Quick assembly disengaging device

A demolition device and quick-installation technology, applied in lifting devices, multi-purpose hand tools, crowbars, etc., can solve problems such as loss of life and property, delay in rescue time, etc.

Inactive Publication Date: 2012-02-08

刘于颇

View PDF10 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] On May 12, 2008, a major earthquake occurred in Wenchuan. A large number of houses collapsed, lives and property suffered heavy losses, and a large number of people were buried under the ruins. , shovels and other crude tools rescued a large number of buried people. Due to the inability to use large machinery, some soldiers even ground their bones... Sometimes it was only because of the barrier of a prefabricated board that the precious rescue time was delayed.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

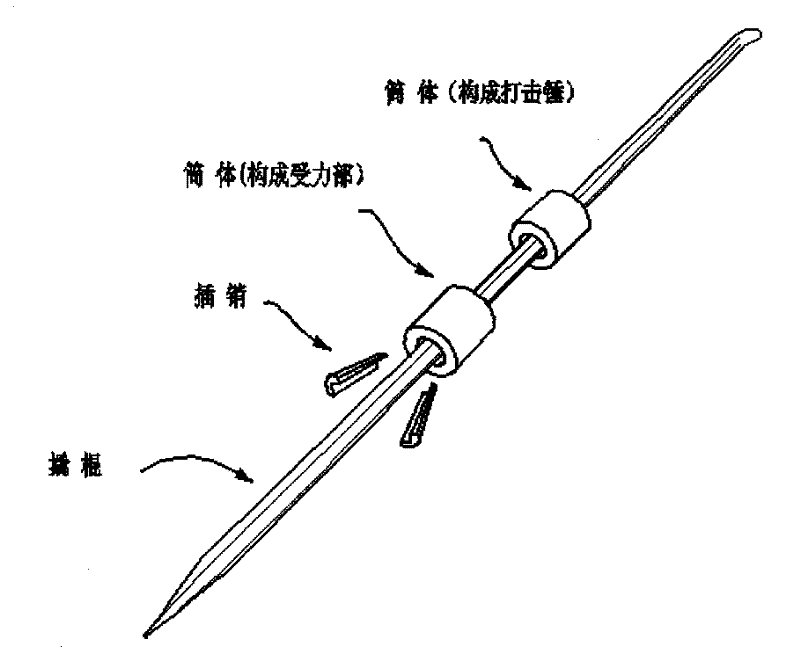

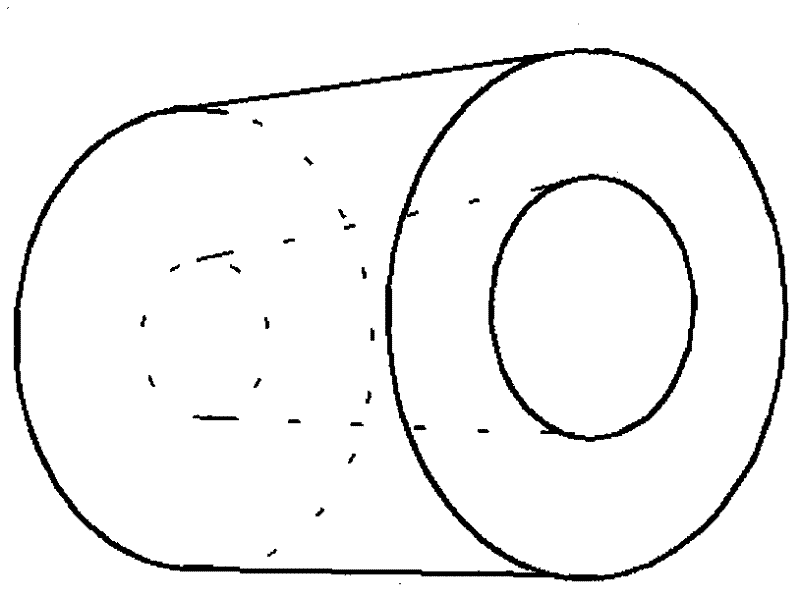

[0008] 1. From the tip of the crowbar, install the image 3 Shown are two perforated metal cylinders with large mouths facing rearward.

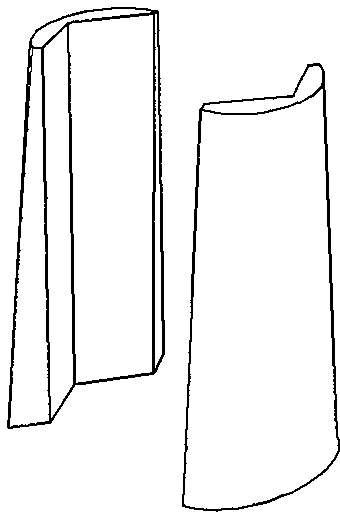

[0009] 2. Will figure 2 The two bolts shown are inserted into the gap between the second cylinder and the crowbar and tapped tightly (six flute, square or round crowbars need correspondingly shaped bolts).

[0010] 3. Swing the unfixed cylinder in the direction of the crowbar and hit it.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a quick assembly disengaging device. Two kinds of parts, namely a bolt and cylinders are assembled on a standard crowbar; and by a self-locking principle, one cylinder is fixed and the other cylinder is used as a peening hammer to form the disengaging device. The disengaging device has the function of the crowbar, becomes the disengaging device once assembled, and can disengage on special parts which cannot be excessively disturbed or have narrow spaces, wherein one cylinder is a metal cylinder, the middle of the cylinder is provided with a taper hole having a larger end and a smaller end, the slope of the taper is kept consistent with the slope of the bolt, a self-locking angle can be reached, and after the cylinder is sleeved in the crowbar, the bolt is inserted into a gap formed between the larger hole and the crowbar, and a stress body is formed after the bolt is tightly knocked; and the other cylinder is used as the peening hammer and moves along the crowbar vertically for peening.

Description

Technical field [0001] The invention belongs to the category of tools. It is used in rescue sites where large machinery, electric and pneumatic tools are inconvenient to operate. Background technique [0002] On May 12, 2008, a major earthquake occurred in Wenchuan. A large number of houses collapsed, lives and property suffered heavy losses, and a large number of people were buried under the ruins. A large number of buried people were rescued with simple tools such as shovels, shovels, etc. Because large machinery could not be used, some soldiers even ground their hands to the bone... Sometimes it was only because of a prefabricated board that the precious rescue time was delayed. From this, I came up with the idea of inventing a simple and efficient rescue tool for soldiers - quick release device. Contents of the invention [0003] The quick-loading demolition device is assembled on a standard crowbar with two parts - the latch and the cylinder. Using the self-lockin...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B25F1/00B25D1/16B66F15/00

Inventor 刘于颇

Owner 刘于颇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com