Uniform spreading device for blast furnace smelting

A material spreading device and blast furnace smelting technology, which is applied in the field of uniform material spreading device for blast furnace smelting, can solve the problems of wasting raw materials such as iron ore, reducing combustion efficiency, and low quality of molten iron, so as to reduce the amount of slag and reduce the cost of enterprises cost, quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

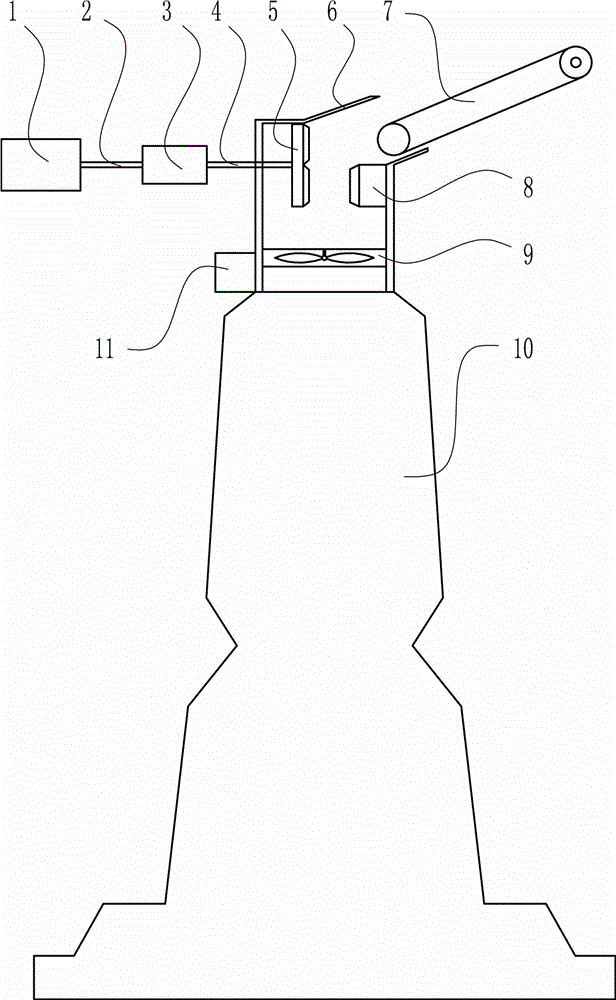

[0025] It also includes a controller 11, which is fixedly arranged on the left outer wall of the hopper 6; the left and right cylinders 1, the motor 3 and the fan 9 are all connected to the controller 11 respectively.

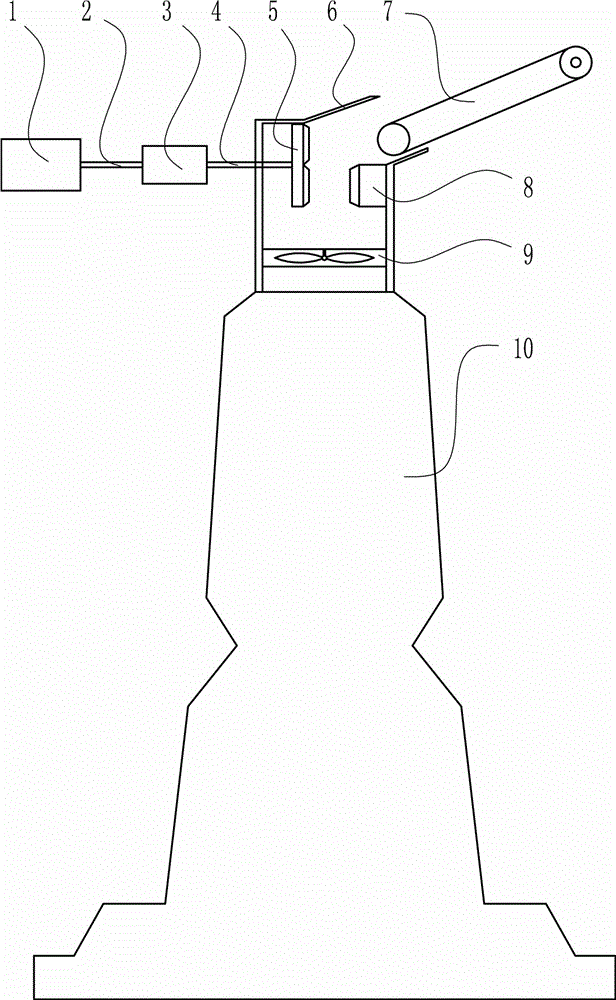

[0026] The motor 3 is a geared motor 3 .

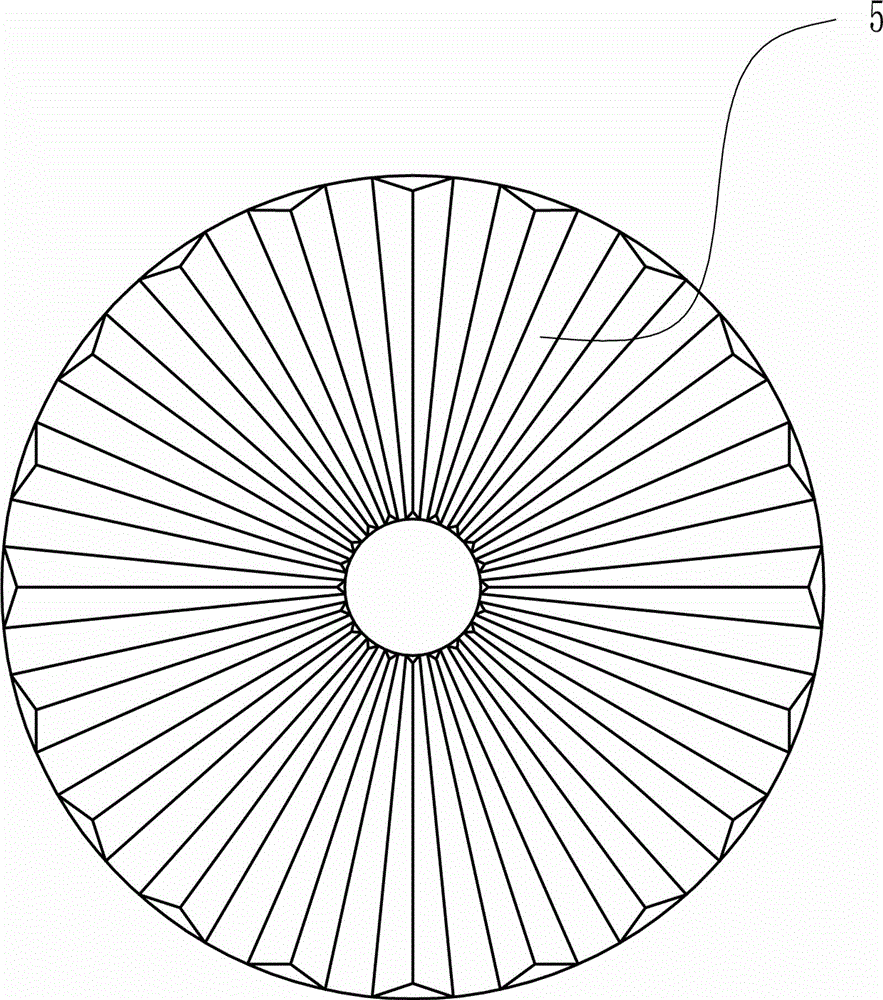

[0027] Working principle: In this device, the hopper 6 is arranged above the blast furnace 10 , and the hopper 6 is connected with the blast furnace 10 . A left disc-shaped grinding disc 5 and a right semi-disc-shaped grinding disc 8 are arranged in the hopper 6, and the left disc-shaped grinding disc 5 and the right semi-disc-shaped grinding disc 8 are movably connected. On the right disc surface of the left disc-shaped grinding disc 5, a plurality of grinding teeth are evenly arranged along its center, and on the left half disc surface of the right semi-disc-shaped grinding disc 8, a plurality of grinding teeth are evenly arranged along its center. tooth. The grinding tooth that is provided with on the right semi-d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com