Three-state beam source furnace shutter for molecular beam epitaxy

A technology of molecular beam epitaxy and beam source furnace, which is applied in the direction of condensed steam, crystal growth, single crystal growth, etc., can solve the problems affecting process stability and repeatability, uncontrollable evaporation beam flow, and affecting the quality of epitaxial film, etc. Achieve the effect of improving equipment production efficiency and reducing equipment maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

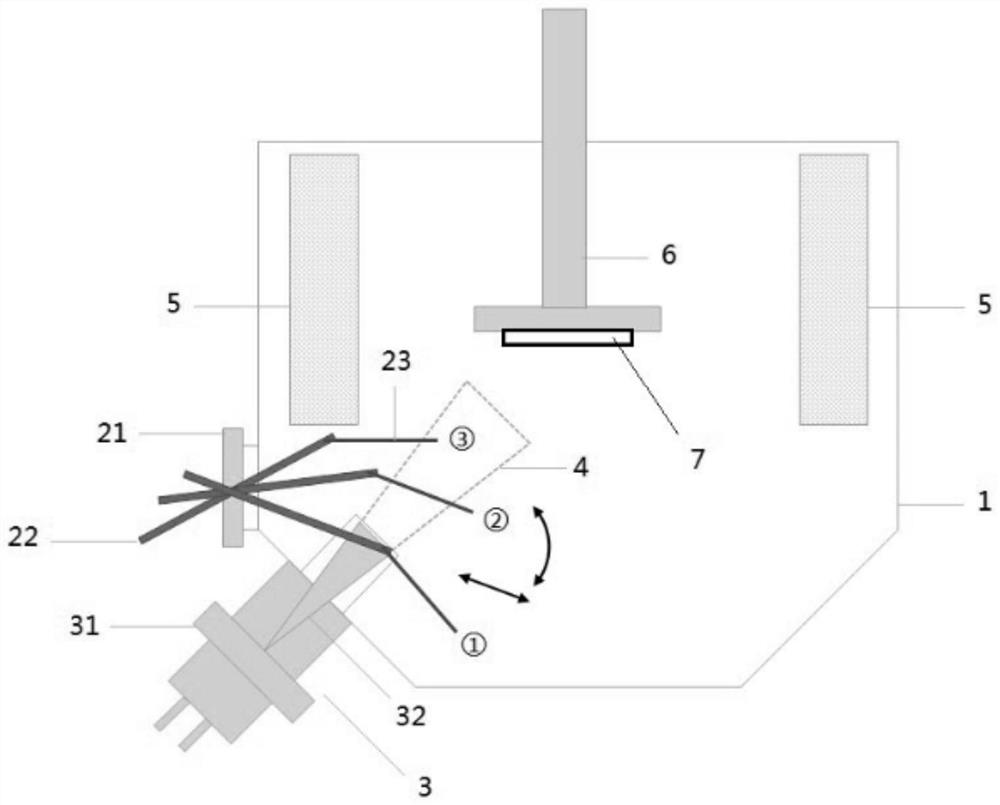

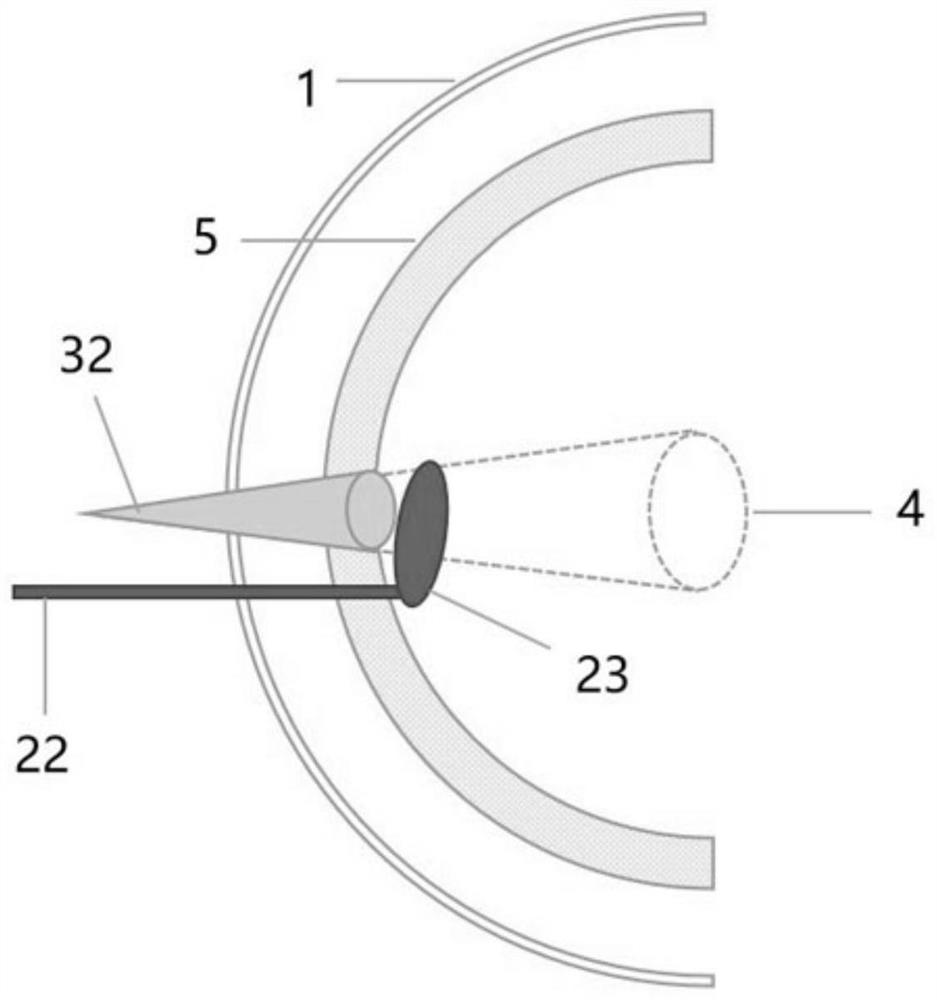

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0018] Figure 1 to Figure 2 An embodiment of the beam source furnace shutter for three-state molecular beam epitaxy of the present invention is shown. The beam source furnace shutter for three-state molecular beam epitaxy in this embodiment includes shutter blades 23 located in the vacuum chamber 1, for A shutter lever 22 that drives the shutter blade 23 to swing up and down and linearly expand and contract, and a shutter flange 21 for installing the shutter lever 22 . Wherein, the shutter blade 23 may be in a suitable shape such as a circle, an ellipse, a drop shape, a square, a rhombus, and a polygon.

[0019] The beam source furnace shutter for three-state molecular beam epitaxy, the shutter blade 23 can be driven by the shutter lever 22 to swing and telescopically move, when the shutter blade 23 completely avoids the beam evapor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com