Straw granulator feeding device

A technology of feeding device and granulator, which is applied in the direction of conveyor, transportation and packaging, method of granulating raw materials, etc., can solve the problems of improving feeding efficiency, sliding at inclination angle, unable to realize splicing of multiple groups of feeding devices, etc. Achieve the effect of increasing the height of raw materials and improving the feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

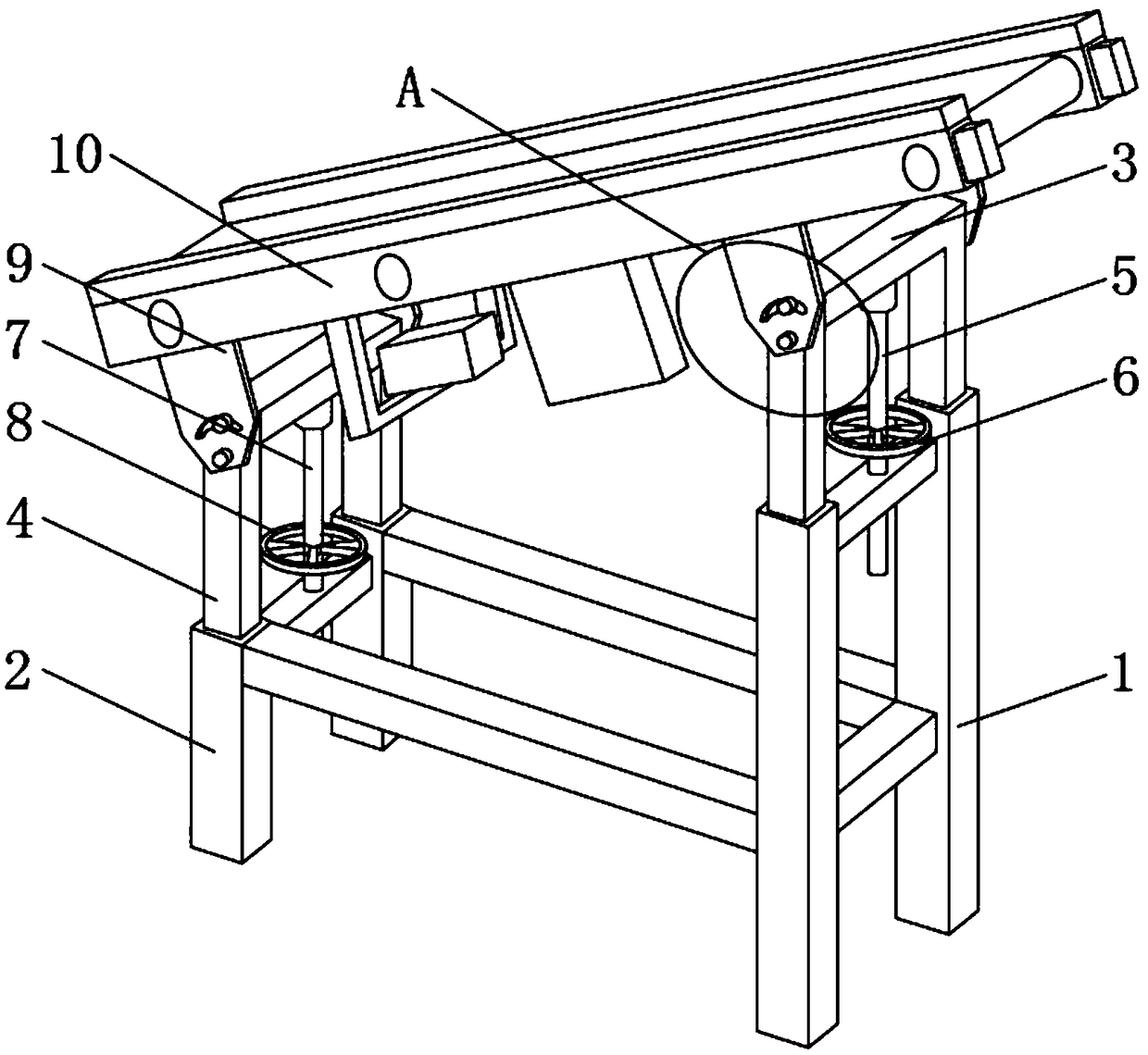

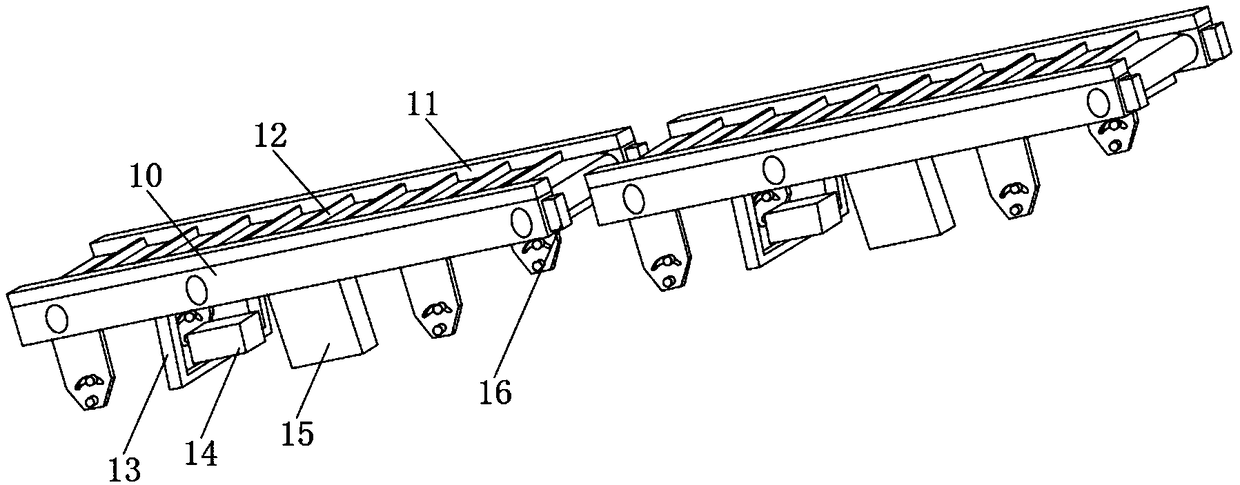

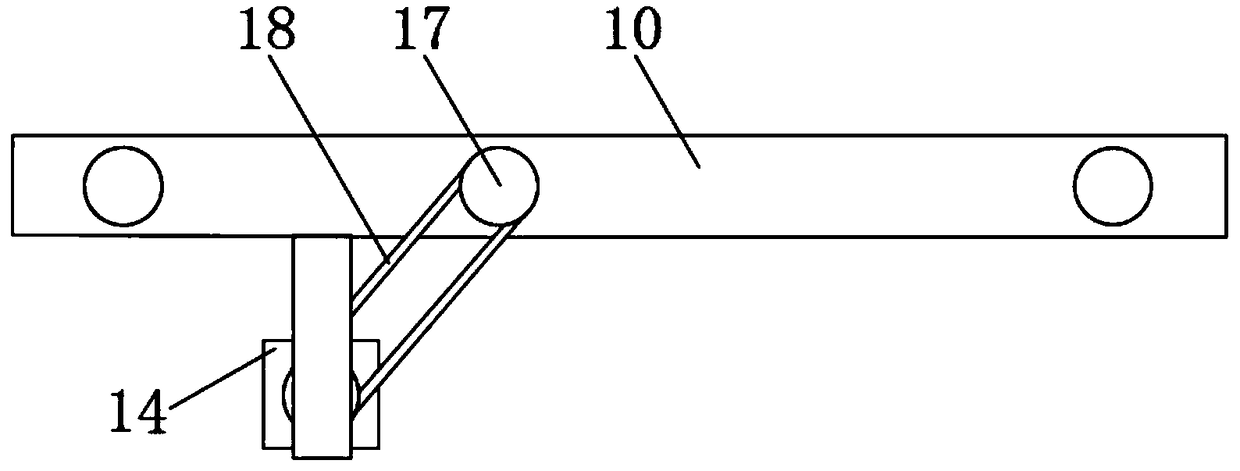

[0025] Such as Figure 1-4 As shown, a feeding device for a straw granulator includes a front underframe 1 and a rear underframe 2, the front underframe 1 and the rear underframe 2 are fixedly connected by cross braces between them, and the height of the front underframe 1 is greater than that of the rear underframe The height of the frame 2, the upper end of the front bottom frame 1 is sleeved with the front telescopic frame 3, the upper end of the rear bottom frame 2 is socketed with the rear telescopic frame 4, and both sides of the front telescopic frame 3 and the rear telescopic frame 4 are provided with connecting pieces 9. A transfer table 10 is fixedly installed on the upper end of the connecting piece 9, and a bump 16 is fixedly installed on one end of the transfer table 10, and a groove is provided at the other end of the transfer table 10, and a fastening bolt is arranged on the upper end of the groove, and the front telescopic The frame 3 is fixedly connected to th...

Embodiment 2

[0027] Such as Figure 1-4 As shown, it includes a front chassis 1 and a rear chassis 2, and the front chassis 1 and the rear chassis 2 are fixedly connected by cross braces between them. The height of the front chassis 1 is greater than the height of the rear chassis 2, and the front chassis 1 The upper end of the front telescopic frame 3 is socketed, the upper end of the rear bottom frame 2 is socketed with the rear telescopic frame 4, and both sides of the front telescopic frame 3 and the rear telescopic frame 4 are provided with connecting pieces 9, and the upper ends of the connecting pieces 9 are fixedly installed. There is a transmission table 10, one end of the transmission table 10 is fixedly equipped with a bump 16, the other end of the transmission table 10 is provided with a groove, and the upper end of the groove is provided with a fastening bolt, and the lower end of the front telescopic frame 3 is provided with a No. 1 screw rod 5 , the outer surface of the circ...

Embodiment 3

[0029] Such as Figure 1-4 As shown, it includes a front chassis 1 and a rear chassis 2, and the front chassis 1 and the rear chassis 2 are fixedly connected by cross braces between them. The height of the front chassis 1 is greater than the height of the rear chassis 2, and the front chassis 1 The upper end of the front telescopic frame 3 is socketed, the upper end of the rear bottom frame 2 is socketed with the rear telescopic frame 4, and both sides of the front telescopic frame 3 and the rear telescopic frame 4 are provided with connecting pieces 9, and the upper ends of the connecting pieces 9 are fixedly installed. There is a transmission table 10, one end of the transmission table 10 is fixedly equipped with a bump 16, the other end of the transmission table 10 is provided with a groove, and the upper end of the groove is provided with a fastening bolt, and both sides of the upper end of the transmission table 10 are fixedly installed. The position plate 11, the two end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com