Beam end ballast blocking and sleeper system integrated device

A technology for a sleeper and a ballast wall, which is applied in the field of rail transit, can solve the problems of sudden change in the rigidity of the track structure, difficult construction of steel sleepers, and poor effect, and achieve the effects of small sudden change in rigidity, good effect, and convenient construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

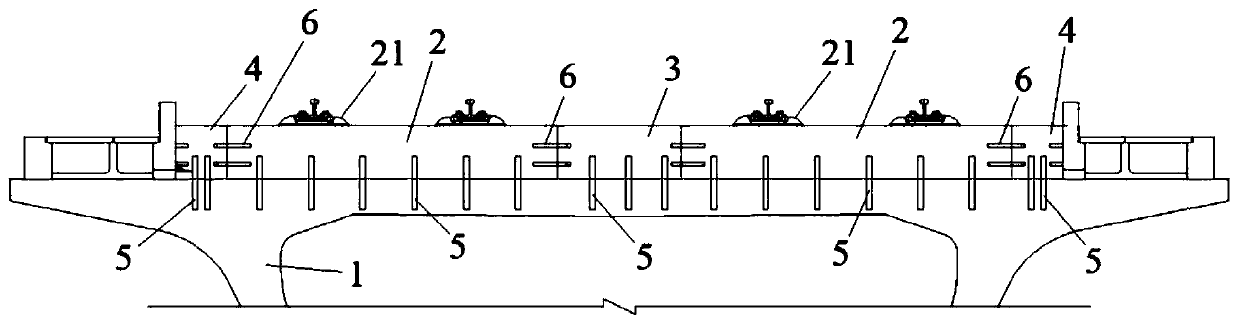

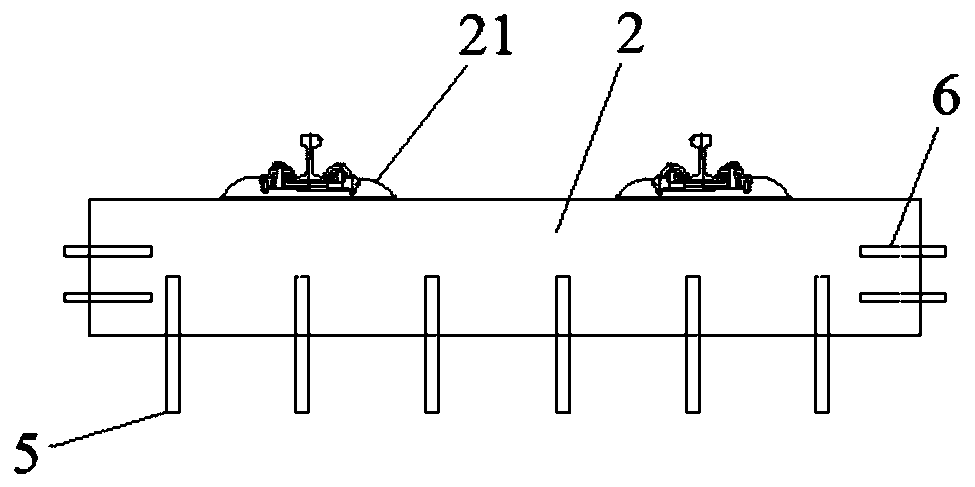

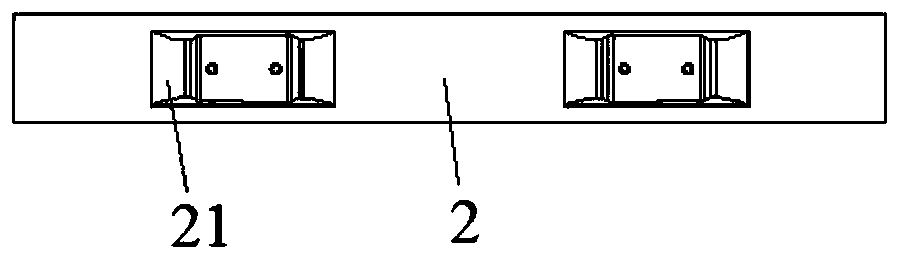

[0029] Such as Figure 1-6 As shown, an integrated device for beam end ballast and sleeper system according to the present invention includes two sleepers 2, an intermediate blocking member 3 and two side blocking members 4 arranged at the end 1 of the bridge.

[0030] Such as figure 1 As shown, the intermediate blocking member 3 is arranged between the two sleepers 2, the side blocking member 4 is arranged at the remaining end of each sleeper 2, the sleeper 2, the intermediate blocking member 3 and the The side blocking members 4 jointly form a ballast retaining wall, which closes the end 1 of the bridge.

[0031] Such as figure 1 As shown, the sleeper 2, the intermediate blocking member 3, and the side blocking member 4 are all connected to the bridge end 1 through a first connector 5; specifically, as figure 2 , 4 As shown in and 5, the first connecting member 5 is a pre-embedded steel bar or a pin, and is respectively arranged in the sleeper 2, the middle blocking member 3 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com