Powder falling mechanism of coffee machine

A coffee machine and powder dropping technology, which is applied to beverage preparation devices, household appliances, applications, etc., can solve the problems of many parts, high production cost, and complex structure of the opening and closing mechanism, and achieve high work efficiency, low production cost, The effect of improving market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

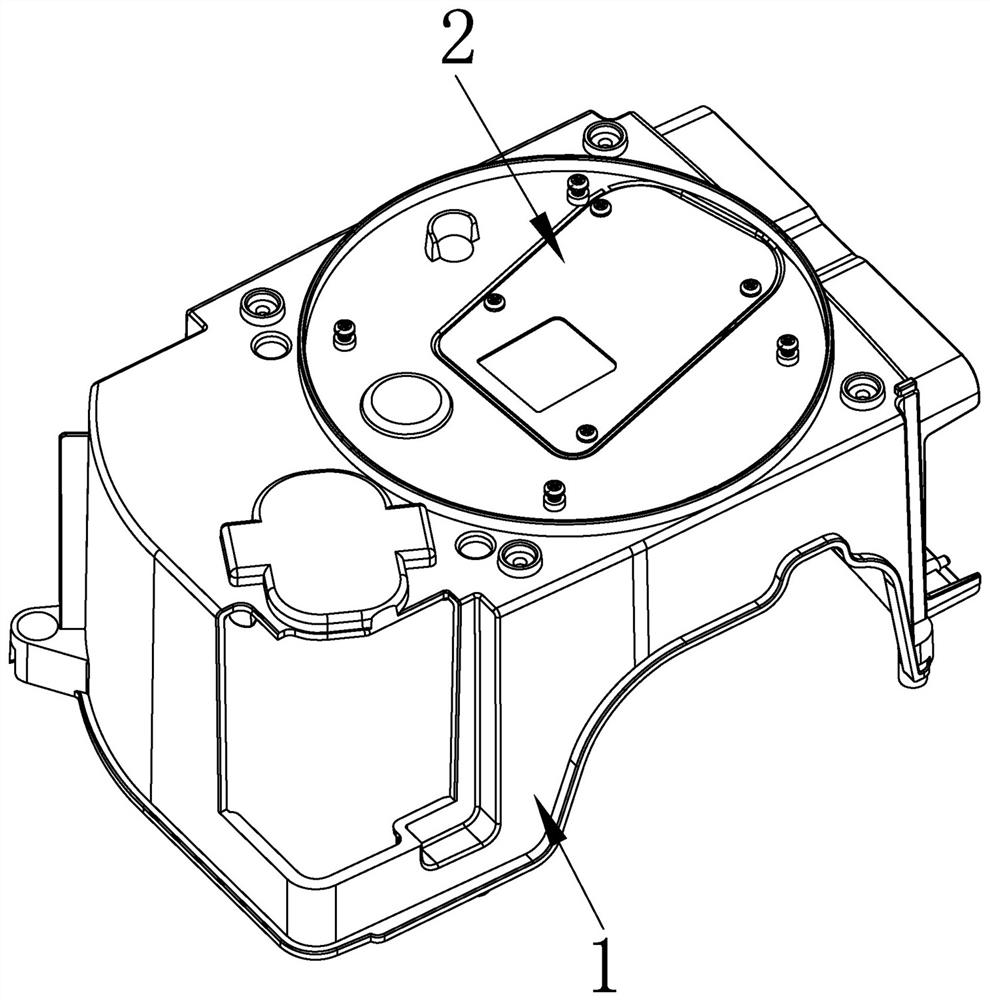

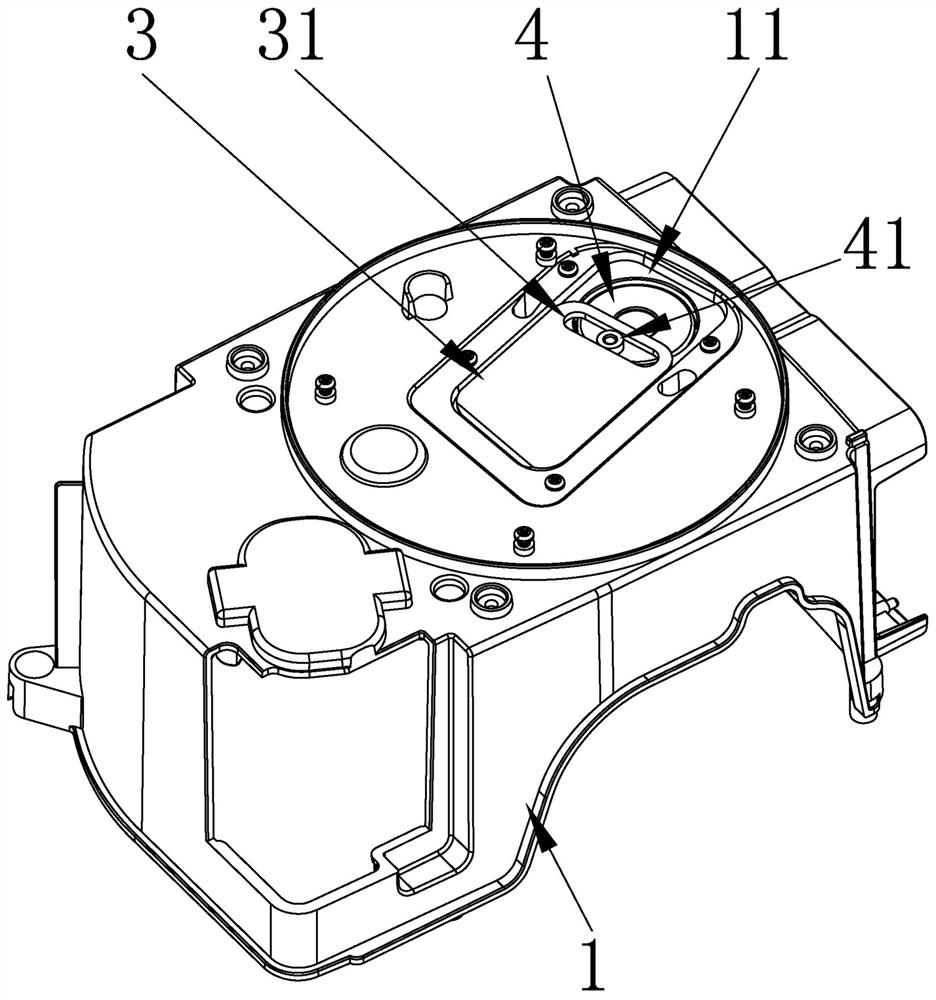

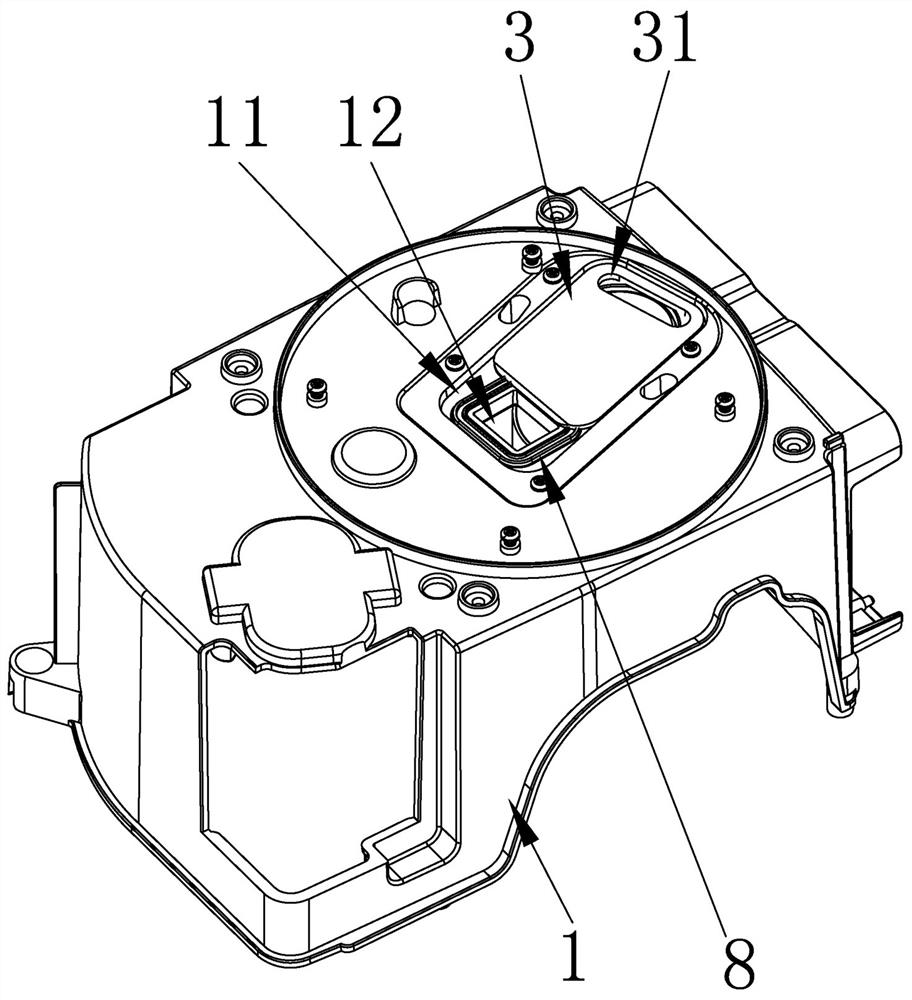

[0019] The present invention will be specifically and further described below in conjunction with the accompanying drawings. A powder dropping mechanism for a coffee machine, characterized in that it includes a powder outlet seat 1, the lower part of the powder outlet seat 1 is recessed inward to form a movable groove 11, and a sliding plate 3 is slidably installed in the movable groove 11 through a driving mechanism;

[0020] One side of the movable groove 11 is provided with a powder outlet 12, and the sliding plate 3 is slidably covered on the upper part of the powder outlet 12, and the driving mechanism drives the sliding plate 3 to slide to realize the opening and closing of the sliding plate 3 to the powder outlet 12; The drive mechanism includes an eccentric wheel 4 and a drive motor 5 connected thereto. The drive motor 5 drives the eccentric wheel 4 to rotate. The eccentric wheel 4 is provided with an eccentric shaft 41 offset from its rotation center, and the eccentric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com