Bridge multistage energy-absorbing guard bar

A technology for guardrails and bridges, used in bridges, bridge parts, bridge construction, etc., can solve the problems of inability to absorb collision energy, poor protection effect of guardrails, secondary traffic accidents, etc., to prevent vehicle rebound and improve stress conditions. , the effect of prolonging the time of the collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

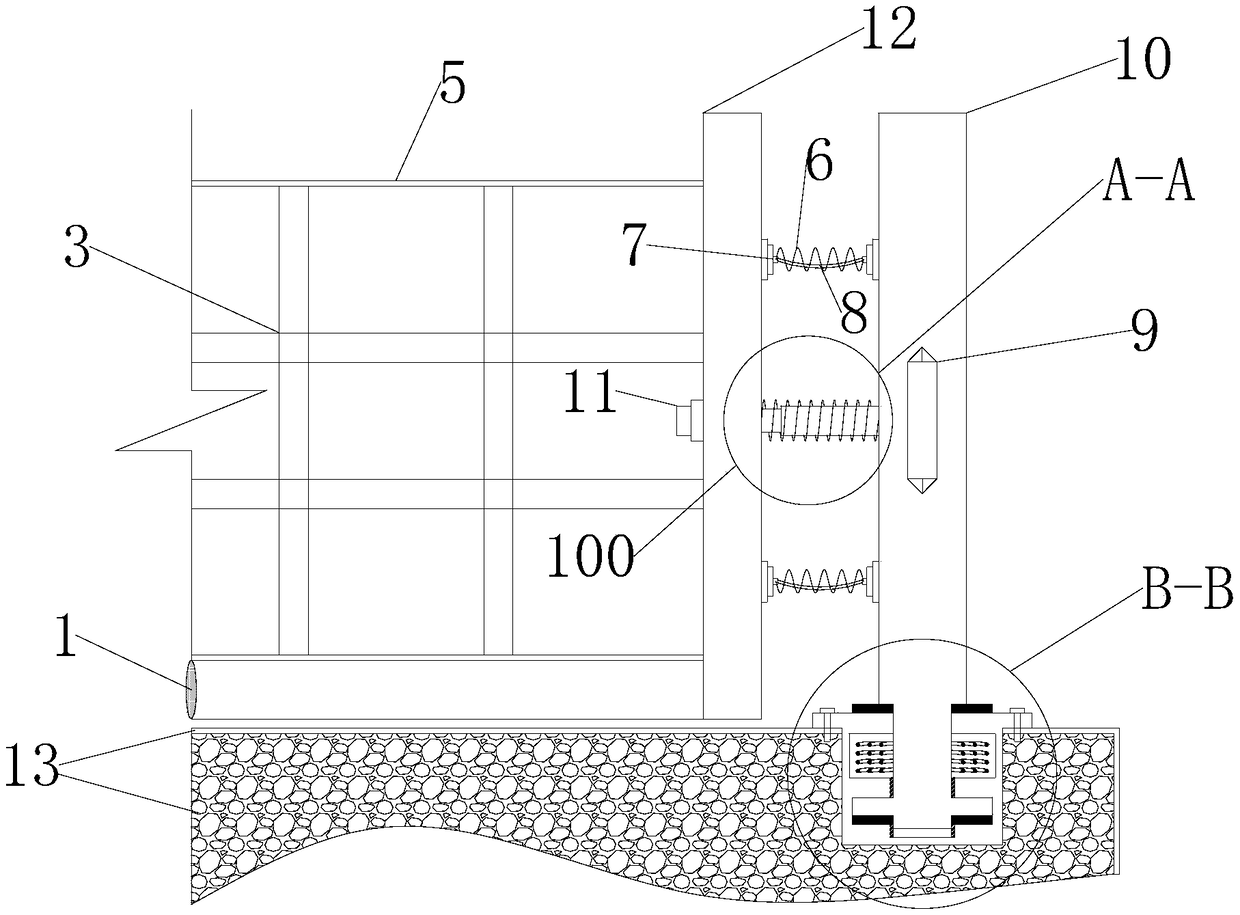

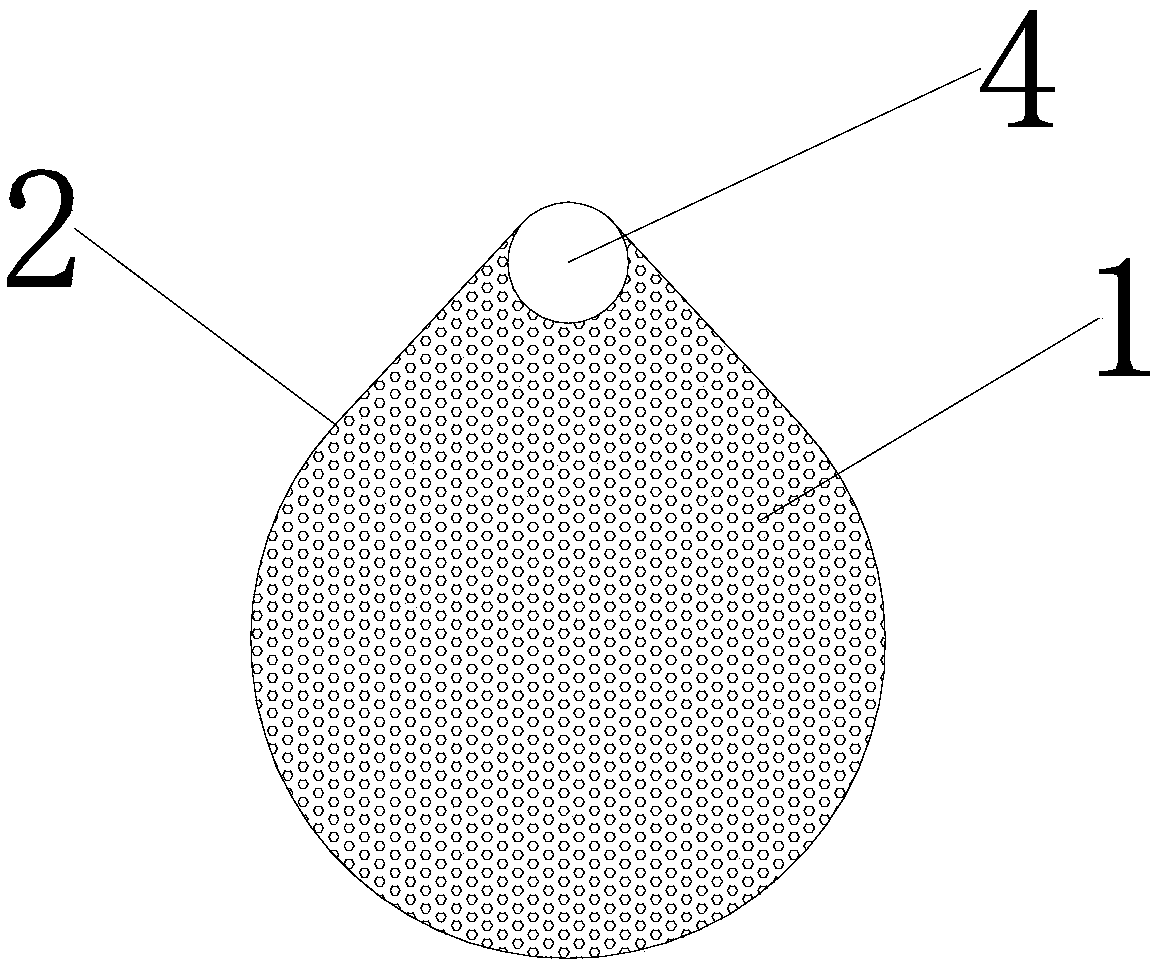

[0029] Such as figure 1 As shown, a bridge multi-stage energy-absorbing guardrail of the present invention includes: a bridge deck structure 13, a guardrail column 10, a rigid column 12 at the end of the guardrail and a sandbag energy-absorbing part 1, wherein a metal shell 206 is arranged in the bridge deck structure 13 , the metal shell 206 is fixed on the bridge deck structure 13 by bolts 201;

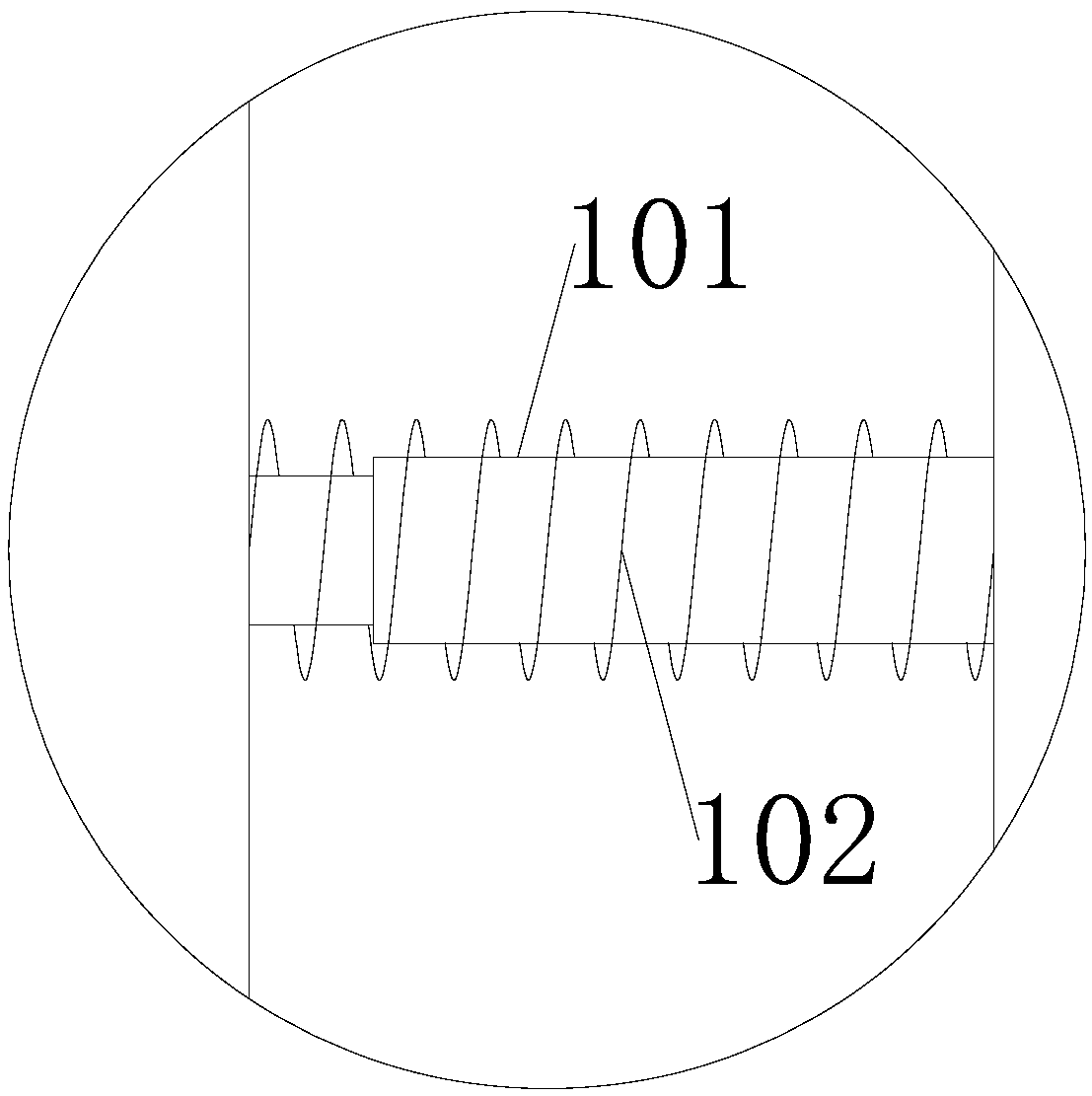

[0030] Such as Figure 4 As shown, the interior of the metal shell 206 is provided with two annular slots distributed up and down, and the two annular slots are separated by a partition, wherein the upper annular slot is used to accommodate The torsion spring 202 of the torsion spring 202 has two fixed ends protruding from the top and bottom ports of the torsion spring 202 respectively, the fixed end protruding from the top is fixed on the rotating shaft 207 at the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com