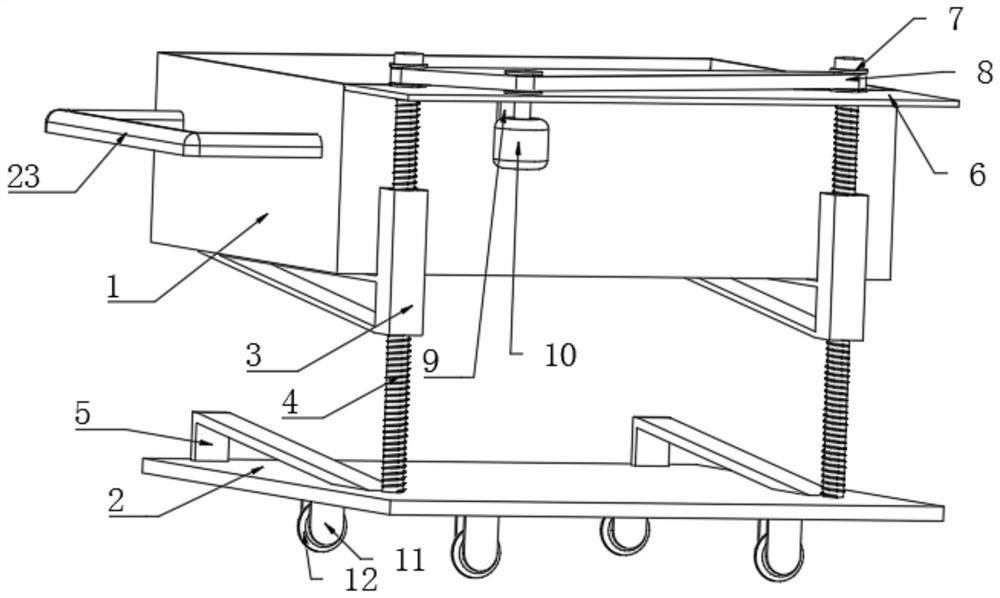

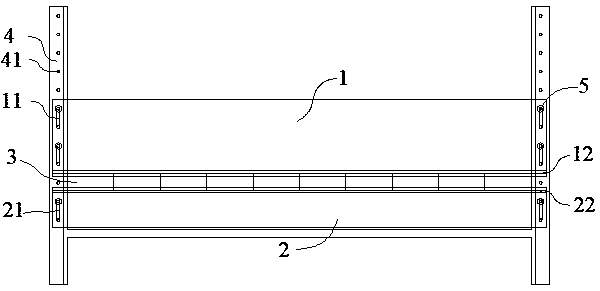

Straw granulator feeding device

PendingCN109399061ARealize splicingEasy to useConveyorsMaterial granulationEngineeringFriction force

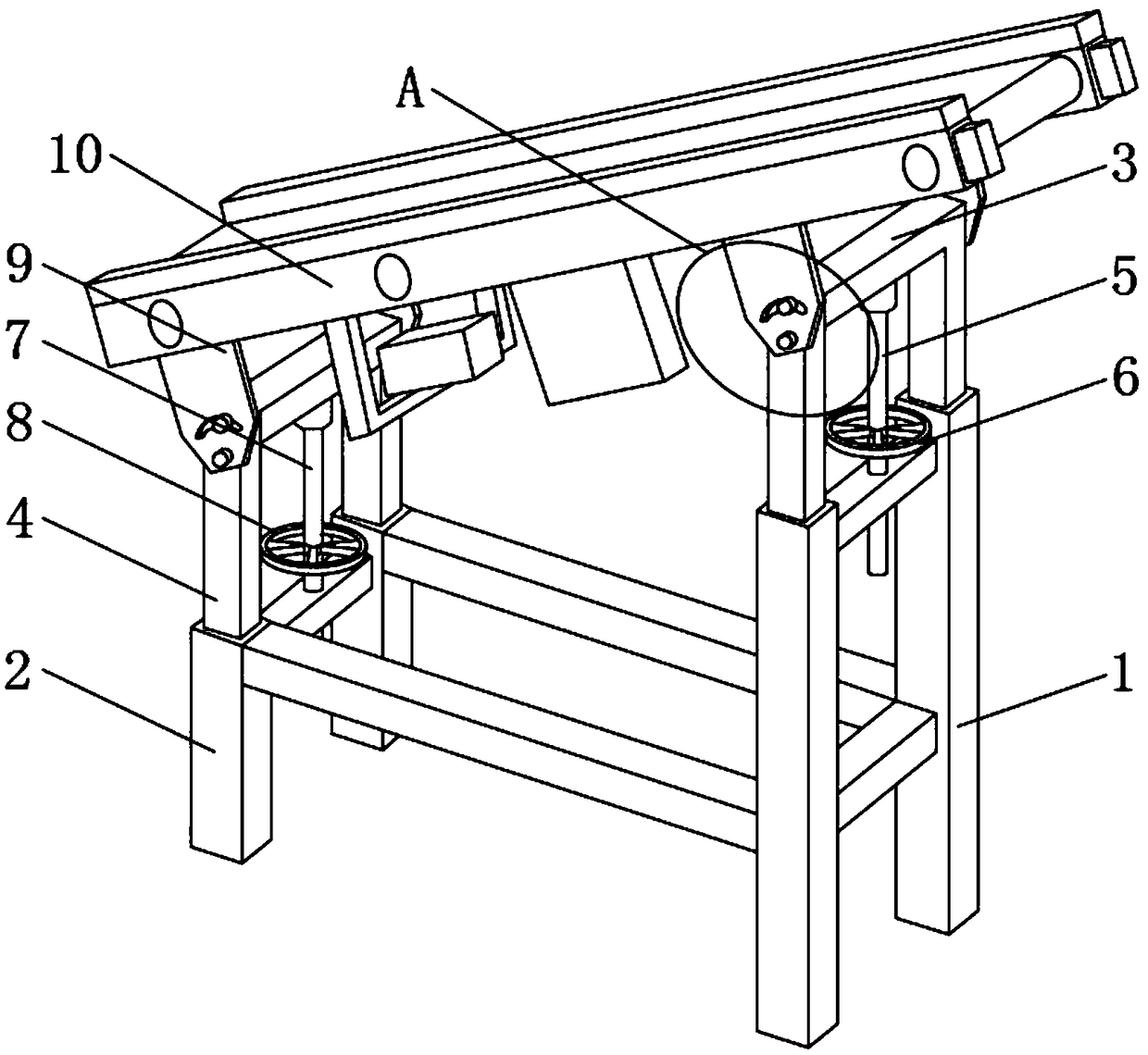

The invention discloses a straw granulator feeding device which comprises a front bottom frame and a rear bottom frame. The front bottom frame and the rear bottom frame are fixedly connected through atransverse brace, the height of the front bottom frame is larger than that of the rear bottom frame, the upper end of the front bottom frame is in sleeved connection with a front telescopic frame, the upper end of the rear bottom frame is in sleeved connection with a rear telescopic frame, and connection pieces are arranged on the two sides of the front telescopic frame and the rear telescopic frame. According to the straw granulator feeding device, splicing of multiple feeding devices can be achieved, the multiple feeding devices can be combined for use according to the needed feeding distance, feeding is better achieved, the feeding efficiency can be improved, sliding caused by the too large inclination angle and insufficient friction force can be avoided, a baffle blocks raw material falling in the conveying process, conveying is better achieved, the inclination angle of a conveying table is adjusted so as to meet the requirement for feeding at different heights, certain practicability is achieved, and a better using prospect is brought.

Owner:安徽翔丰再生能源有限公司

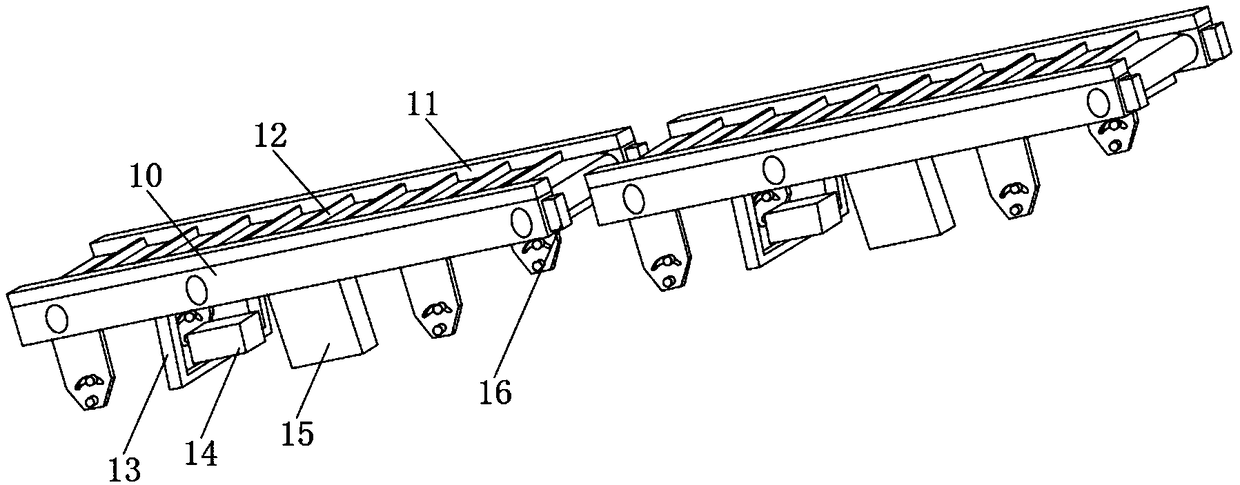

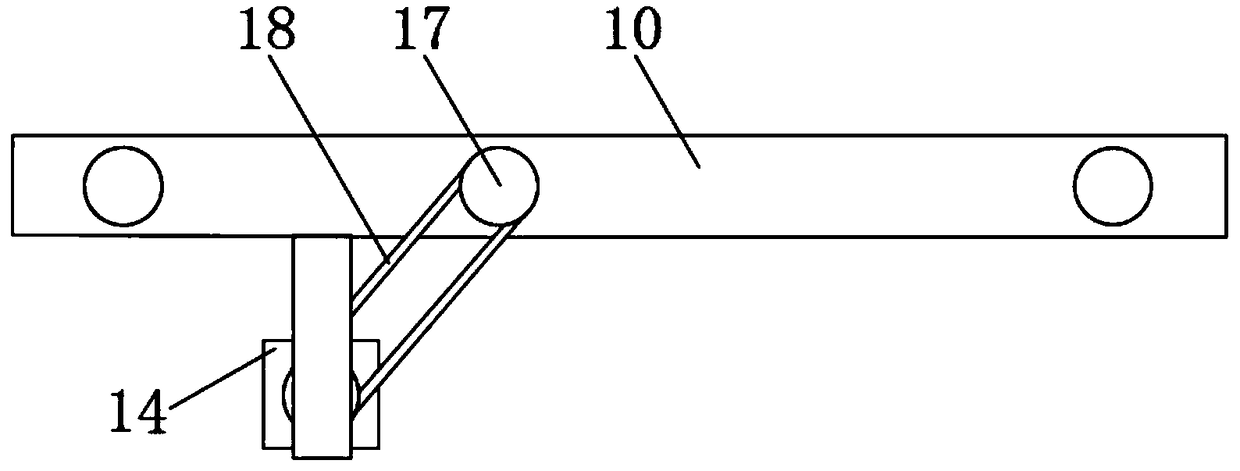

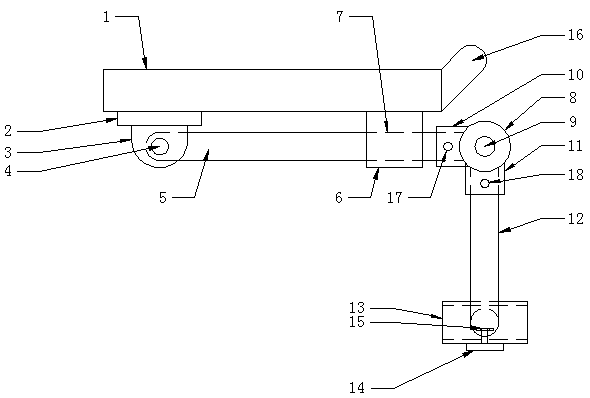

Overturning dinner table on medical sickbed

InactiveCN108836678ASimple structureReduce occupancyNursing bedsAgricultural engineeringDinner table

The invention discloses an overturning dinner table on a medical sickbed. The overturning dinner table includes a dinner table plate, mounting bases are symmetrically arranged on one side of the bottom of the dinner table plate, connectors are arranged at the bottoms of the mounting bases, pins are arranged on the inner sides of the connectors respectively, the connectors are fixedly connected tofirst supporting rods through the pins, clamping blocks are symmetrically arranged on the side, away from the mounting bases, of the bottom of the dinner table plate, a clamping groove is formed in the bottom of each clamping block and matched with the corresponding first supporting rod, a connecting device is arranged at the end, away from the corresponding mounting base, of each first supportingrod and provided with a locking button, a first connecting sleeve is arranged on the side, close to the corresponding mounting base, of each connecting device, and one end of each first supporting rod extends to the inner side of the corresponding first connecting sleeve; a second connecting sleeve is arranged at the bottom of each connecting device, a second supporting rod is arranged at the bottom of each second connecting sleeve and is of an L-shaped structure, and the top of each second supporting rod extends to the inner side of the corresponding second sleeve. The overturning dinner table has the advantages of being much simpler in structure and capable of being folded for storage and reducing spatial occupation.

Owner:蚌埠市诚海医疗器械有限公司

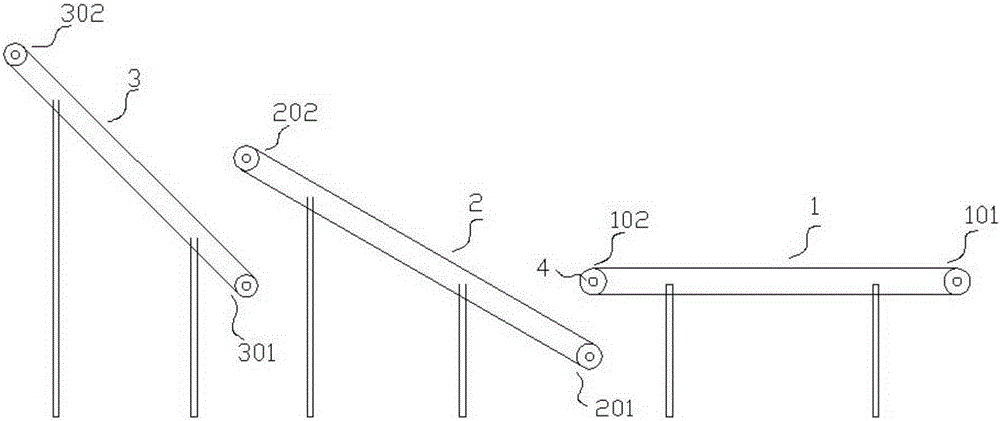

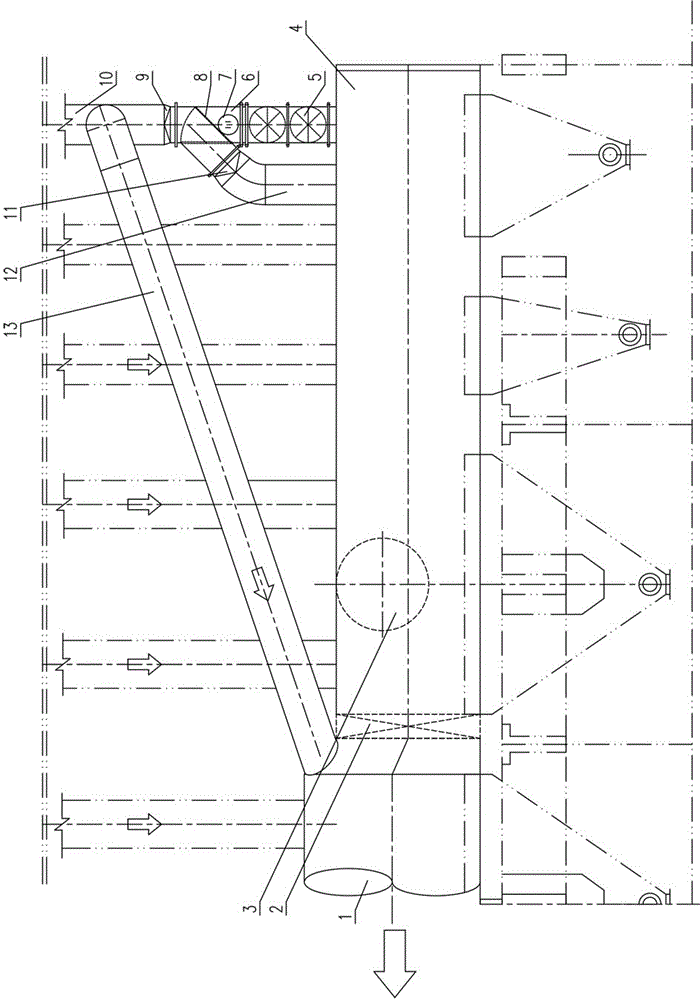

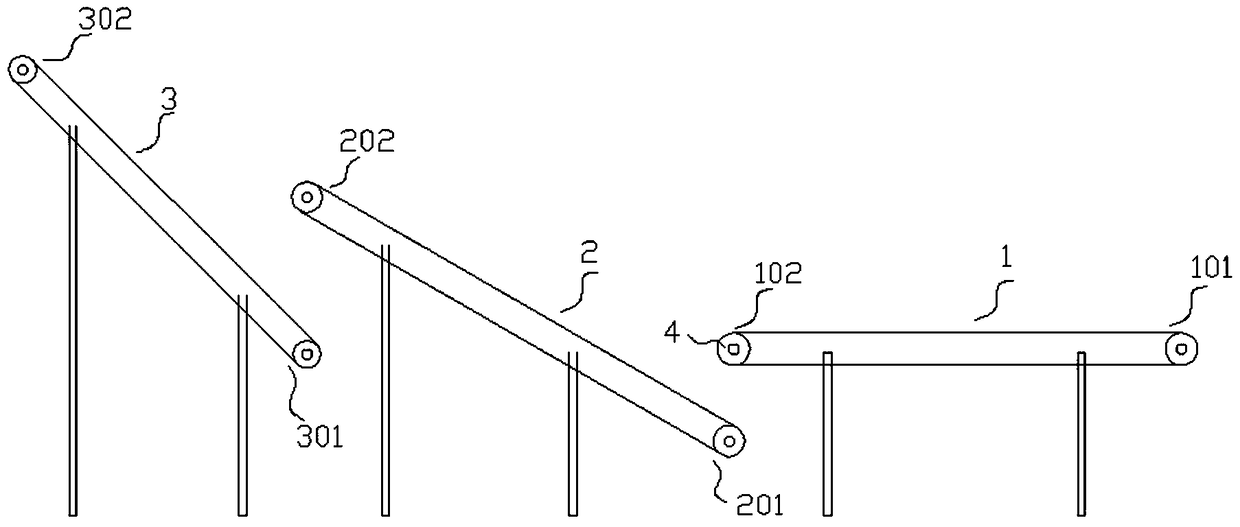

Paper mill fuel conveying device with screening function

ActiveCN105292986AEasy to separateImprove efficiencyLoading/unloadingLump/pulverulent fuel feeder/distributionScreening effectEngineering

The invention discloses a paper mill fuel conveying device with the screening function. The paper mill fuel conveying device comprises a first conveying belt, a second conveying belt and a third conveying belt. Baffles are erected on the two sides of the first conveying belt to define the first conveying belt into a containing space with an opening in the upper portion. The first conveying belt is horizontally arranged, and one end of the first conveying belt serves as an output end. The second conveying belt inclines relative to the ground by 25 degrees to 35 degrees, the lower end of the second conveying belt is overlapped below the output end of the first conveying belt, and at least one rotary thumbing handle is erected above the middle portion of the second conveying belt to thumb raw materials on the second conveying belt to be flat. The third conveying belt inclines relative to the ground by 40 degree to 50 degrees, and the lower end of the third conveying belt is arranged below the higher end of the second conveying belt to receive falling materials. Conveying and screening can be integrated, the structure is simple, the screening effect is good, and time and labor are saved. The raw materials are firstly layered while the raw materials are conveyed, fuel with the larger size is separated out firstly, then impurities and fuel are separated, and the separation effect is improved.

Owner:SUZHOU XINENG ENVIRONMENTAL SCI & TECH CO LTD

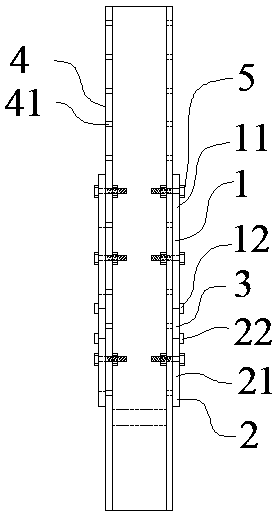

Beam end ballast blocking and sleeper system integrated device

PendingCN111270567APlay the role of ballastSimple structureBallastwayReinforced concreteArchitectural engineering

The invention discloses a beam end ballast blocking and sleeper system integrated device, which comprises a reinforced concrete sleeper, wherein side edge blocking components are arranged at the two ends of the sleeper respectively and jointly form a ballast blocking wall, and the sleeper and the side edge blocking components are connected to the end of a bridge through first connecting pieces. Byapplying the beam end ballast blocking and sleeper system integrated device, a ballast blocking effect can be achieved, the effect of a sleeper can also be achieved, and the sleeper and the side edgeblocking components can be directly constructed and arranged at the end of the bridge at the same time. The integrated device is convenient in construction, effectively seals the end of the bridge, prevents railway ballasts on the bridge from falling off, and can solve the problem that the distance between fasteners does not meet the standard requirement after the ballast blocking wall is arranged at the beam end. The integrated device is simple in structure, convenient to use, small in sudden change of the track structure rigidity during application and good in effect.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

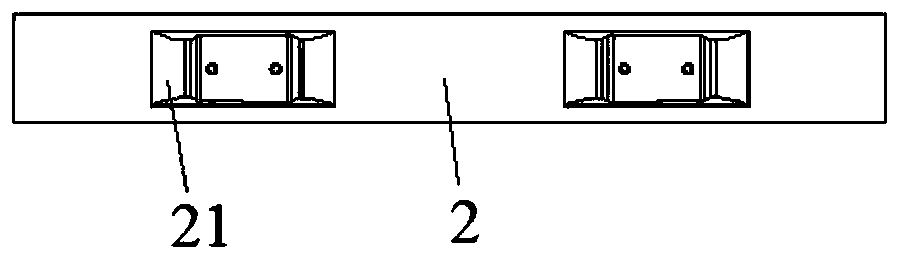

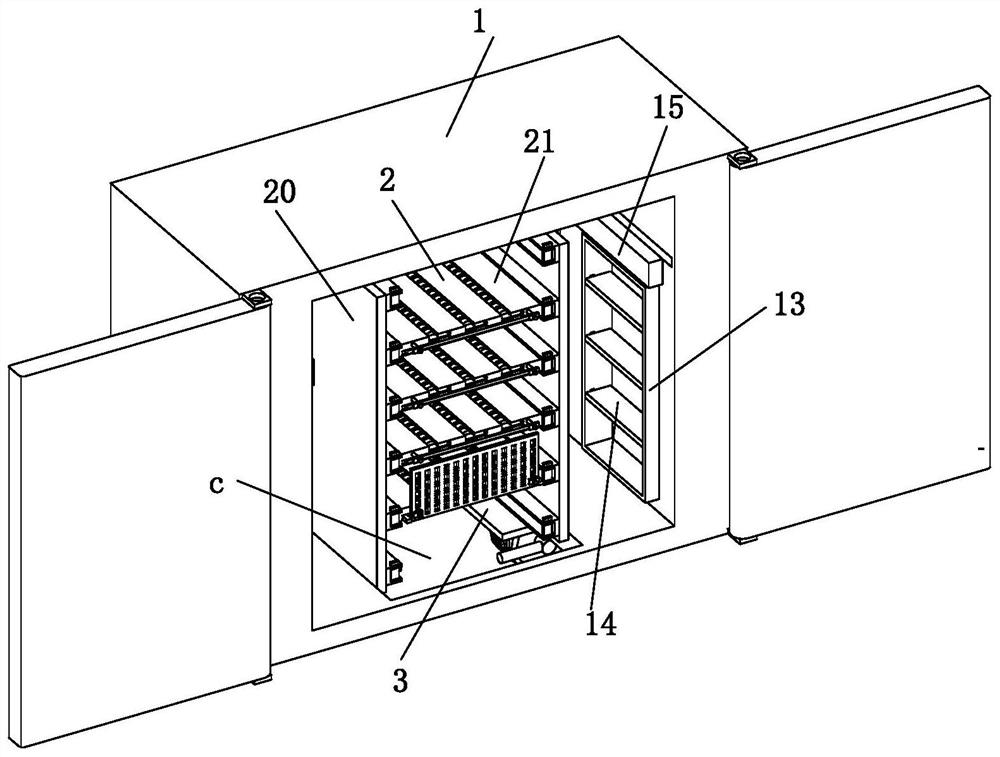

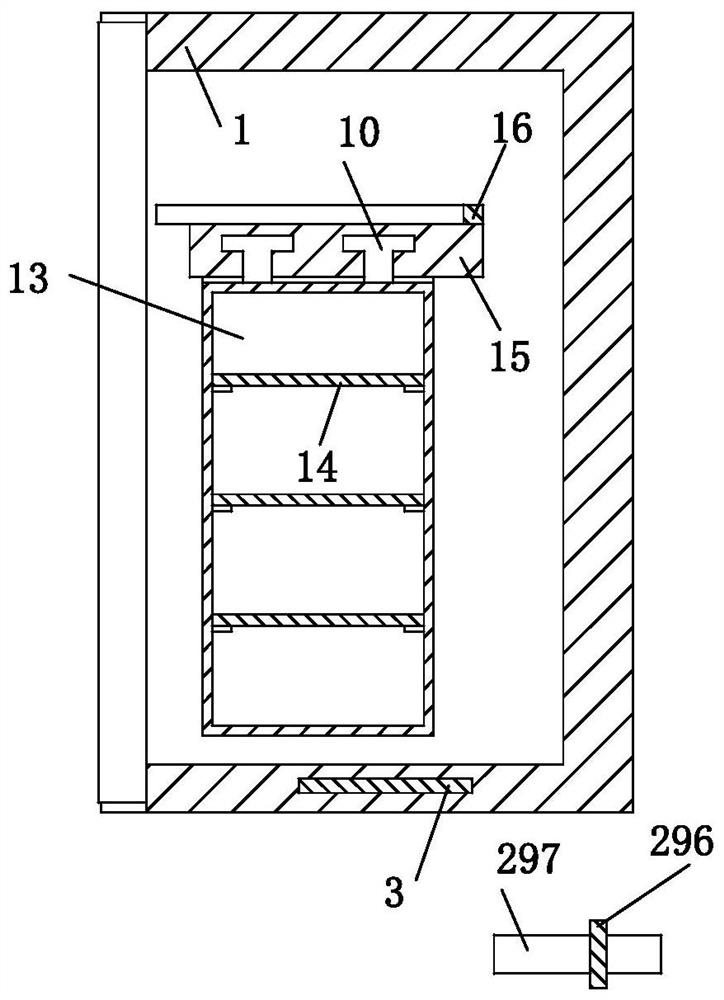

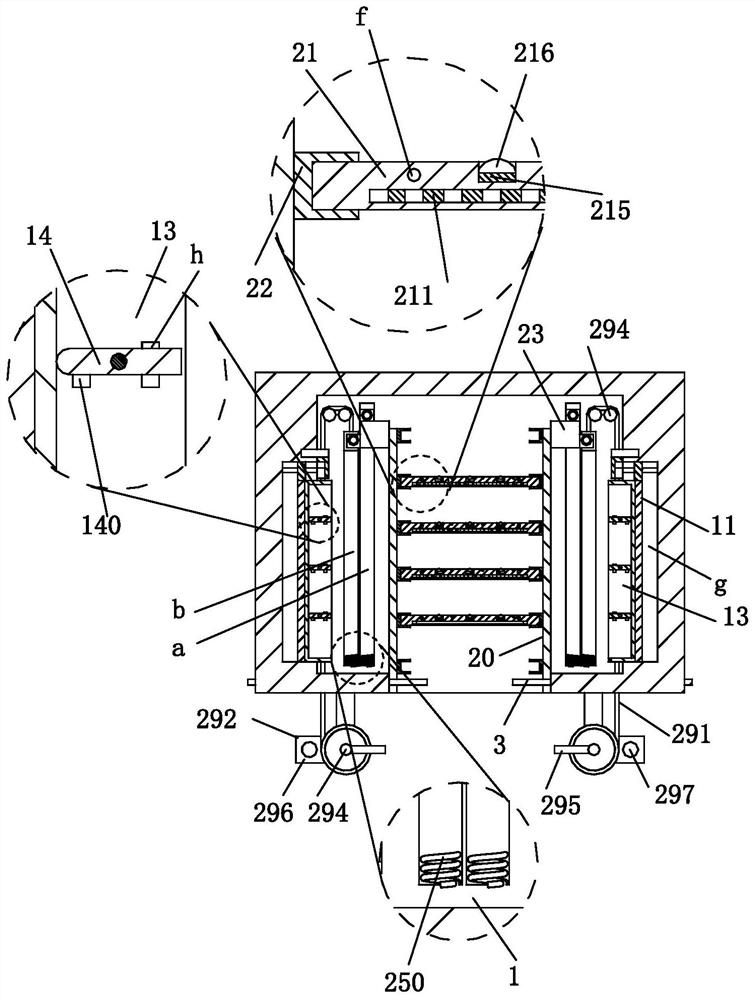

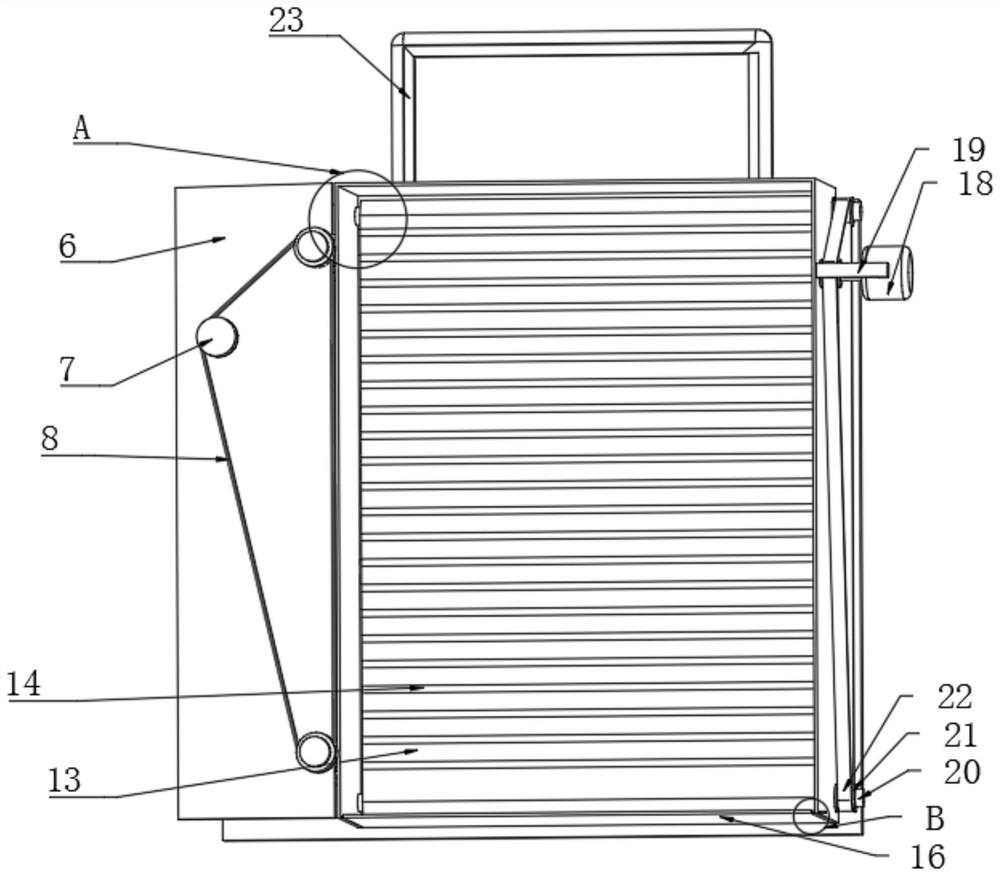

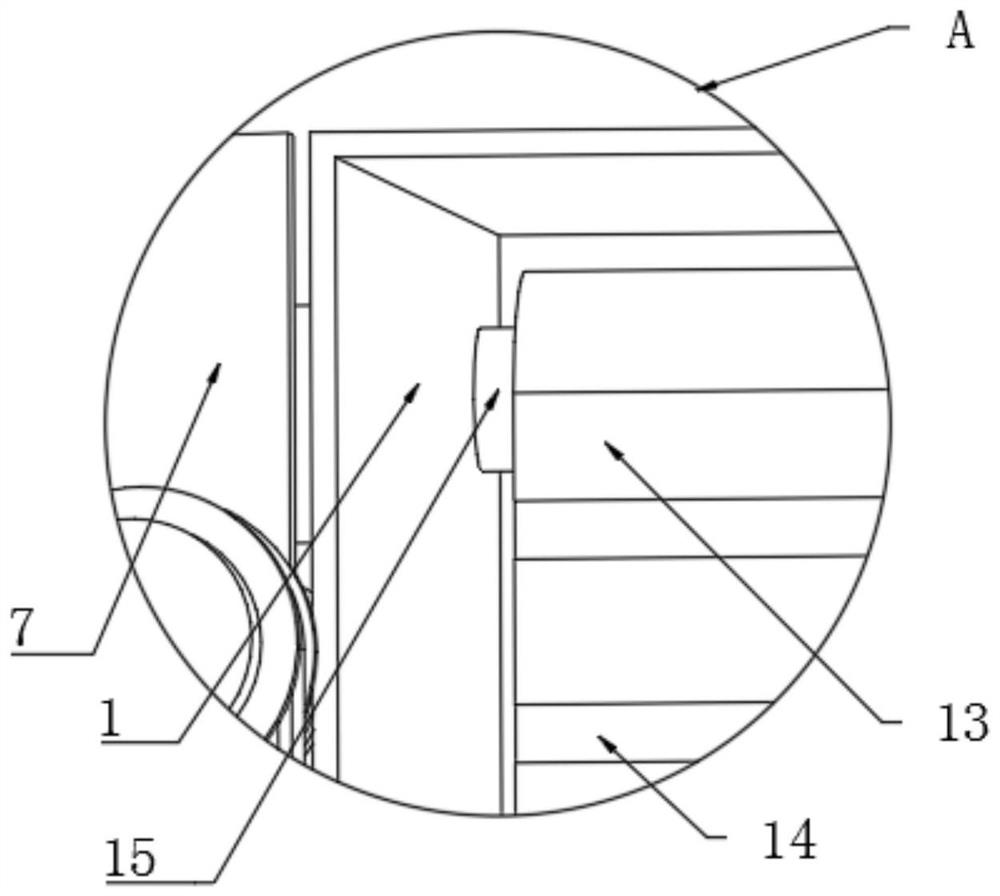

Cabinet with lifting function

ActiveCN113558383AMaximize the use of internal spaceImprove ease of useFurniture partsVariable dimension cabinetsInterior spaceStructural engineering

The invention relates to a cabinet with a lifting function. The cabinet comprises a cabinet body, a lifting mechanism and supporting plates, the cabinet body is hung on an existing wall, the lifting mechanism is arranged in the cabinet body, a rectangular through groove is formed in the middle of the lower end face of the cabinet body, first through grooves are symmetrically formed in the left inner side wall and the right inner side wall of the rectangular through groove, and the supporting plates are clamped in the first through grooves. The cabinet with the lifting function adopts the design concept of a double-lifting mode, three independent article storage structures are arranged in the cabinet, and the three storage structures can be lifted, so that the internal space of the cabinet is utilized to the maximum extent, and meanwhile, the article storage space is also increased; and the lifting mechanism has two lifting modes: an automatic lifting mode and a manual lifting mode, and due to the design of the double lifting modes, the cabinet can still complete the lifting action under the condition of power failure or damage of the manual lifting structure.

Owner:深圳和海枫建设科技有限公司

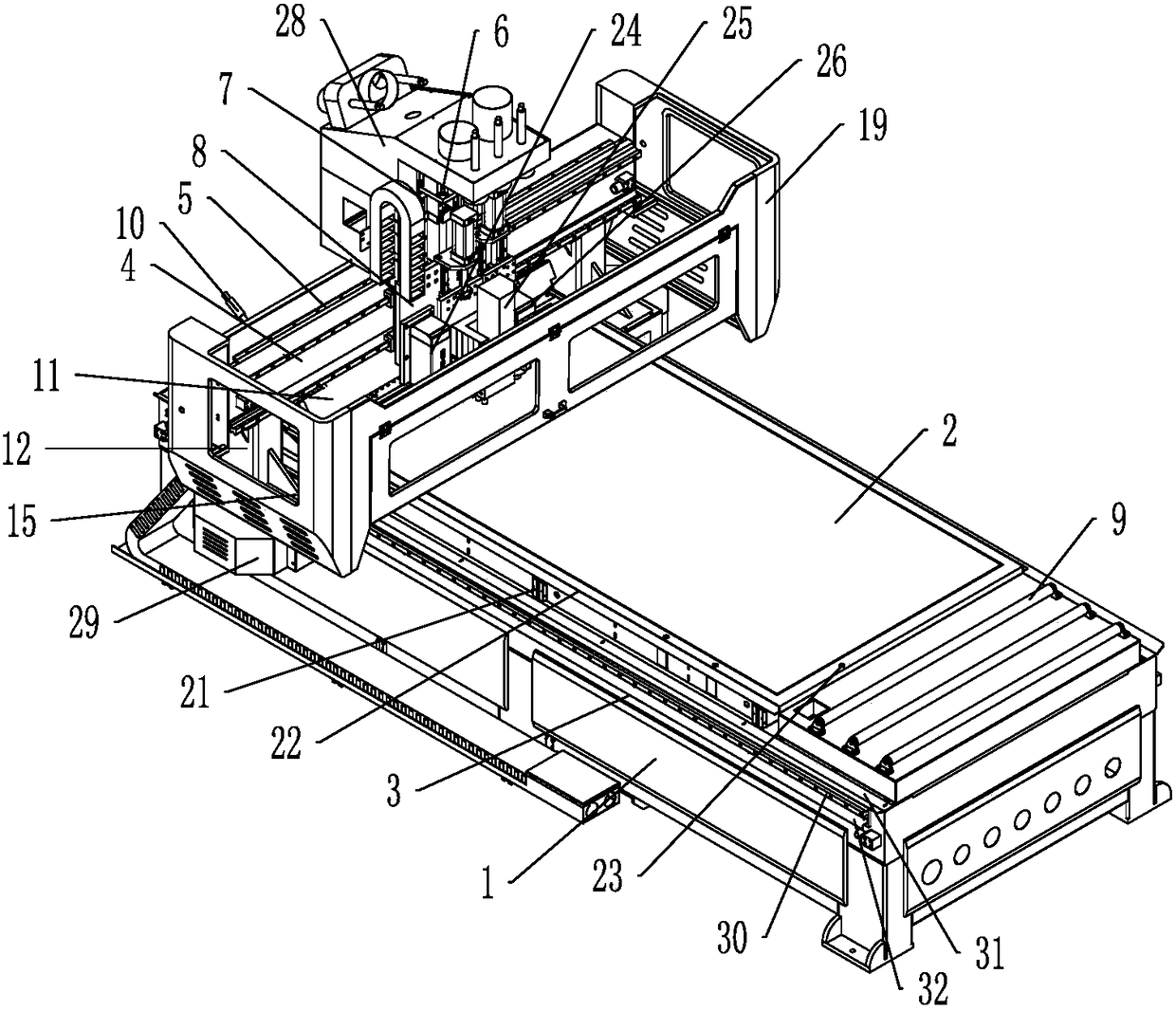

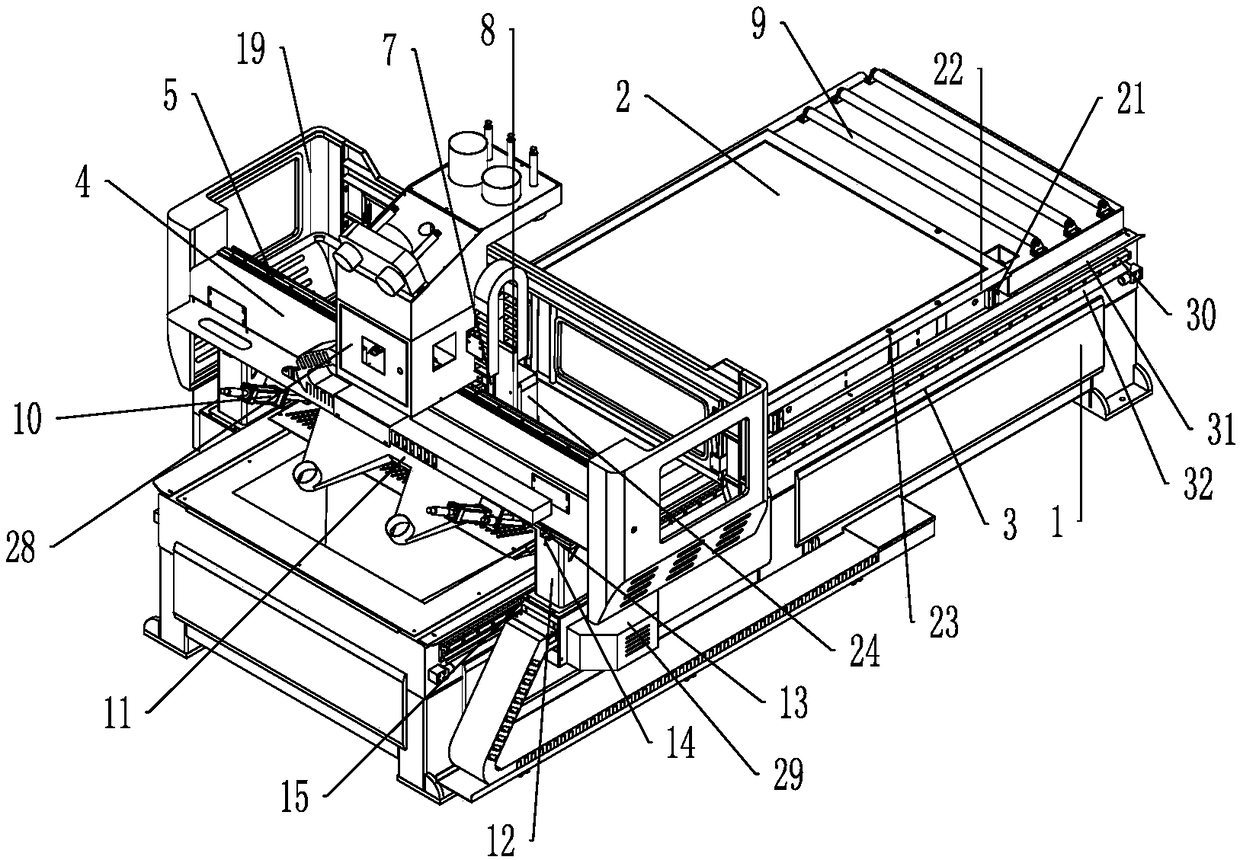

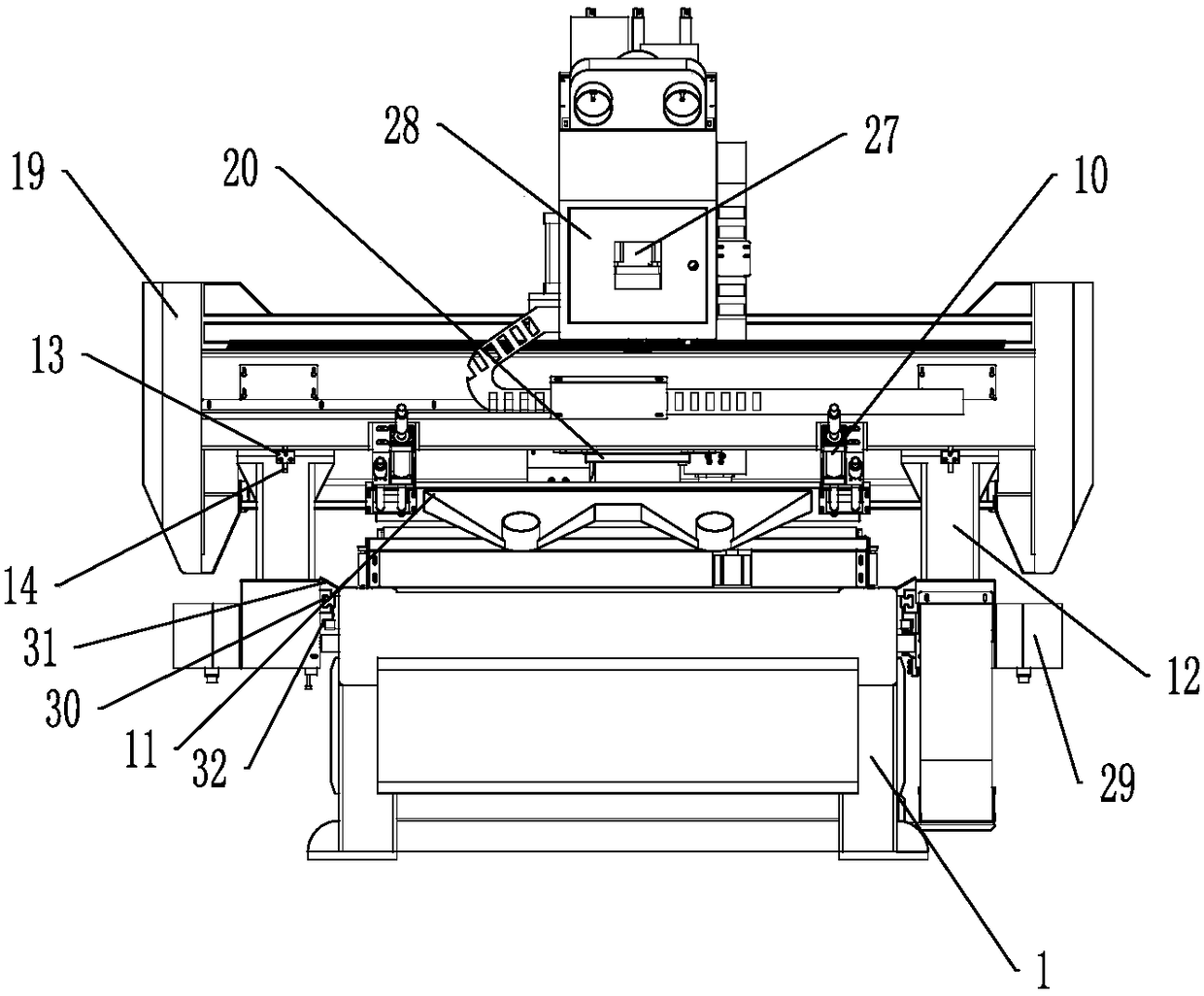

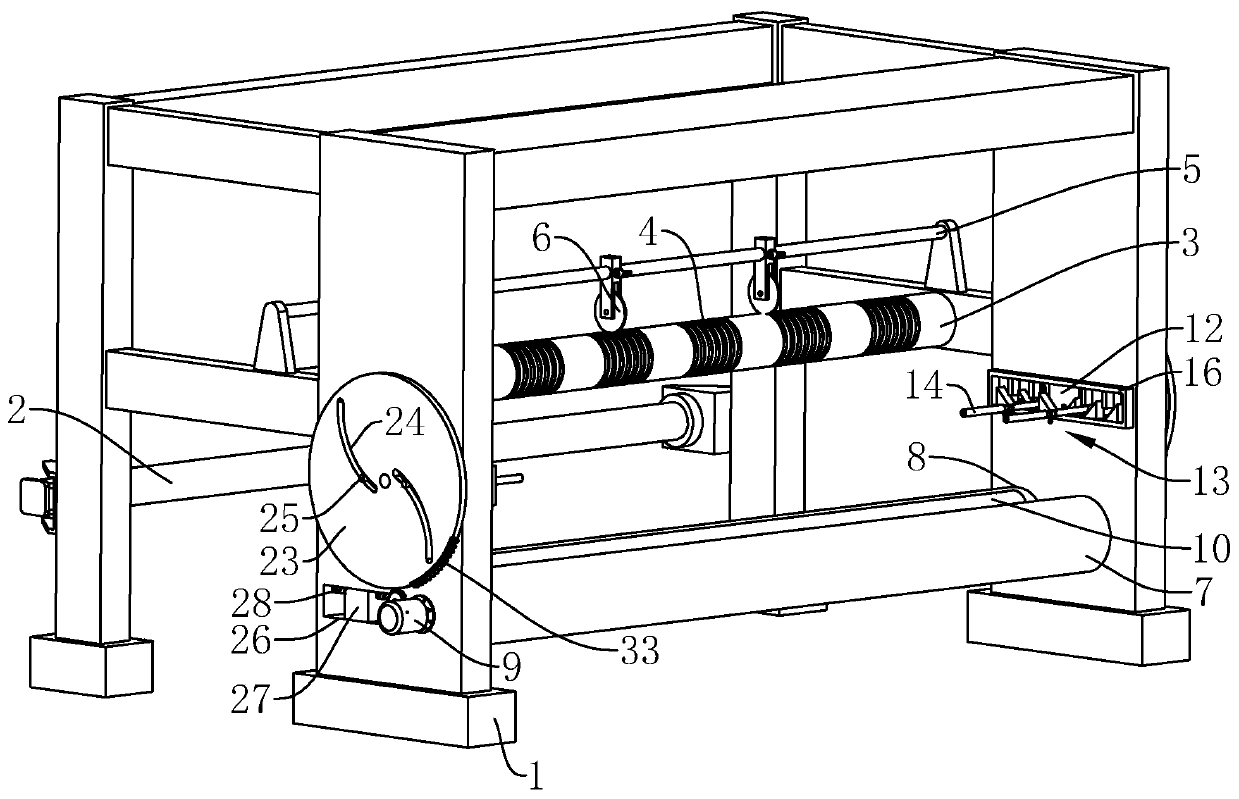

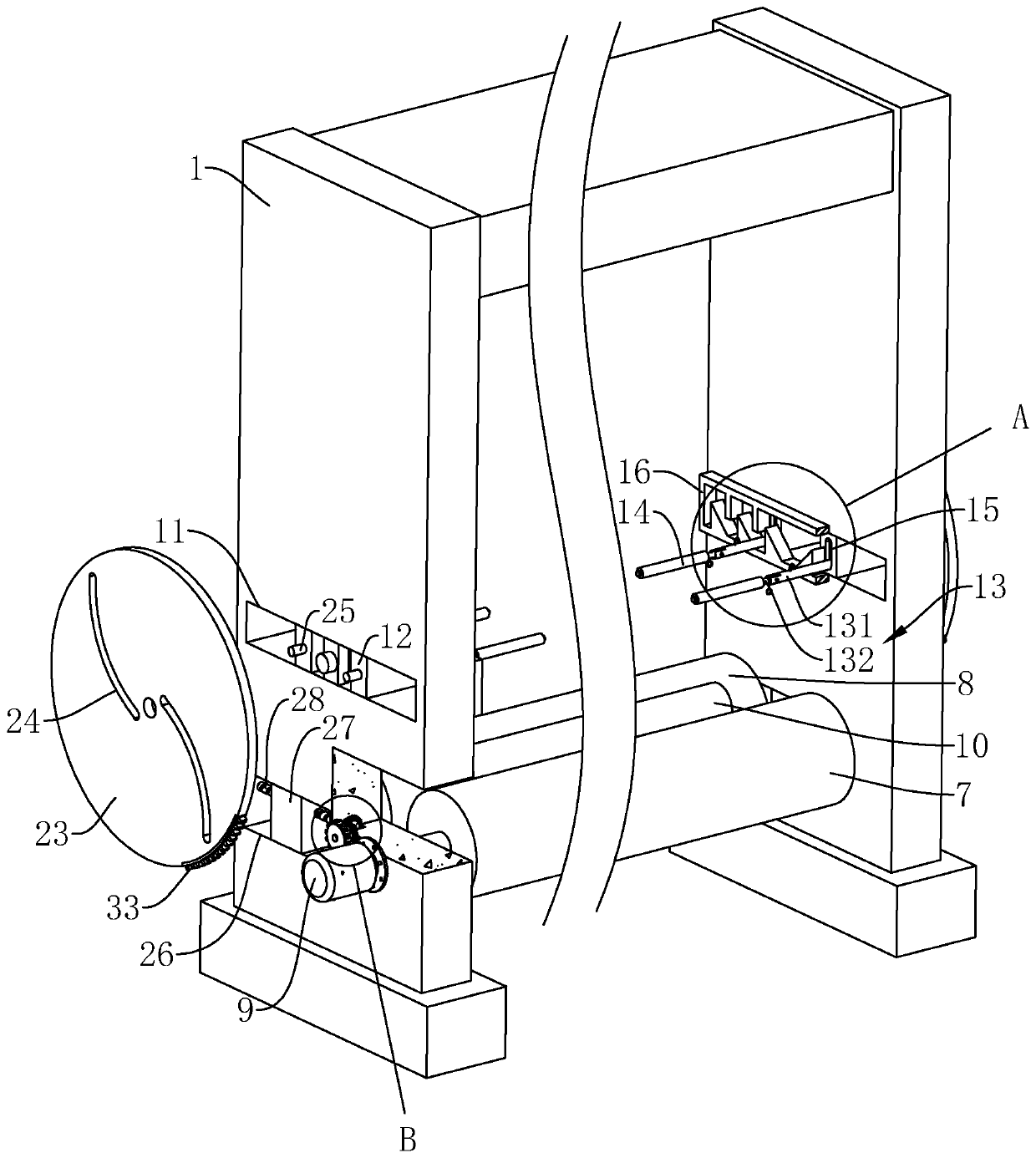

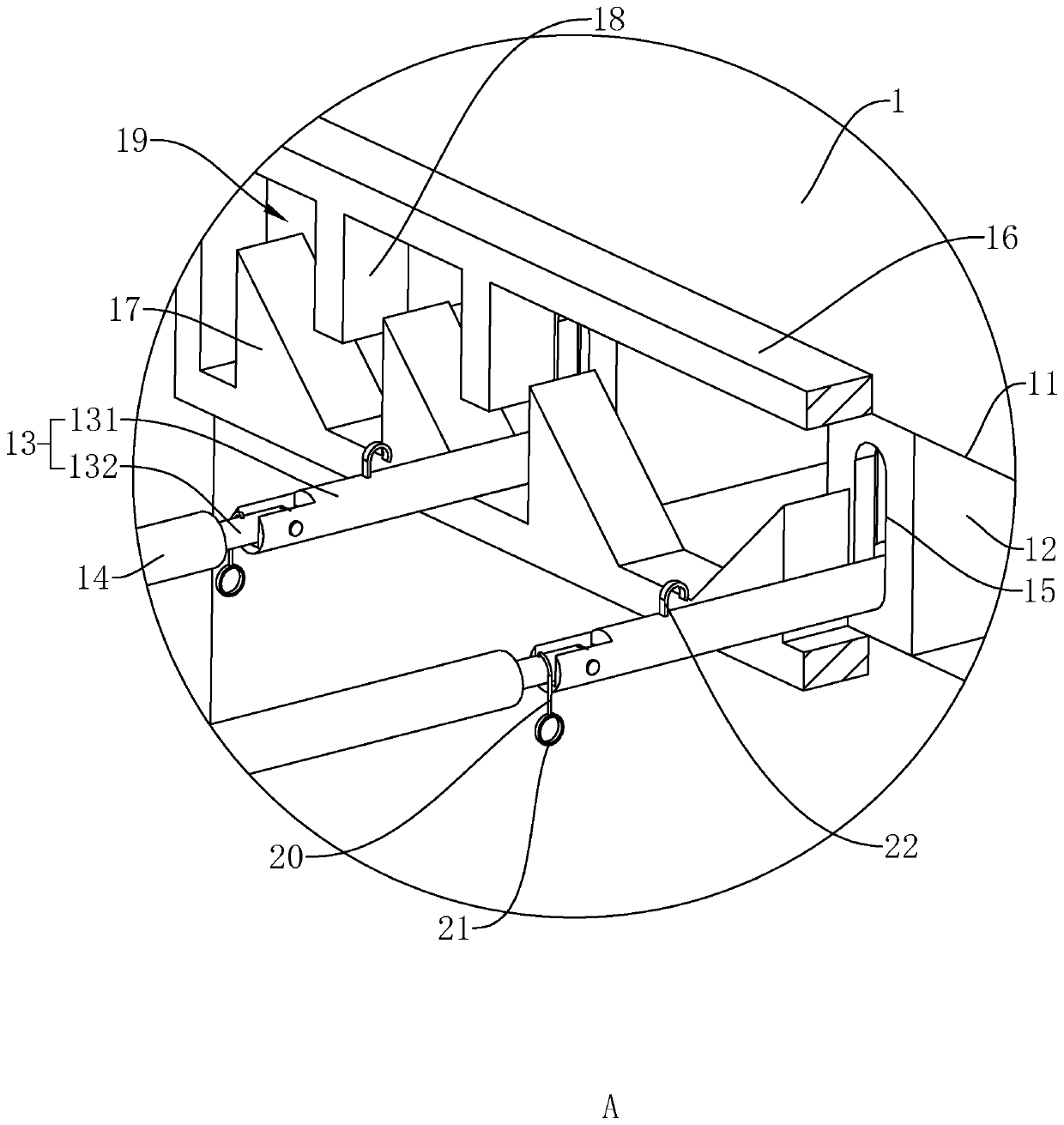

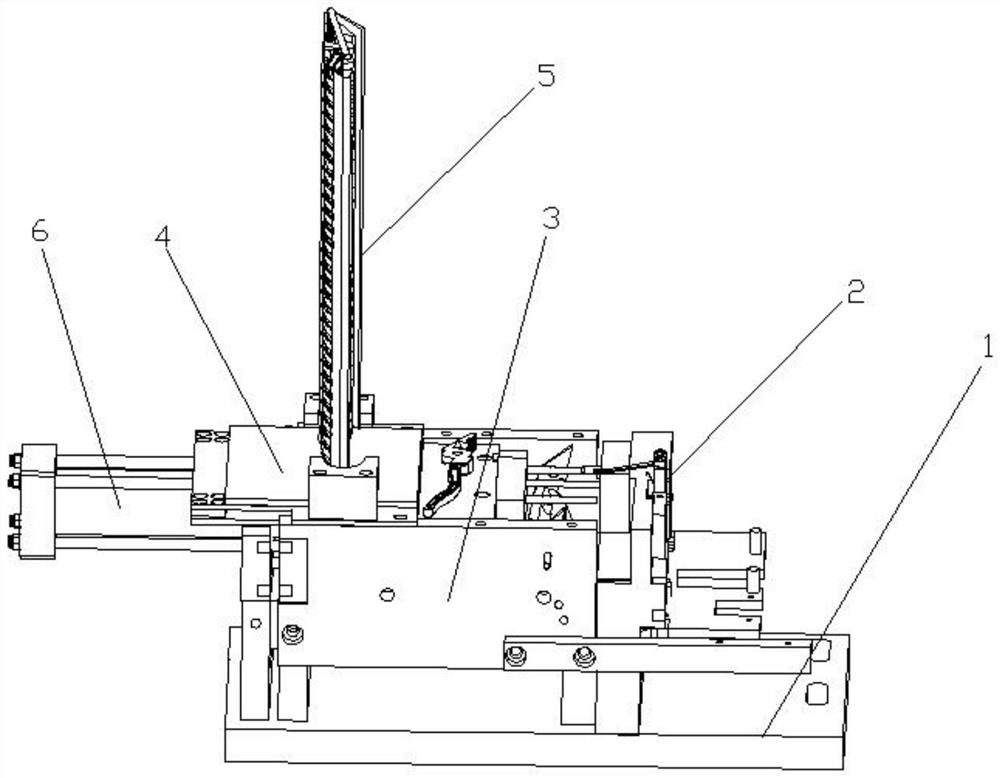

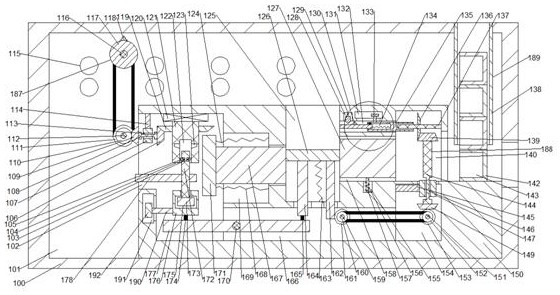

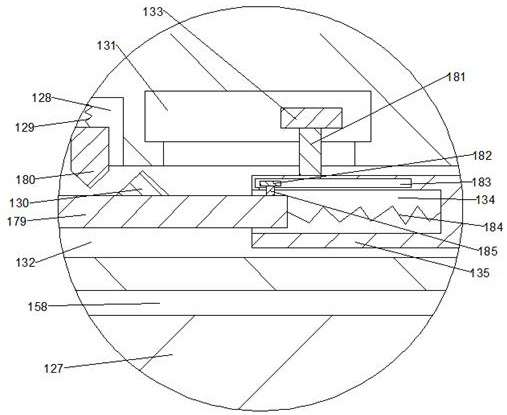

Double-procedure gang drill cutting machine

PendingCN108356925AFast loading and unloadingImprove processing efficiencyMulti-purpose machinesDrill cuttingsEngineering

The invention relates to a double-procedure gang drill cutting machine. The cutting machine comprises a worktable bracket; a worktable is arranged at the top of the worktable bracket; a Y-directionalmoving mechanism is arranged above the worktable; two Y-directional racks, transversely and symmetrically arranged in the Y-directional moving mechanism, are fixedly arranged on the two sides of the worktable bracket; an X-directional rack, transversely arranged in an X-directional moving mechanism, is fixedly arranged at the top of a cross beam in the Y-directional moving mechanism; a Z-directional moving mechanism is arranged on the loading side, near the cutting machine, of the X-directional moving mechanism; a Z-directional driving motor in the Z-directional moving mechanism is longitudinally fixed on an X-directional carriage plate in the X-directional moving mechanism; a machining device is arranged on the loading side, near the cutting machine, of a Z-directional carriage plate in the Z-directional moving mechanism; a loading auxiliary device is arranged at a loading end, near the worktable, of the top of the worktable bracket; and a pushing device is arranged on the cross beamin the Y-directional moving mechanism. The cutting machine can conveniently and quickly load and unload materials, improves the machining efficiency, and guarantees the product quality.

Owner:济南恒创数控机械有限公司

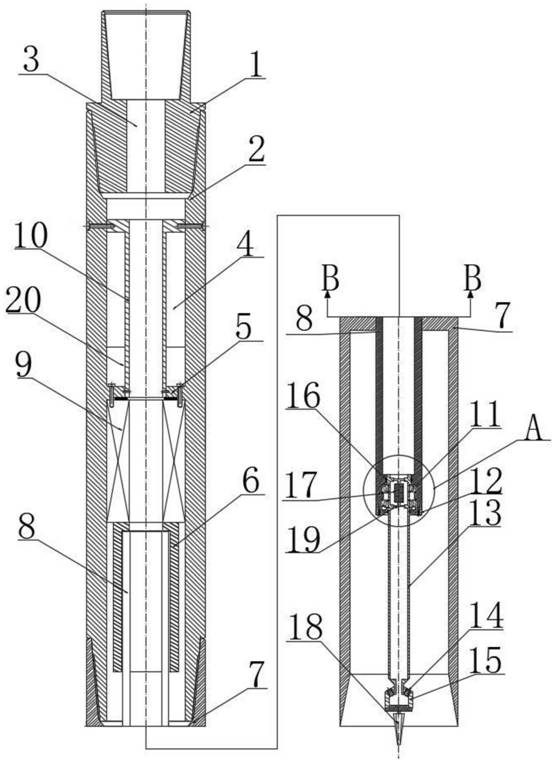

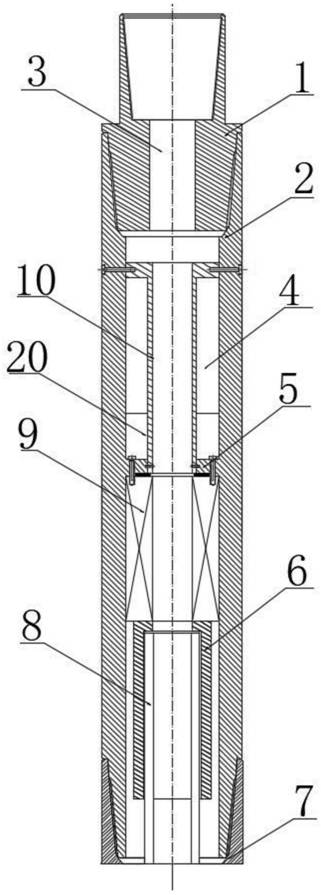

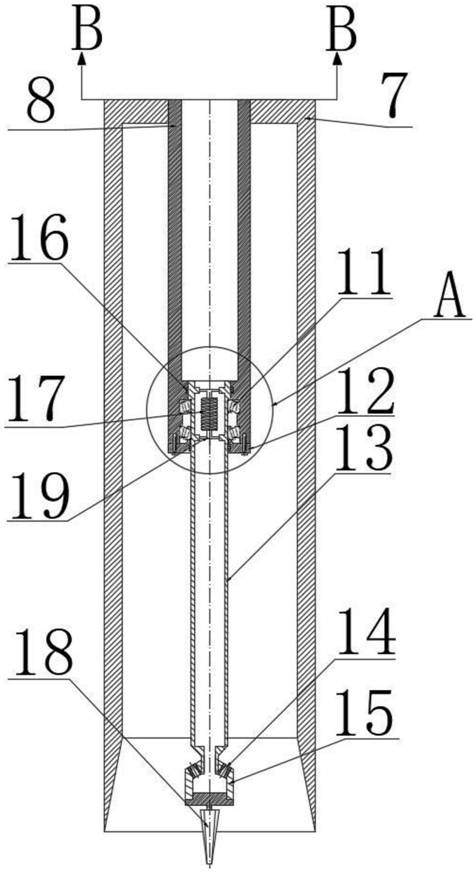

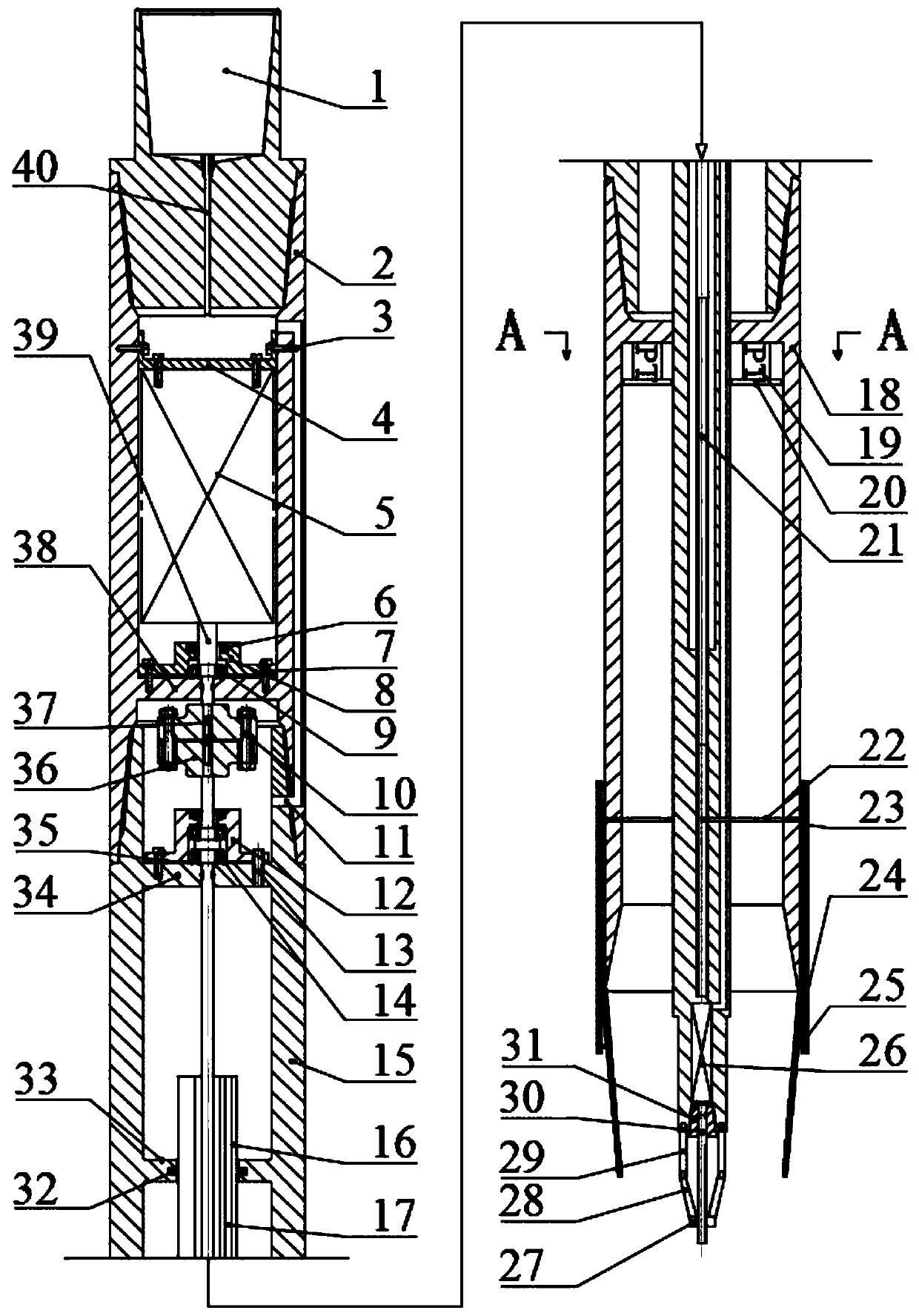

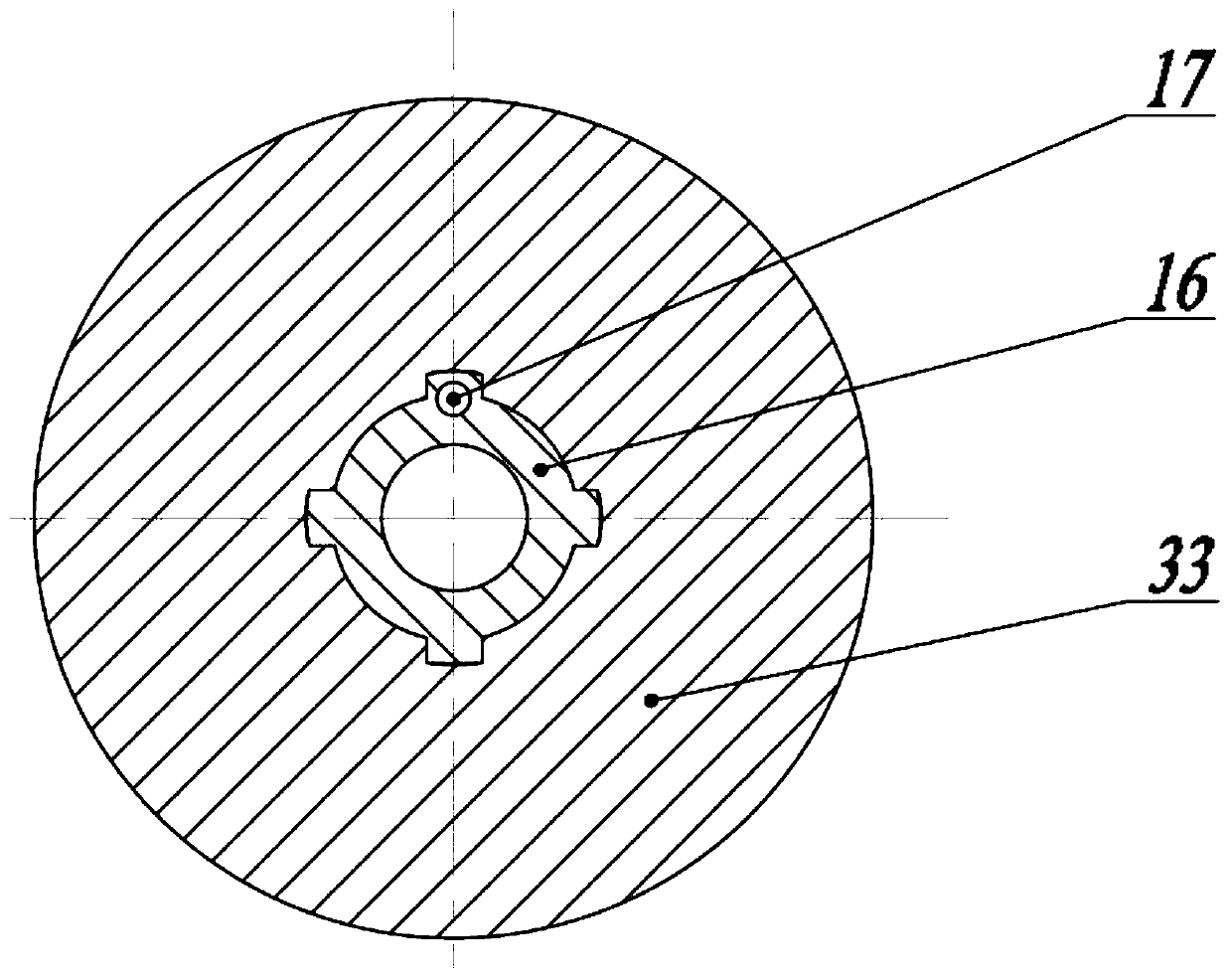

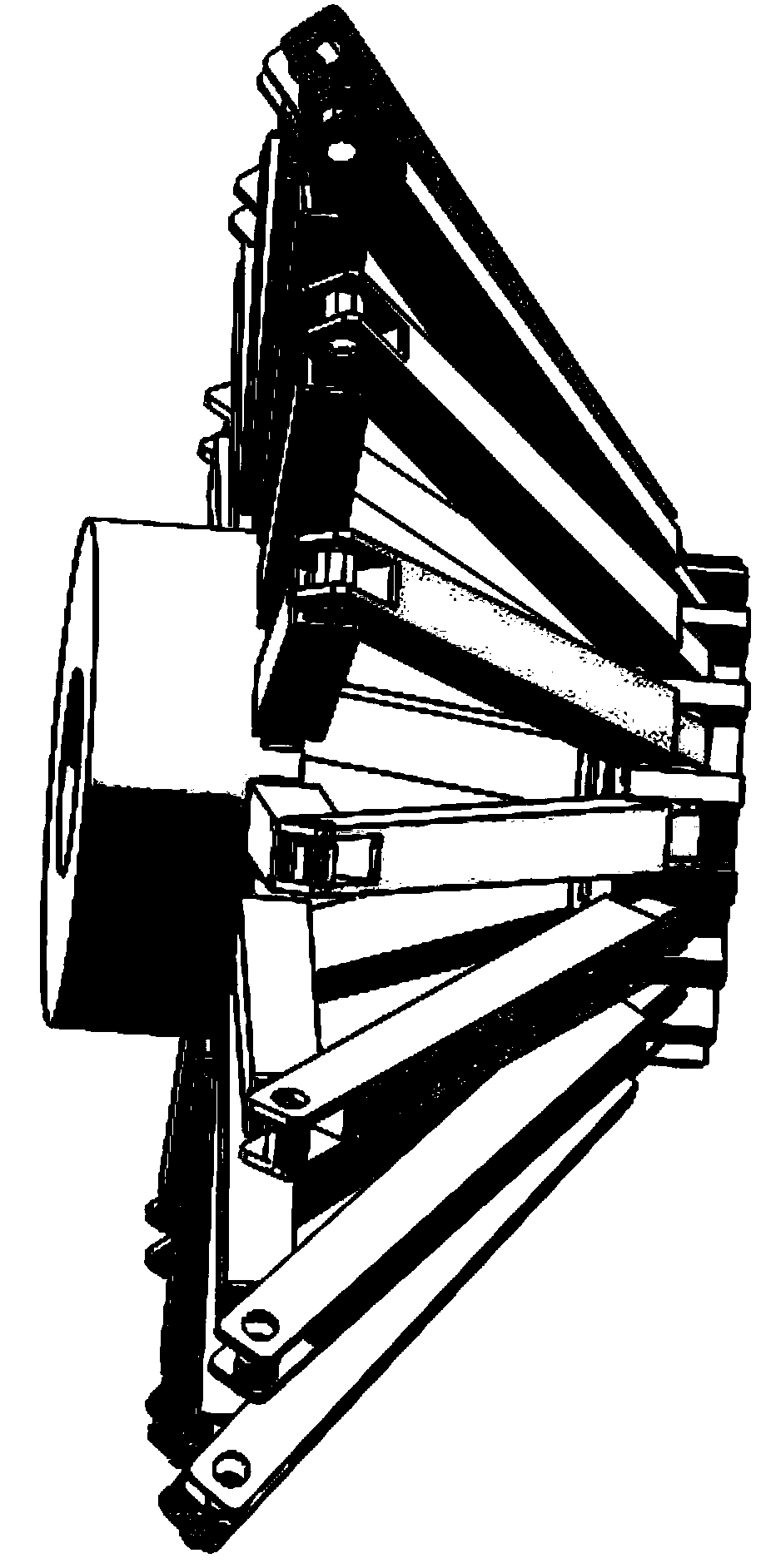

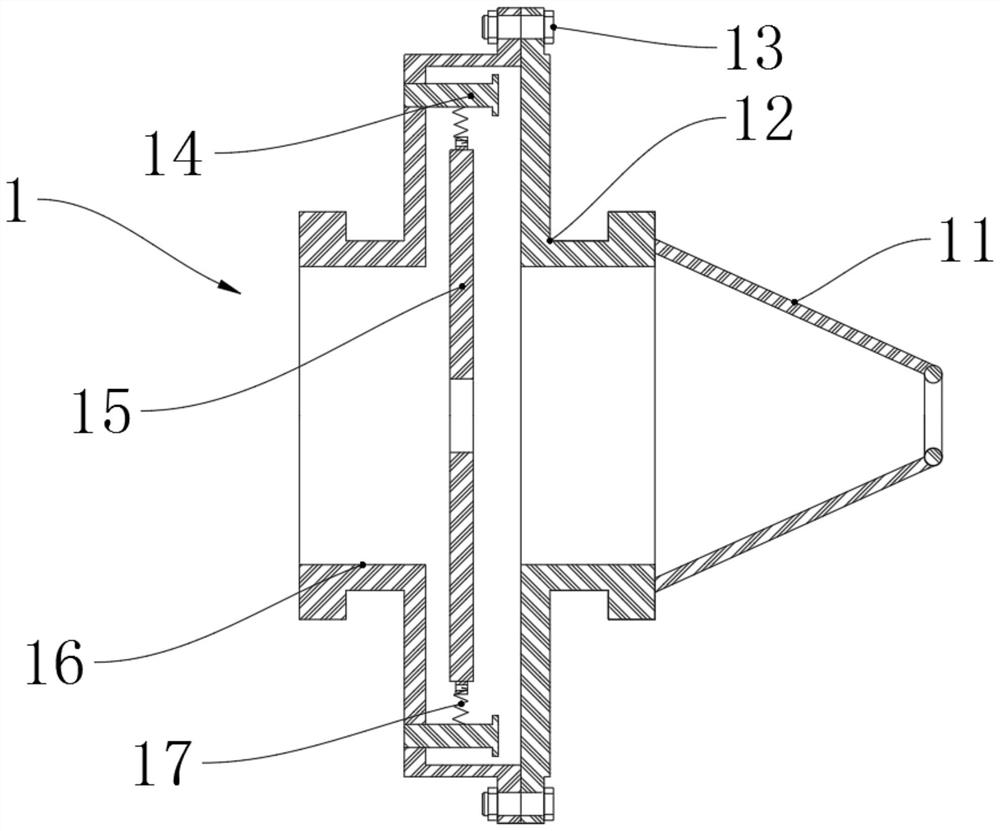

Rotary rock debris fishing tool with replaceable spray head for horizontal well

PendingCN113958280ABlock fallCan't solve multiple timesBorehole/well accessoriesMarine engineeringElectric machine

The invention relates to a rotary rock debris fishing tool with a replaceable spray head for a horizontal well in the petroleum and natural gas industry. The rotary rock debris fishing tool comprises an annular battery, a screw rod rotor, a screw rod, an annular motor, a fishing inner cylinder, nozzles, the spray head, a turbine, a rock debris blocking umbrella, a PLC control module and the like. According to the rotary rock debris fishing tool, the rotary motion of the motor is converted into the linear motion of the fishing inner cylinder through screw rod transmission; the screw rod turbine in the fishing inner cylinder rotates through water power, and the spray head installed at the tail end of the inner cylinder can be freely replaced according to working conditions; the multiple nozzles arranged on the spray head can impact rock debris without dead angles; and the PLC control module controls the rock debris blocking umbrella to close a cylinder opening. The rotary rock debris fishing tool has the advantages that the spray head and the nozzles can be replaced according to the working conditions, the rock debris can be fished in an all-dimensional mode, operation can be conducted for multiple times, and the rock debris can be automatically prevented from falling off during recycling.

Owner:SOUTHWEST PETROLEUM UNIV

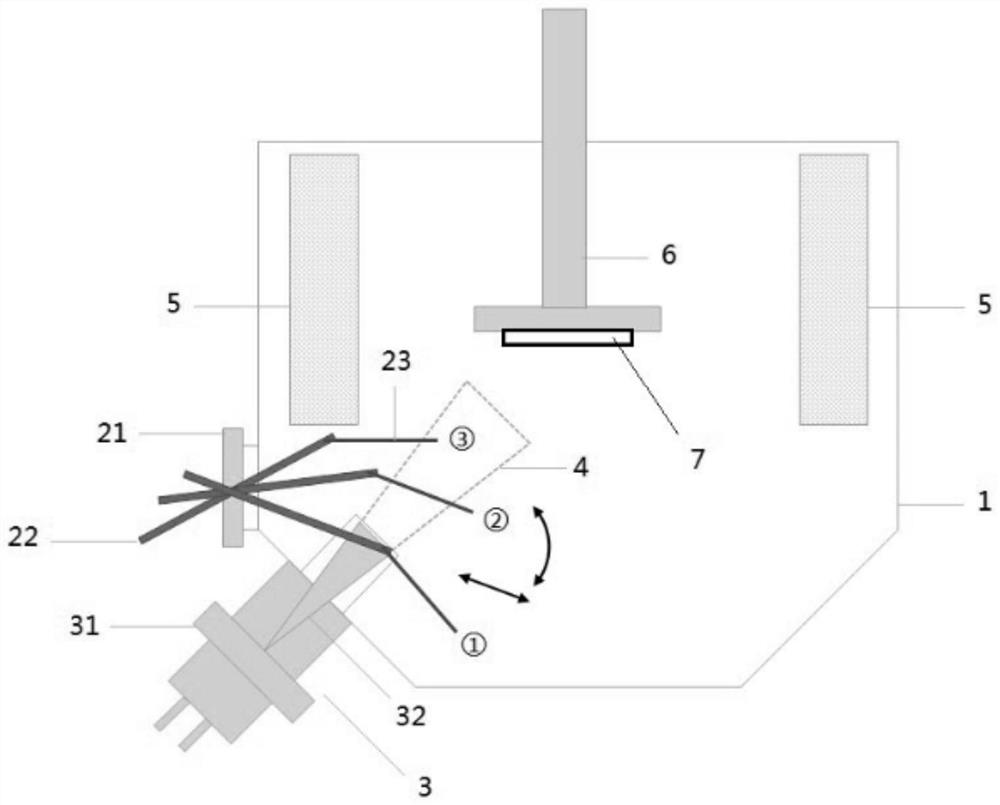

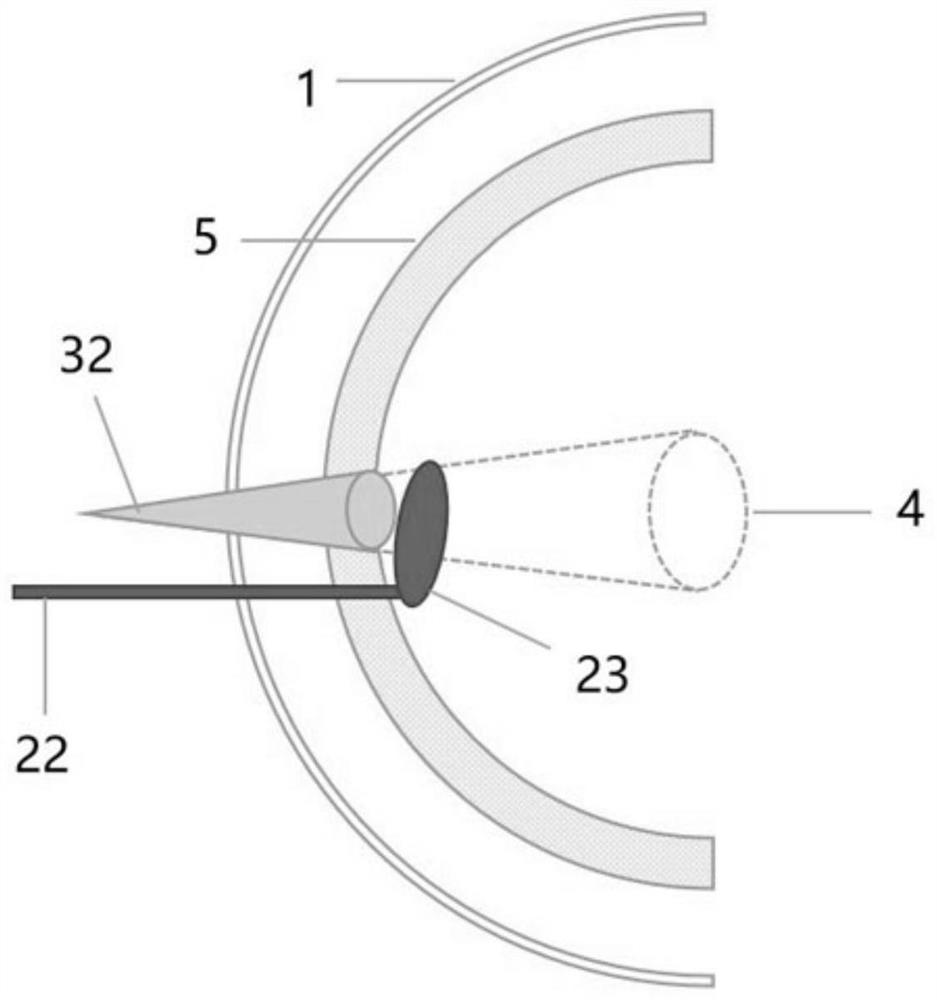

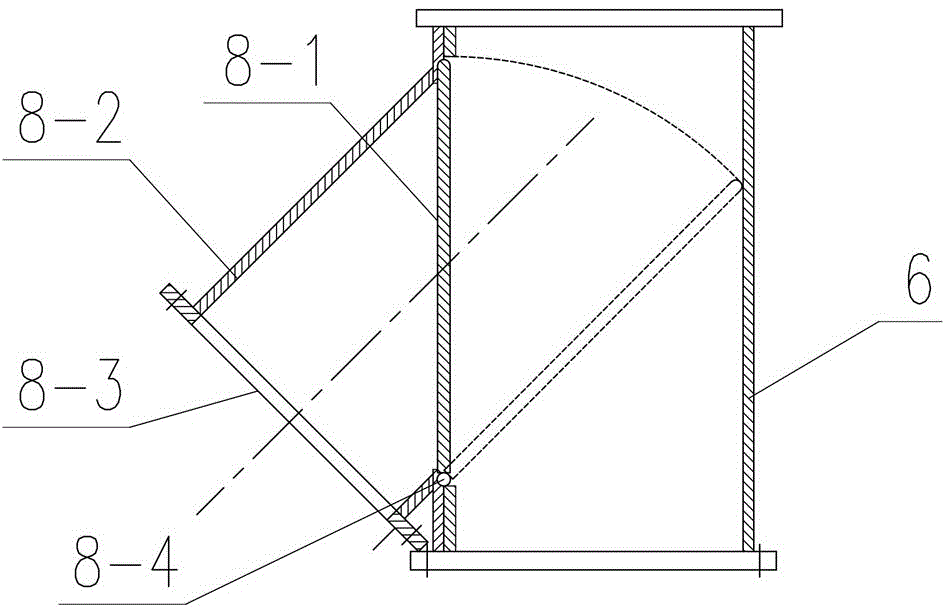

Three-state beam source furnace shutter for molecular beam epitaxy

ActiveCN112746318AReduce equipment maintenance timeImprove equipment productivityFrom condensed vaporsCold shieldChemistry

The invention discloses a three-state beam source furnace shutter for molecular beam epitaxy. The three-state beam source furnace shutter is characterized in that a third beam source furnace protection state is added on the basis of a beam opening state and a beam closing state, and the shutter in the beam source furnace protection state can effectively prevent material fragments adsorbed on the inner wall of a cold shield from falling into a beam source furnace. The three-state beam source furnace shutter has the advantages that the source material in the beam source furnace can be protected from being polluted by material fragments, the quality of an epitaxial film is optimized, meanwhile, the stability and repeatability of evaporation beams are effectively improved, the equipment maintenance time is shortened, and the equipment production efficiency is improved.

Owner:HUNAN SEMICOREPI SEMICON TECH CO LTD

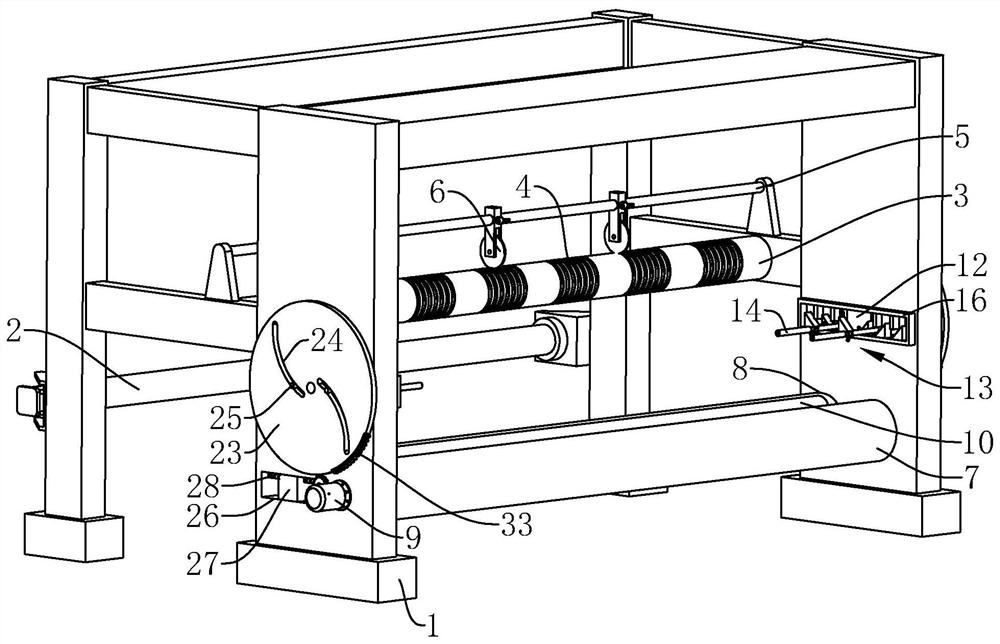

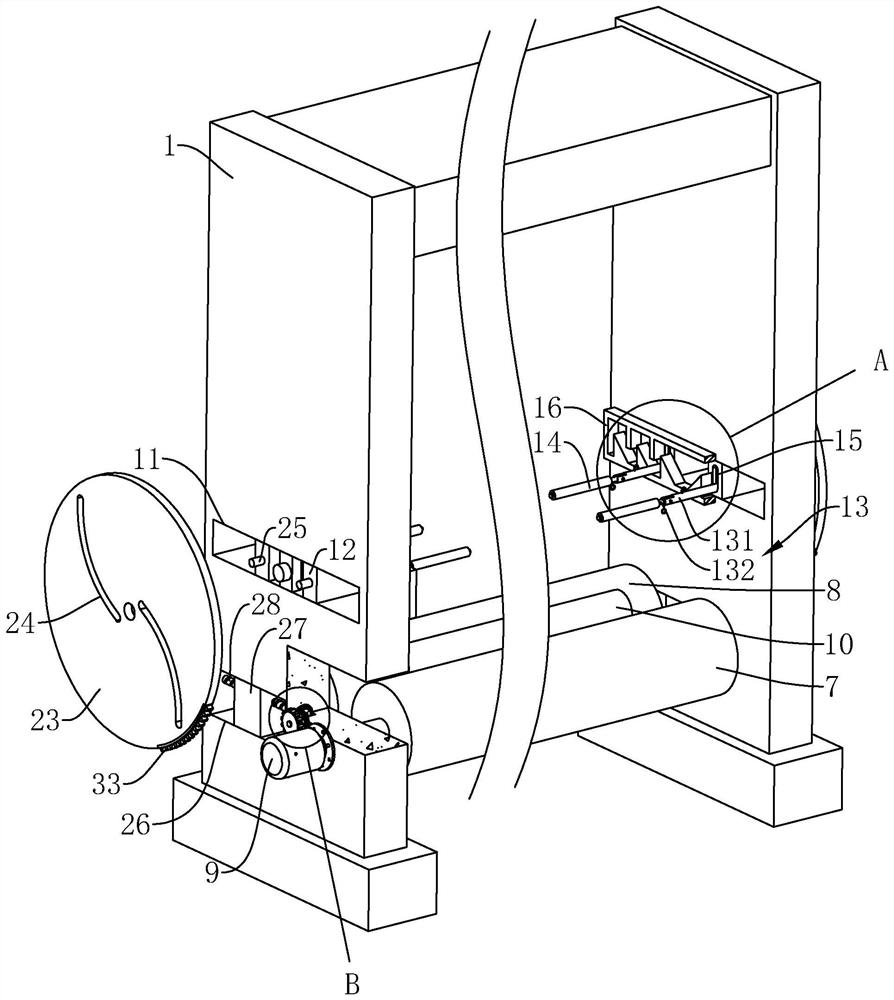

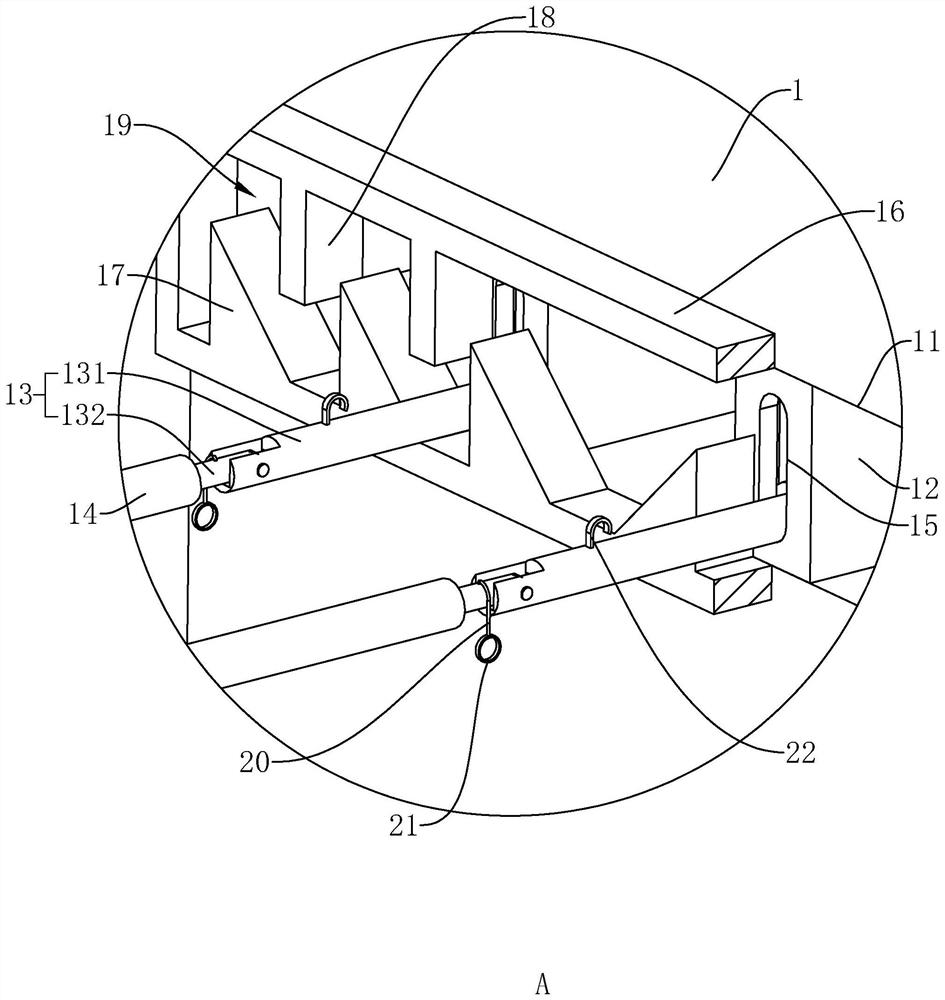

Paper slitting device

ActiveCN111517135ABlock fallWind evenlyMetal working apparatusWebs handlingElectric machineryStructural engineering

Owner:杭州宏成纸业有限公司

Bridge multistage energy-absorbing guard bar

PendingCN108824190APlay a protective effectExtension of timeBridge structural detailsOn columnEngineering

Owner:CHANGAN UNIV

Wool pre-carding device for wool carding machine

InactiveCN108642610ASolve efficiency problemsTroubleshoot technical issues with poor performanceCarding machinesCardingEngineering

The invention relates to the technical field of wool pre-carding, and discloses a wool pre-carding device for a wool carding machine. The device comprises a pre-carding base, wherein a storage grooveis formed in the pre-carding base, a pre-carding cylinder is arranged right above the storage groove, the left end face of the pre-carding cylinder is connected with an output shaft of a first pre-carding motor, first pre-carding vertebral teeth are evenly distributed on the side wall in a pre-carding cylinder cavity, first pre-carding needles and second pre-carding needles are evenly distributedon the left end face and right end face in the pre-carding cylinder cavity, gaps are formed among the second pre-carding needles, the first pre-carding needles and second pre-carding vertebral teeth evenly distributed on the outer side wall of a pre-carding shaft, the right side face of the pre-carding shaft penetrates through the right end face of the pre-carding cylinder, extends to the outer portion of the pre-carding cylinder and is connected with an output shaft of a second pre-carding motor, and a water jet of which a water outlet end is provided with blowholes is arranged between the pre-carding cylinder and first blower fan blades. The wool pre-carding device for the wool carding machine solves the problem of low efficiency and poor effect of opening and untying tangled wool of anexisting wool pre-carding device.

Owner:方高健

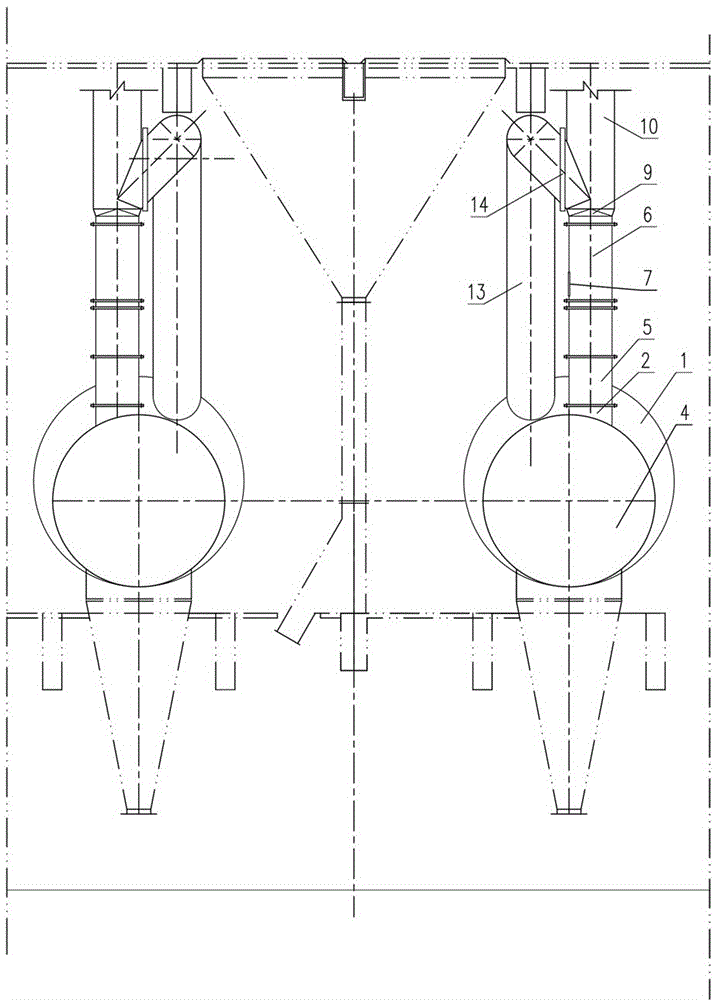

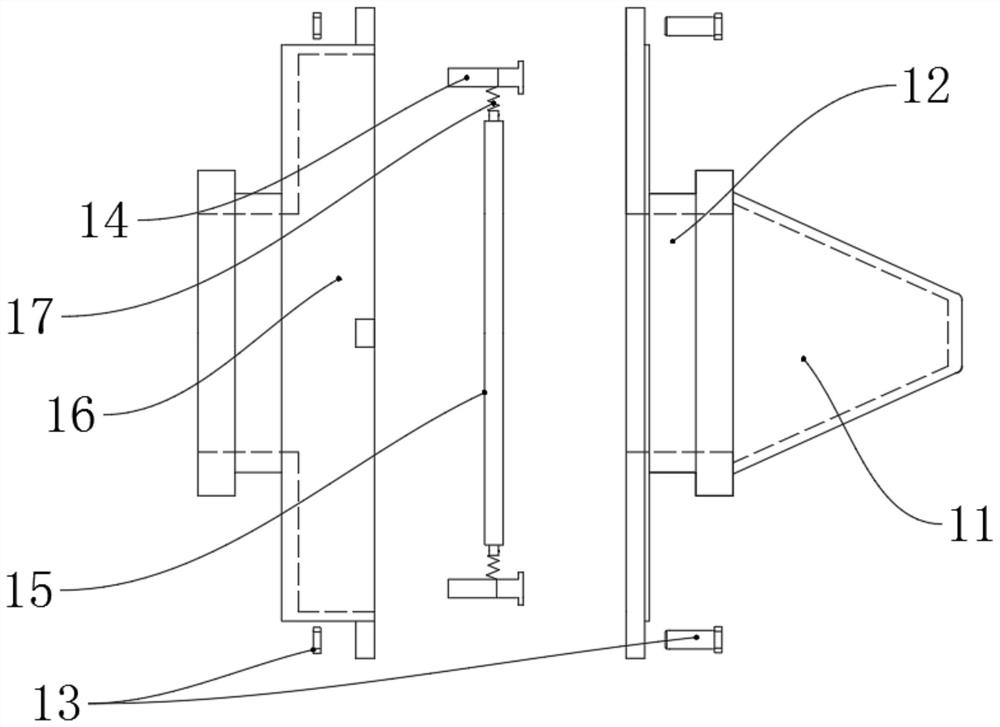

Horizontal interval umbrella type rock debris fishing tool

The invention relates to a horizontal interval umbrella type rock debris fishing tool for the petroleum and natural gas industry. The fishing tool comprises a motor, a fishing inner cylinder, a pressure sensor, a lead screw I, a plate I, a plate II, a spring, a micro motor, a nut, a connecting rod I, a connecting rod II, a lead screw II and the like; the motor is powered on, the lead screw I is driven to rotate, the rotary motion of the lead screw I is converted into linear motion of the fishing inner barrel, the fishing inner barrel, the plate I and the plate II are driven to extend out, thespring supports the plate II, and rock debris is gathered; the micro-motor is powered on to rotate, a lead screw nut mechanism is used for converting the rotary motion into the linear motion, so thatthe connecting rod I and the connecting rod II are driven to open into an umbrella shape; and the motor rotates reversely, and the rock debris is fished, and the pressure sensor is used for measuringwhether the rock debris is filled or not. The fishing tool has the advantages that the rock debris in the front cannot be pushed away, multiple times of operation can be achieved, the rock debris canbe gathered, a barrel opening is well sealed during recovery, and falling of the rock debris is prevented.

Owner:SOUTHWEST PETROLEUM UNIV

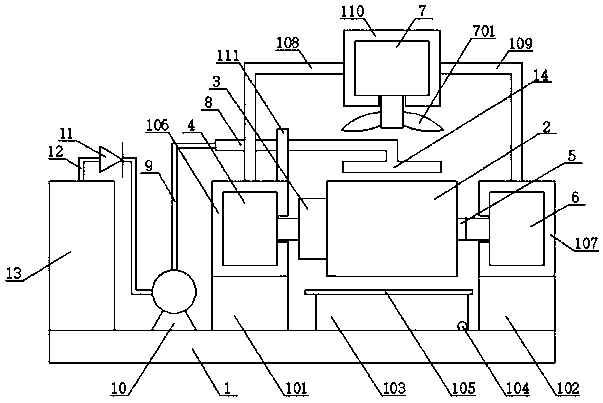

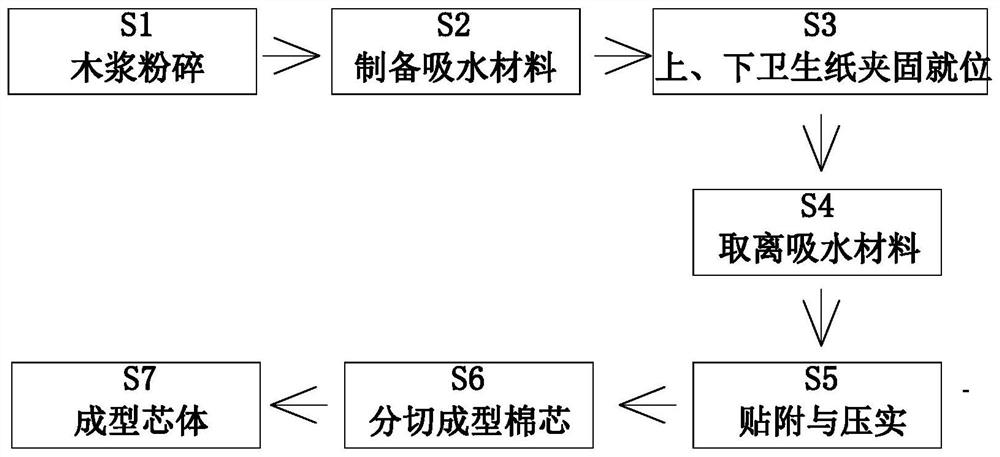

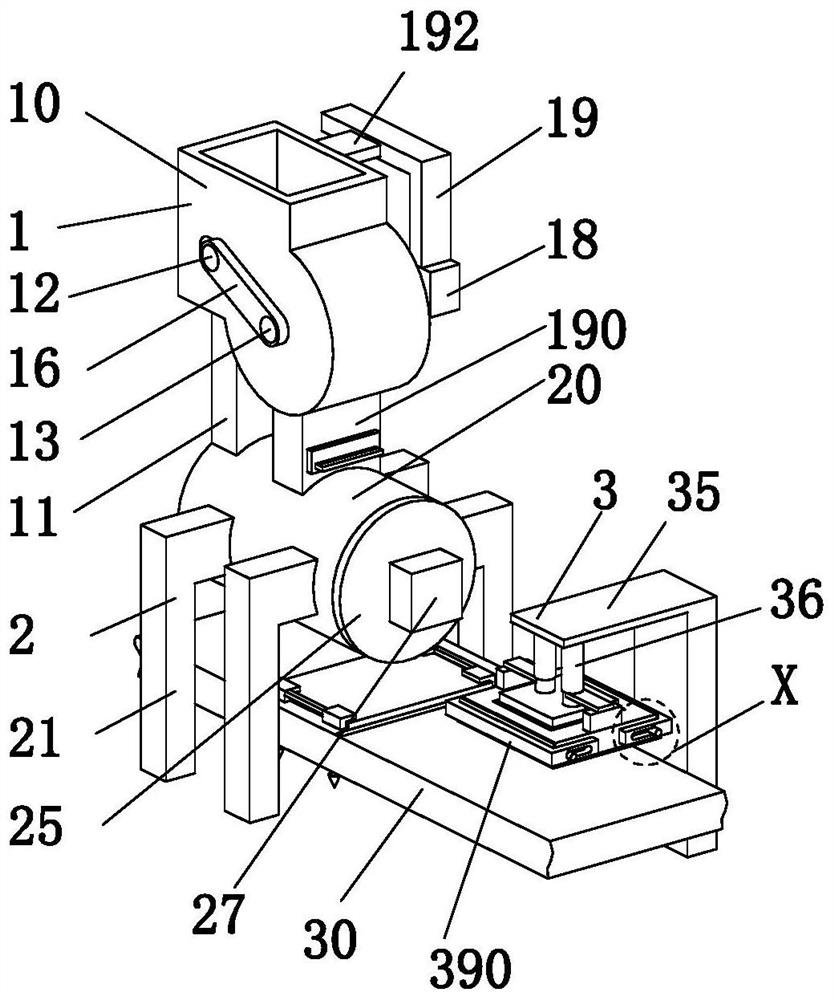

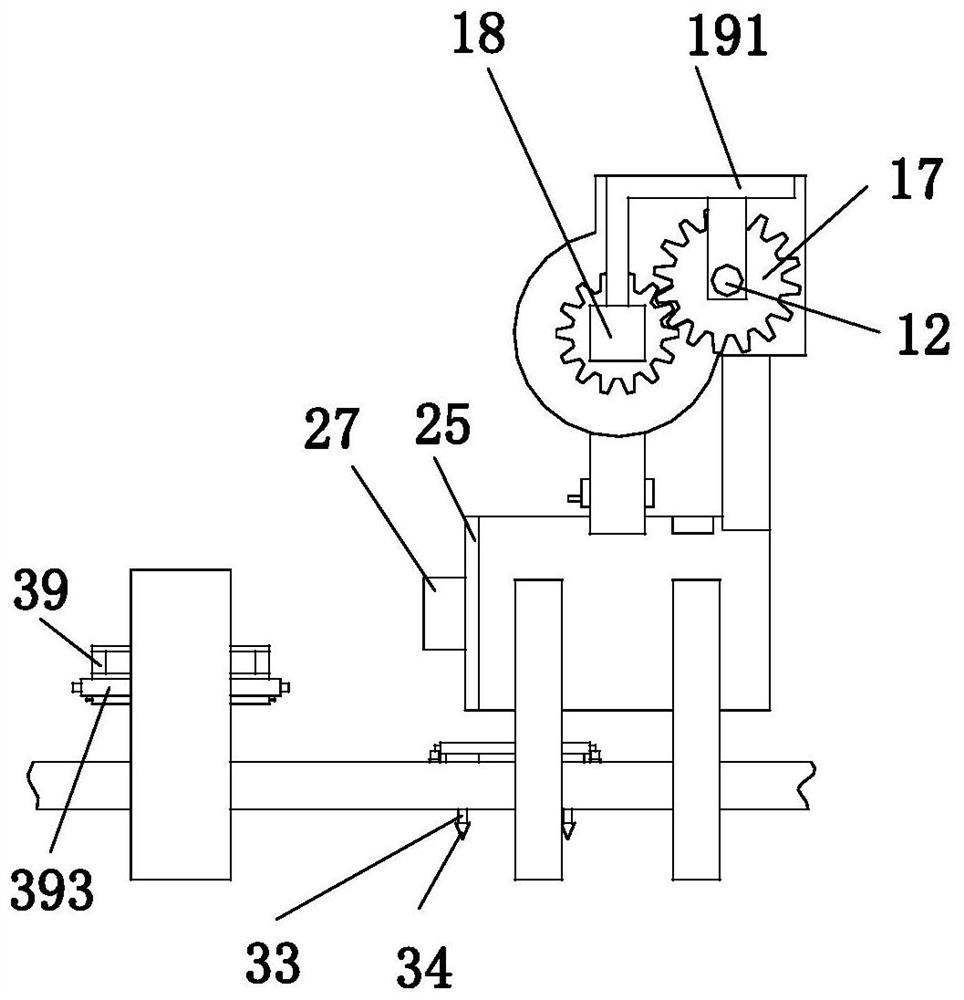

A kind of manufacturing and processing method of core body of baby diaper

ActiveCN112972122BIncrease the degree of crushingAchieve scrape cleanAdhesive articlesAbsorbent padsToilet paperIndustrial engineering

The present invention relates to a method for manufacturing and processing the core body of baby diapers, which uses a device for manufacturing and processing the core body of baby diapers. The lower end of the mechanism is connected with the upper end of the mixing mechanism, the lower end of the mixing mechanism is connected with the existing working ground, and the right end of the mixing mechanism is provided with a forming mechanism. The crushing mechanism can carry out secondary crushing treatment on wood pulp to improve the crushing degree of wood pulp. The set mixing mechanism can realize the scraping and cleaning of the inner wall of the mixing tank while realizing the discharge and mixing of water-absorbing materials. The set forming mechanism The overall clamping flexibility of the structure that can clamp toilet paper is relatively large, so that it can be easily adapted to the clamping of toilet paper within a certain thickness range.

Owner:美馨卫生用品有限公司

Smoke circulating and converting device of sinterer dust reduction pipe

ActiveCN105605932ADoes not affect operationRaise the inlet flue gas temperatureIncreasing energy efficiencyWaste heat treatmentCold airElectric control

The invention belongs to the technical field of sinterer equipment and sinterer waste heat power generation, and particularly relates to a smoke circulating and converting device of a sinterer dust reduction pipe. The smoke circulating and converting device comprises a sinterer big smoke way main pipe, a smoke way tail pipe, a tail-end dust reduction pipe and an electric control system, an electric pipeline valve is arranged at a position where the sinterer big smoke way main pipe is connected with the smoke way tail pipe, a smoke waste heat air extraction door is arranged on the smoke tail pipe, the tail-end dust reduction pipe is composed of a smoke dust vertical pipe, a smoke dust bypass pipe, a smoke bypass pipe, a pipeline switching device and a pipeline grating device, an electric pipeline valve, the pipeline switching device and the smoke waste heat air extraction door are all connected with the electric control system. The smoke dust vertical pipe is composed of a round vertical pipe, a round-to-square pipeline joint, a square vertical pipe, an electric air locking device I, an electric air locking device II and a manhole door. Low-temperature air in the tail dust reduction pipe does not enter a waste heat boiler any more, so that influence of cold air which leaks in is avoided and inlet smoke temperature and waste heat utilization efficiency of the waste heat boiler are improved greatly.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

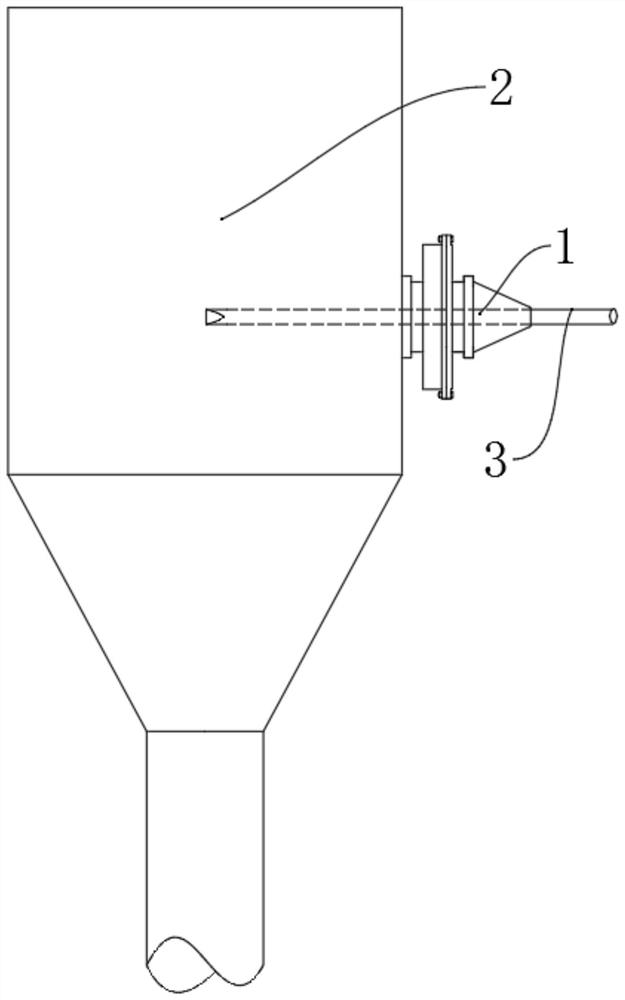

Anti-gushing and anti-scalding device for clearing blockage of cyclone preheater of cement kiln

PendingCN113776348AEffective protectionBlock fallPreheating chargesIncrustation removal devicesProcess engineeringMechanical engineering

The invention discloses an anti-gushing and anti-scalding device for clearing blockage of a cyclone preheater of a cement kiln. The anti-gushing and anti-scalding device for clearing blockage of the cyclone preheater of the cement kiln comprises a supporting base, a baffle, a supporting column, a spring, a protection piece and a protection sleeve, one end of the supporting base is connected with the cyclone preheater, the other end of the supporting base is movably connected with one end of the protection piece, and the other end of the protection piece is connected with the protection sleeve; the supporting base is provided with a connecting hole and a counter bore, and at least two symmetrical supporting columns are distributed on the circumference of the bottom of the counter bore; the baffle is arranged in the counter bore, connected with the supporting column through a spring and suspended in the counter bore, and a first through hole is formed in the baffle. According to the anti-gushing and anti-scalding device for clearing blockage of the cyclone preheater of the cement kiln, the anti-gushing and anti-scalding device has the characteristics that an anti-blocking device can be used for protecting the cyclone preheater of the cement kiln during blocking removal, and can effectively avoid injury to operators during blocking removal, and the like.

Owner:GUANGXI YUFENG CEMENT

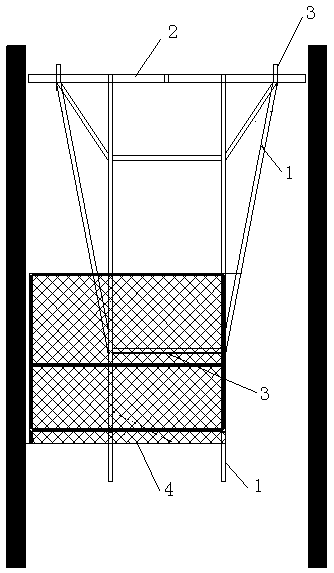

Moveable type operating platform for conducting construction in shaftway of elevator shaft

InactiveCN107654059ASolve the problem that it is inconvenient to set up the operating platformBlock fallBuilding support scaffoldsEngineeringSafe operation

The invention relates to the field of elevator construction, in particular to a moveable type operating platform for conducting construction in a shaftway of an elevator shaft. The moveable type operating platform is characterized in that the moveable type operating platform comprises channel steel, steel plates, steel pipes and reinforcement meshes. The channel steel of the platform is erected toa structural part and a shear wall of the elevator shaftway, so that longitudinal and horizontal supports of the operating platform are formed, the channel steel and the steel plates form an operating face of the operating platform, and the reinforcement meshes are arranged at gaps between the steel pipes and the steel plates. By adopting the moveable type operating platform, the problem that arrangement of the operating platform in the elevator shaft way is not convenient can be effectively solved, meanwhile, the top of the operating platform and beams and walls of the shaftway form a completely closed plane, sundries can be prevented from dropping out, and the site environment of safe operation of a construction elevator is ensured.

Owner:SHANGHAI BAOYE GRP CORP

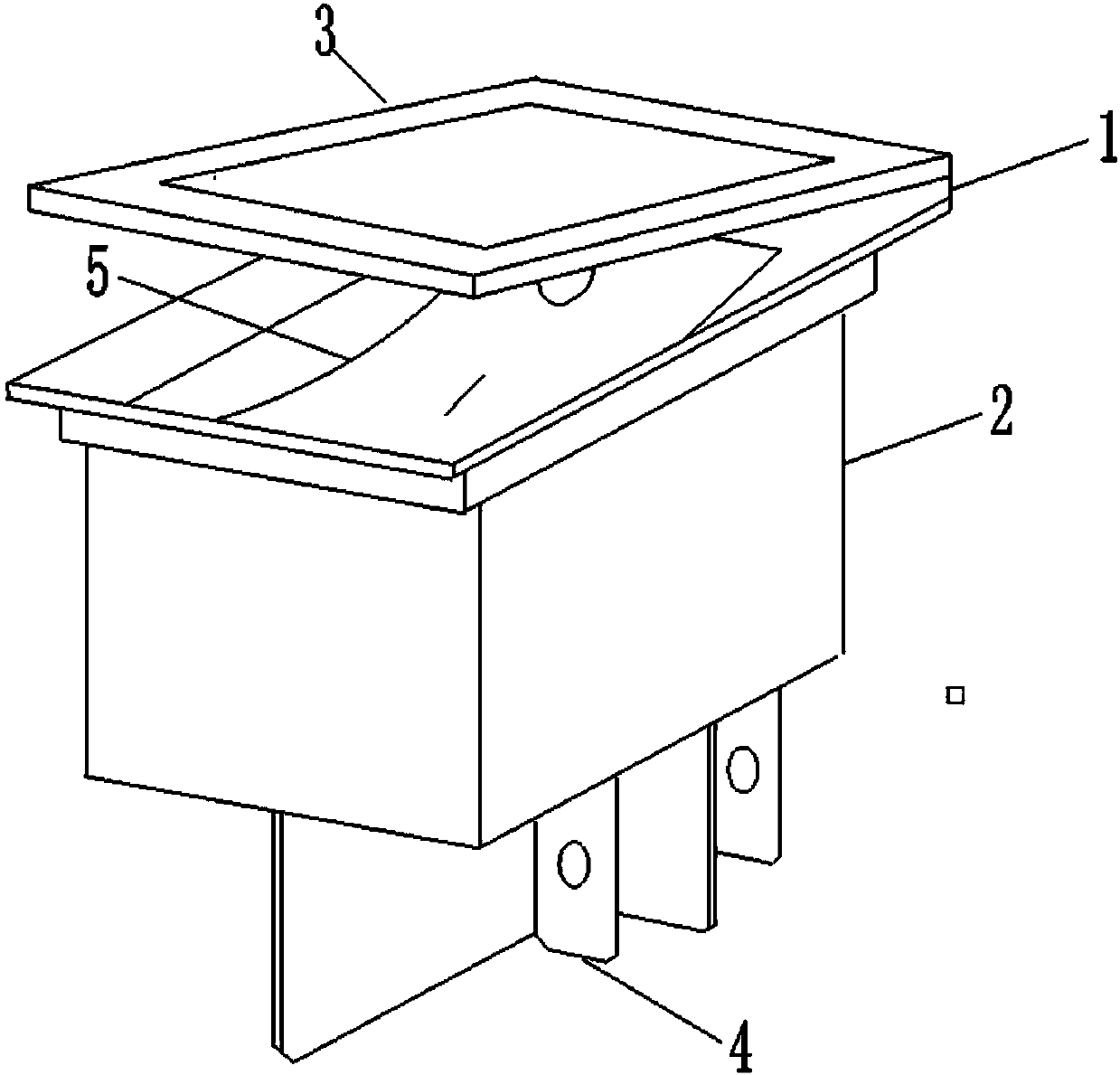

Adjustable waterproof anti-collision rocker switch

InactiveCN107845524AAchieve directional displacementHigh transparencyElectric switchesEngineeringCollision resistance

The invention discloses an adjustable waterproof anti-collision rocker switch, which comprises terminals, a button, an upper shell body, a lower shell body and a rubber waterproof cap, wherein the upper shell body is arranged on the lower shell body, the waterproof cap is arranged on the upper shell body, the button is arranged in the lower shell body, the terminals are arranged on the lower surface of the lower shell body, the button is connected with the terminals by means of a circuit, and the upper shell body can be moved and positioned relative to the lower shell body by means of a movable positioning member; the upper shell body is of a frame-shaped structure that penetrates up and down; the movable positioning member comprises ridges and sliding grooves which are used cooperatively,and a plurality of the ridges are longitudinally fixed on the inner surface of the upper shell body, a plurality of the sliding grooves are longitudinally fixed on the inner side of the lower shell body, the upper shell body is provided with identical cross grains at parts corresponding to the sliding grooves, and the rubber waterproof cap for protecting the button is arranged on the upper shellbody. By adopting the design, the adjustable waterproof anti-collision rocker switch realizes the beneficial effects of collision resistance, water resistance and convenient operation when compared with the existing rocker switch.

Owner:浙江新昌益昌高压清洗机配件有限公司

Municipal administration well lid moving device

ActiveCN111517244AAdjustable distanceBlock fallLifting framesArchitectural engineeringStructural engineering

The invention belongs to the technical field of municipal engineering, and provides a municipal administration well lid moving device. A bearing plate is included. A lifting plate is arranged on the upper side of the bearing plate. A guiding assembly for providing guiding for lifting of the lifting plate is arranged on the bearing plate. The bearing plate is provided with a storage battery and anelectric telescopic rod. The bottom of the lifting plate is provided with a fixed elevating pipe and a movable elevating pipe. The fixed elevating pipe is fixed to the bottom of the lifting plate. Thelifting plate is provided with an adjusting assembly for adjusting the position of the movable elevating plate. The bearing plate is provided with a first strip-shaped opening for the movable elevating pipe to penetrate. Stop assemblies are arranged at the bottoms of the fixed elevating pipe and the movable elevating pipe. According to the municipal administration well lid moving device, a sliding block slides on a guiding sliding rod, the position of the movable elevating pipe is adjusted, accordingly the distance between the fixed elevating pipe and the movable elevating pipe is adjusted soas to adapt to well lids different in size, and the application range is enlarged.

Owner:仁诚建设有限公司

Pipe-jacking well opening soil body reinforcing process for soft soil foundation

ActiveCN113737771AExpand the scope of reinforcementPass safelyProtective foundationSoil preservationStructural engineeringPipe

The invention relates to the technical field of pipe-jacking construction, in particular to a pipe-jacking well opening soil body reinforcing process for a soft soil foundation, and relates to the technical field of pipe jacking construction. Soil bodies around the pipe-jacking well opening are reinforced by two ways: tamping and compaction grouting. In the tamping step, the soil bodies around a pipe jacking well opening are tamped in the advancing direction of a jacking pipe, and then a pit left after tamping is filled and leveled up with soil, then the next round of tamping is conducted, and soil filling and tamping are conducted circularly till the condition of stopping circulation is met. The method has the effect of improving the defects of long construction period, high cost and low tunneling efficiency when a pipe jacking machine goes in and out of the opening of the pipe jacking well.

Owner:广东一新长城建筑集团有限公司

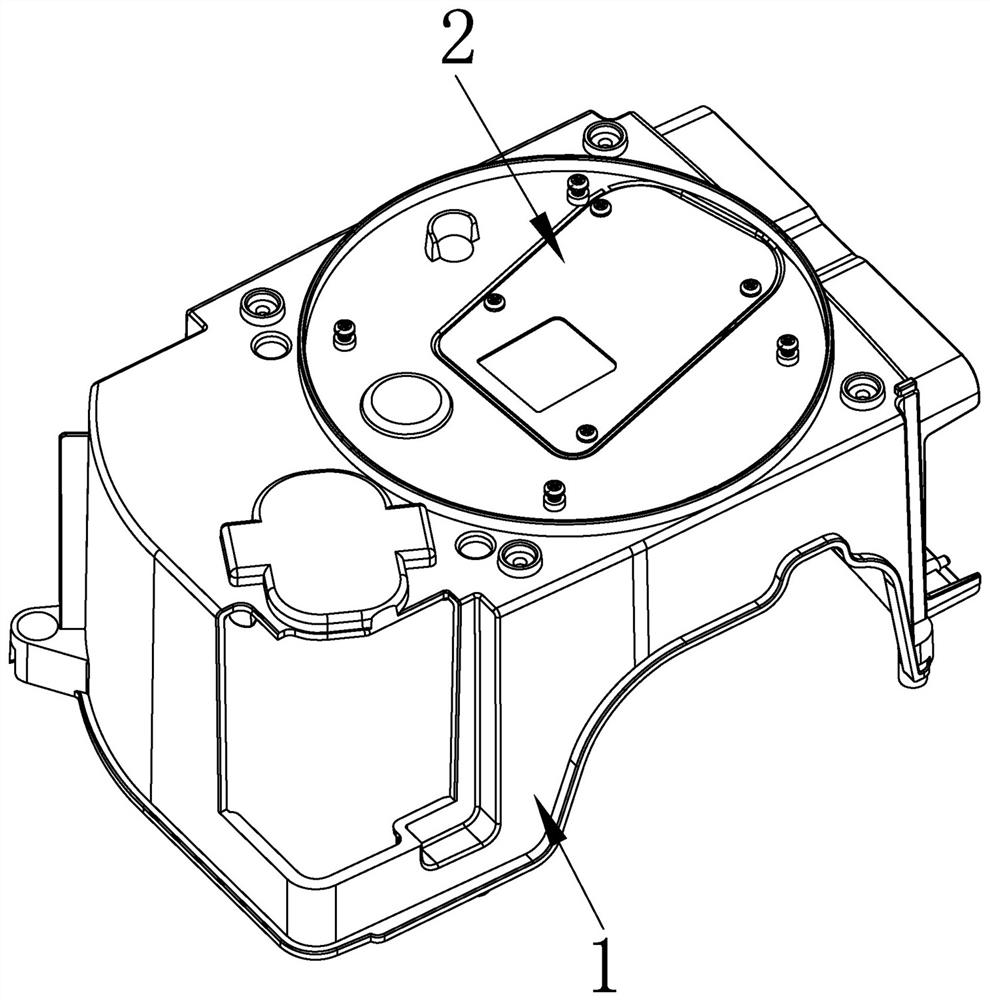

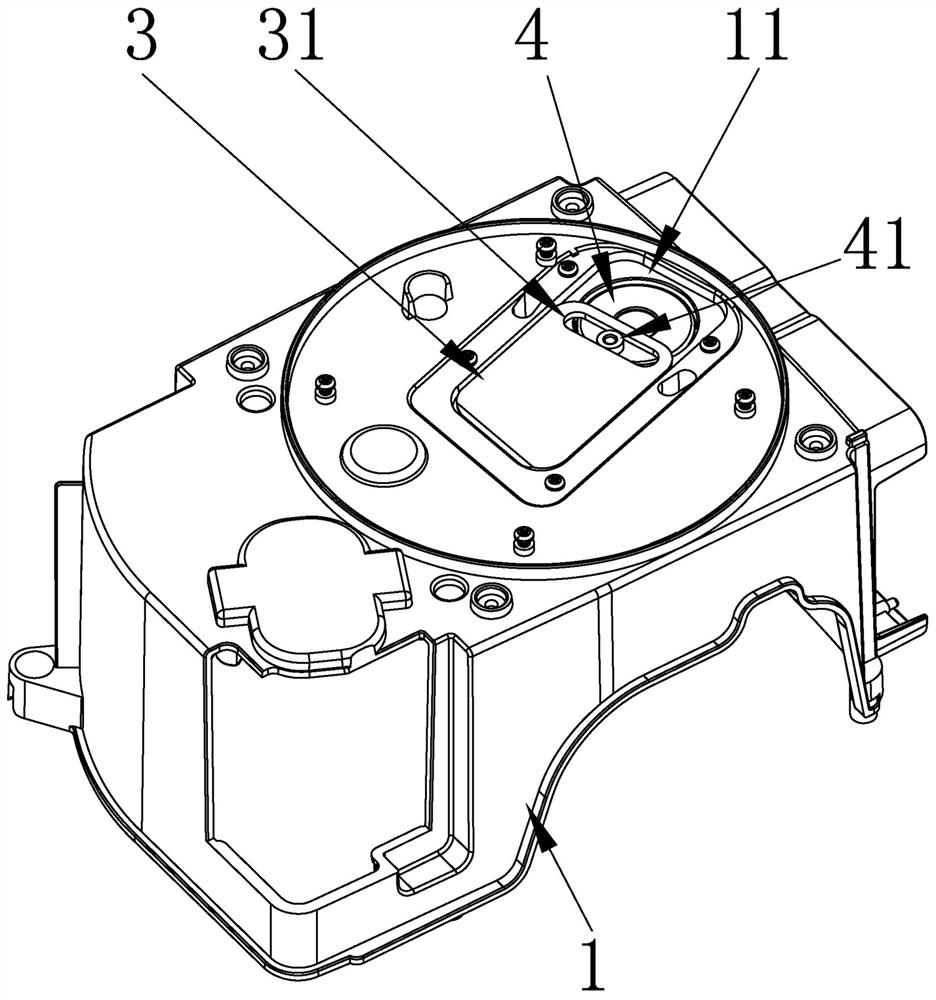

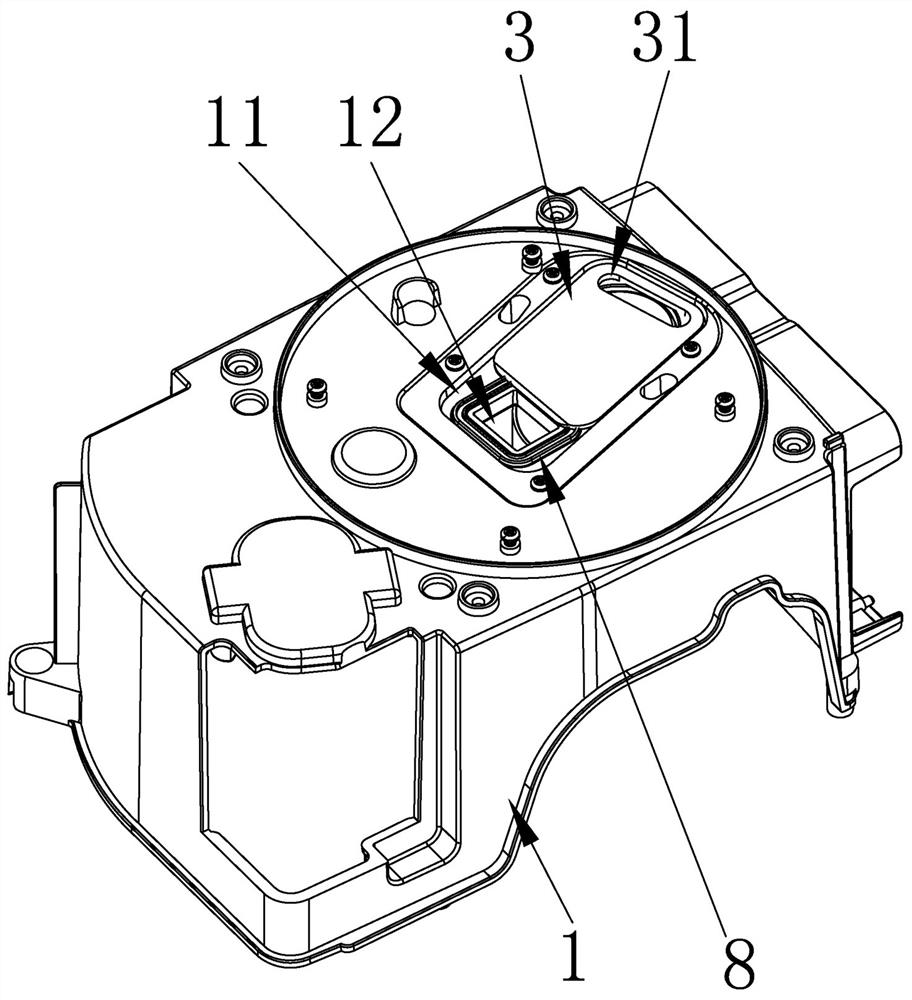

Powder falling mechanism of coffee machine

The invention relates to a powder falling mechanism of a coffee machine, which is characterized in that the powder falling mechanism comprises a powder outlet base, the lower portion of the powder outlet base is concaved inwards to form a movable groove, and a sliding plate is installed in the movable groove in a sliding mode through a driving mechanism; a powder outlet is formed in one side of the movable groove in a penetrating mode, the sliding plate covers the upper portion of the powder outlet in a sliding mode, and the driving mechanism drives the sliding plate to slide to open and closethe powder outlet. The driving mechanism comprises an eccentric wheel and a driving motor connected with the eccentric wheel, the driving motor drives the eccentric wheel to rotate, the eccentric wheel is provided with an eccentric shaft deviating from the rotating center of the eccentric wheel, the eccentric shaft is clamped in a sliding groove in one side of the sliding plate, and when the driving motor drives the eccentric wheel to rotate, the eccentric shaft and the sliding groove interact to drive the sliding plate to slide. The powder falling mechanism has the beneficial effects that the powder discharging mechanism and the driving mechanism are simple in structure, high in working efficiency and low in manufacturing cost, and the market competitiveness of the coffee machine is effectively improved.

Owner:GUANGDONG HOMEZEST TECH CO LTD

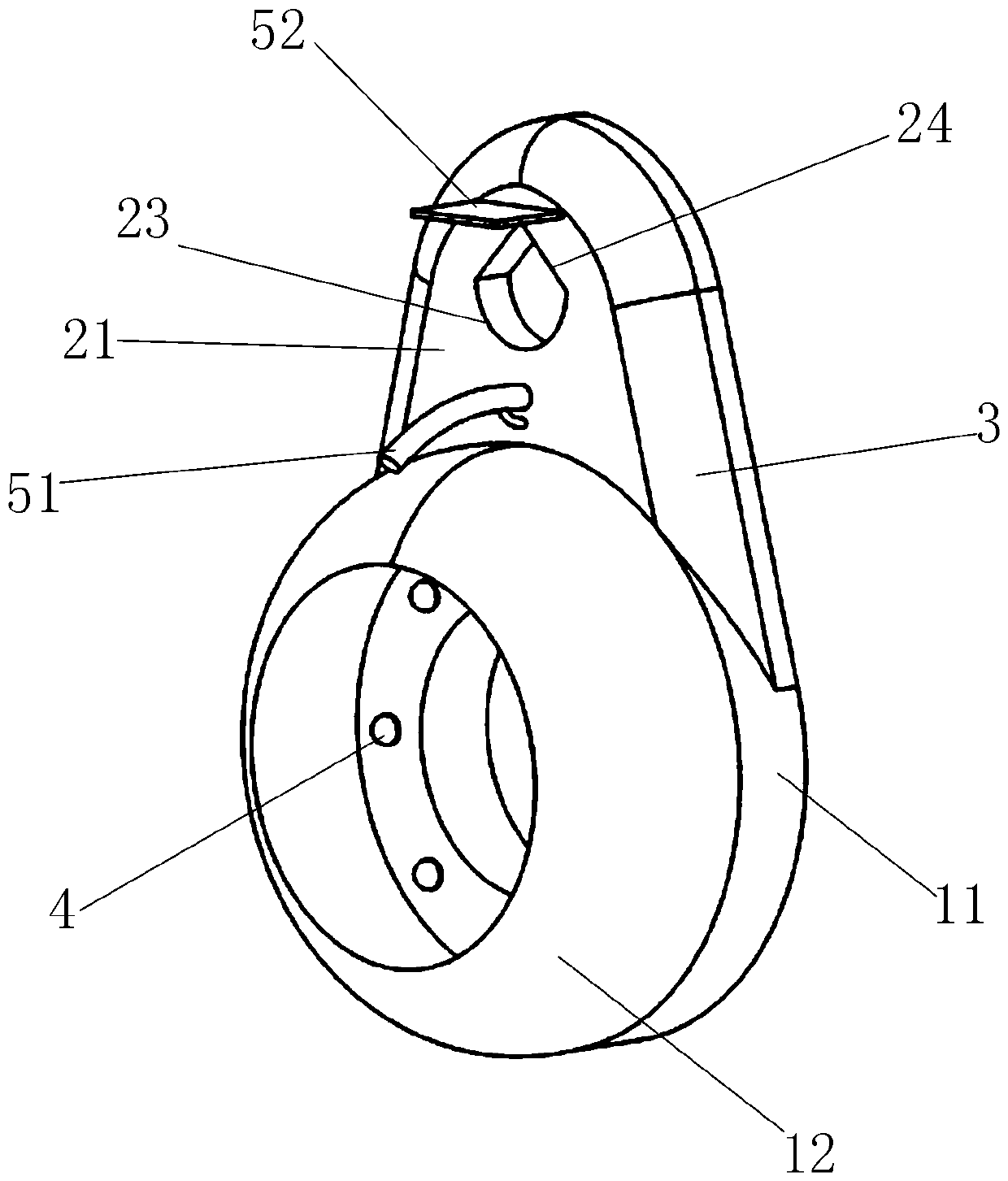

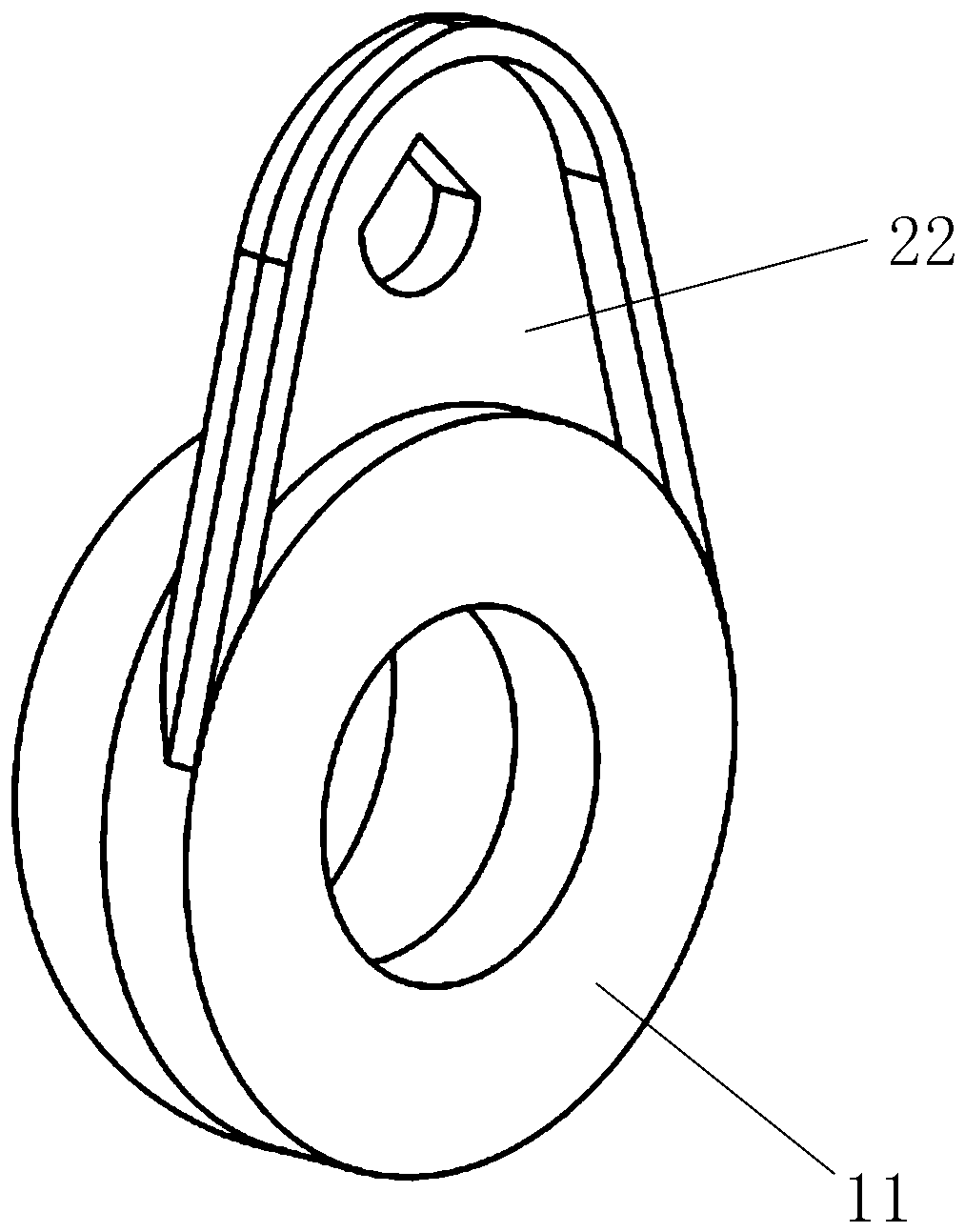

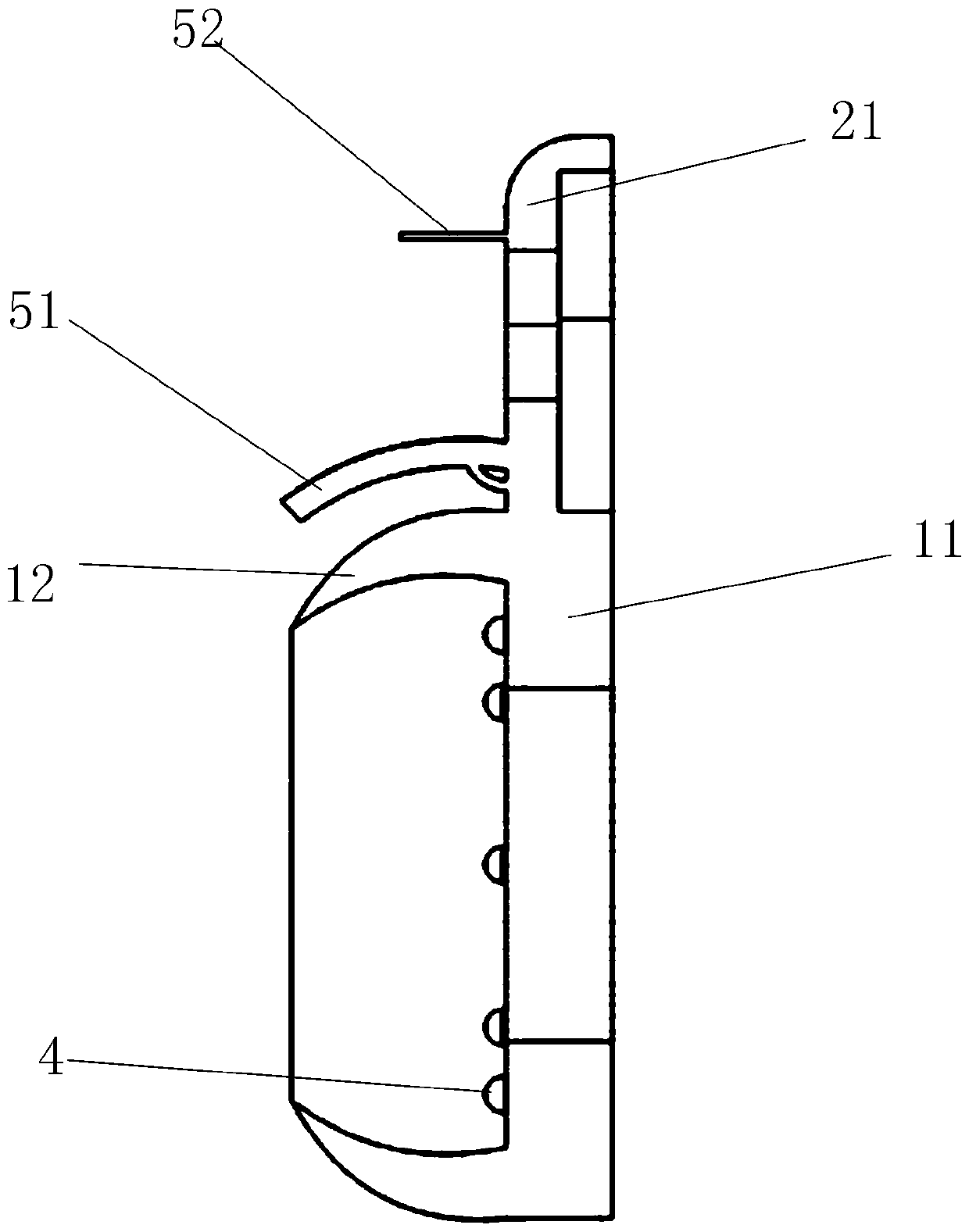

Safe guide wheel ring bushing device of enameling machine

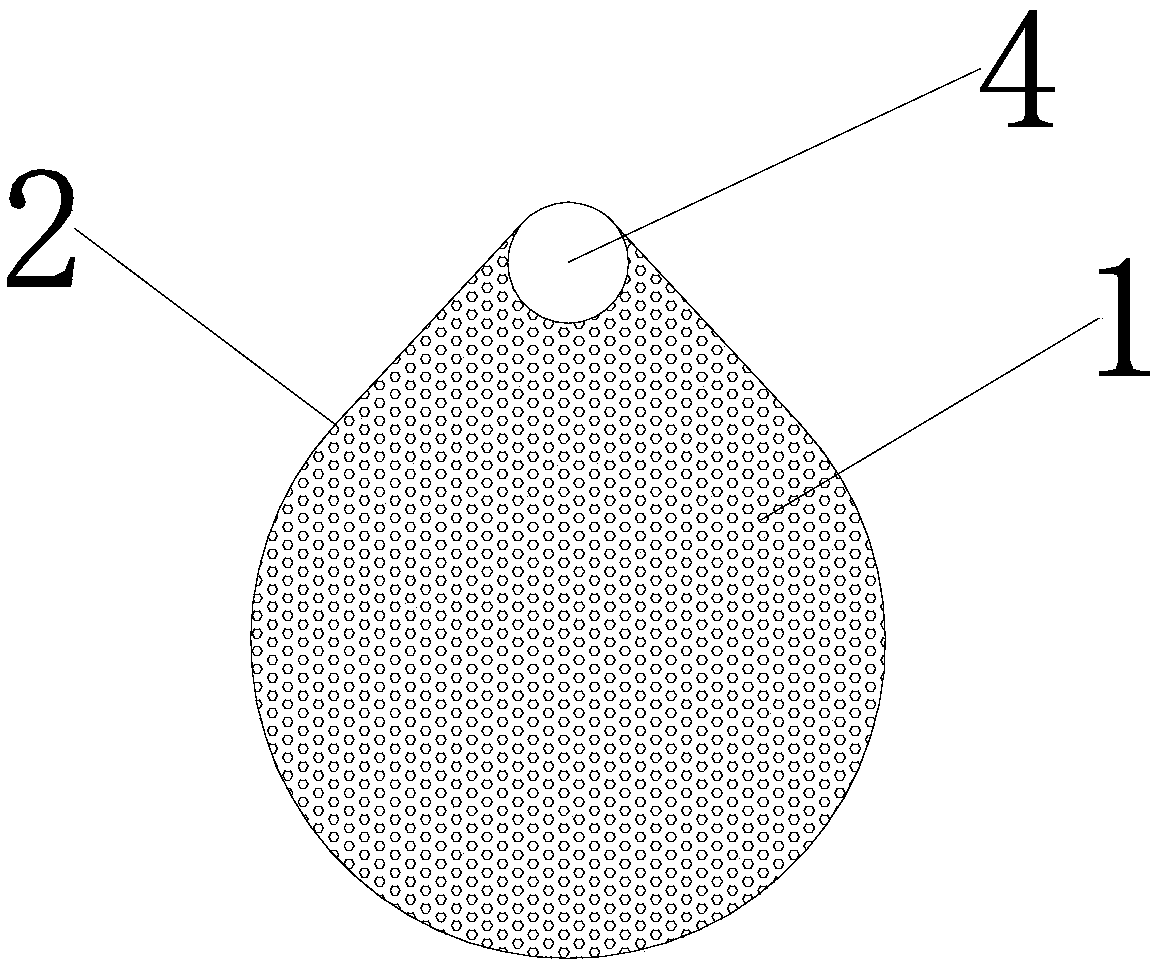

PendingCN107785124AExtended service lifeAvoid pollutionInsulating conductors/cablesCircular discEngineering

The invention relates to a safe guide wheel ring bushing device of an enameling machine, and relates to the field of enameled wire production. By means of the safe guide wheel ring bushing device, a metal wire is prevented from jumping and falling in the enameling process, the transporting process of the metal wire is more stable and smooth, meanwhile, a metal wheel is protected from being attached and eroded by debris, the oxidized speed of the surface of the metal wheel is reduced, and therefore, the service life of the metal wheel is prolonged. The safe guide wheel ring bushing device comprises a wheel wrapping part and a handheld part, wherein the metal wheel is wrapped with the wheel wrapping part, and the handheld part is used for applying force and taking the wire; the wheel wrapping part comprises an external wrapping part and an internal wrapping part, the external wrapping part is a disc-shaped panel, the internal wrapping part is an arc-shaped panel which extends to the sideaway from the external wrapping part from the edge of the surface of the external wrapping part and is gradually close to the central axis direction of the external wrapping part, and the handheld part is a panel which is from bottom to top from the lateral side of the top half part of the external wrapping part and is gradually narrowed.

Owner:湖州华上电工科技股份有限公司

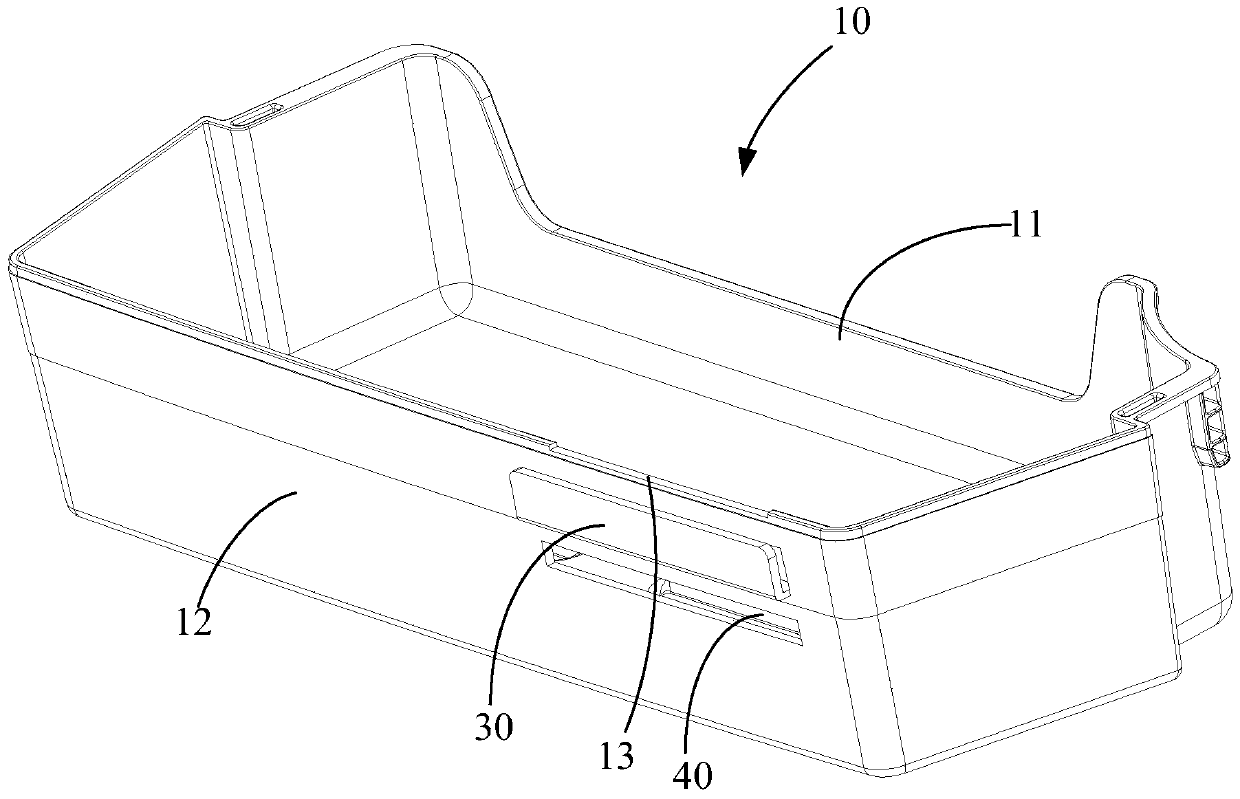

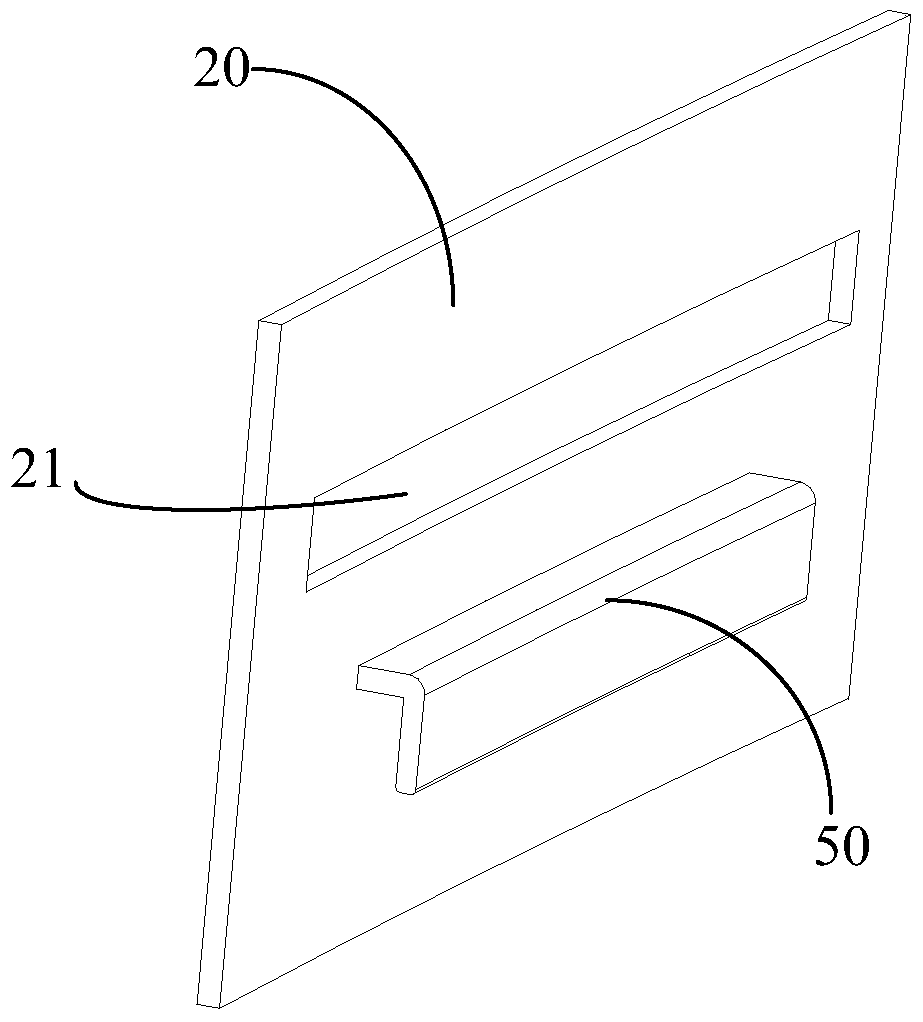

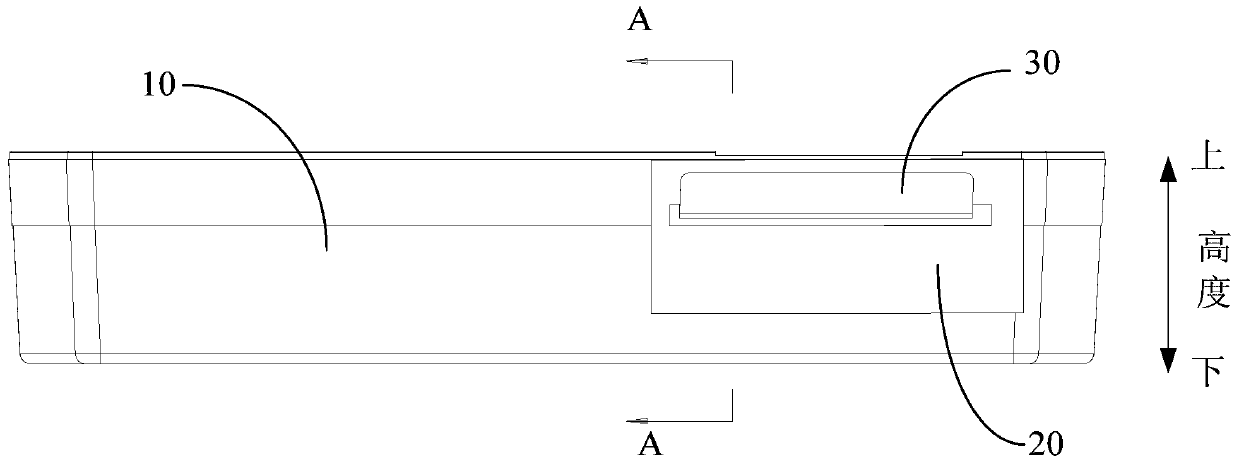

Refrigerator bottle frame, refrigerator door and refrigerator

ActiveCN105091488BBlock fallEasy accessLighting and heating apparatusCooling fluid circulationRefrigerator carEngineering

The invention discloses a refrigerator bottle frame, a refrigerator door and a refrigerator. The refrigerator bottle frame comprises a bottle frame body and a baffle. A first side plate of the bottle frame body is connected with a door body of the refrigerator. The baffle is arranged on a second side plate, opposite to the first side plate, of the bottle frame body. The second side plate is provided with a first installing position and a second installing position used for installing the baffle. When the baffle is located at the first installing position, the upper edge of the baffle is higher than the upper edge of the second side plate. When the baffle is located at the second installing position, the upper edge of the baffle is lower than or is flush with the upper edge of the second side plate. A large containing space can be formed between the baffle and the door body of the refrigerator in a manner that the baffle and the second side plate of the bottle frame body are movably connected. When few articles are arranged in the bottle frame body, the upper edge of the baffle is arranged to be lower than the bottle frame body so that a user can take and place the articles conveniently.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

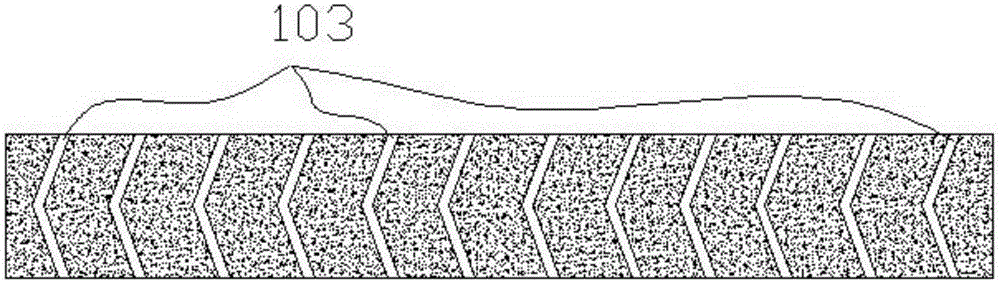

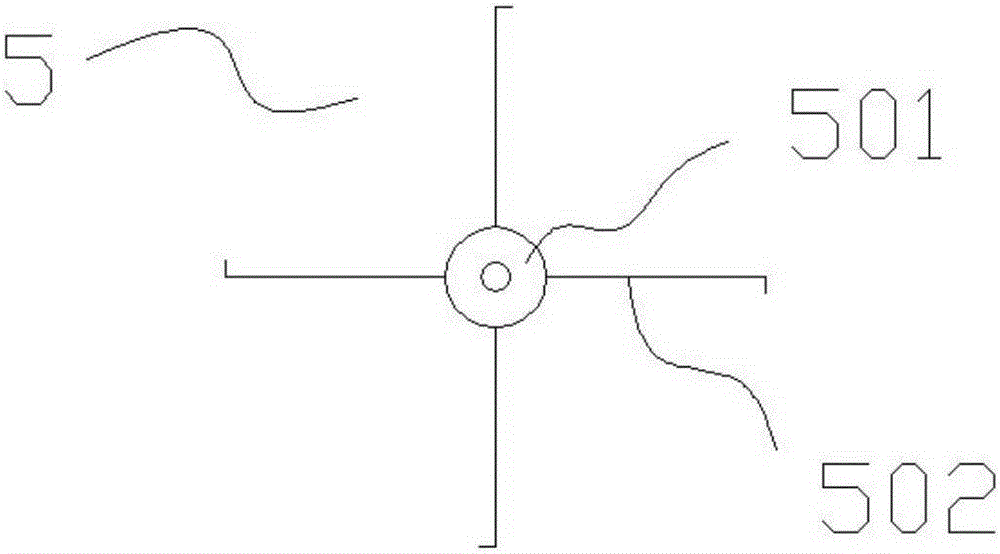

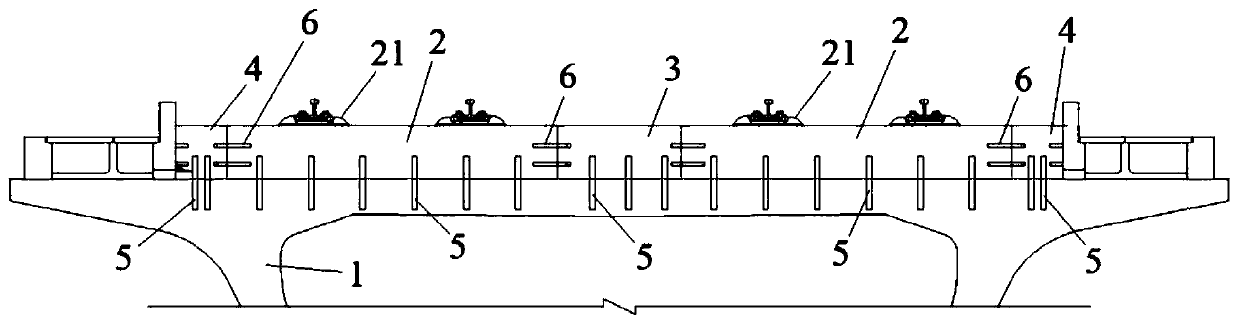

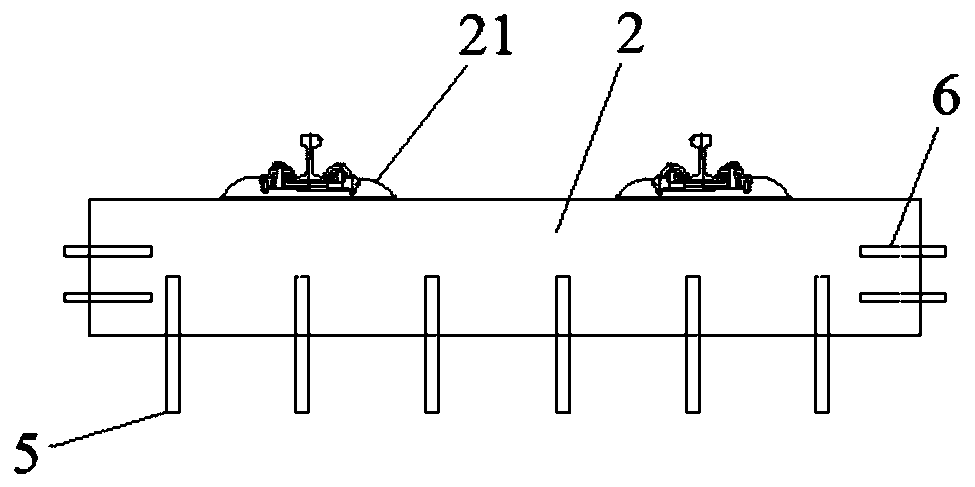

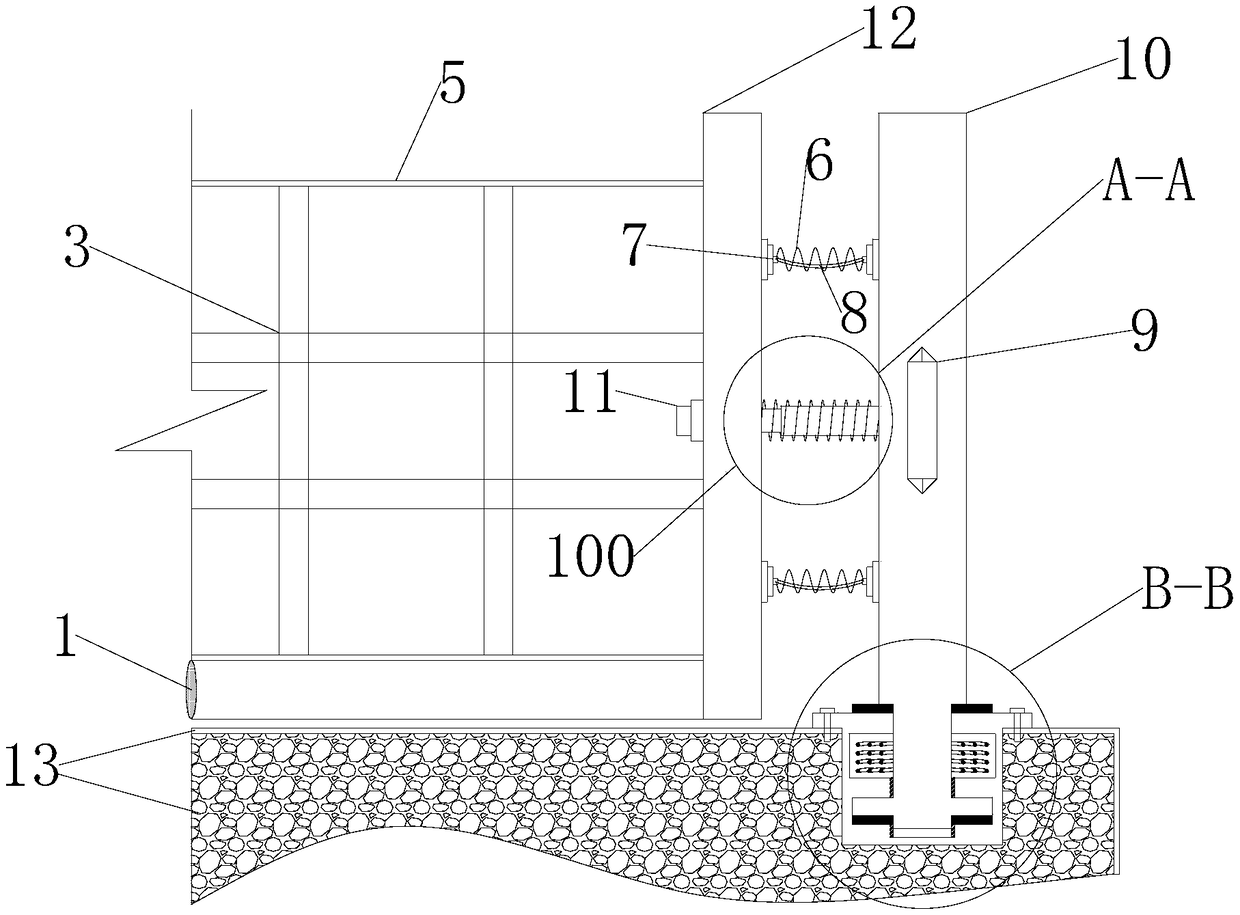

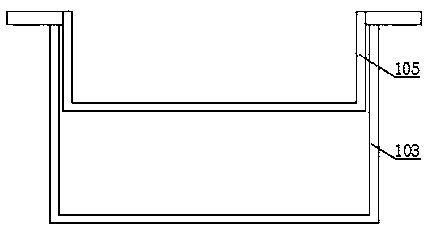

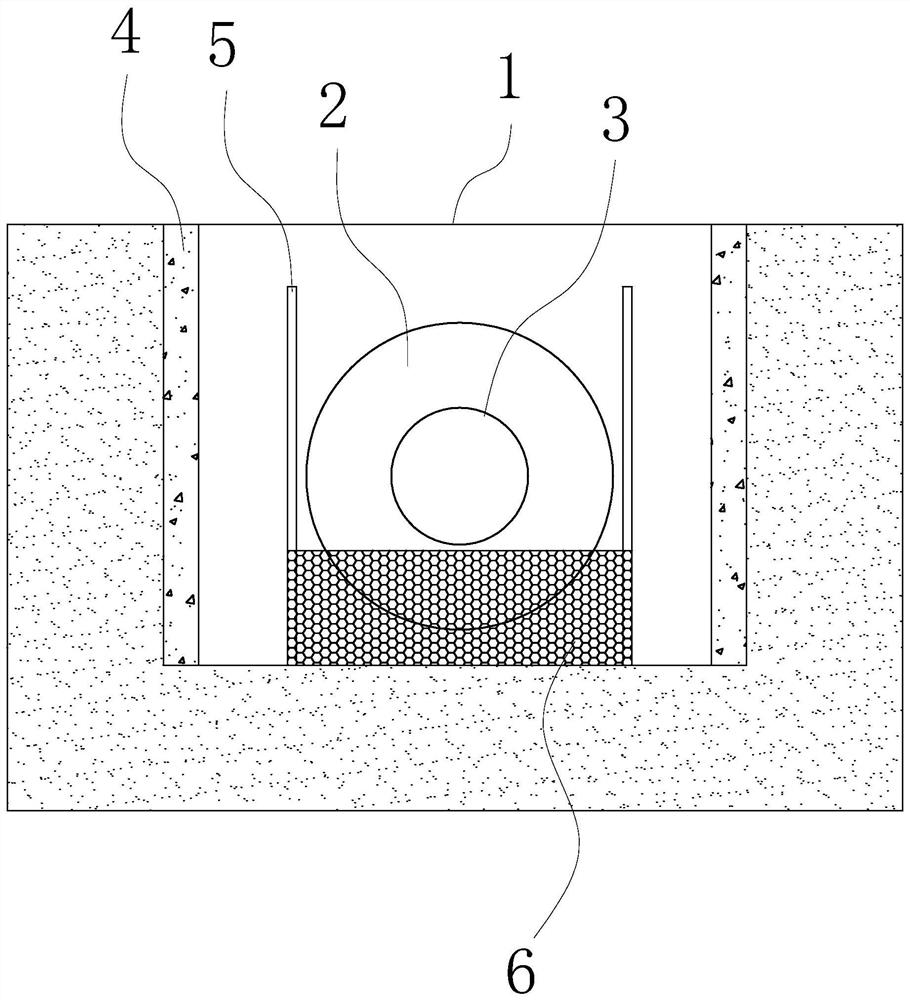

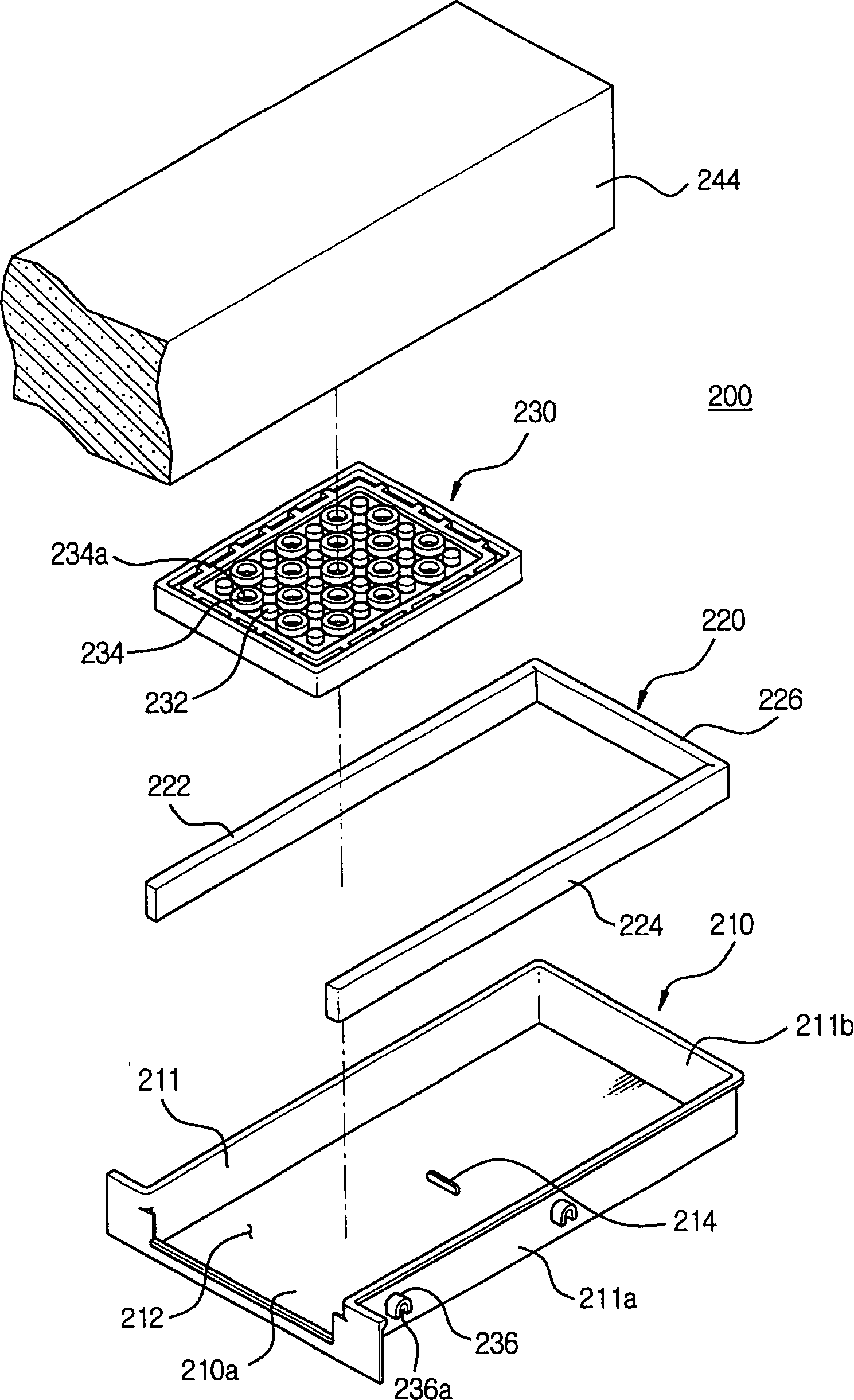

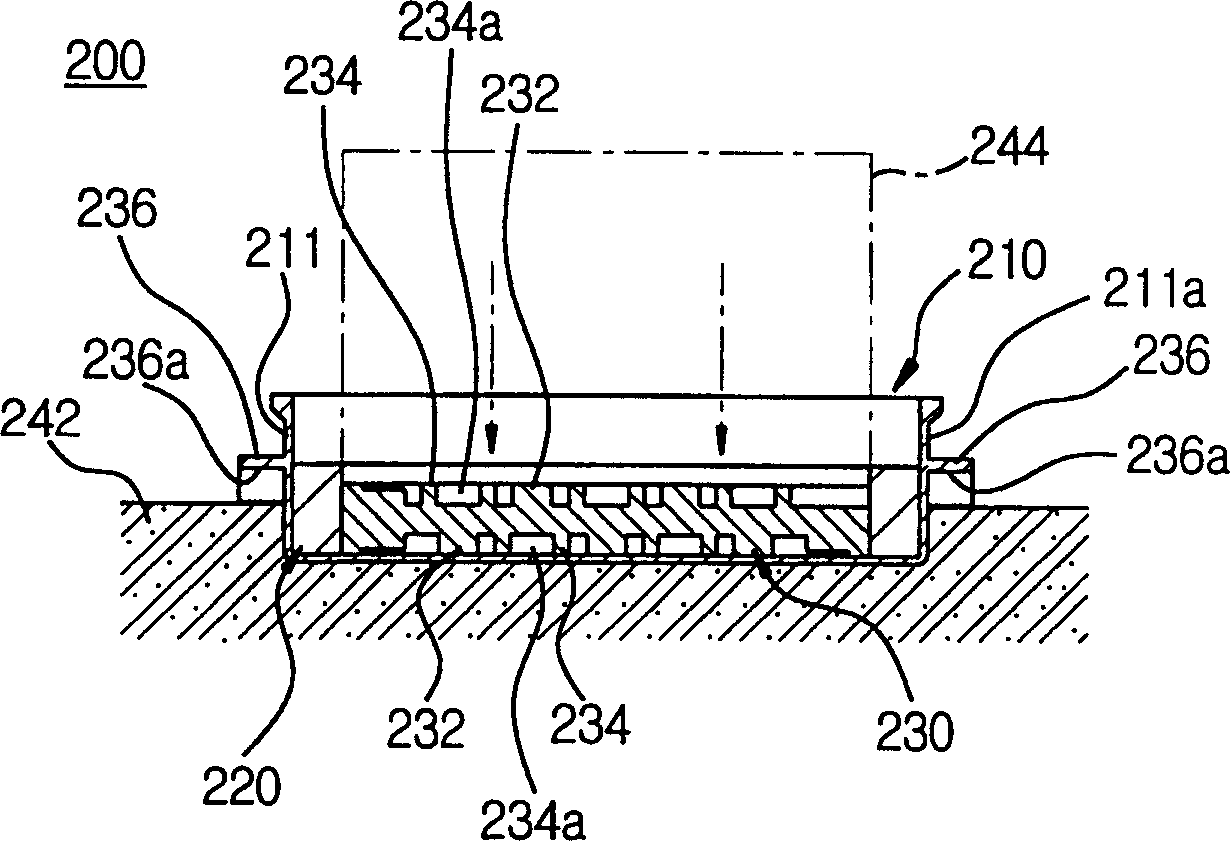

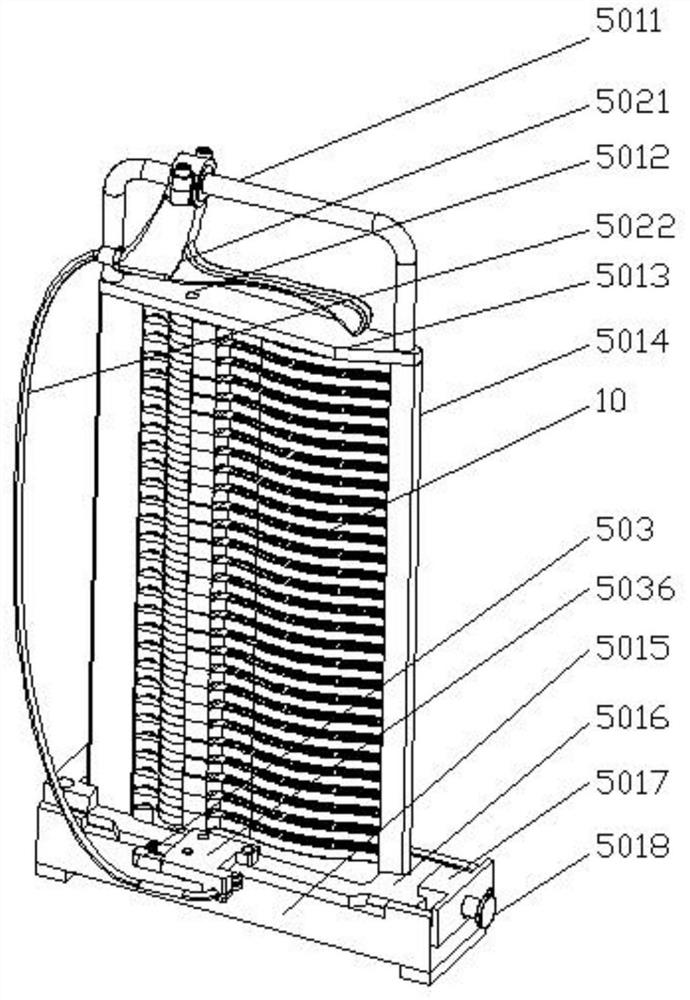

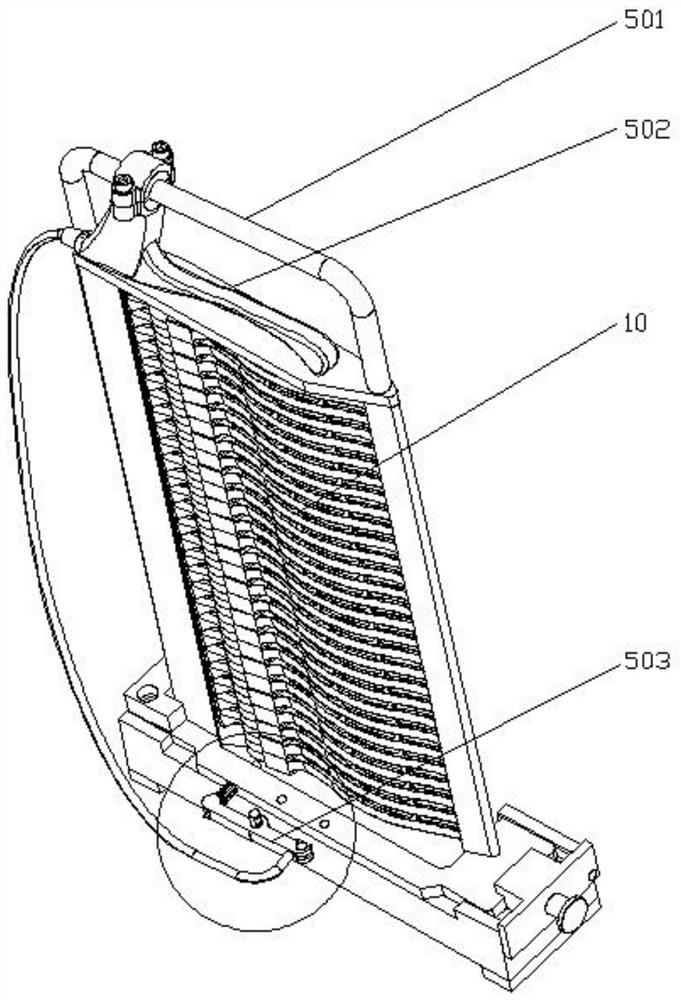

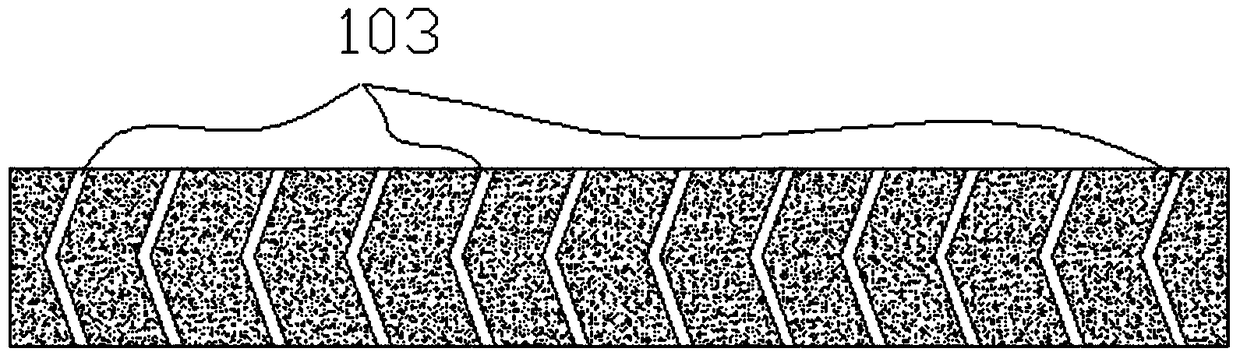

Vibration eliminating structure for concrete sleeper

The present invention discloses a vibration eliminating structure for concrete sleeper. In the vibration eliminating structure, a structure has two parallel side walls and another side wall which is mounted on the roadbed and forms a retainer space among the side walls. A first vibration eliminating component is tightly attached to each side walls for absorbing level vibration transmitted from the sleeper. The first vibration eliminating component is made of elastic materials. A second eliminating component is also made of elastic materials and is tightly attached to a first frame, a second frame and a third frame. The vibration eliminating structure can prevent foreign objects falling into the retainer space from the roadbed by adopting the structure.

Owner:李镕学 +1

Automatic blanking, feeding and positioning device for automatic machining of pliers

ActiveCN112059816AAvoid investmentVarious driving effectsGrinding carriagesGrinding drivesEconomic benefitsEngineering

The invention discloses an automatic blanking, feeding and positioning device for automatic machining of pliers. The device comprises a bottom plate, wherein a frame is fixedly arranged on the upper surface of the bottom plate; a feeding device for transporting a plier body, a positioning device for positioning the plier body and a blanking device for placing the plier body on the feeding device are arranged on the frame; the blanking device comprises a fixing frame used for fixing the plier body; a material blocking device used for preventing the plier body from falling is arranged at the lower end of the fixing frame; and a switch device used for controlling the material blocking device to be opened and closed is arranged on the fixing frame. According to the device, different actions ofautomatic blanking, feeding, positioning and clamping can be completed under the same drive, the investment of a plurality of drive devices is avoided, the manpower and automatic investment cost is reduced, and the economic benefits are increased.

Owner:湖南东方神鹰科技股份有限公司 +1

A paper cutting device

ActiveCN111517135BBlock fallWind evenlyMetal working apparatusWebs handlingElectric machineHorizontal bar

Owner:杭州宏成纸业有限公司

Conveying device for new material production

InactiveCN112849238AIncrease frictionPrevent inertial collisionHand carts with multiple axesHand cart accessoriesElectric machineryTransmission equipment

The invention discloses a conveying device for new material production. The conveying device for new material production comprises a conveying box, fixing shafts are symmetrically and fixedly connected to a front cavity and a rear cavity of the conveying box, rotating columns are rotationally connected to the outer surfaces of the fixing shafts, the rotating columns are connected with the rear end face of the conveying box in a penetrating mode, and a conveying belt is slidably connected to the outer surfaces of the rotating columns. A second motor supporting frame is fixedly connected to the rear end face of the conveying box, a second motor is fixedly connected to the lower end face of the second motor supporting frame, a supporting plate is rotatably connected to the lower end face of a threaded rod, and a pushing rod is fixedly connected to the left end of the conveying box. A rotating plate is rotatably connected with the right end of the conveying box. Connecting frames are symmetrically and fixedly connected to the lower end face of the supporting plate, and wheels are rotationally connected to the opposite ends of the connecting frames. The invention relates to the technical field of the conveying equipment. The conveying device for new material production solves the problems that in the conveying process, materials are damaged and collide with one another due to inertia, and manual unloading is needed.

Owner:苏州糖瑞翠电子科技有限公司

Paper Mill Fuel Delivery Unit with Screening

ActiveCN105292986BEasy to separateImprove efficiencyLoading/unloadingLump/pulverulent fuel feeder/distributionScreening effectEngineering

Owner:SUZHOU XINENG ENVIRONMENTAL SCI & TECH CO LTD

A manufacturing device for express packaging boxes

ActiveCN110253665BBlock fallSimple structureMetal working apparatusPolypropyleneIndustrial engineering

The invention discloses a manufacturing device for express packaging box, comprising a work box, a work space is arranged in the work box, a drive block is fixedly connected to the lower end wall of the work space, and an upper end wall is arranged in the drive block to communicate with the work space The collection tank is provided with a reciprocating groove in the left end wall of the collection tank; There is a transmission space in the right end wall of the lifting space. The left end wall is connected to the lifting space. The device has a simple structure and convenient operation. A large number of subsequent cutting operations save labor.

Owner:浙江华邦物联技术股份有限公司

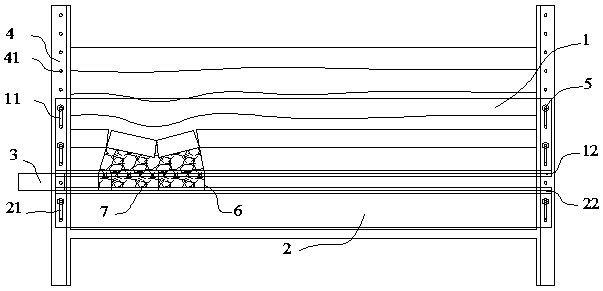

A leak-proof physical similarity simulation experiment frame

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com