Anti-gushing and anti-scalding device for clearing blockage of cyclone preheater of cement kiln

A cyclone preheater and anti-splash technology, which is applied in the direction of preheating fee, descaling device, lighting and heating equipment, etc., can solve the problems of unblocking personnel's operation injury, material splashing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

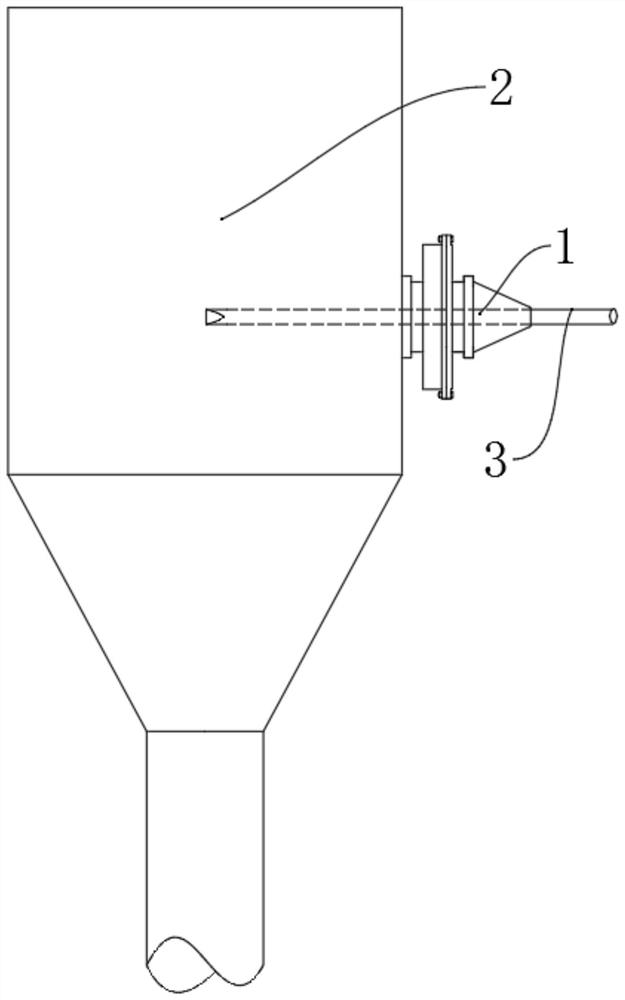

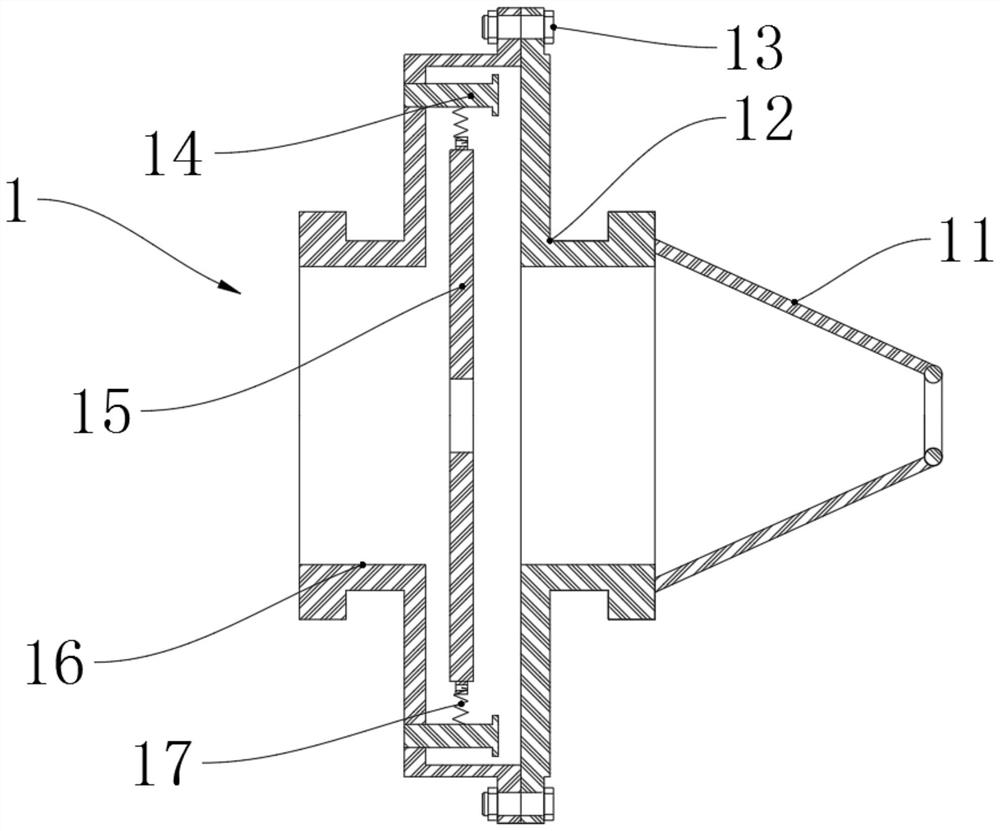

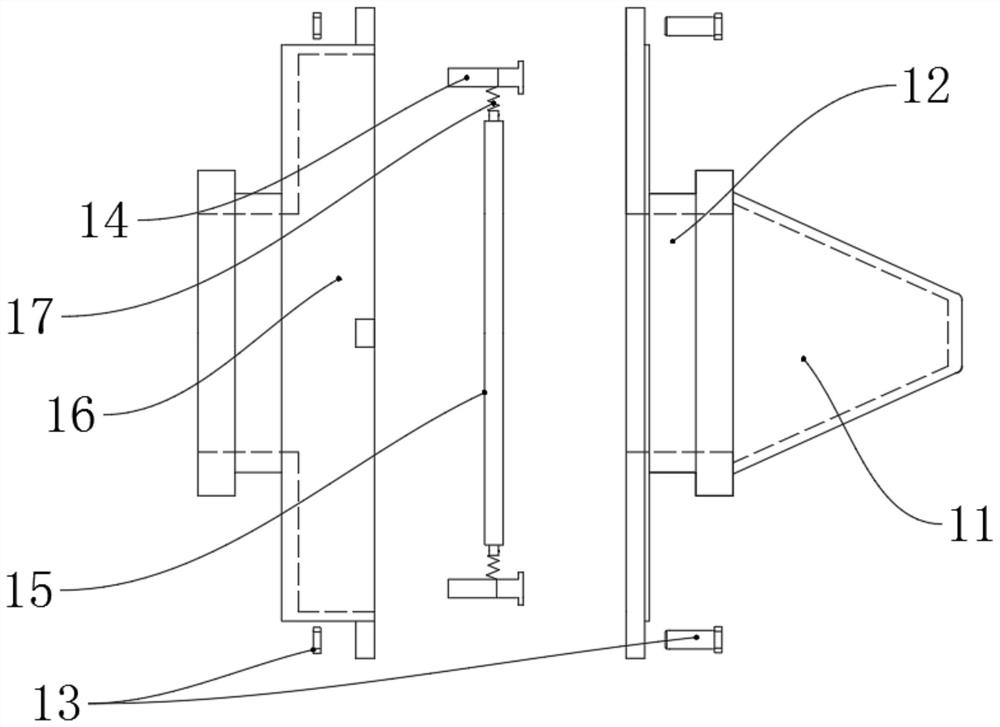

[0032] Such as Figure 1-11 As shown, a kind of anti-spray scald device for clearing the blockage of a cyclone preheater in a cement kiln, said anti-spray scald device includes a support seat 16, a baffle plate 15, a support column 14, a spring 17, a protective piece 12 and a protective cover 11; One end of the support seat 16 is connected to the cyclone preheater 2, and the other end is movably connected to one end of the protective member 12, and the other end of the protective member 12 is connected to the protective cover 11; the support seat 16 is provided with a connection hole 162 and the counterbore 163, at least two symmetrical support columns 14 are distributed on the bottom circumference of the counterbore 163; the baffle plate 15 is placed in the counterbore 163, and is connected with the support column 14 by a spring 17, and is suspended in the air. Inside the counterbore 163 , the baffle plate 15 defines a first through hole 151 .

[0033] When the baffle plate ...

Embodiment 2

[0040] Compared with Embodiment 1, the difference lies in that: a connection structure form of the support seat and the protective member is provided.

[0041] The support base 16 is connected to the protective member 12 through bolts 13 . The bolts can facilitate splicing and separation between the support seat and the protective piece.

Embodiment 3

[0043] Compared with Embodiment 2, the difference is that: in order to facilitate the connection between the support seat and the protective member, a support 161 is added; in order to facilitate the installation of the support column in the counterbore, a support hole 164 is added.

[0044] At least two supports 161 are distributed on the circumferential side of the supporting seat 16 . The support 161 is used for the movable connection between the support seat and the protective element. The commonly used number of bearings 161 is 2, 3, 4, 6 or 8, etc.

[0045]One end of the screw rod in the bolt 13 passes through the guard 12 and the support 161 and is connected with the nut.

[0046] A plurality of support holes 164 are distributed around the bottom surface of the counterbore 163 , and the support holes 164 are used for installing the support column 14 .

[0047] The support column 14 is inserted into the support hole 164 and is firmly connected with the support hole 164...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com