Continuous squeezing method and device for directly cooling squeeze wheel race and material stop block surfaces

An extrusion method and extrusion wheel technology, applied in metal extrusion control equipment, metal extrusion, metal processing equipment, etc., can solve the problems affecting equipment production efficiency and material utilization, extrusion wheel and block temperature It is difficult to drop, the extrusion wheel and the blocking block are damaged, etc., to achieve the effect of improving the production efficiency of the equipment, improving the utilization rate of materials, and reducing the temperature difference between inside and outside.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A continuous extrusion method for directly cooling the surface of the extrusion wheel groove and the retaining block. The cooling of the extrusion wheel or the retaining block is that the liquid cooling medium directly cools the extruded metal surface covered by the extrusion wheel groove or For the outer surface of the block, the direct cooling of the liquid cooling medium is to use the liquid cooling medium to spray directly on the extruded metal or the outer surface of the block covered by the groove surface of the extrusion wheel through the pump source, so as to quickly lower the extrusion wheel and the block. The temperature of the material block, the speed sensor measures the speed of the extrusion wheel, the temperature sensor measures the temperature of the extrusion wheel and the block material respectively, and the measurement signal is input to the PLC programmable controller or industrial control computer, and stored in the PLC and the industrial control mark...

Embodiment 2

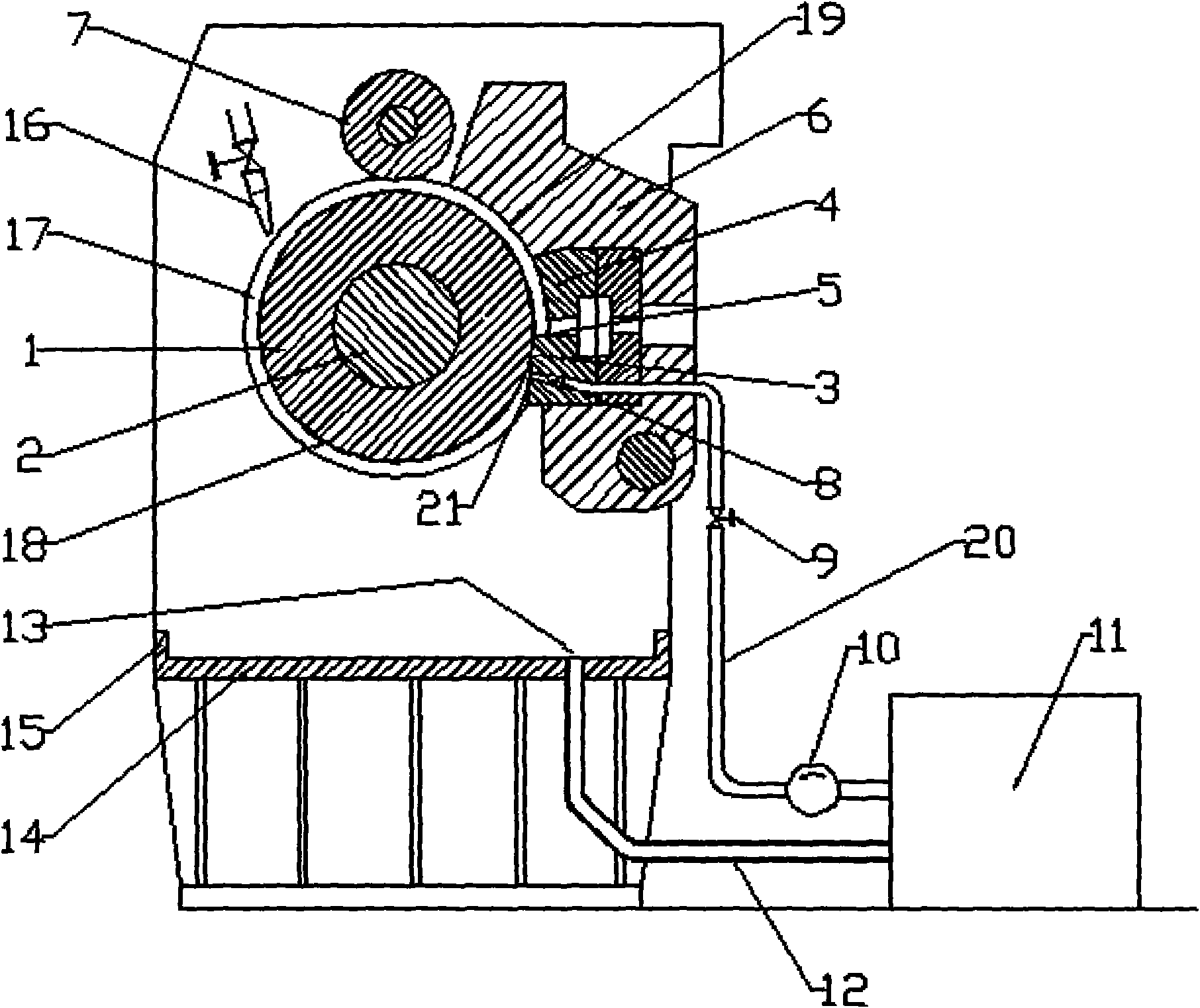

[0029] like figure 1 Shown is a continuous extrusion device that directly cools the surface of the extrusion wheel groove and the stopper block. The rotary extrusion wheel 1 is installed on the rotating shaft 2, and the extrusion wheel 1 has a circumferential groove 17. The surface of the circumferential groove 17 of the wheel 1 is covered with extruded metal 18, and the extruded metal 18 completely rotates synchronously with the circumferential groove 17 on the extrusion wheel 1, and the cavity 4 with the arc sealing surface 19 is installed on the shoe seat 6, the blocking block 3 on the cavity 4 goes deep into the circumferential groove 17 of the extrusion wheel 1, and when the extruded metal rod material (not shown in the figure) passes through the compaction wheel 7, it is 1. When the frictional force is driven to the stopper 3, driven by the frictional extrusion force, high temperature and high pressure will be generated, enter the channel 5 of the cavity 4, and extrude t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com