Novel guide rail for replacing pipe jacking machine in relay well and quickly assembling head of pipe jacking machine

A new type of guide rail and pipe jacking machine technology, applied in the direction of pipes/pipe joints/pipe fittings, mechanical equipment, pipeline laying and maintenance, etc., can solve problems such as difficult construction, troublesome guide rail connection and installation guide rail, etc., to achieve fast loading and unloading speed and simple structure The effect of stabilizing and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

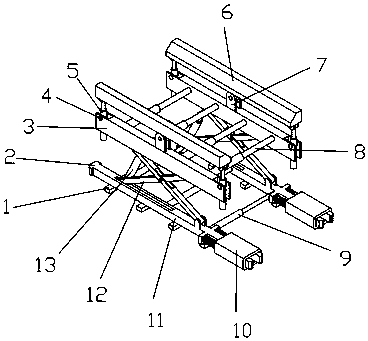

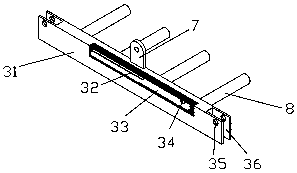

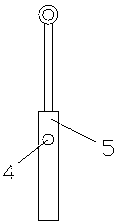

[0047] see Figure 1-8 As shown, a new type of guide rail for replacing the pipe jacking machine in the relay well and quickly assembling the head of the pipe jacking machine, including a rail sleeper 1, a buckle 2, a rotating shaft 4, a hydraulic telescopic rod 5, a placement guide rail adjustment hinge 7, and a lifting and shrinking adjustment rod 9 and lifting hydraulic rod 13, also includes lifting support rail 3, pipe jacking machine head placement guide rail 6, support connection telescopic rod 8, guide rail connection joint 10, bottom support guide rail 11 and lifting structure 12, guide rail sleeper 1 is set on the bottom support On the lower end surface of the guide rail 11, and the guide rail sleepers 1 are evenly distributed on the lower end surface of the bottom support guide rail 11. One end of the bottom support guide rail 11 is provided with a buckle 2, and the other end is connected with the guide rail connecting joint 10. There are two bottom support guide rail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com