A kind of manufacturing and processing method of core body of baby diaper

A processing method and technology of diapers, which are applied in the fields of baby underwear, adhesive products, medical science, etc., can solve problems such as easy formation of layers, influence of mixing effect, unevenness of wood pulp particles, etc., so as to improve the degree of uniformity, The effect of increasing satisfaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

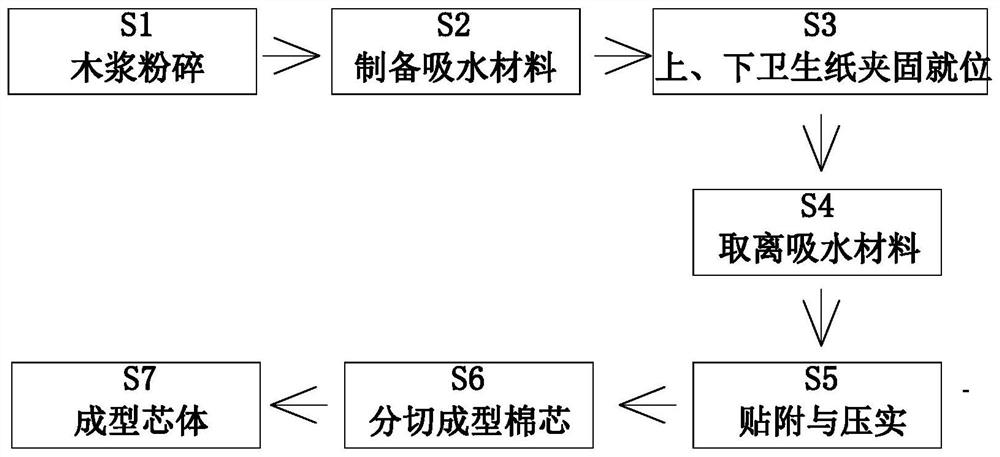

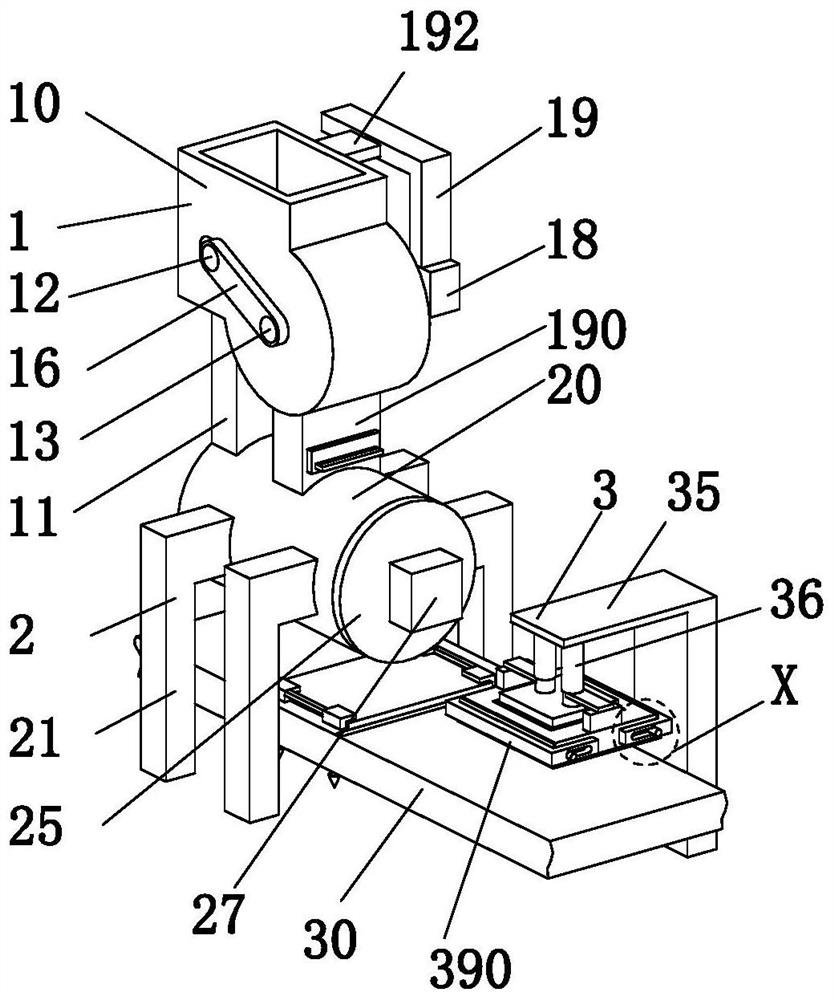

[0049] Such as Figure 1 to Figure 15 A method for manufacturing and processing infant diaper cores is shown, which uses an infant diaper core manufacturing and processing device. The infant diaper core manufacturing and processing device includes a crushing mechanism 1, a mixing mechanism 2, and a molding mechanism 3. The specific processing methods of the infant diaper core production and processing device are as follows:

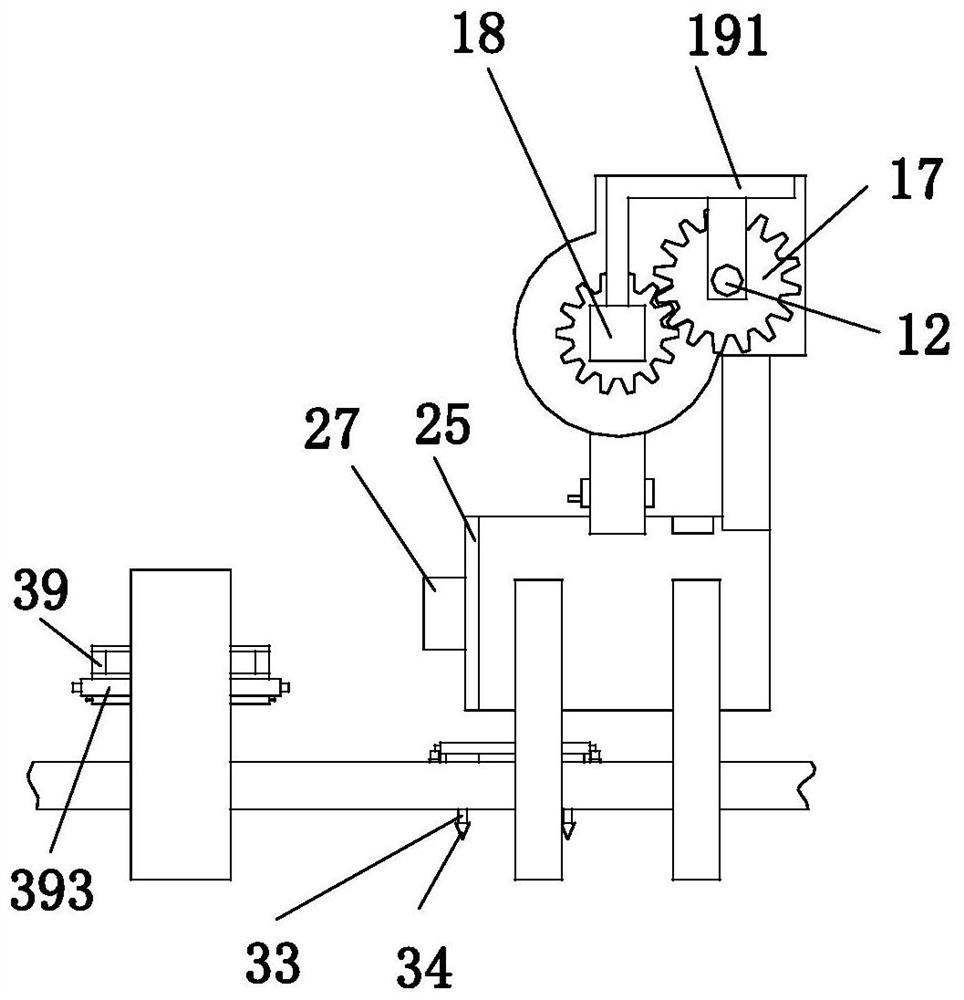

[0050] S1. Wood pulp crushing: Pour the wood pulp into the crushing cabinet 10 manually and drive the second shaft 13 to rotate through the No. 1 motor 18. The No. 2 shaft 13 drives the main gear 15 to rotate synchronously, and the No. 1 shaft 12 drives the auxiliary gear 14 Under the cooperation of the two linkage gears 17...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com