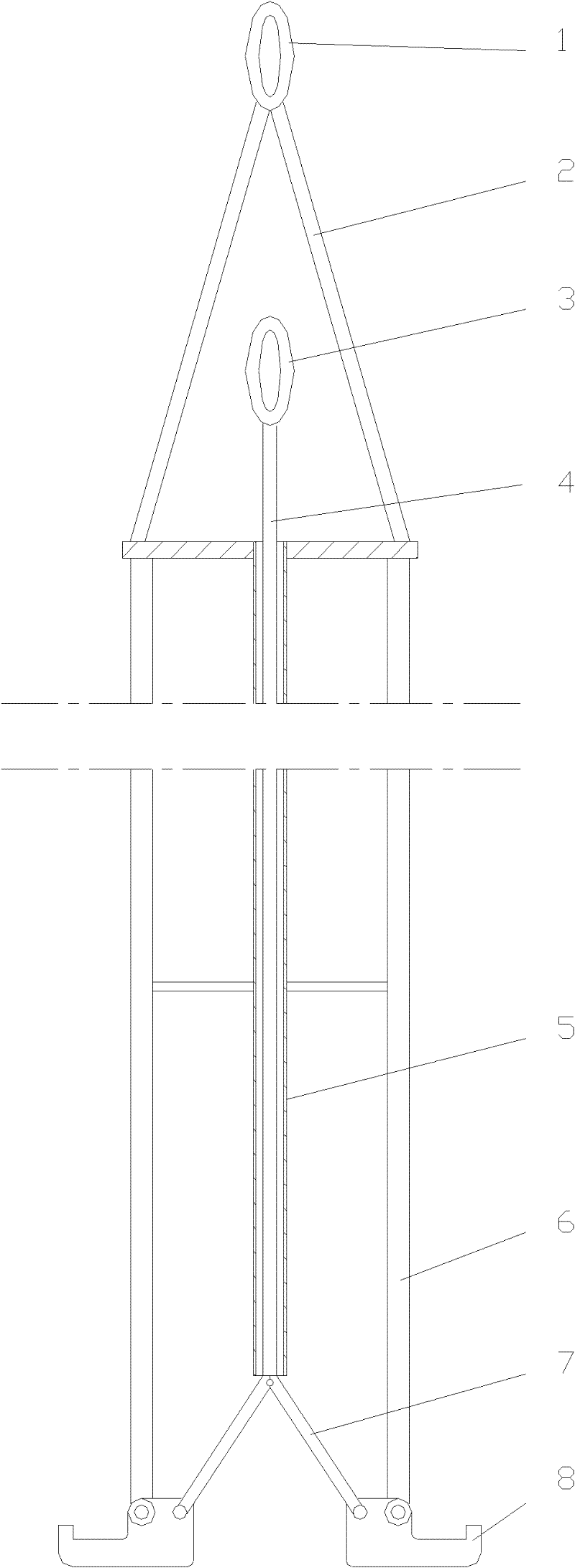

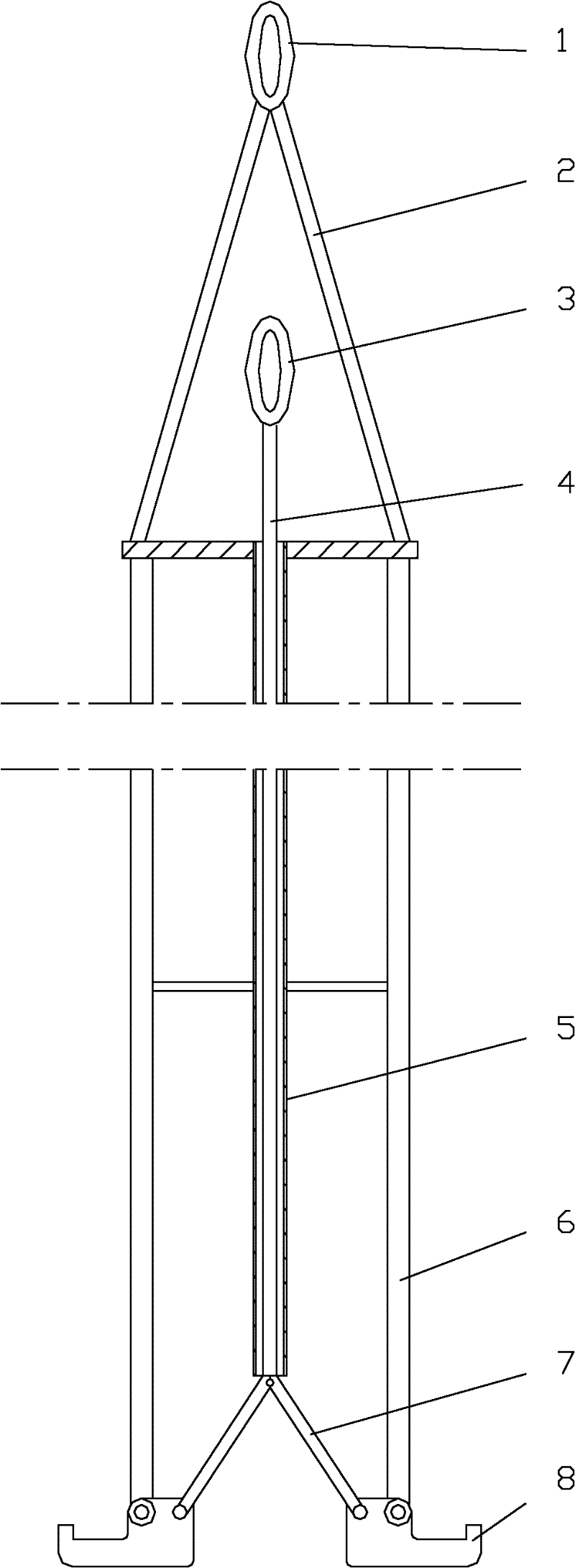

Special lifting appliance for pit type heat treatment furnace

A heat treatment furnace and spreader technology, applied in the field of tubular billets, can solve the problems of time-consuming and laborious tightening and separation process, inability to use multiple pit furnaces together, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] As shown in the accompanying drawings, the upper ends of the two poles 6 that are fixed together fix the pole suspension ring 1 through the upper chain, the lower ends of the poles 6 are hinged with the hook head 8, and the guide cylinder 5 is fixed between the two poles 6, and the guide cylinder Pull bar 4 is slipped through in 5, and the upper end of pull bar 4 fixes pull bar suspension ring 3, and the lower end of pull bar 4 is hinged the upper end of hook head slide chain 7, and the lower end of hook head slide chain 7 is hinged with described hook head 8.

[0010] During use, hang the pole suspension ring 1 on the main hook of the crane, and hang the pull rod suspension ring 3 on the auxiliary hook of the crane. The auxiliary hook of the crane pulls the pull rod ring 3, so that the hook head 8 is retracted between the two support rods 6. The present invention is inserted into the tubular blank to be heat treated, the hook head 8 hooks the bottom end of the tubular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com