Gas storage tank bearing device for LNG (liquefied natural gas) single-fuel ship

A technology for gas storage tanks and ships, applied in the field of ships, can solve problems affecting ship stability, potential safety hazards, and upward shift of the center of gravity of the ship, achieving the effect of compact spatial structure layout, lowering the center of gravity, and solving stability problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] A device for placing an air storage tank for an LNG single-fuel ship according to the present invention will be described in detail below in conjunction with the accompanying drawings.

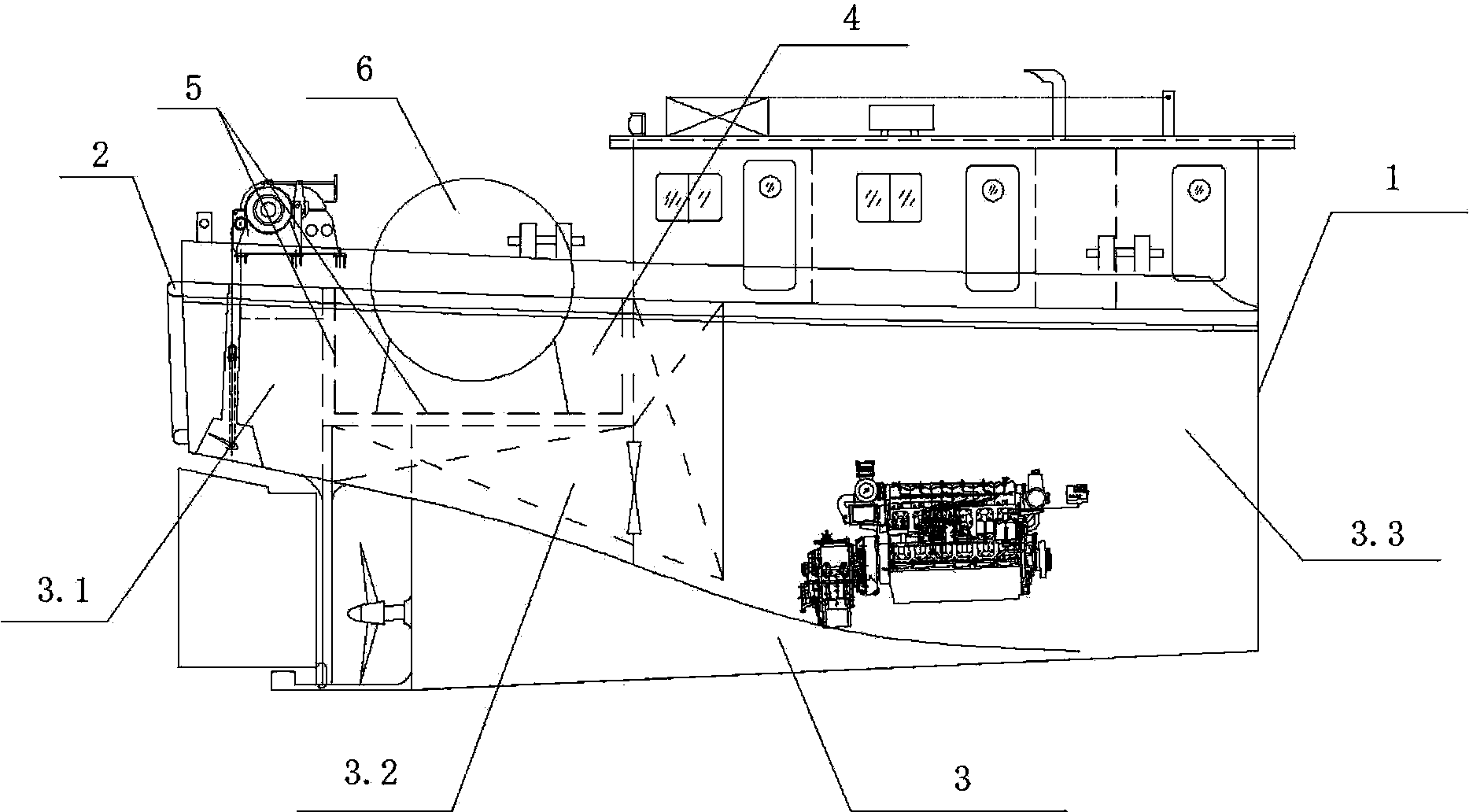

[0015] as attached figure 1 As shown, a gas storage tank placement device for LNG single-fuel ships, its structure includes a hull 1, the hull 1 is divided into two parts by the deck 2 into the open air and the cabin 3, and the cabin 3 includes the stern tank 3.1 in sequence from the stern , the ballast water tank 3.2 and the engine room 3.3, the gas storage tank cabin 4 connected with the deck 2 is arranged between the ballast water tank 3.2 and the deck 2, and the gas storage tank cabin 4 is connected into a polyhedral box shape by a support plate 5 And the air storage tank compartment 4 is surrounded by the ballast water tank 3.2, and the air storage tank 6 is placed at the bottom of the air storage tank compartment 4.

[0016] The gas tank compartment 4 is in the shape of a cuboid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com