Double-procedure gang drill cutting machine

A cutting machine and double-process technology, which is applied in the field of double-process plus row drilling and cutting machine, can solve the problems of workpiece wear, time-consuming and labor-intensive, etc., and achieve the effects of improving service life, ensuring processing, and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

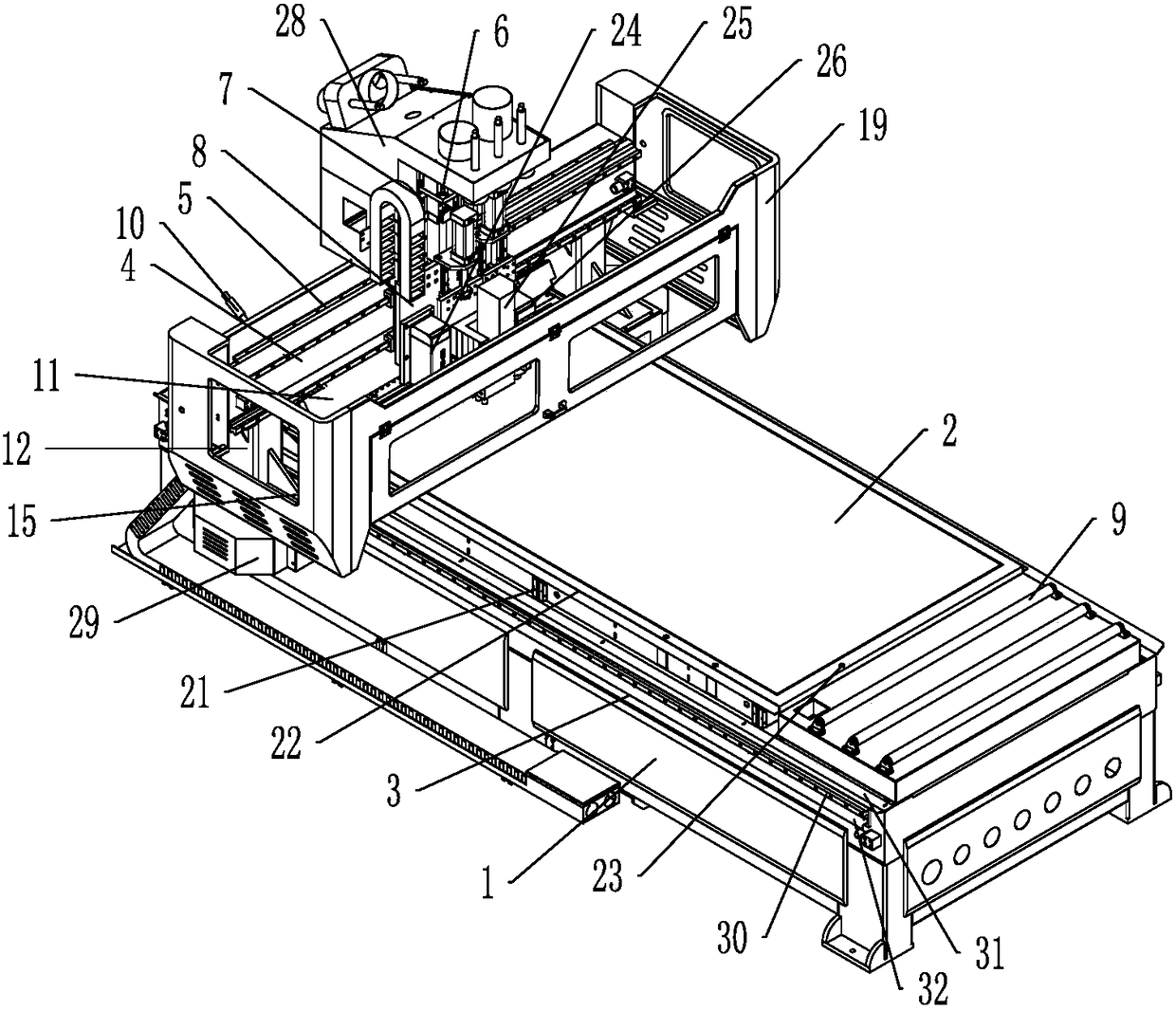

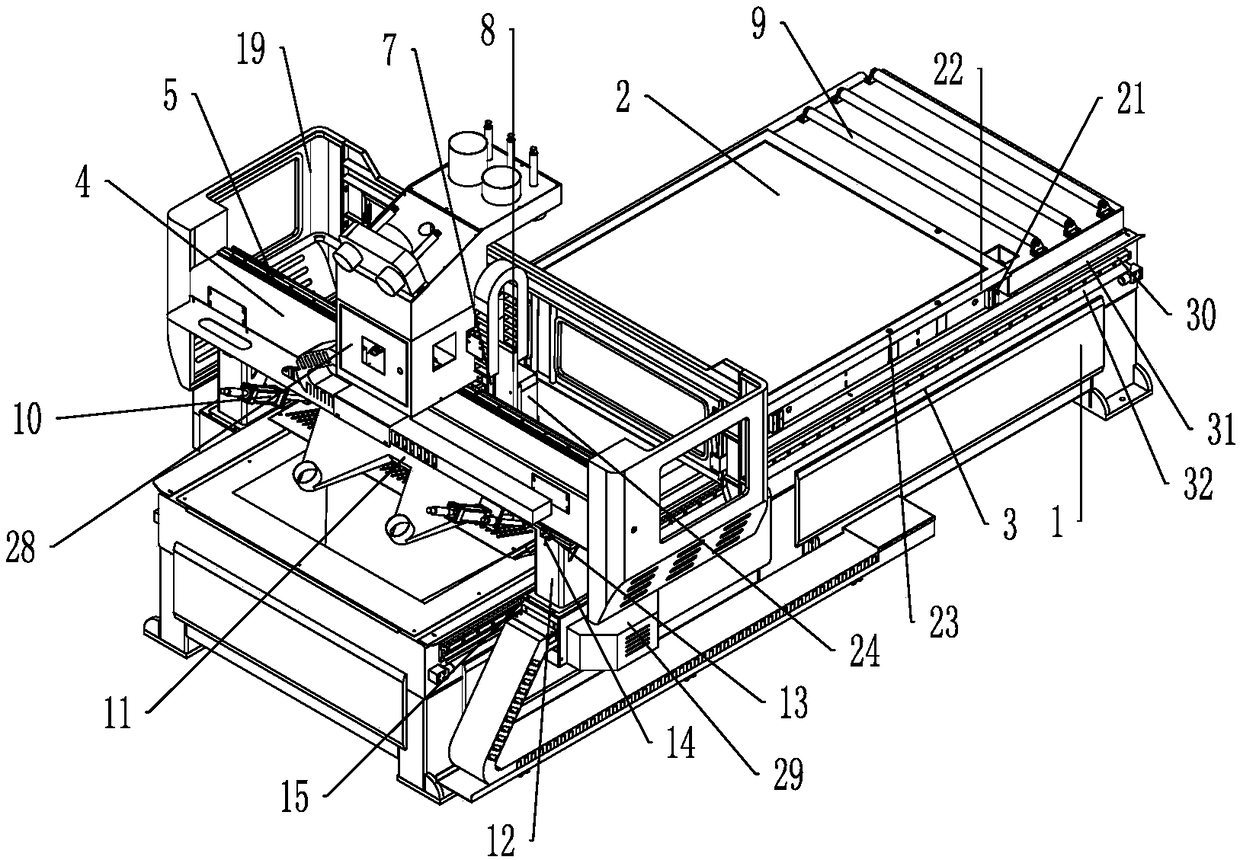

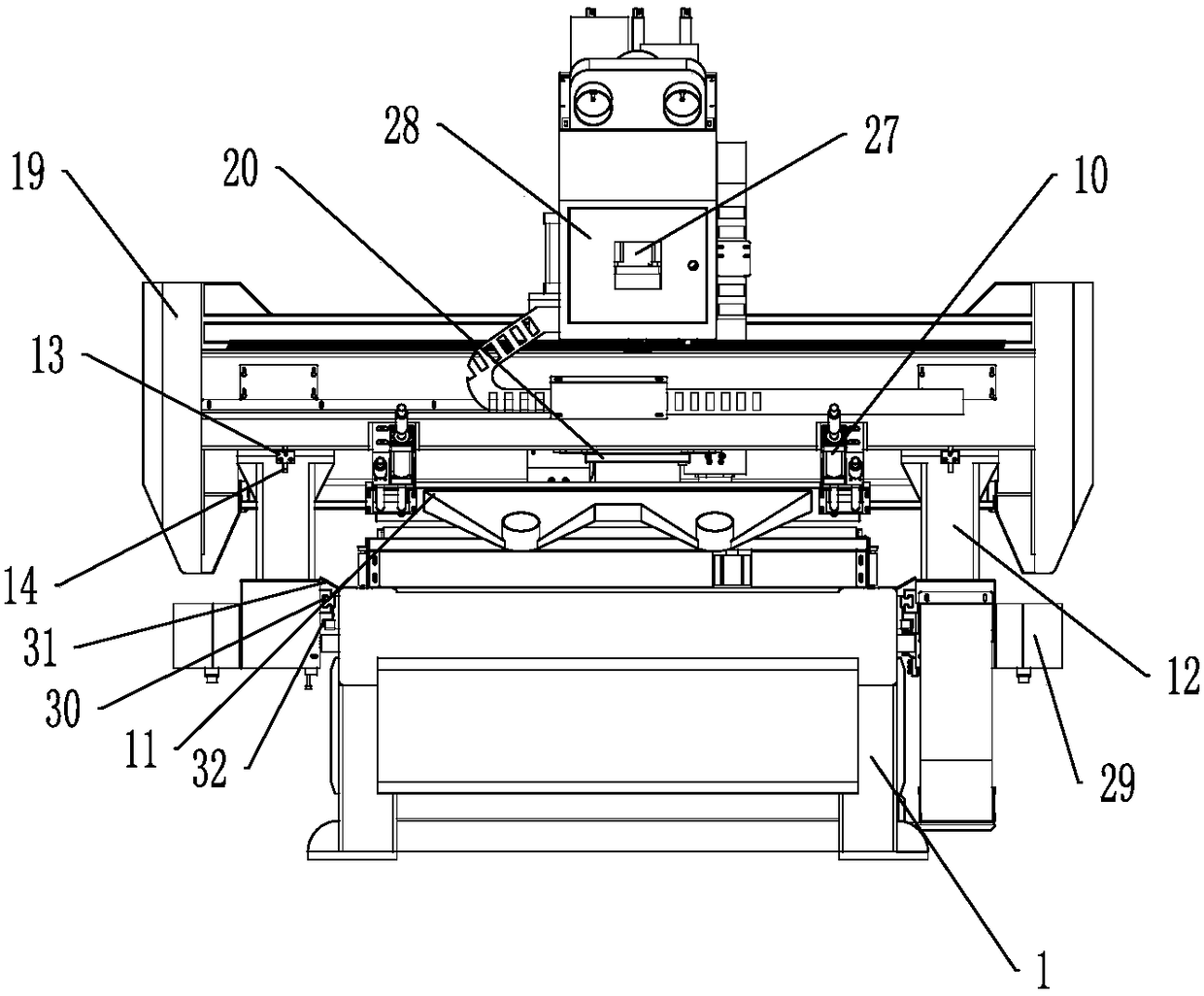

[0022] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

[0023] Such as Figure 1-5 As shown in , a double-process plus row drilling and cutting machine includes a workbench support 1, a workbench 2 is provided on the top of the workbench support 1, and a Y-direction moving mechanism is provided above the workbench 2. The Y The moving mechanism includes a beam 4 arranged above the support of the workbench. The two ends of the beam 4 are connected to a column 12 through bolts, and the bottoms of the two columns 12 are fixedly connected to a Y-direction sliding plate 15, and the Y-direction sliding plate 15 and the guide rails located on both sides of the workbench frame 1 and above the Y-direction rack 3 are movably clamped, and a horizontally arranged Y-direction drive motor 16 is fixed on the outside of the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com