Beef processing chopper mixer and use method thereof

A technology for chopping and mixing machine and beef, applied in the field of food processing, can solve the problems of low work efficiency, waste of time, low product quality, etc., and achieve the effects of improving work efficiency, convenient use and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

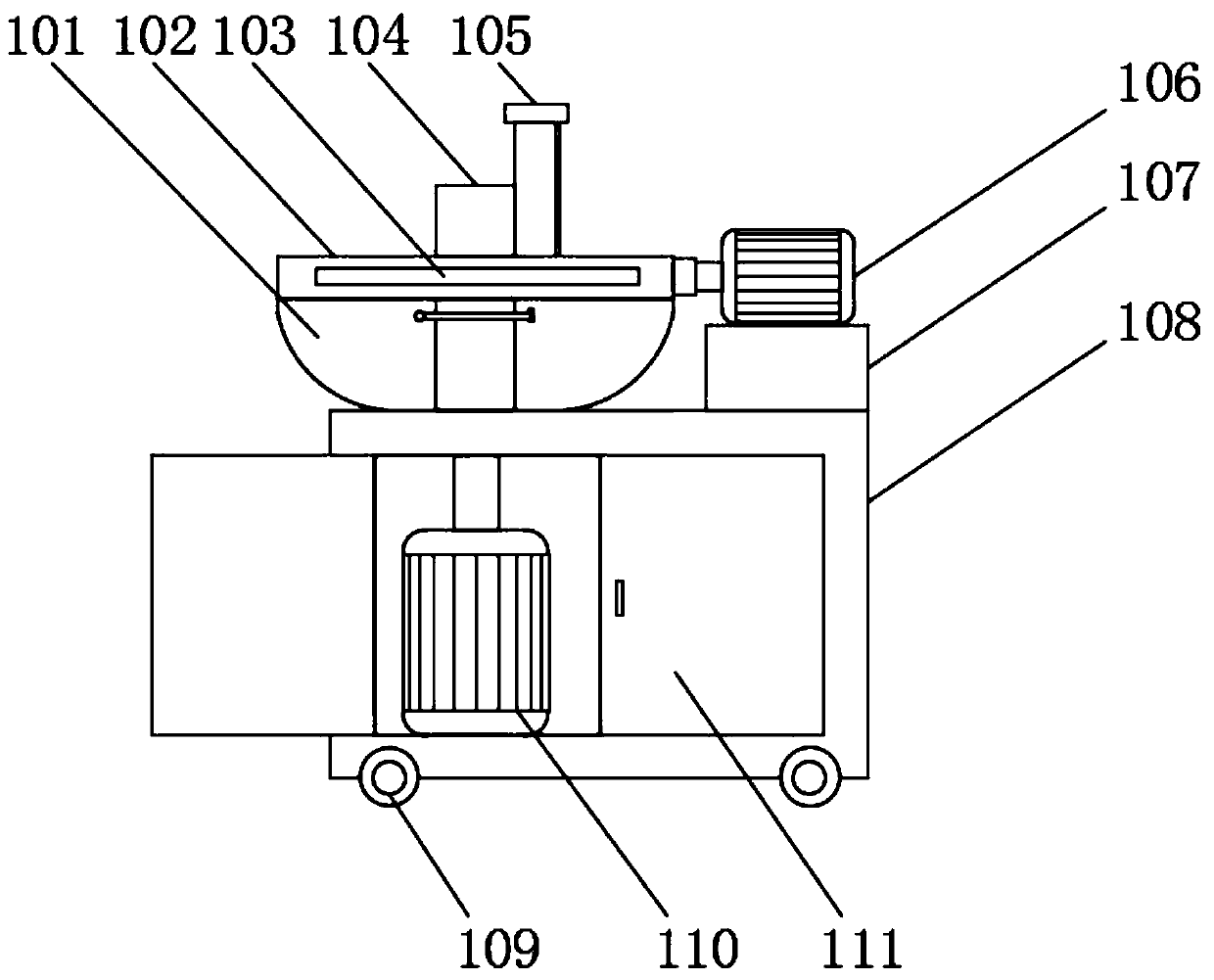

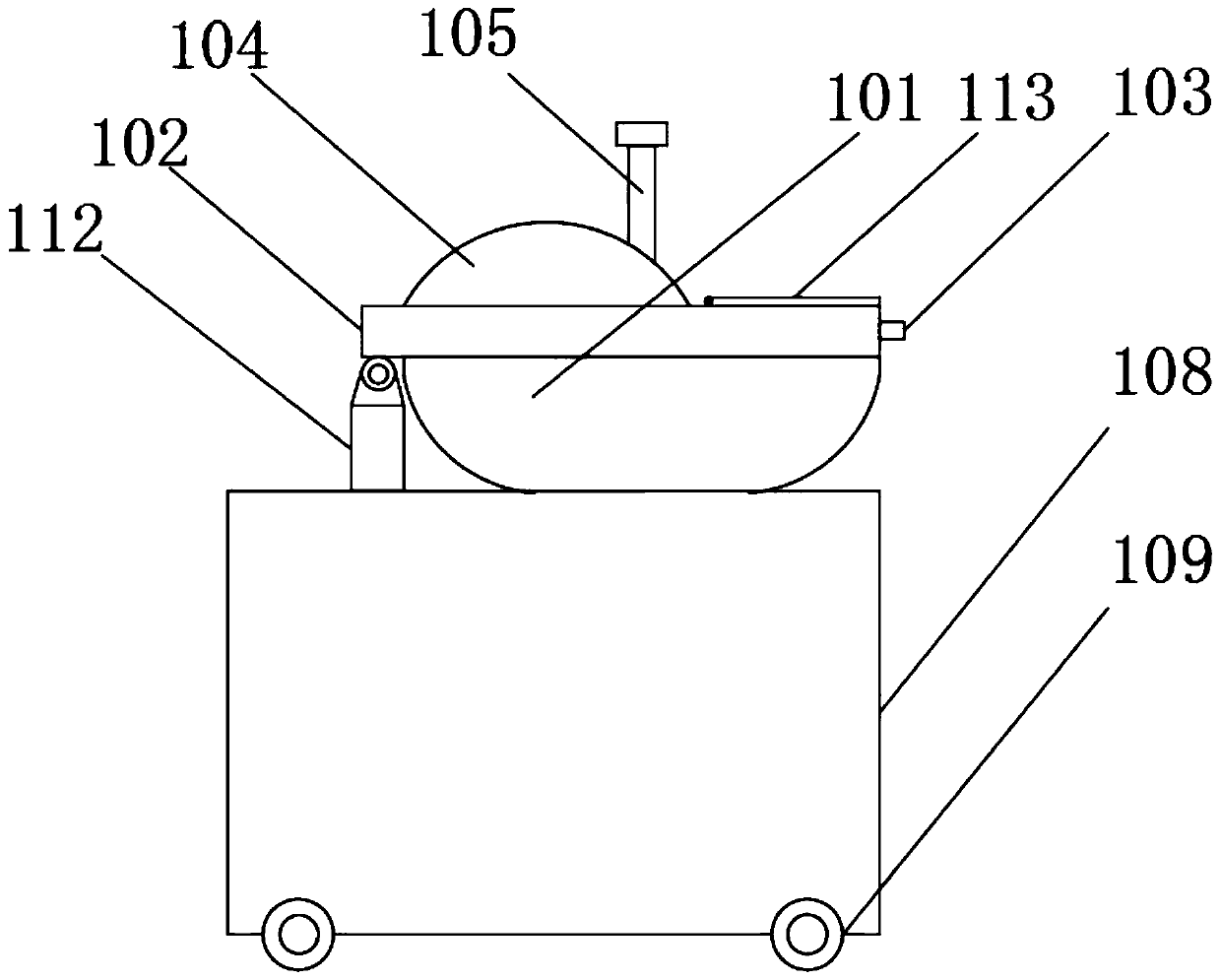

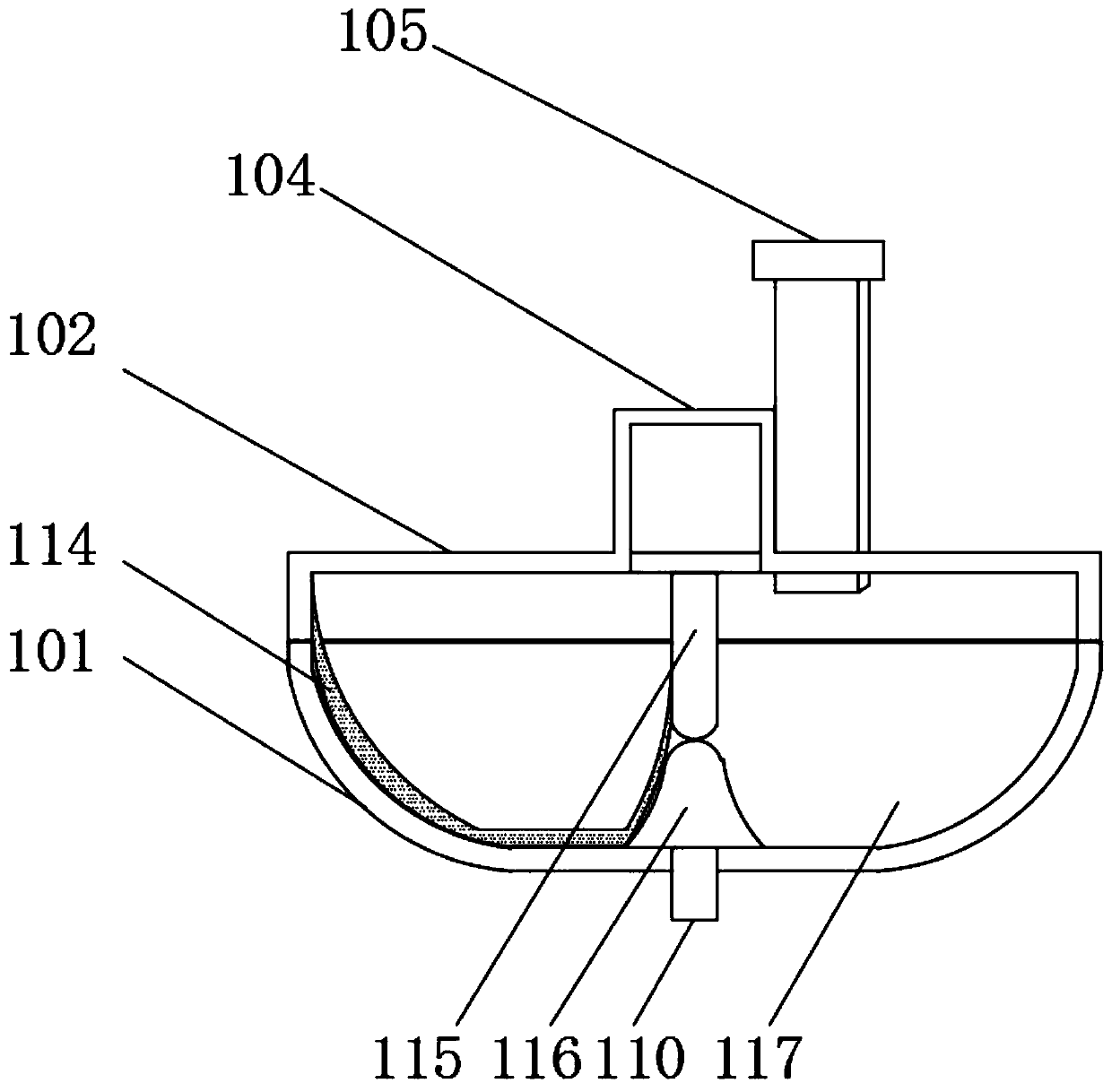

[0037] see Figure 1-8 As shown, the present embodiment is a beef processing and chopping machine, including a chopping pot body 101, a chopping cover body 102, a load-bearing box 108, and a chopping pot body 101 is installed on one side of the top of the load-bearing box 108. The top of the body 101 is provided with a chopping cover body 102, and the top of the load-bearing box 108 is away from the side of the chopping pot body 101. A spacer 107 is installed, and the top of the spacer 107 is equipped with a first drive motor 106. Two driving motors 110, the output shaft of the second driving motor 110 runs through the top of the load-bearing box 108 and is connected to the bottom of the chopping and mixing pot body 101. The beef in the middle moves to the chopping knife 119, and the fast rotating chopping knife 119 cuts and pulverizes the beef into meat sauce;

[0038] The chopping pot body 101 is bowl-shaped, and a raised cap 116 is installed at the bottom center of the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com