Novel cutting type pulverizer

A shearing, pulverizer technology, applied in cocoa, grain processing, food science, etc., can solve the problems of inconvenient adjustment of the tooth disc gap, inability to adapt to the technological process, difficult to control the product fineness, etc., to achieve compact structure, high performance Reliable, small footprint results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

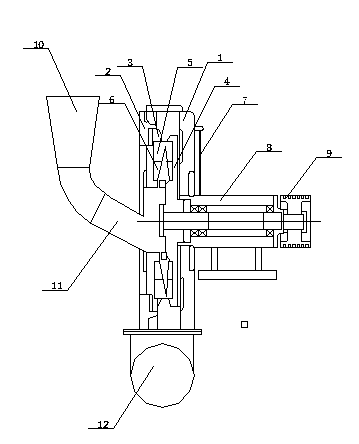

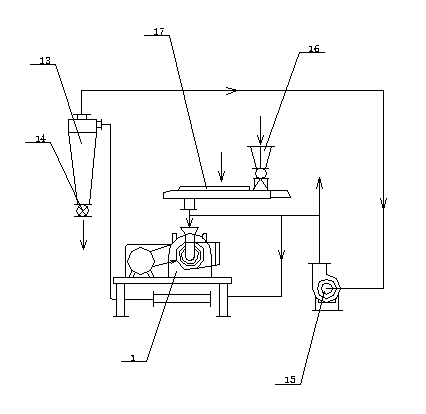

[0012] refer to figure 1 , figure 2 , the specific embodiment adopts the following technical scheme: it is composed of body 1, machine door 2, static disk shell 3, moving disk shell 4, outer gear ring 5, inner gear ring 6, suction cover 7, bearing seat 8, belt wheel 9, feed hopper 10, feed pipe 11, and discharge hopper 12; machine body 1 is provided with organic door 2, and body 1 is provided with static disc shell 3 and dynamic disc shell 4, static disc shell 3 and dynamic disc shell 4 An outer ring gear 5 is arranged between them, and the outer ring gear 5 meshes with the inner ring gear 6. A suction cover 7 is arranged on one side of the upper end of the body 1, and a bearing seat 8 is arranged on one side of the middle part of the body 1. The bearing seat 8 and the belt The wheel 9 is connected, and the feed hopper 10 is arranged on the other side of the middle part of the body 1 through the feed pipe 11, and the lower end of the body 1 is provided with a discharge hoppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com