Patents

Literature

37results about How to "Expand the scope of reinforcement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

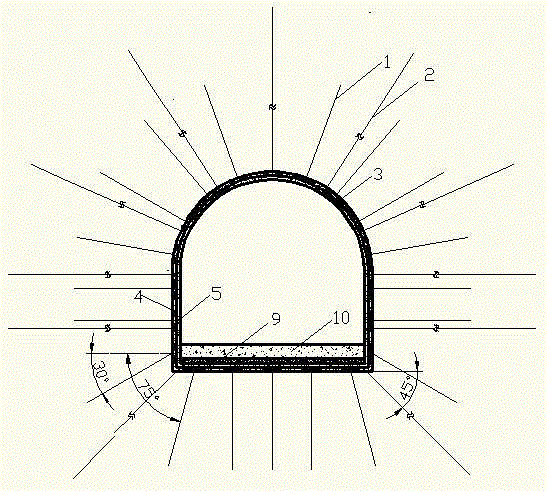

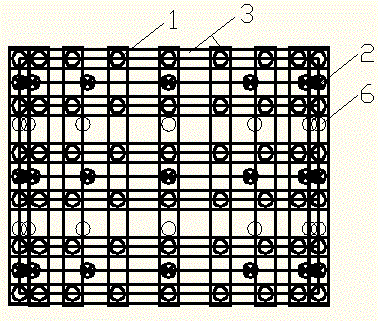

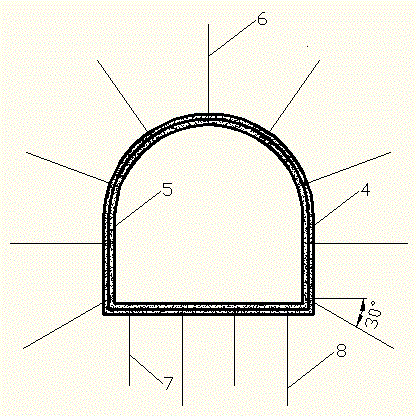

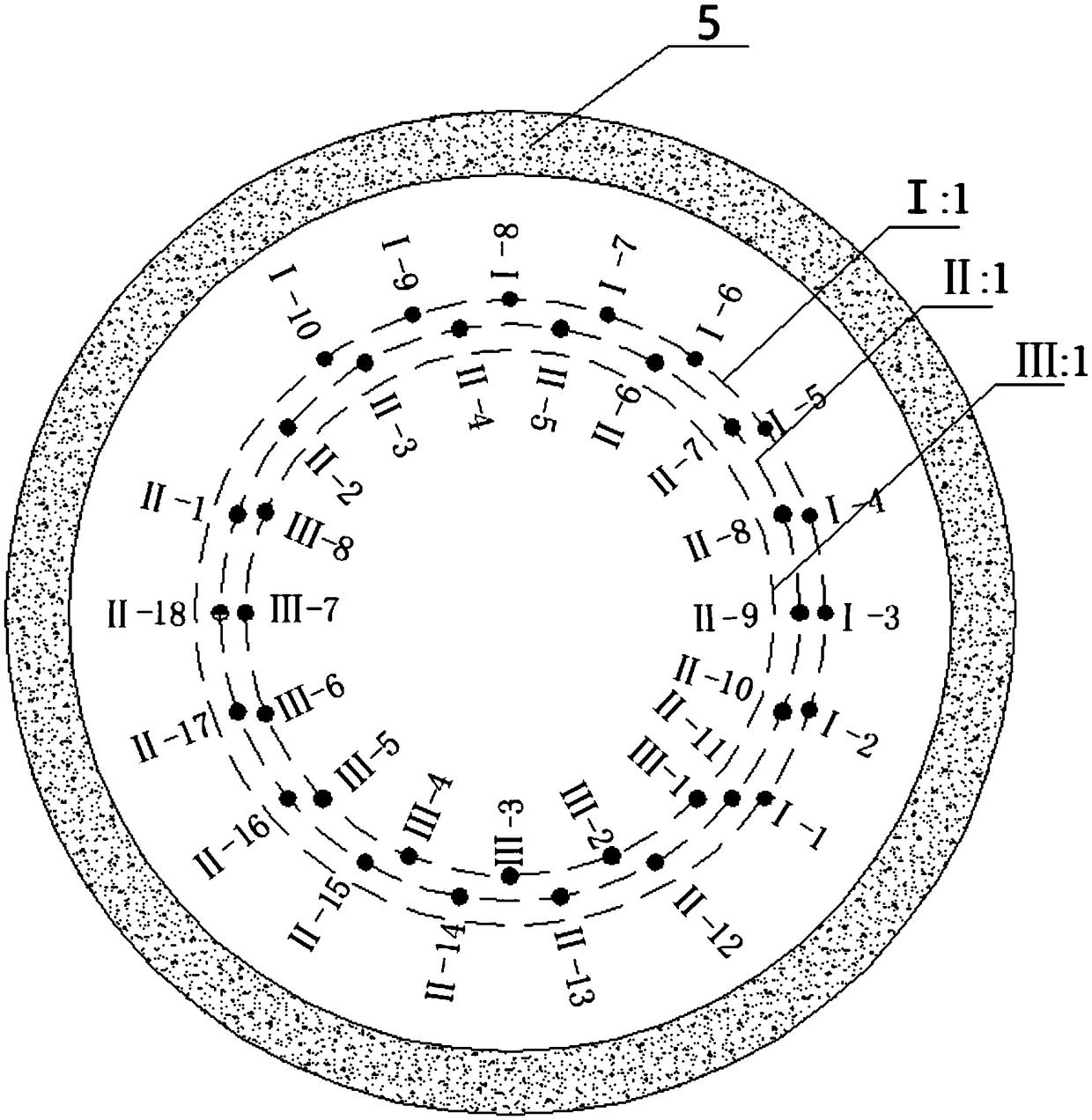

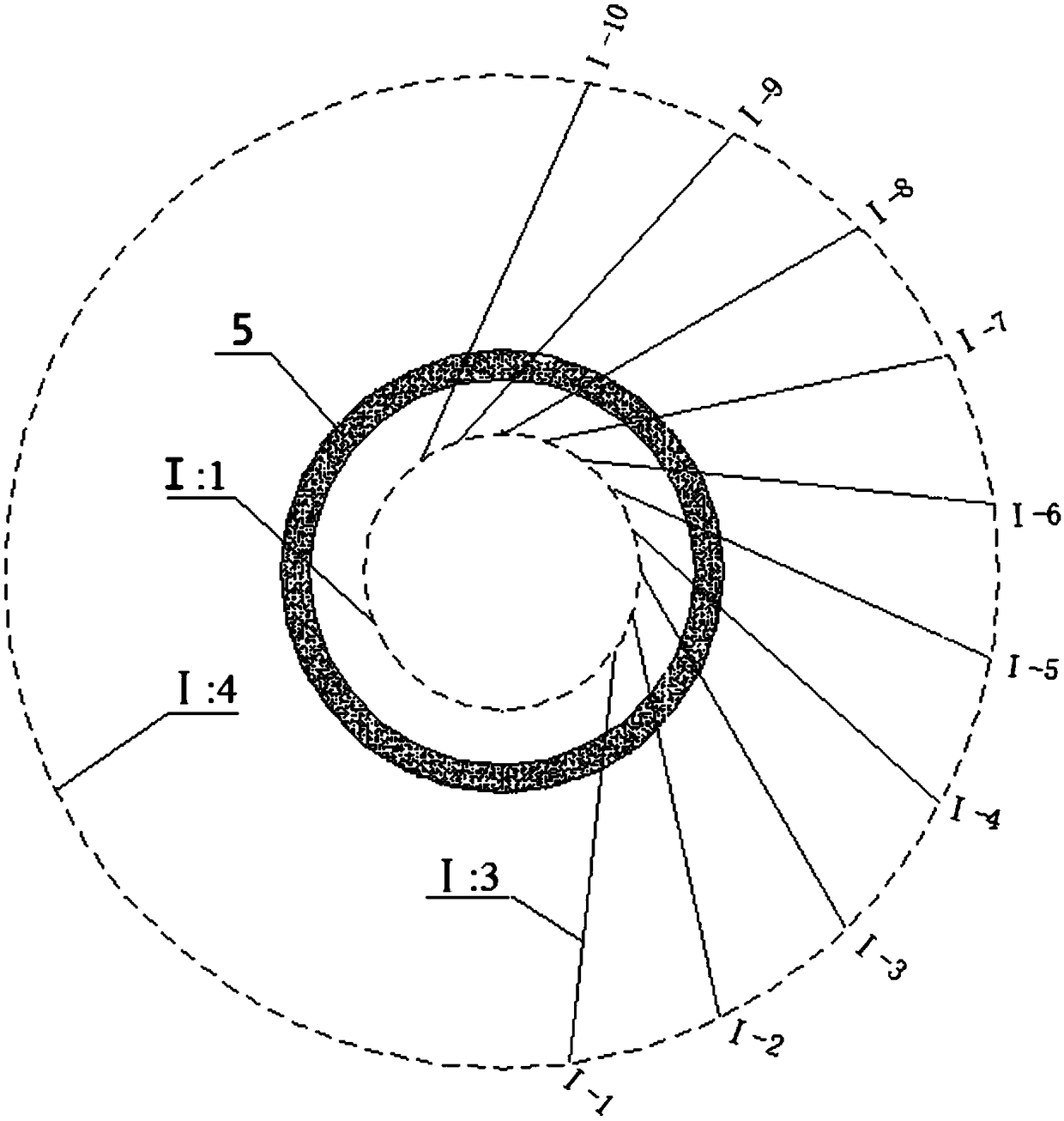

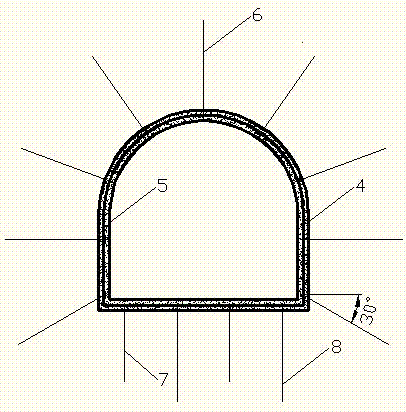

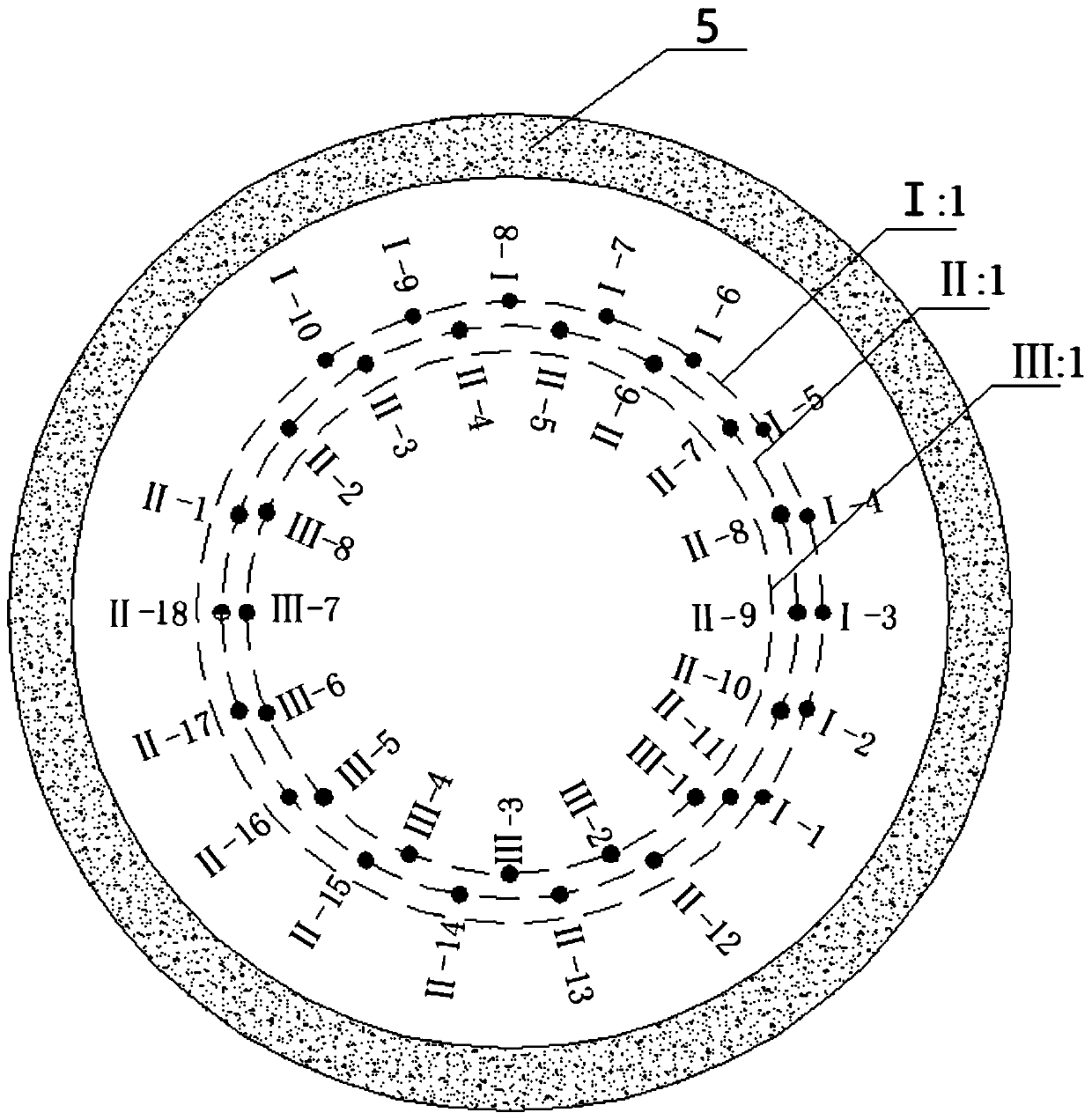

Total-section closed type deep-shallow coupling yielding, bolting-grouting and supporting method for incompact and fractured soft-rock roadway

InactiveCN105178981AImprove support strengthWatch protection effect is goodUnderground chambersTunnel liningCouplingStructure of the Earth

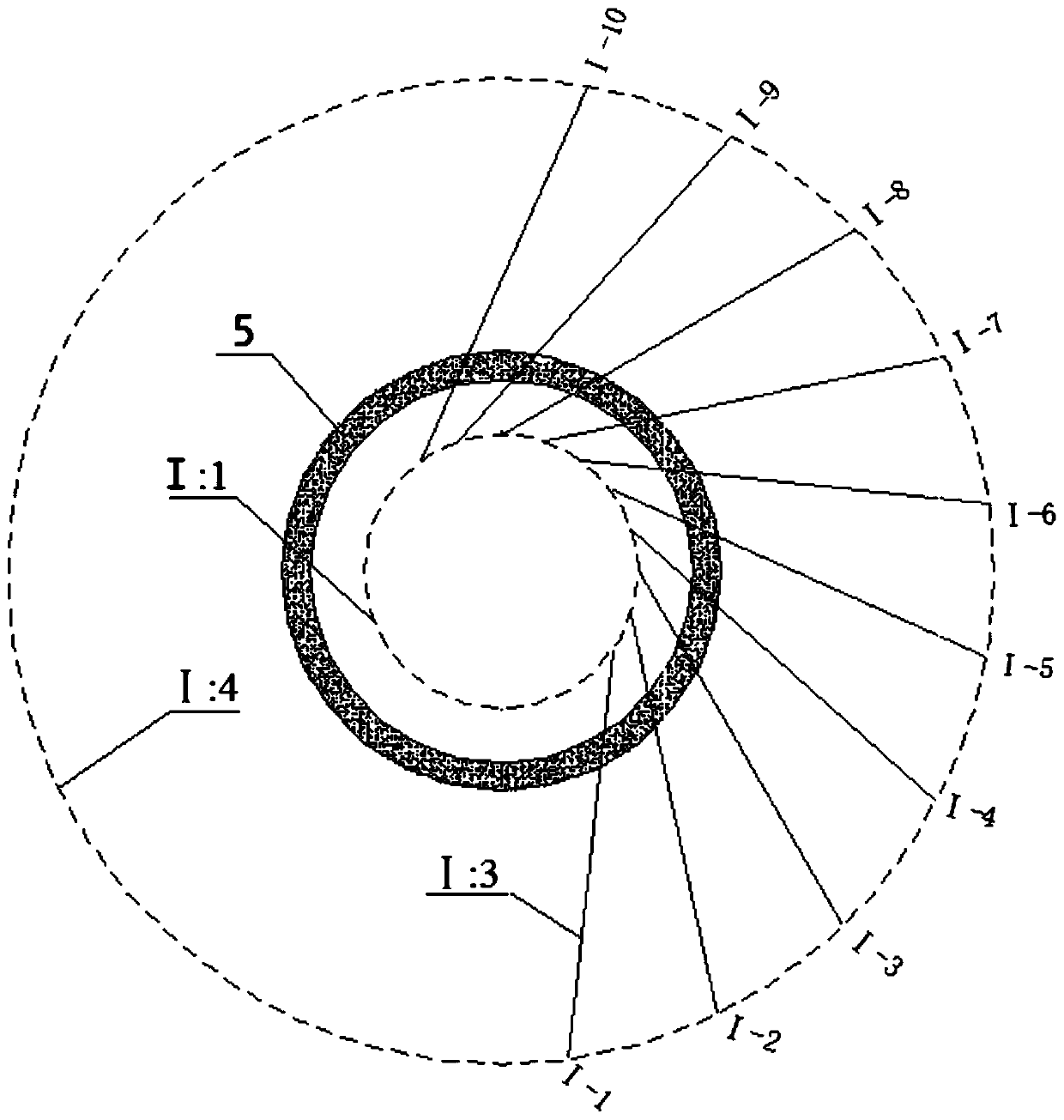

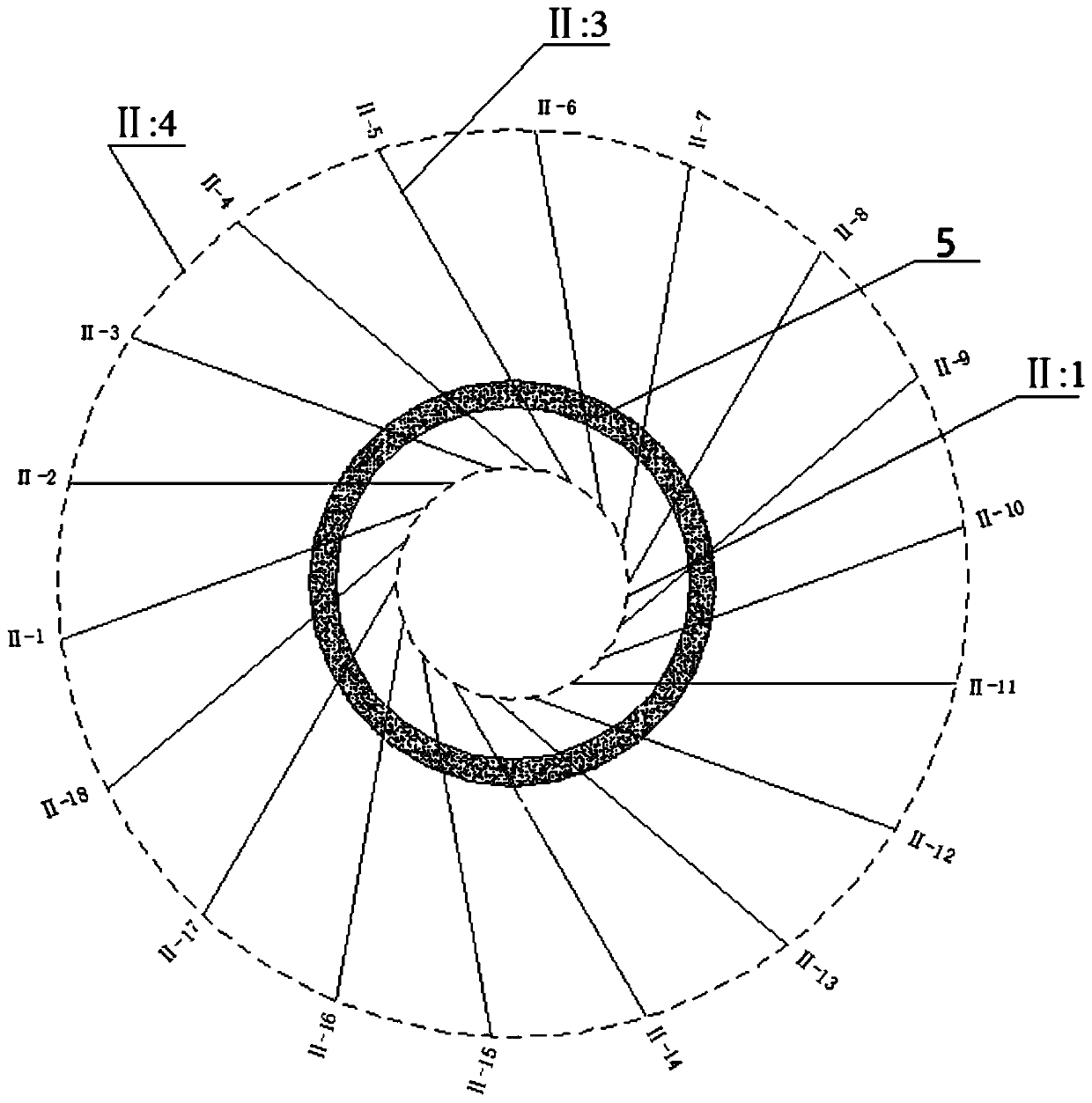

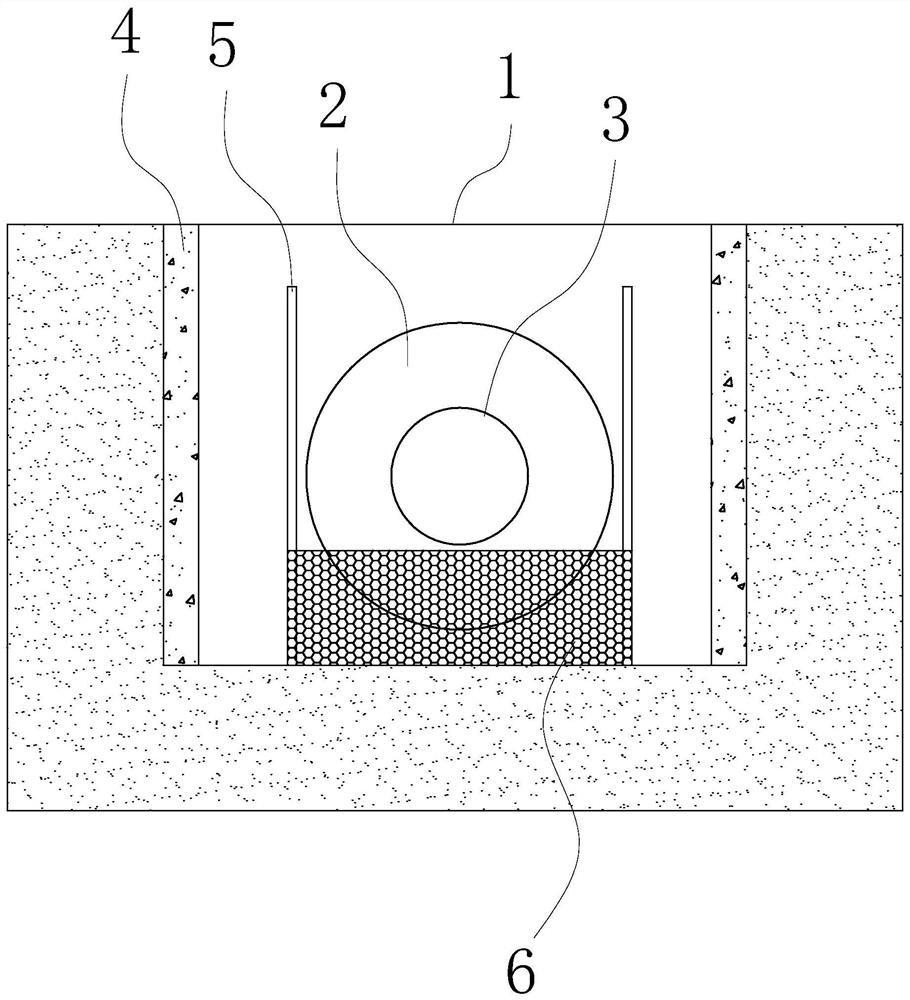

The invention relates to a total-section closed type deep-shallow coupling yielding, bolting-grouting and supporting method for an incompact and fractured soft-rock roadway. On the basis of a multilayered cooperative supporting principle, a spraying net combined isolating arch, an anchor rod extruding reinforcing arch, a total-section closed type grouting reinforcing ring and a deep slurry diffusion reinforcing arch are respectively formed on surrounding rock of the roadway from shallow to deep finally, and are combined to form a multilayered effective combined arch by a suspension effect of a high-strength grouting anchor cable, advantages of yielding supporting, bolting-grouting supporting and deep-shallow coupling supporting are combined organically, bearing range, integrity and bearing capability of a supporting structure are improved obviously, a control effect on deformation characteristics of large deformation, high speed, long duration, wide destroying range, peripheral pressing, obvious floor heaves and the like of the surrounding rock of the incompact and fractured soft-rock roadway is excellent, and various deformations of the surrounding rock of the incompact and fractured soft-rock roadway are controlled effectively. The total-section closed type deep-shallow coupling yielding, bolting-grouting and supporting method is particularly suitable for a large-section incompact and fractured soft-rock roadway of a deep well, is simple in work procedures and low in cost, and has high field promotion and application value; and parallel operation can be realized.

Owner:CHINA UNIV OF MINING & TECH

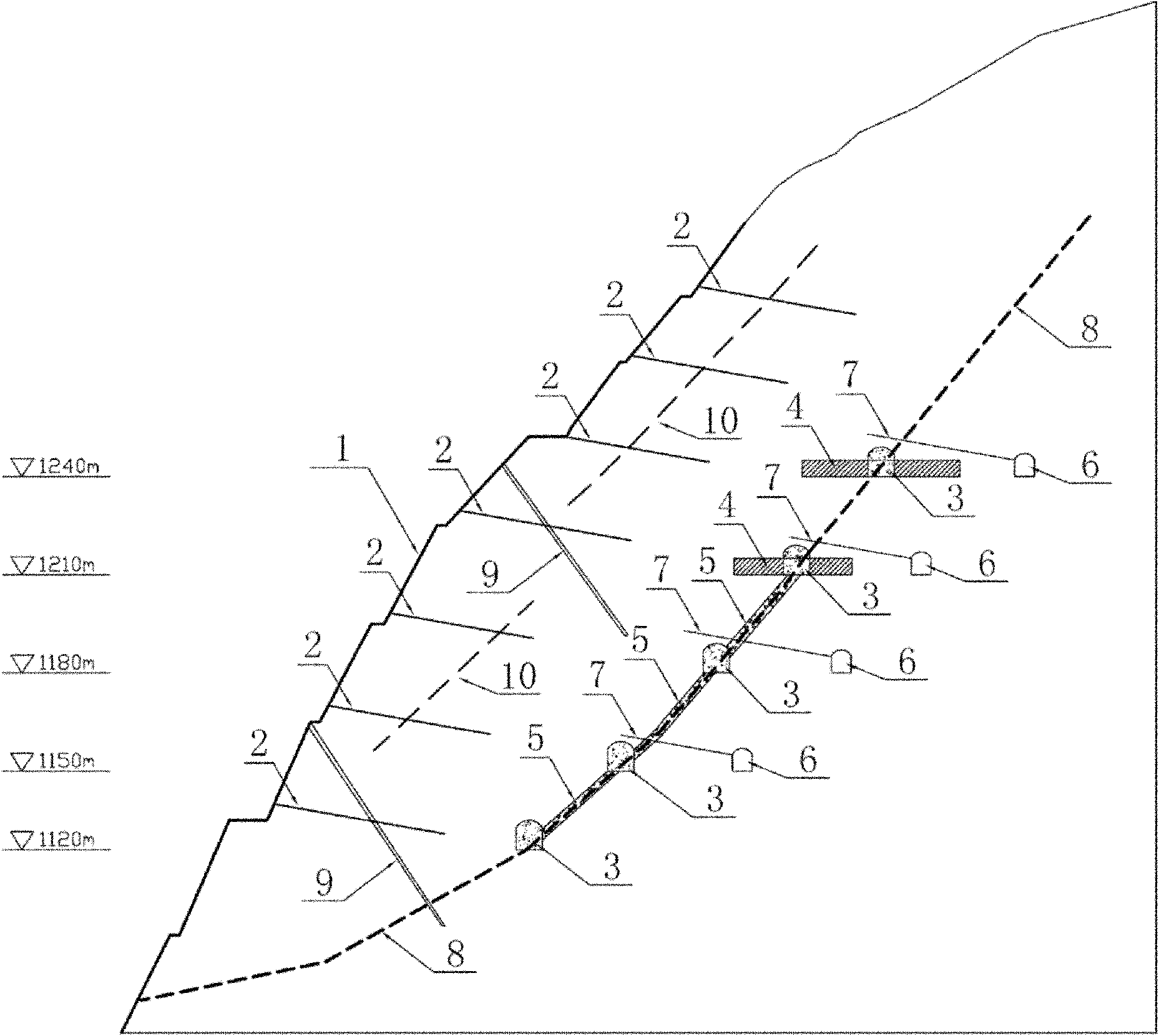

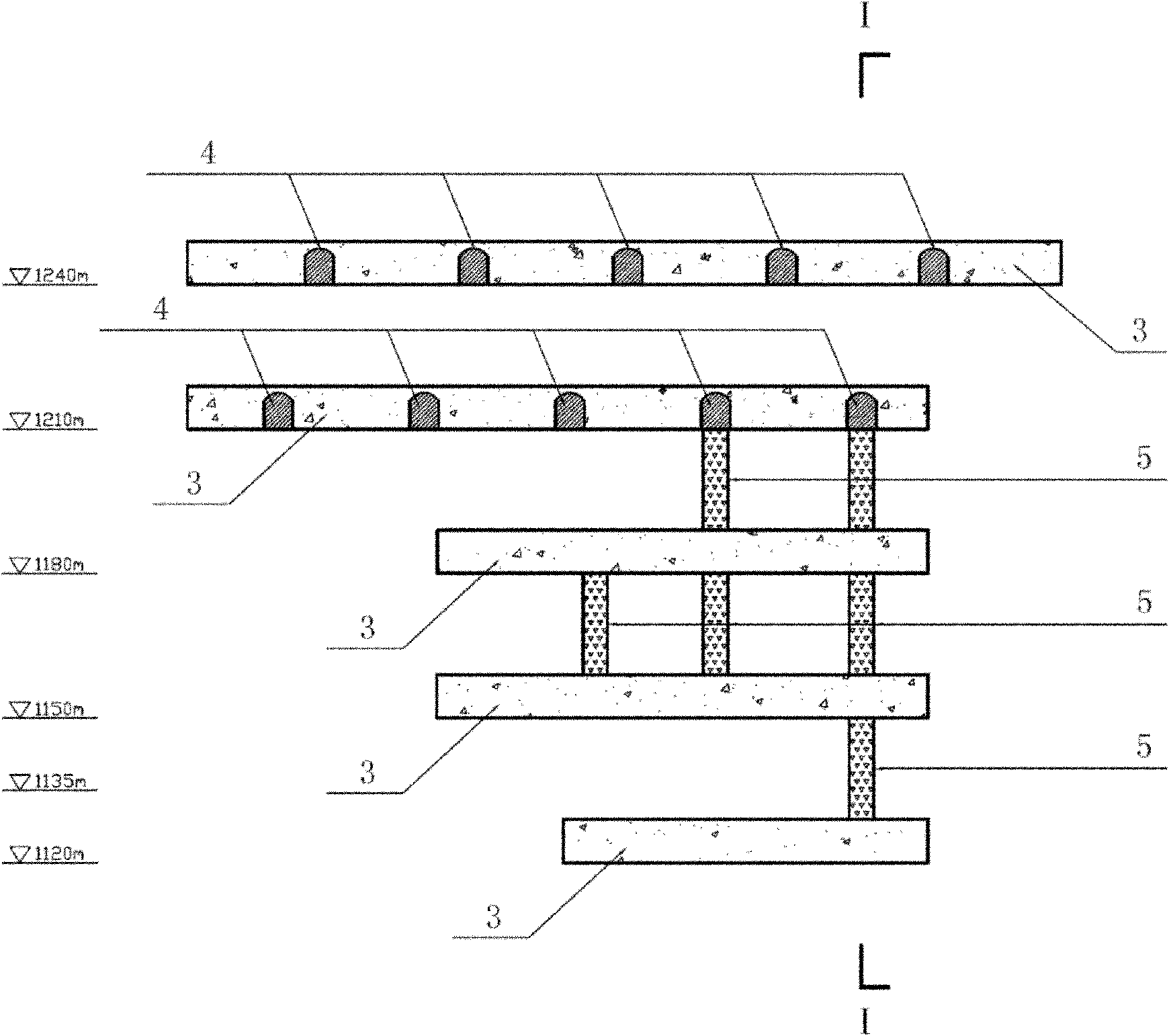

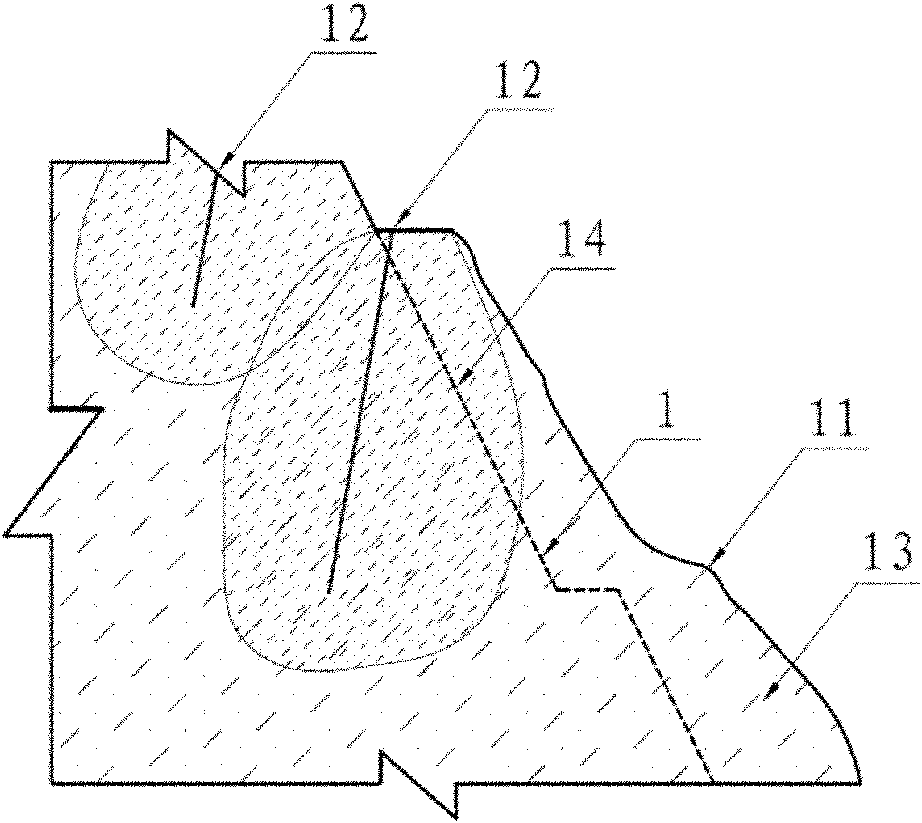

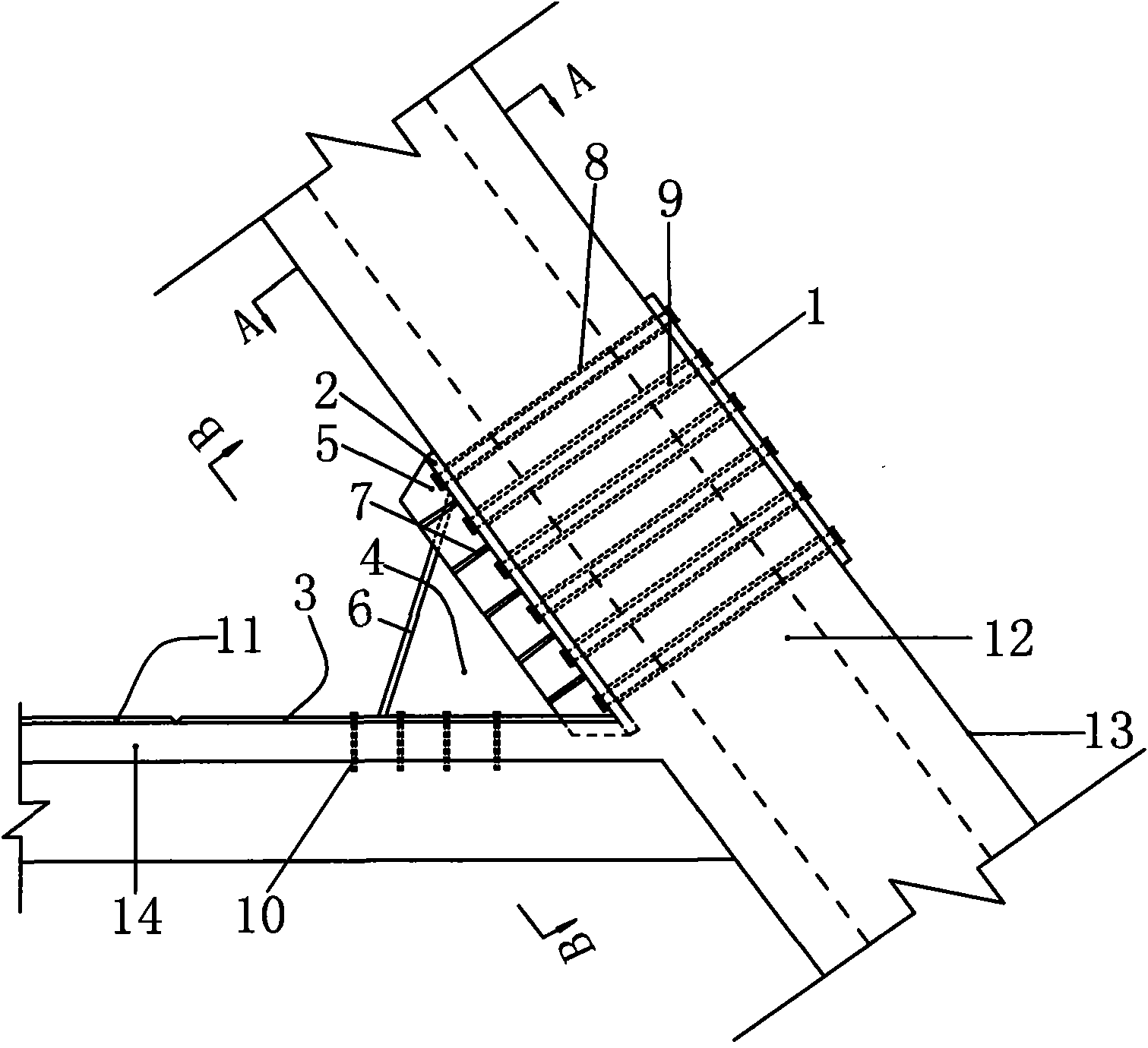

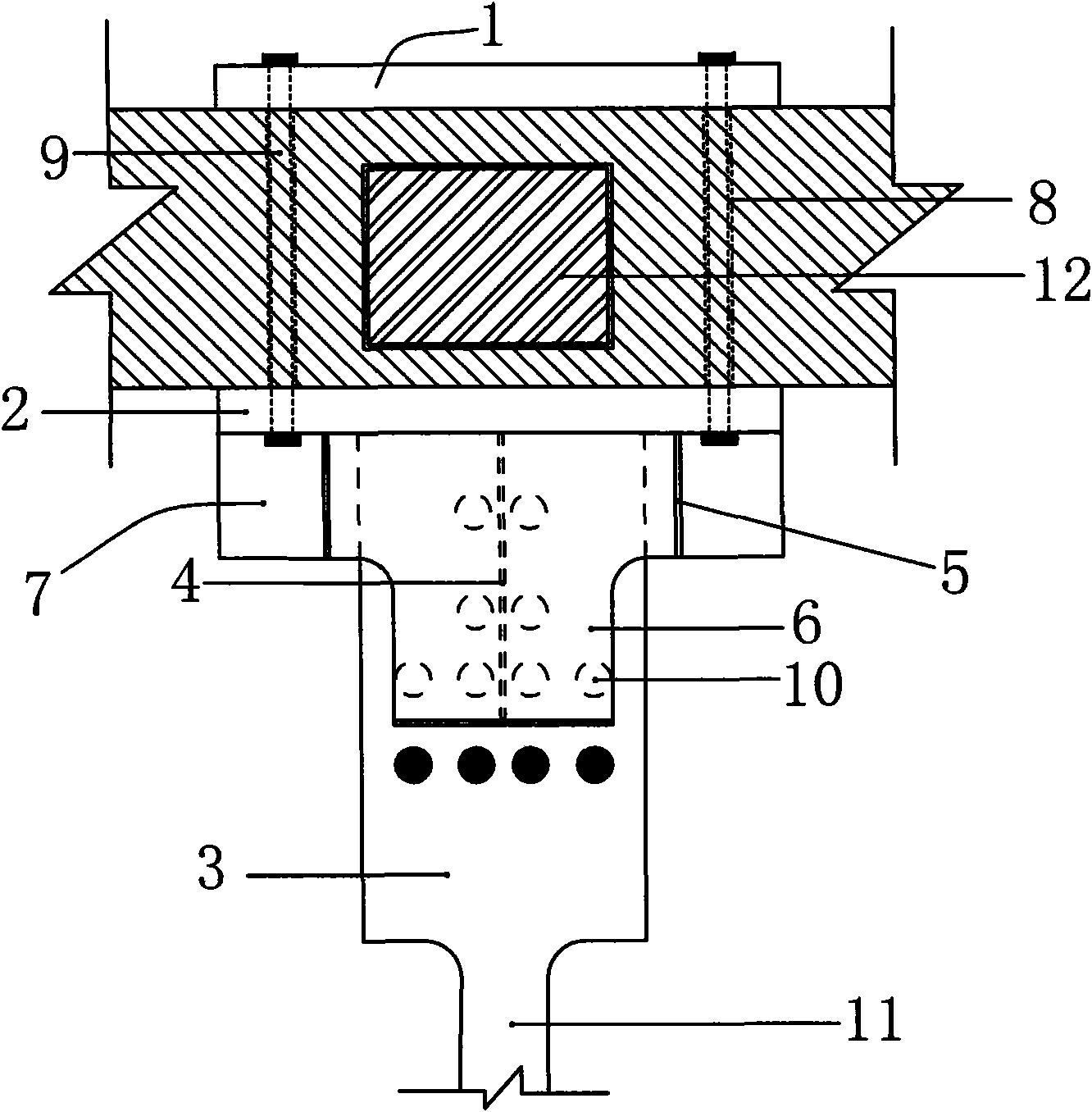

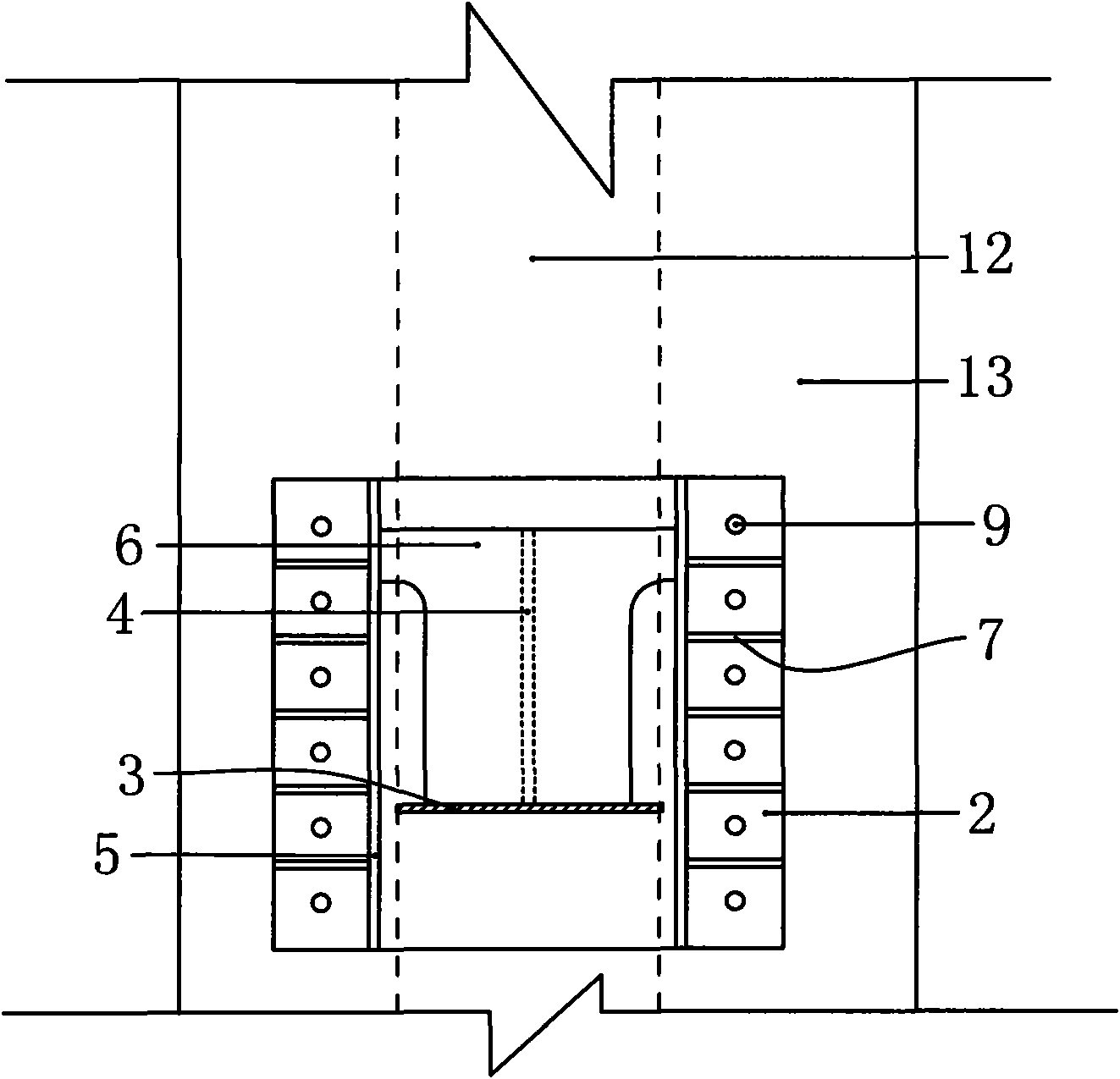

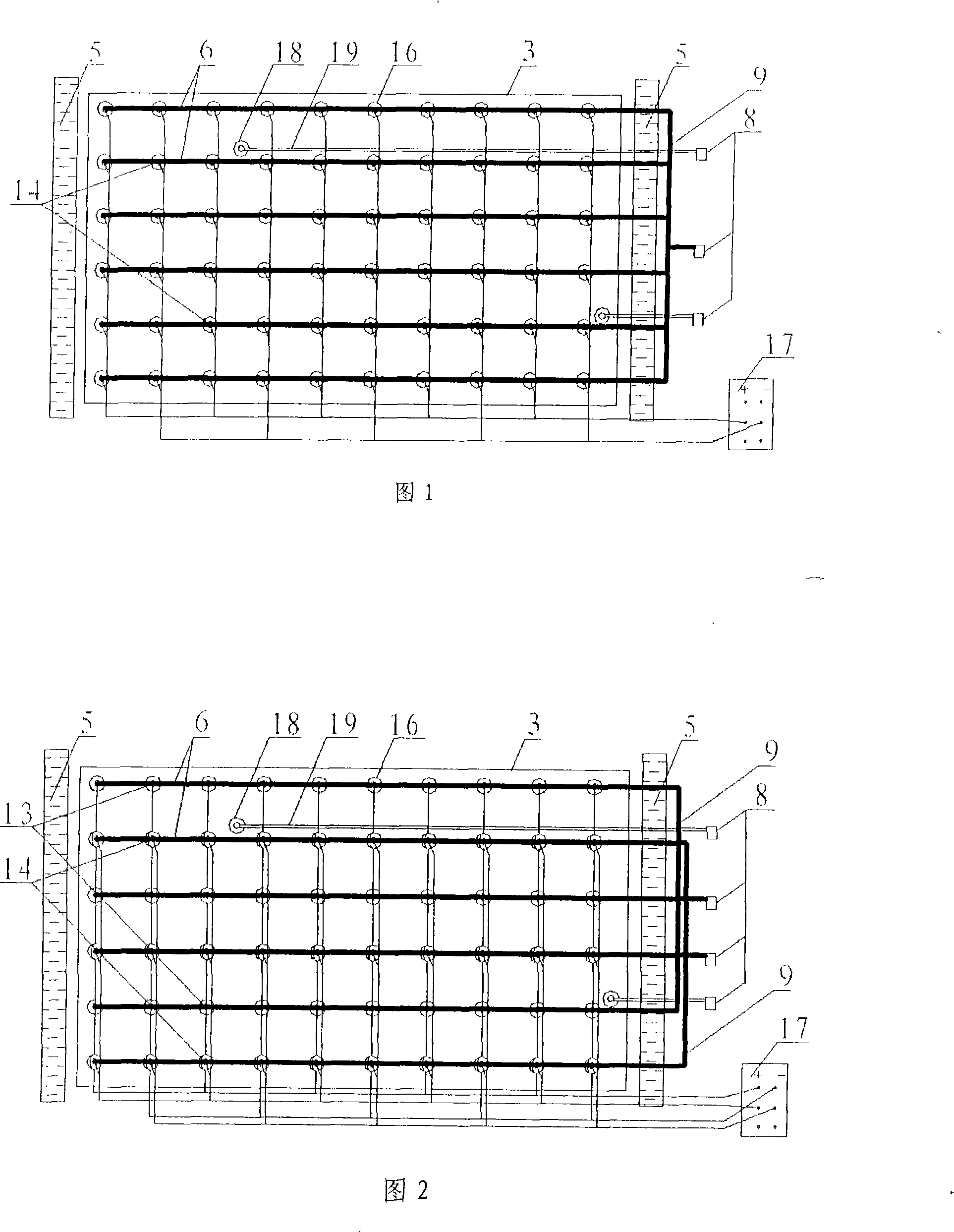

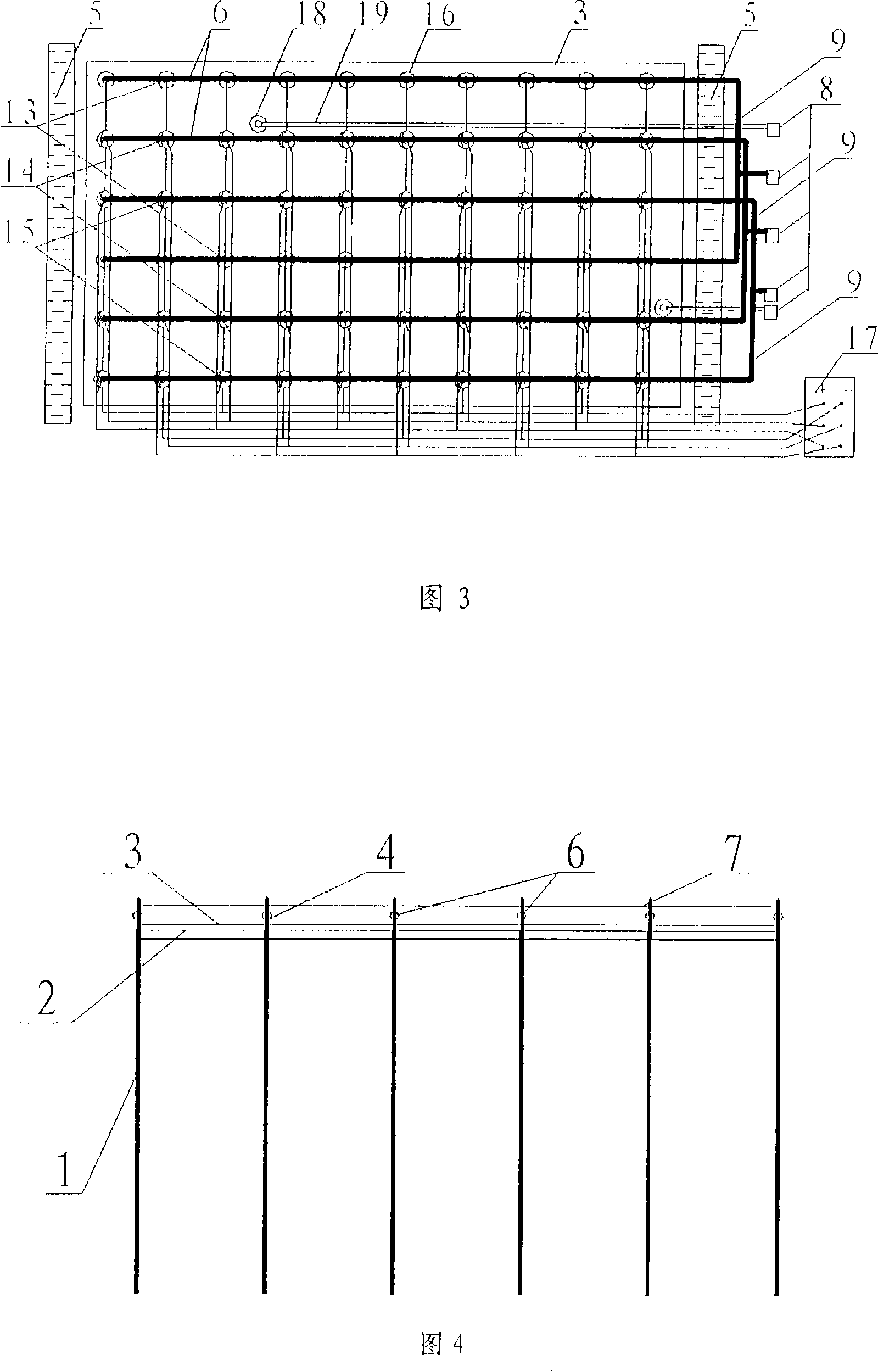

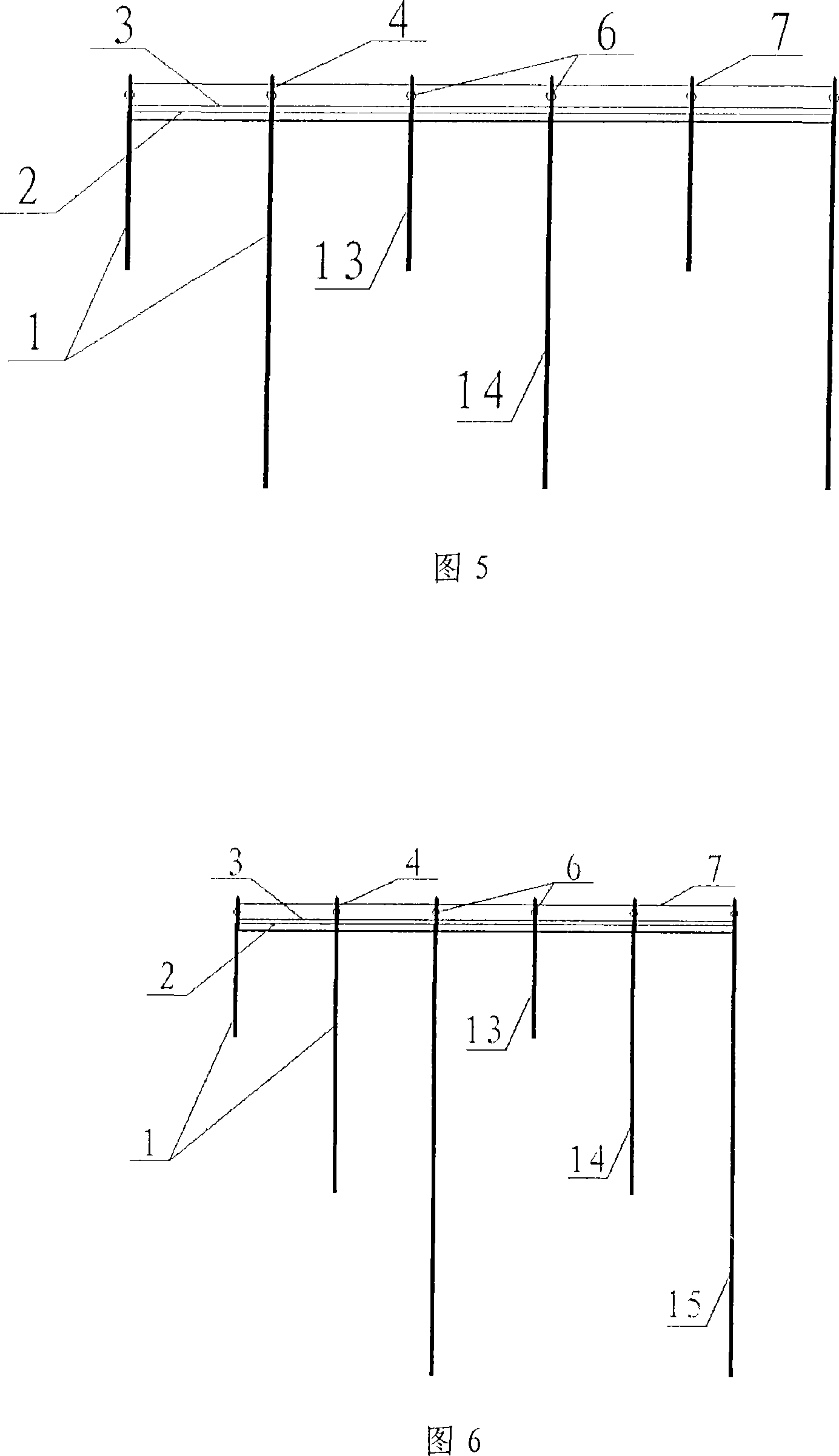

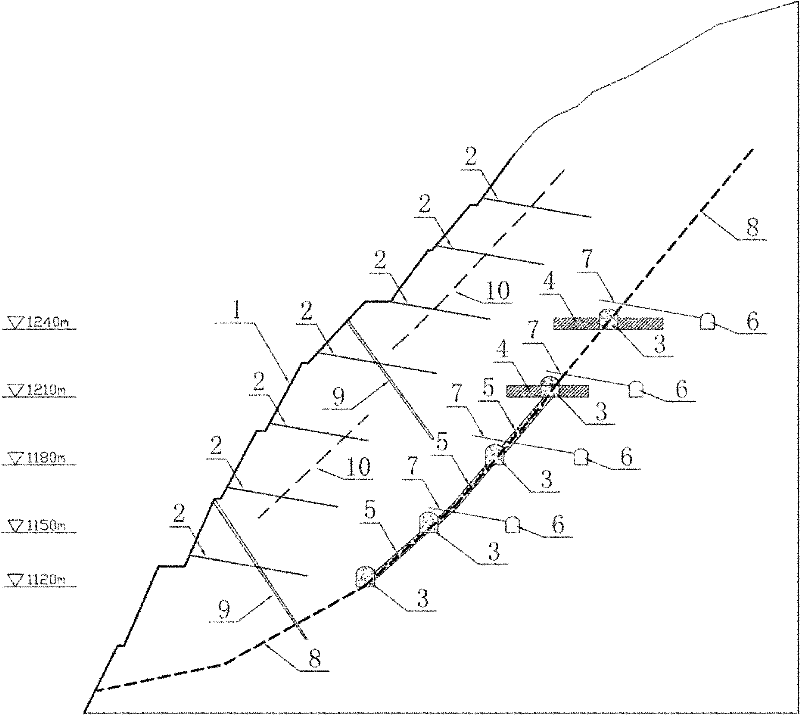

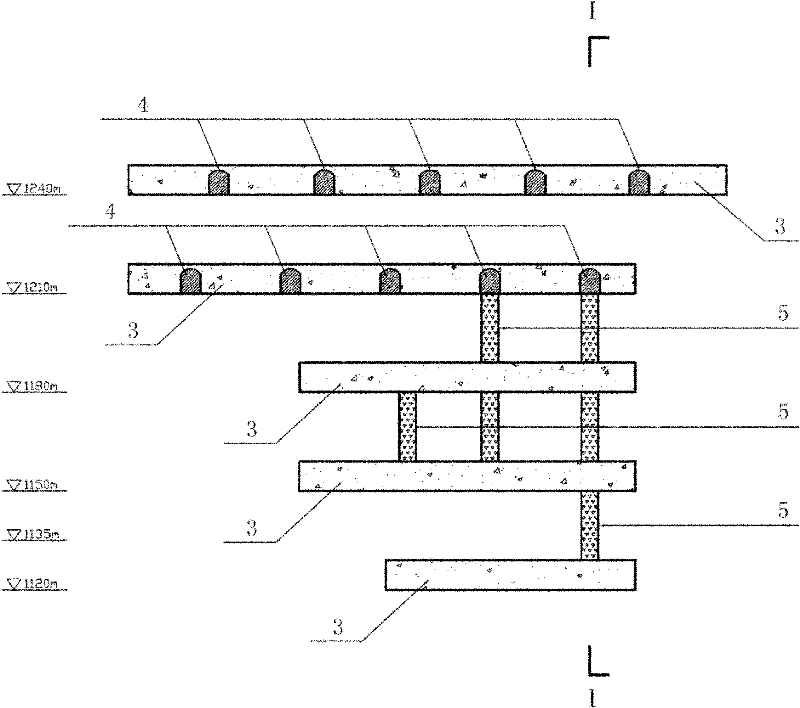

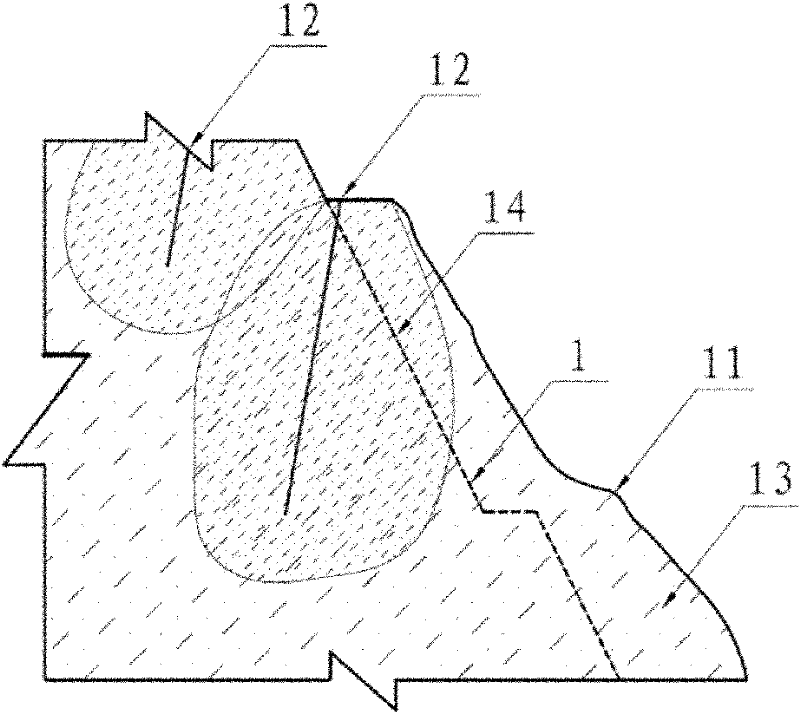

Side slope reinforcing method and structure

ActiveCN102021911AExpand the scope of reinforcementGood governanceExcavationsStructural engineeringLarge size

The invention discloses side slope reinforcing method and structure. The side slope reinforcing method comprises a step of building a concrete anti-shear structure in a slope body. The side slope reinforcing method is characterized in that the concrete anti-shear structure is an integral structure comprising anti-shear tunnels, anchored tunnels and displacement inclined shafts, wherein the anti-shear tunnels and the anchored tunnels are formed through pouring; a plurality of layers of the anti-shear tunnels are arranged at intervals along the strike direction of a slip crack surface in a compressive-shear area of the slip crack surface as seen from the side surface of the concrete anti-shear structure, and each layer of the anti-shear tunnels all horizontally extend on the slip crack surface; a plurality of the anchored tunnels are arranged at intervals along the strike directions of the anti-shear tunnels on the selected anti-shear tunnels as seen from the front surface of the concrete anti-shear structure, and the anchored tunnels all penetrate through the anti-shear tunnels along the directions facing to the slip crack surface; and besides, the two layers of anti-shear tunnels are connected into an integer through a plurality of the displacement inclined shafts extending between the selected upper and lower layers of the anti-shear tunnels along the slip crack surface. The integer formed by the anti-shear tunnels, the anchored tunnels and the displacement inclined shafts through the pouring is suitable for treating a large-size rocky high-steep side slope with deeper burial depth on the slip crack surface.

Owner:POWERCHINA CHENGDU ENG

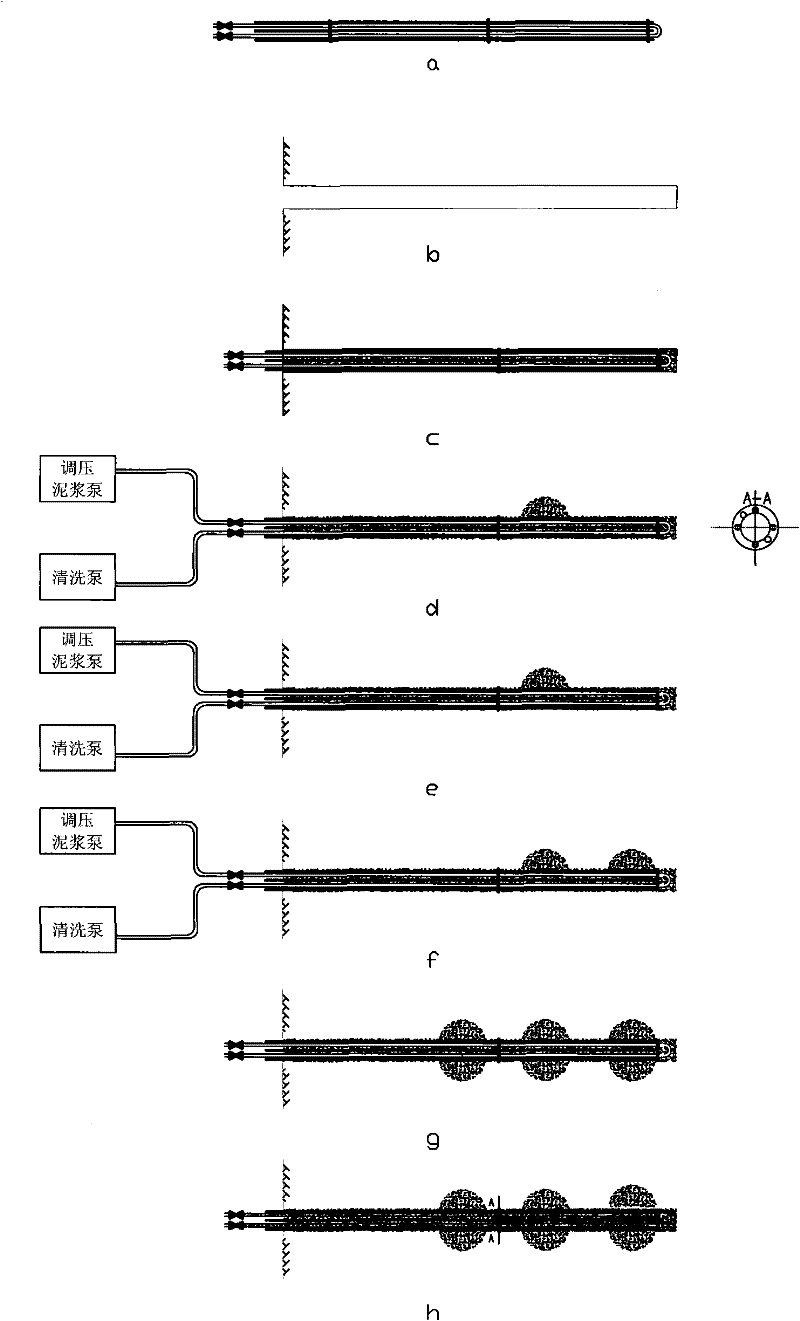

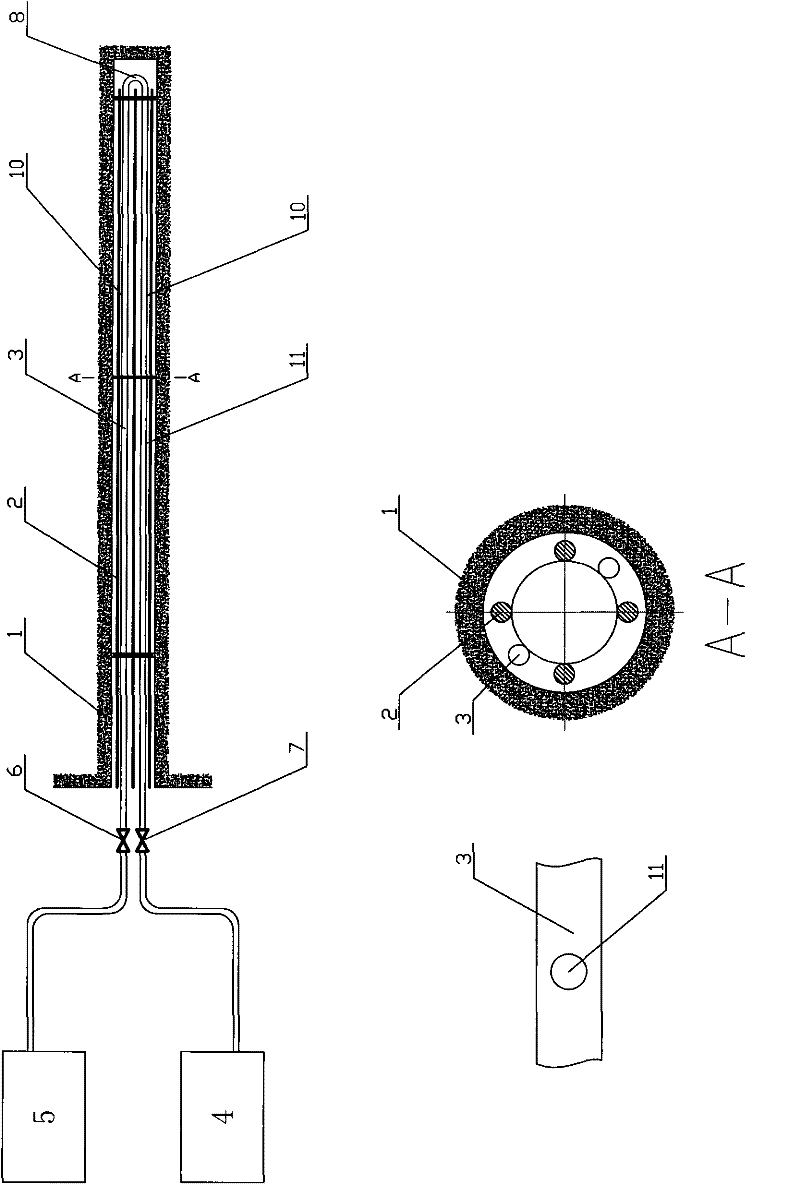

Repeated adaptive grouting system and construction method

A repetitive self-adaptive grouting system and its construction method. The grouting system includes an open-circuit or closed-circuit grouting system consisting of a grouting pipe with a pressure-opening check valve, an adjustable pressure grouting pump, a cleaning pump, and an anchor hole. system, repeating segmental pressure regulation and secondary splitting grouting for the bolts that have completed the hole-forming grouting of the bolts. Change the splitting grouting pressure by adjusting the pressure grouting pump to open the grouting valves at different positions on the grouting pipe to complete the splitting grouting at a specific position, then use the cleaning pump to clean the grouting pipe, and repeat the adjustment for the pressure grouting pump Different pressures are used to open the grouting valves at different positions to split the grouting again, and this process is repeated many times to complete the multiple grouting splitting design requirements. The application system and its construction method finally realize the splitting of the bolt by multiple staged pressure grouting, increase the side friction resistance of the bolt, improve the load bearing capacity of the bolt, and reduce the deformation of the bolt, so as to effectively deal with the weak soil and rock layers The reinforcement can effectively enhance the entire anchoring system.

Owner:CHINA JINGYE ENG +1

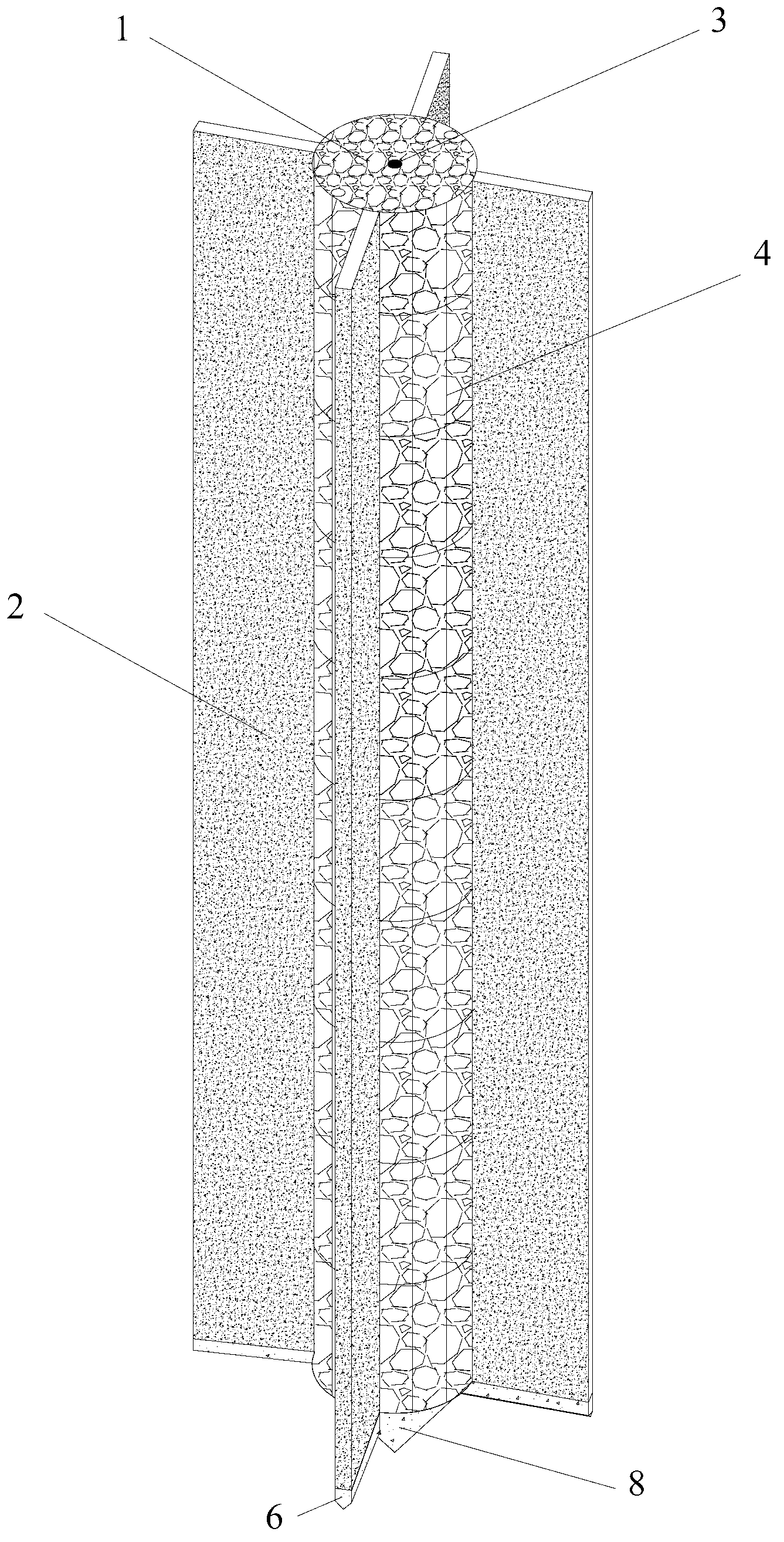

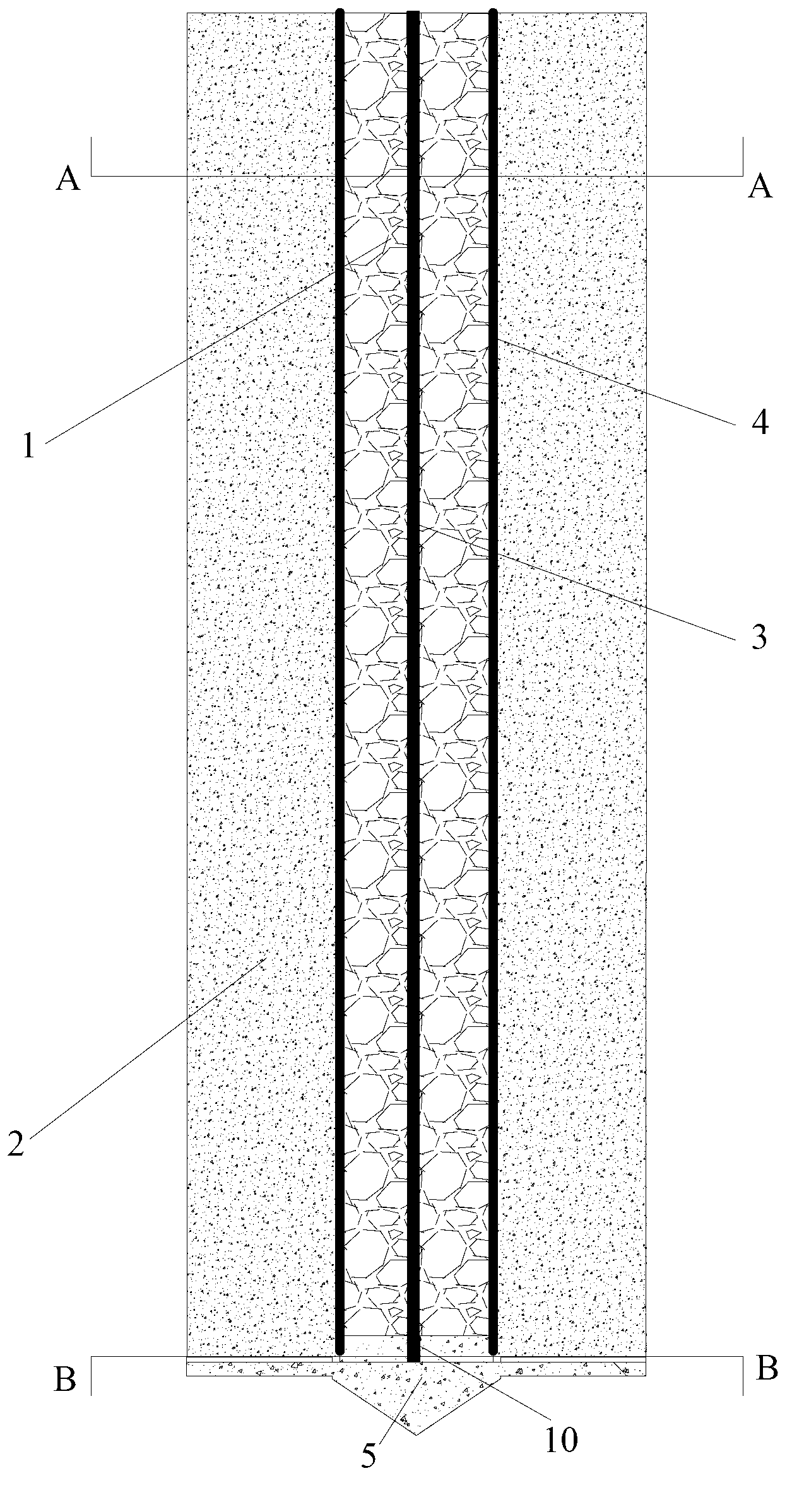

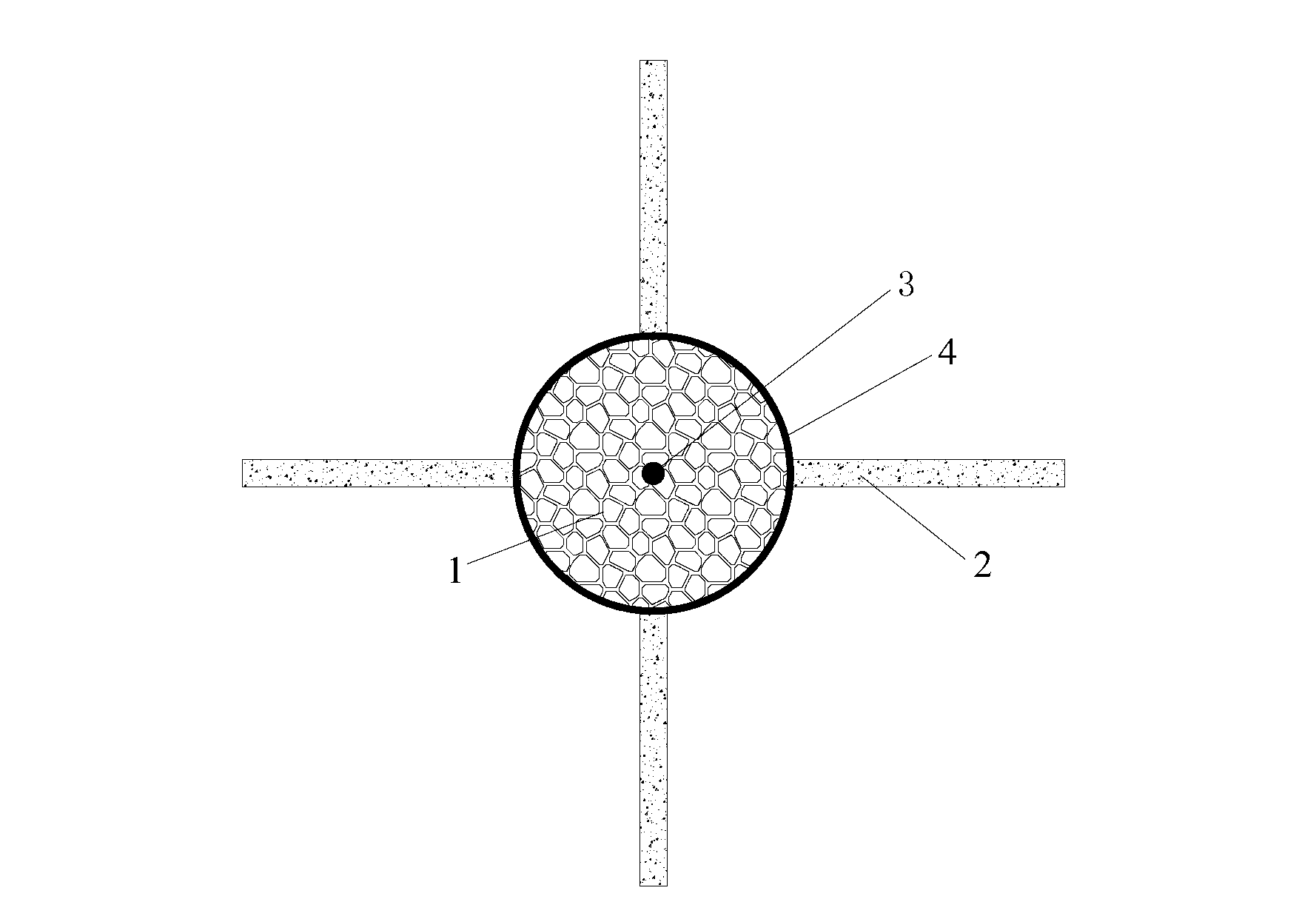

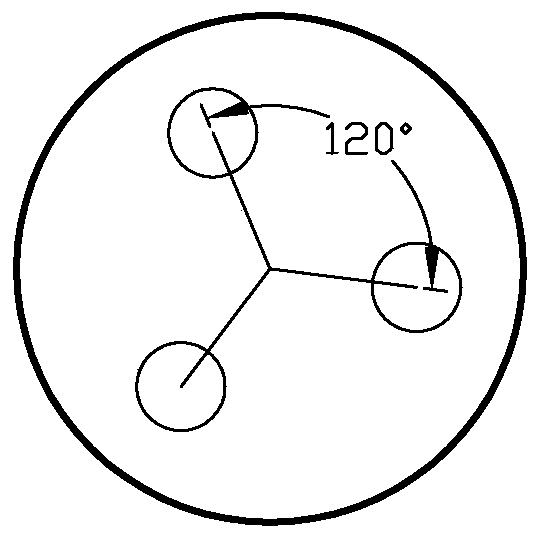

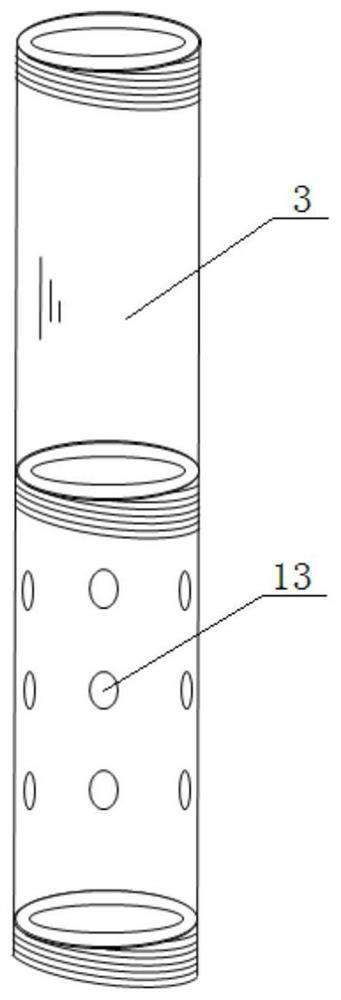

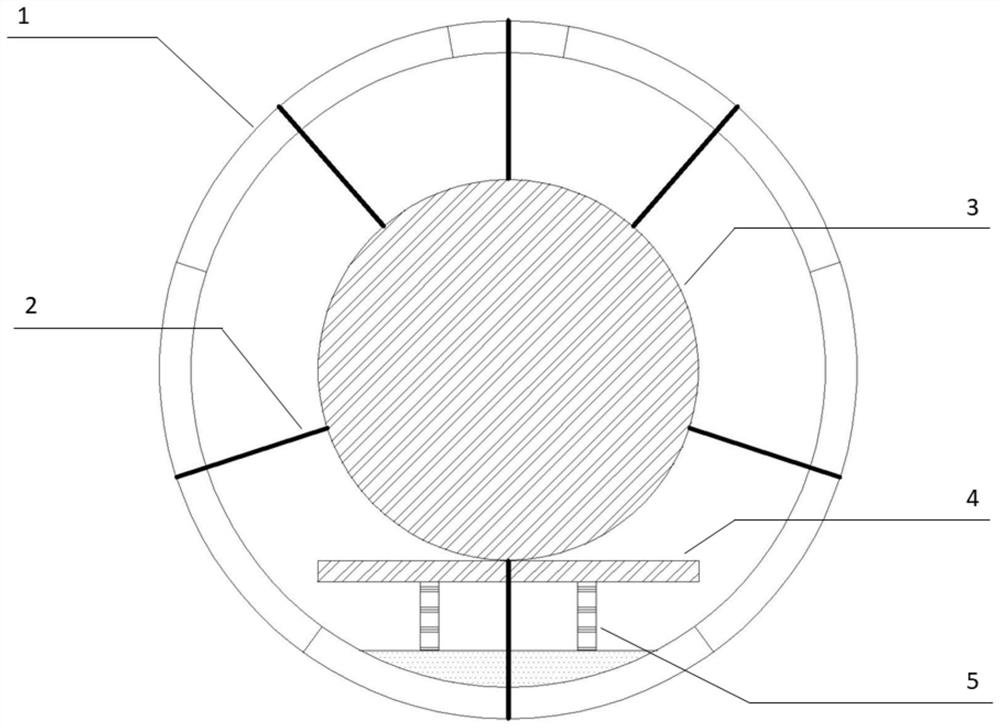

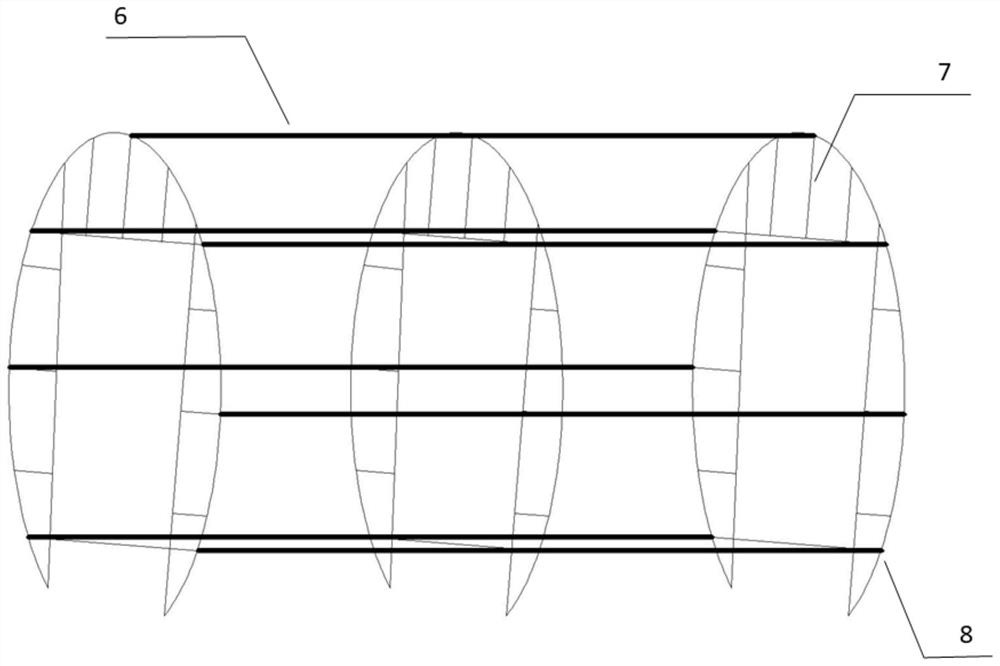

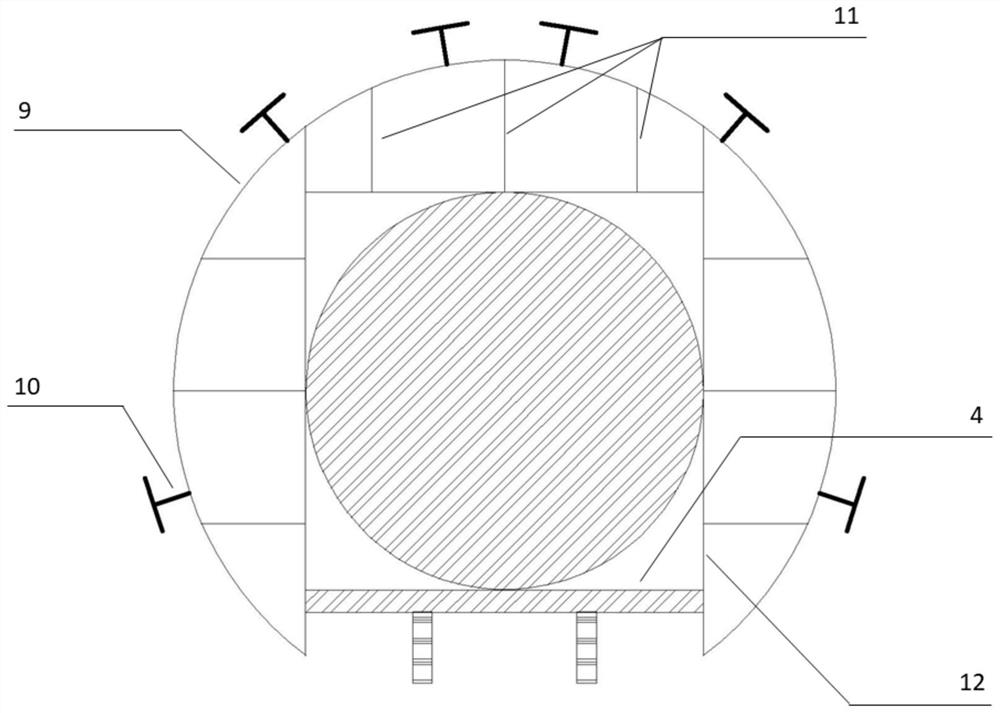

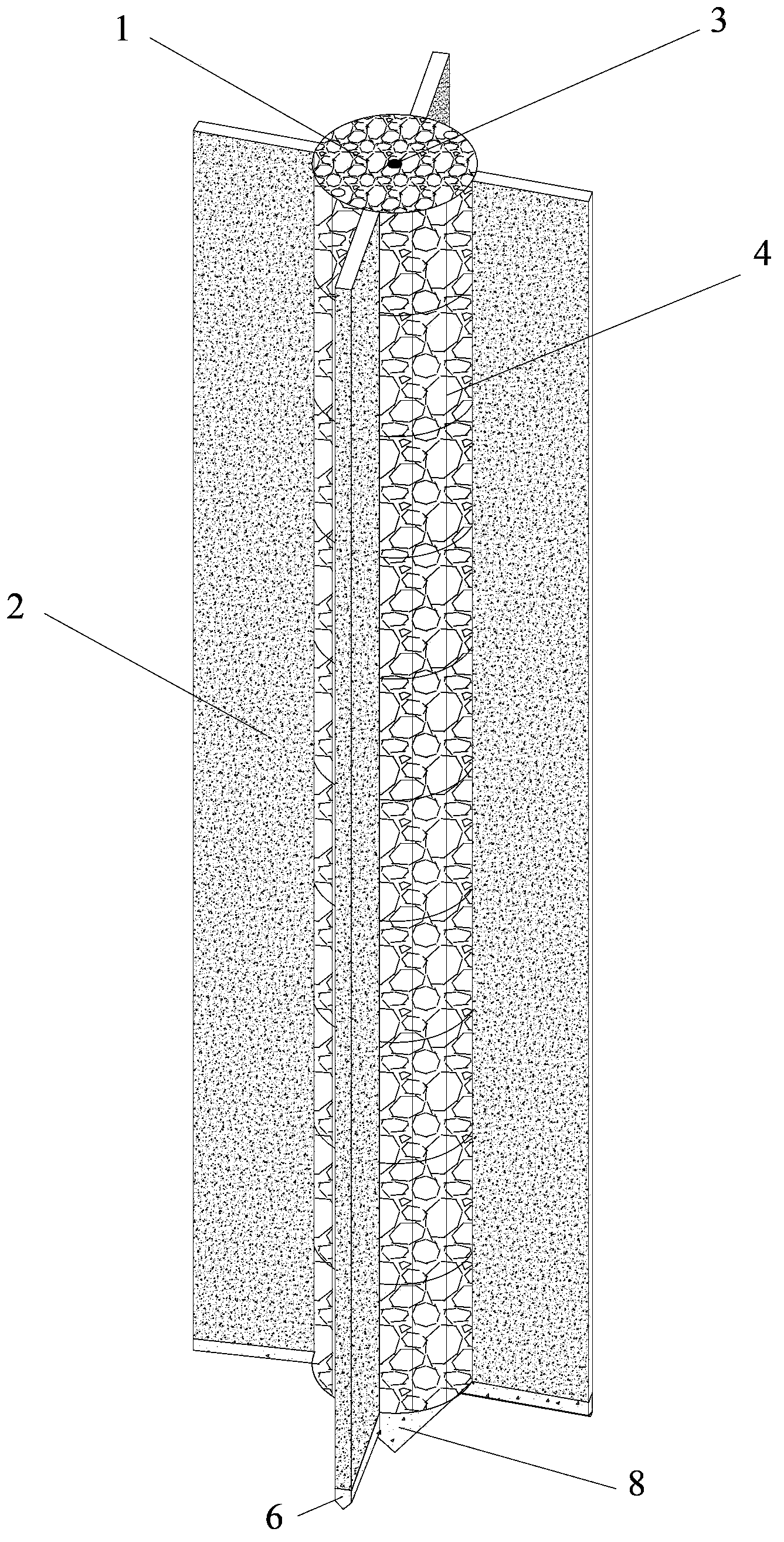

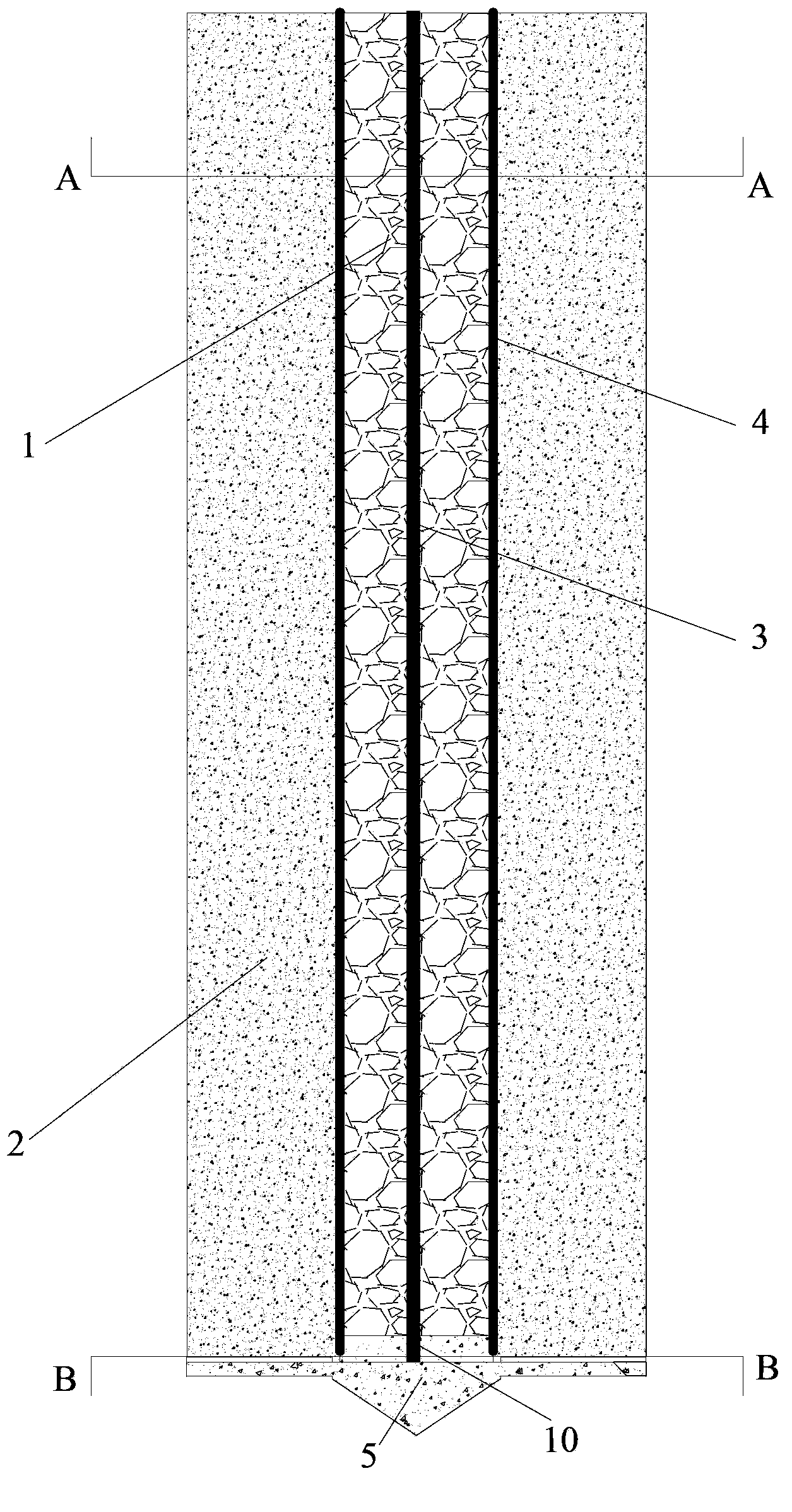

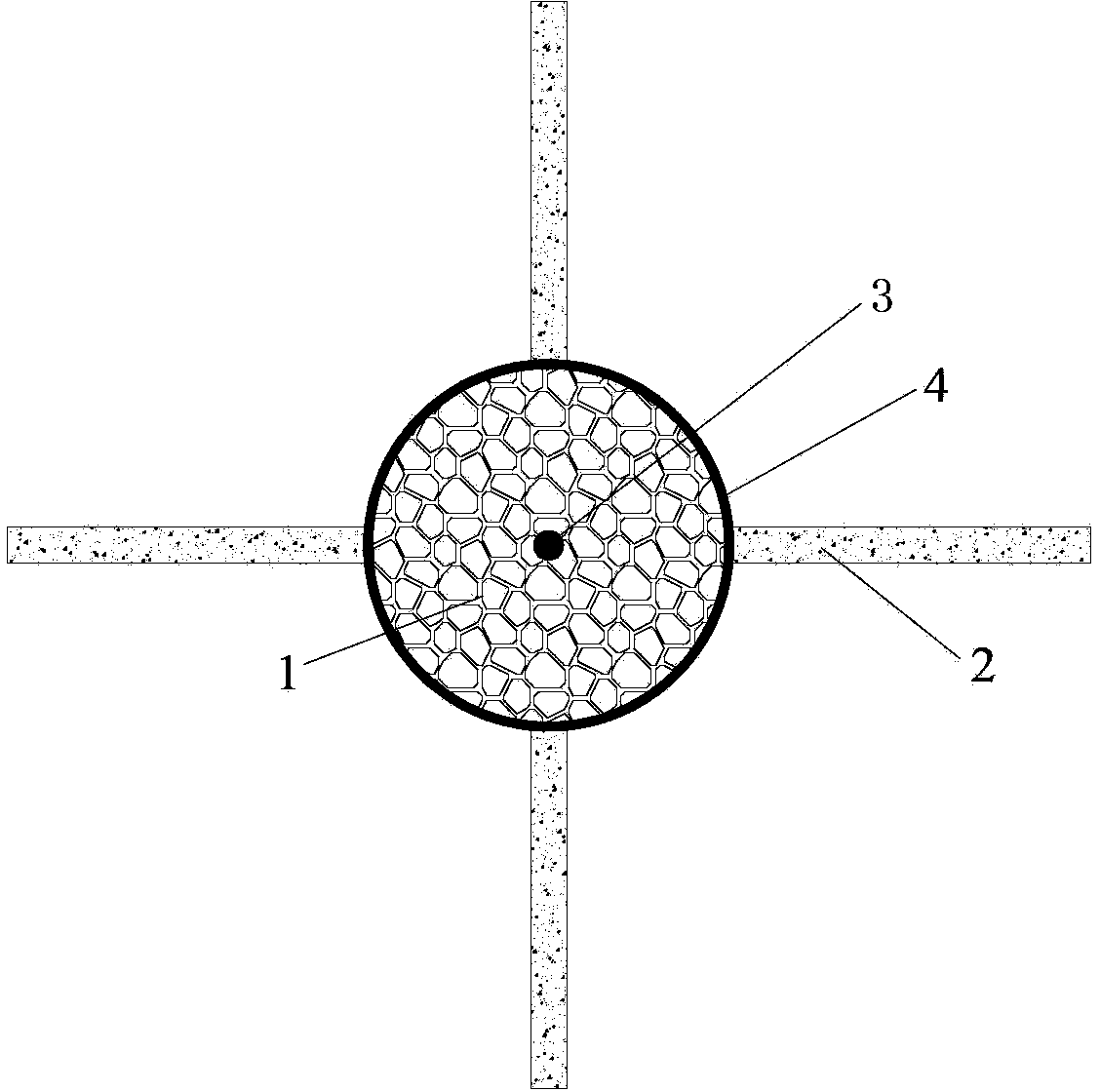

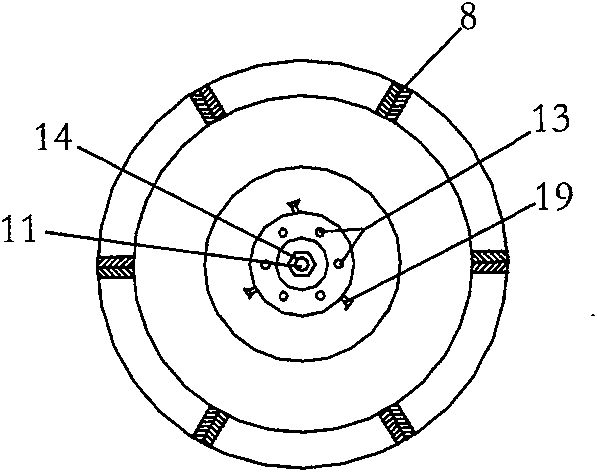

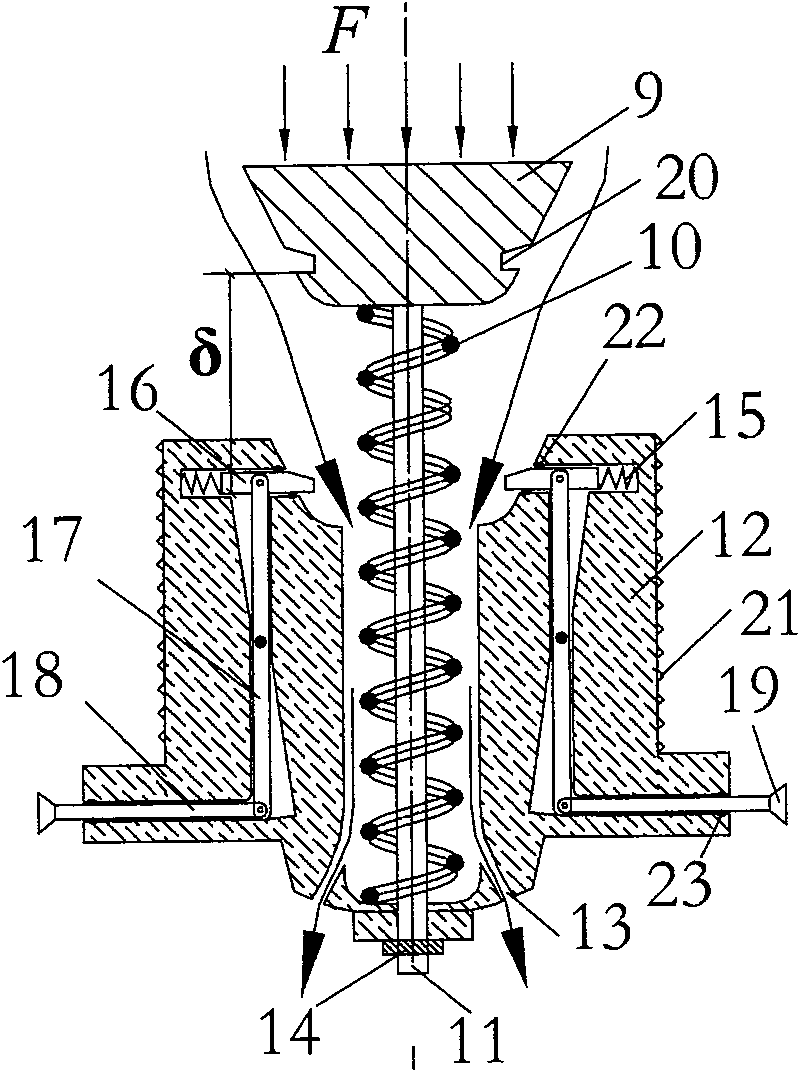

Post-grouting gravel pile with sand wall wing plates and construction method

InactiveCN103061328AUniform consolidationRealize three-dimensional drainageBulkheads/pilesSoil preservationReinforced concreteWhole body

The invention relates to a post-grouting gravel pile with sand wall wing plates. The post-grouting gravel pile with the sand wall wing plates is characterized by mainly comprising a grouting gravel pile, a plurality of sets of sand wall wing plates and precast reinforced concrete pile tips, wherein the sand wall wing plates are uniformly distributed along the ring direction of the grouting gravel pile and are connected with the grouting gravel pile to form a whole body, the top part of a pile body extends into a sound cushion layer, the precast reinforced concrete pile tips comprise a gravel pile tip and a sand wall pile tip and are respectively arranged at the bottoms of the gravel pile and a sand wall, a grouting pipe is preset in the middle of the grouting gravel pile body, and the bottom of the grouting pipe is connected with the precast pile tips. With the adoption of the post-grouting gravel pile, the performance of water drainage of a granular material during a prepressing period can be exerted, and the grout can also be grouted into the pile body by a grouting pipe according to the sedimentation condition to form a rigid composite pile type, thus increasing the effective reinforcing depth of a gravel pile foundation and realizing effective unification of a drainage consolidation method and a composite foundation method.

Owner:FANGTAI CONSTR GRP +1

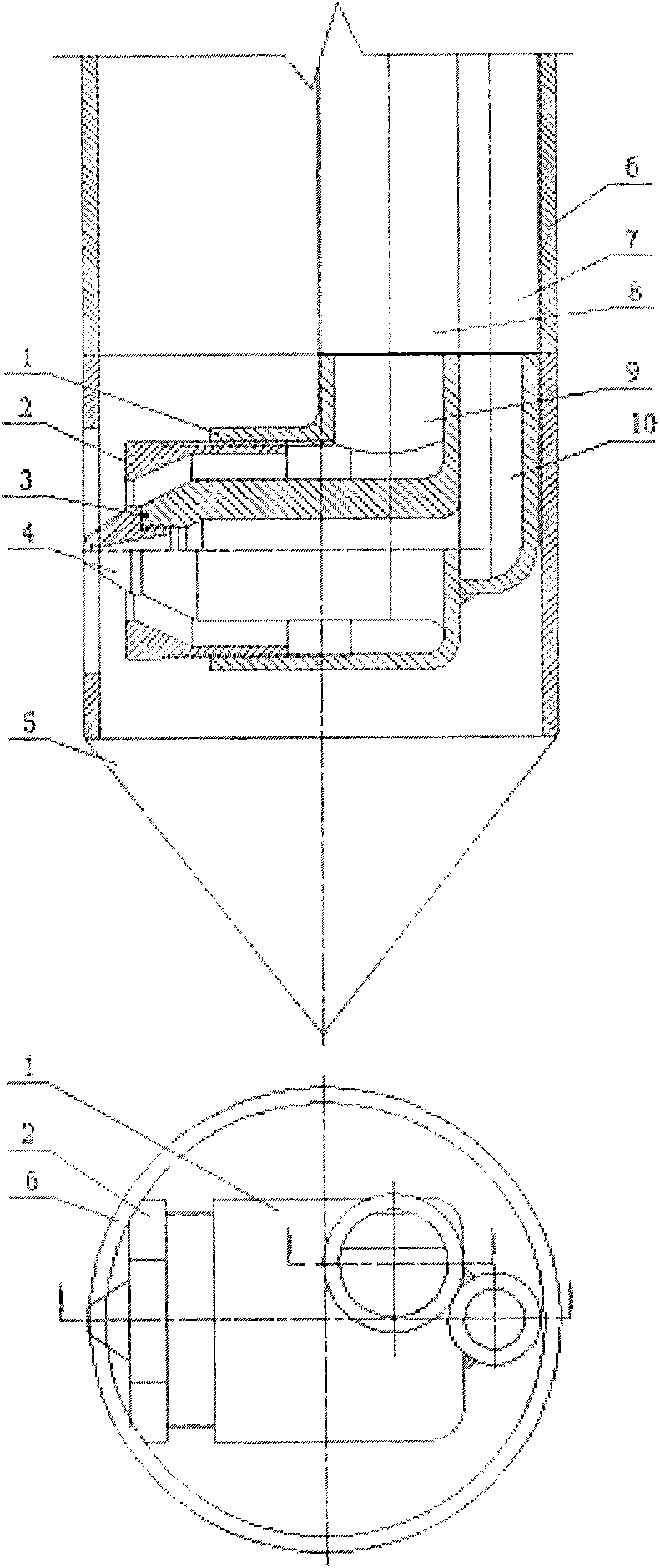

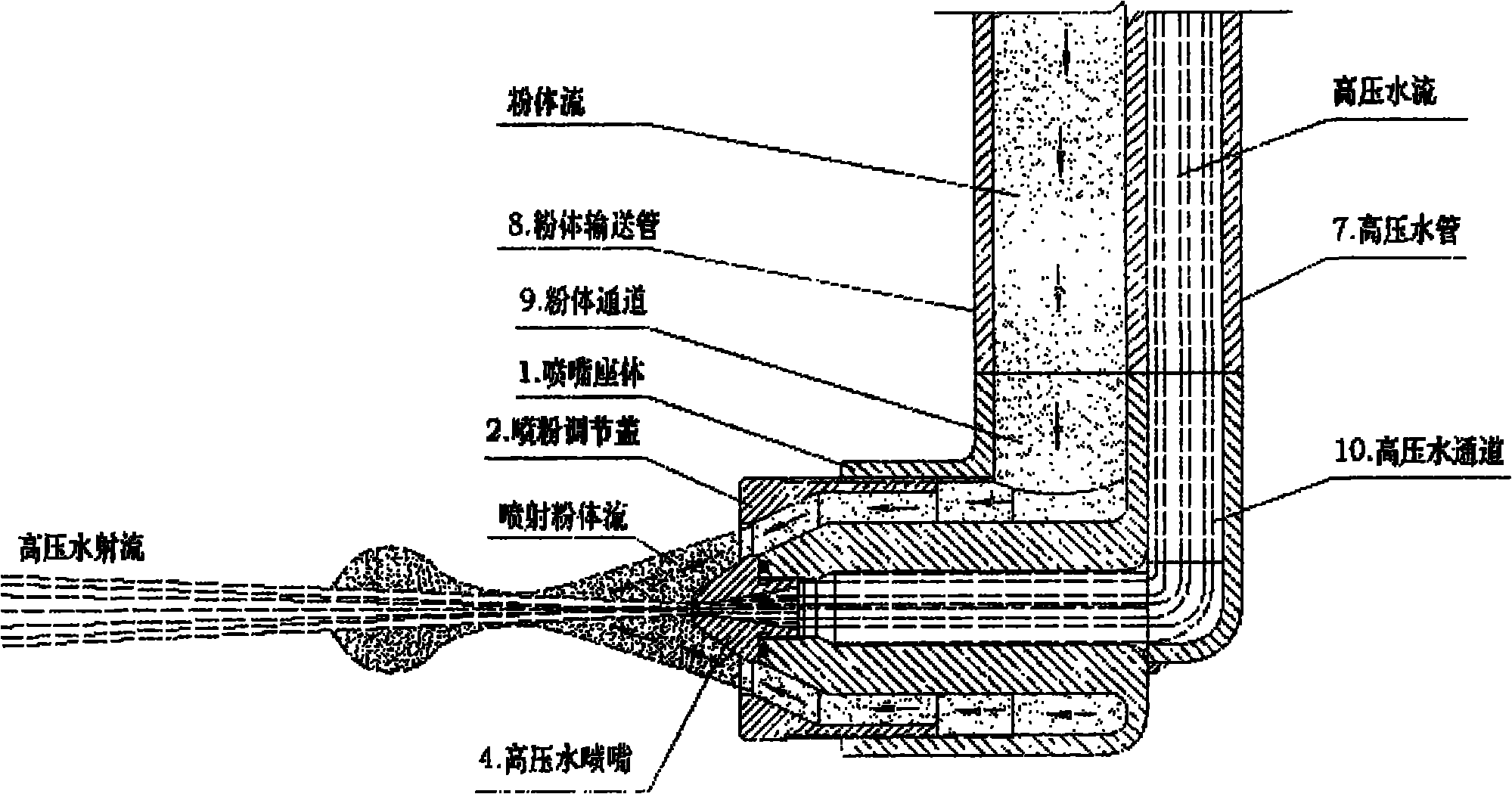

High pressure powder-spray nozzle for high pressure powder spray method

InactiveCN101787693AReduce wasteReduce moisture contentSoil preservationHigh pressure waterHigh pressure

The invention relates to a high pressure powder-spray nozzle for a high pressure powder spray method, and aims to form a continuous and complete reinforced body with good water stop effect and expand the application range of a spraying and casting method in a underground water prevention and treatment project of a water-saturated sand layer, at the same time reduce the moisture content of the reinforced body, and contamination of mud and cement waste of a grout oozing body caused by the unit reinforced body, thereby reducing the construction costs. The nozzle comprises a nozzle base body, a powder spraying regulation cover, a sealing ring, a high-pressure water nozzle, a drill, a drill rod, a high-pressure water pipe, a powder conveying pipe, a powder passage and a high-pressure water passage, wherein the nozzle base body is connected with the drill rod; the drill rod is internally provided with the high-pressure water pipe and the powder conveying pipe; the high-pressure water nozzle is in thread connection with the high-pressure water pipe; the powder spraying regulation cover is in thread connection with the powder spraying passage; the powder spraying nozzle encloses around the high-pressure water nozzle, and has a certain conical degree; and when the powder is sprayed out, and ring form powder concentrates into a beam and spray to the high-pressure water jet.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

Bored pile foundation bearing stratum reinforcing and strengthening construction method

The invention relates to a bored pile foundation bearing stratum reinforcing and strengthening construction method. The bored pile foundation bearing stratum reinforcing and strengthening constructionmethod comprises the following steps that step one, grouting holes are drilled; step two, the grouting holes are cleaned; step three, grouts are prepared; step four, grouting is carried out; and stepfive, grouting hole openings are closed. Hole flushing carried out by adopting double-pipe high-pressure jet grouting is a key strengthening process, through high-pressure water flushing and cutting,soil in sediments, argillaceous contents in pile body separation segments and argillaceous contents in pile bottom fragmental intense weathering and weak intercalated layers can be flushed clean, andthe groutability of the grouts and the quality of induration are further improved, so that the bearing capacity of a sediment segment, pile bottom rock stratum fragments and weak intercalated layersis further improved; and in the grouting process, floral tubes are inserted into the grouting holes in a mode of floral tube grouting after rotary jet grouting is completed, and the problem that in the grouting hole forming, the pile tip soil body strength is reduced due to disturbance of soil around piles and the problem that water softening by soaking exacerbates the pile tip soil body strengthto be reduced during grouting hole cleaning are solved.

Owner:湖南化工地质工程勘察院有限责任公司

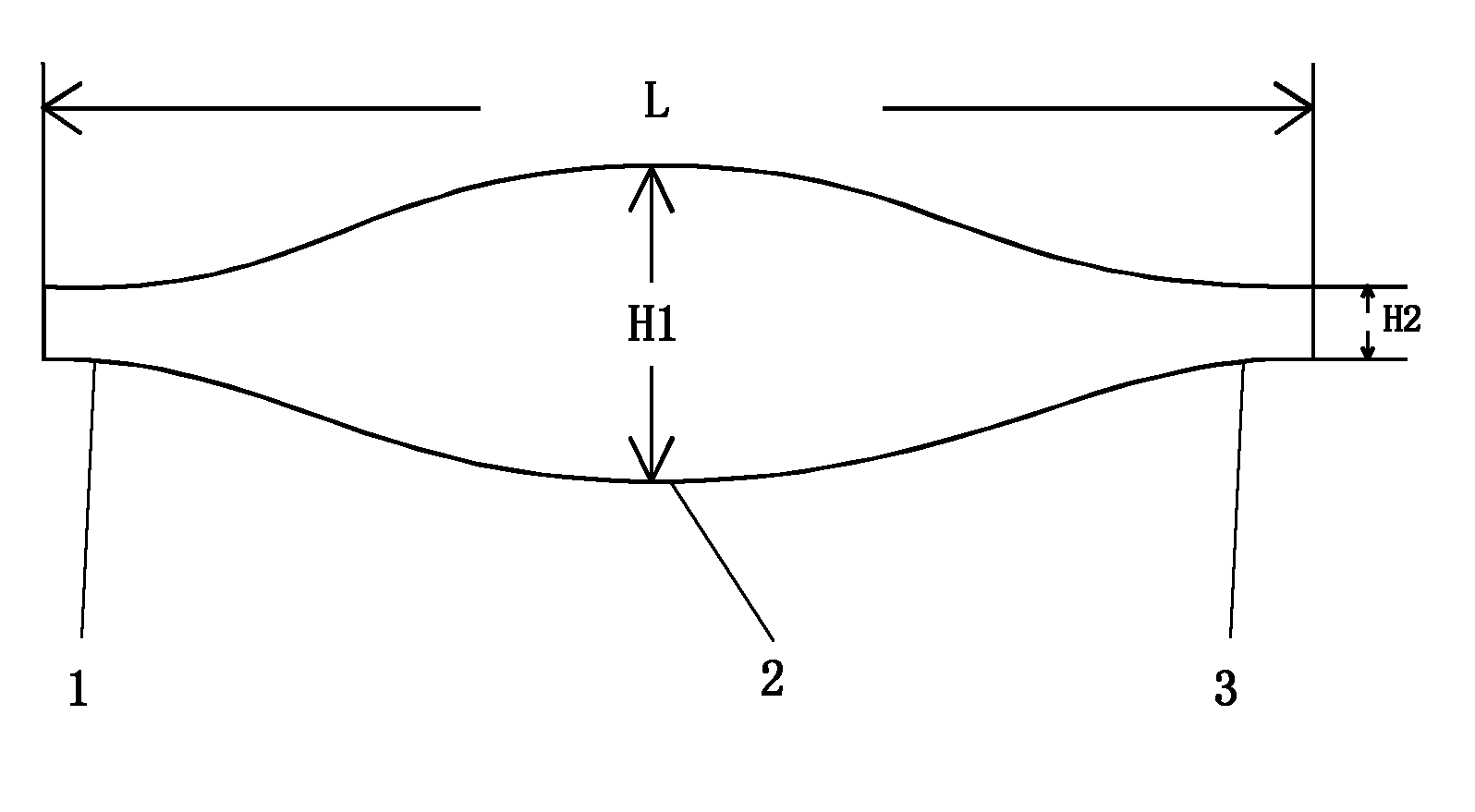

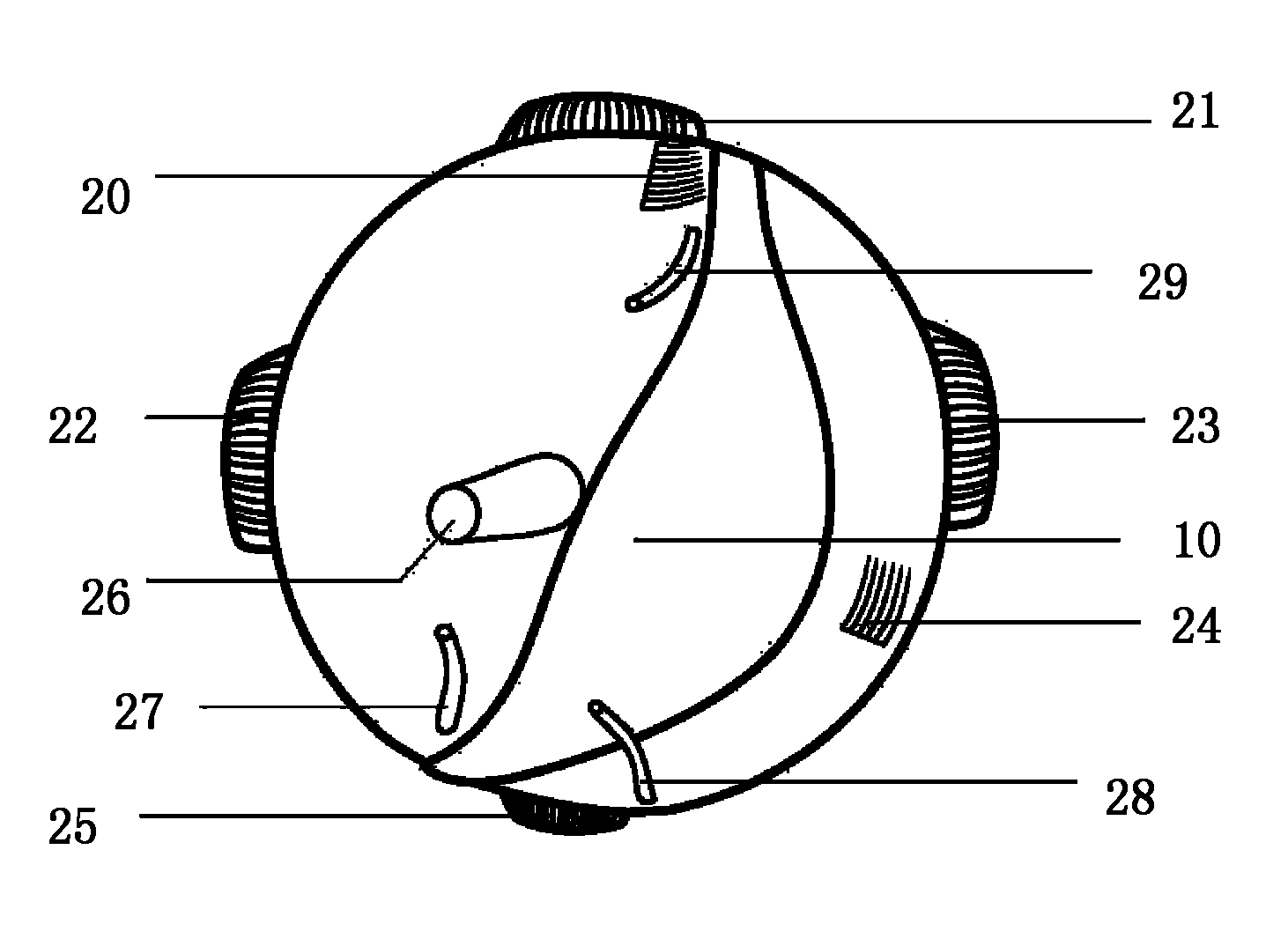

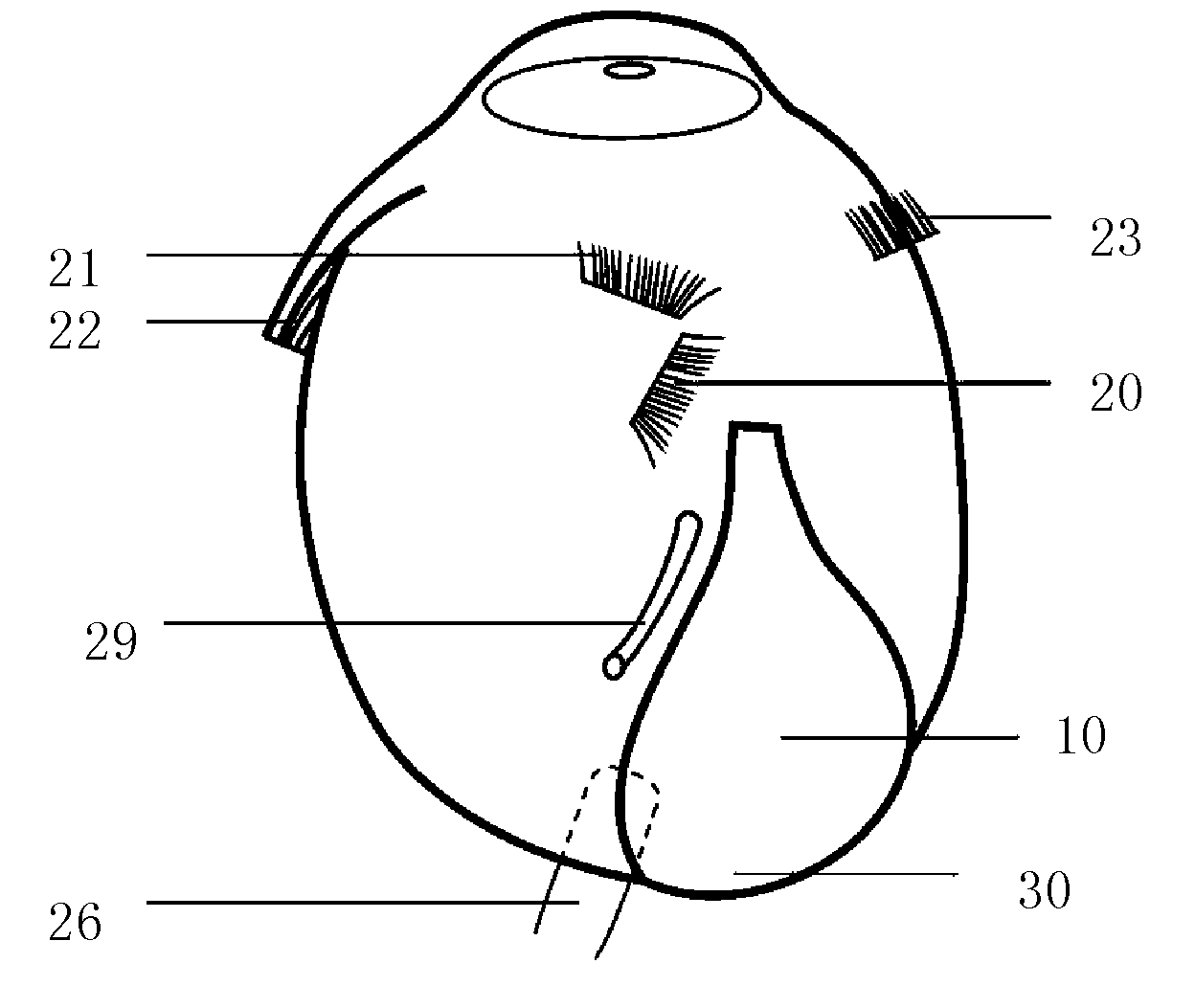

Biomembrane material strip belt for high-myopia posterior scleral reinforcement surgery and manufacture method thereof

The invention relates to an ophthalmic medical appliance and a manufacture method of the ophthalmic medical appliance, in particularly to a biomembrane material strip belt for a high-myopia posterior scleral reinforcement surgery. Base materials of the biomembrane material strip belt have a wide resource, the biomembrane material strip belt is blue after the treatment, the manufactured blue biomembrane material strip belt has good visuality and cannot easily get lost in the implantation process; the hardness and the elasticity are proper, the adaptability is good, the implantation is easy, and the biomembrane material strip belt is easily pasted, sewed and fixed with a receptor sclera; after the implantation into the human body, the toxicity is low, the mechanical strength is high, the tissue compatibility is good, the degradation resistance capability is high, and the calcification is not easy to occur; and the whole body of the biomembrane material strip belt is in a fusiform shape, the thickness is 0.15 to 0.45mm, the side part is an inclined surface, the middle section is widest, the middle section is gradually narrowed in arc-shaped transition respectively towards the left end and the right end, the length is 30 to 60mm, the width of the middle section is 10 to 16mm, the width of the left and the right end is 2 to 3mm, through the special shape design of the strip belt, the venae vorticosae can be prevented from being pressed, the reinforcement range is enlarged, the inclined surface of the side part is in 30 to 45 degrees, the marking at the positive surface and the opposite surface is realized, and the twisting turning is not easy to cause during the implantation.

Owner:BEIJING XINKANGCHEN MEDICAL SCI & TECH DEV

Method for consolidating tilting combination structure

InactiveCN101560837AExpand the scope of reinforcementReasonable structureBuilding repairsSheet steelEngineering

The invention discloses a method for consolidating tilting combination structure, mainly comprising the steps of laying a bonding course steel band on the surface of a concrete building to be consolidated, and welding a third steel board at the two ends of the bonding course steel band to be extended to the edge of a circumferentially connected profile steel concrete member, then arranging fixing points with the same structure respectively at the edge of the two ends, concretely, bolting a first steel board and a second steel board to the profile steel concrete member, wherein, the second steel board faces the third steel board, sequentially welding a first reinforced steel board, a second reinforced steel board, a T-shaped profile steel board and a triangular steel board between the second steel board and the third steel board in a way of reasonable combination. In the consolidation method, only a welding-bolting technology is used for fixing a plurality of steel boards in certain shapes to the building to be consolidated and the connected member to form a spatial multi-directional stress system, having the characteristics of convention construction, reasonable structure and high strength, and the method can be used for flexibly solving the consolidation problem for structural members in high-rise buildings with large space and large span.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

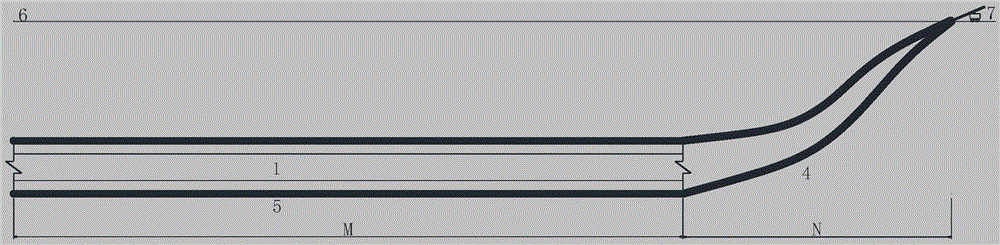

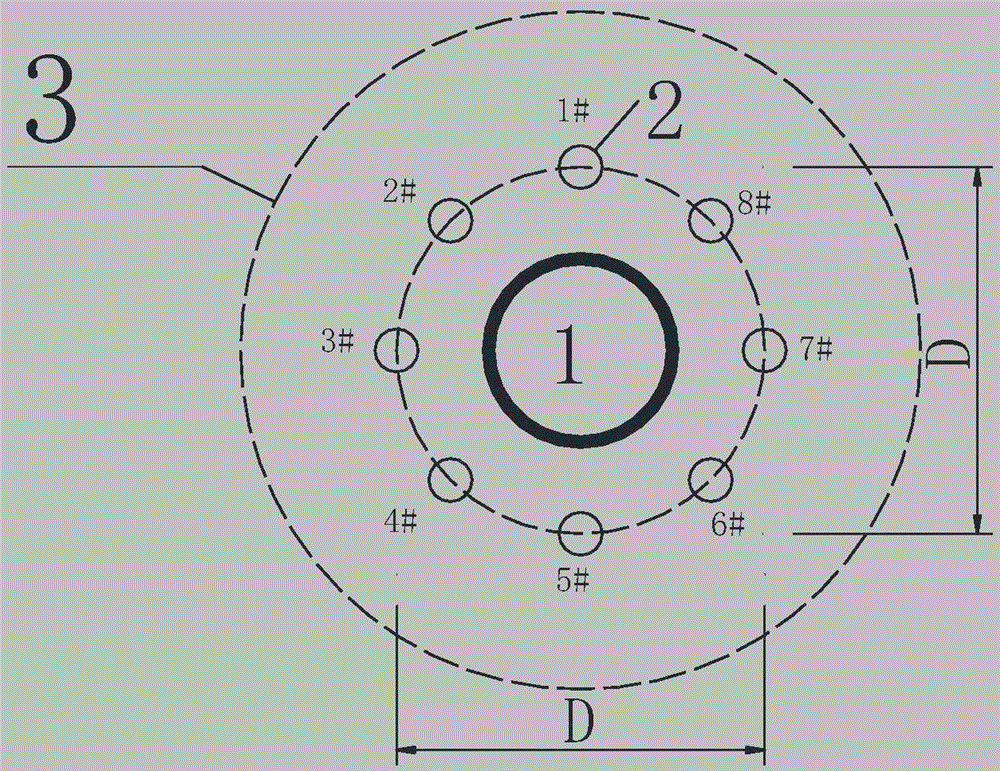

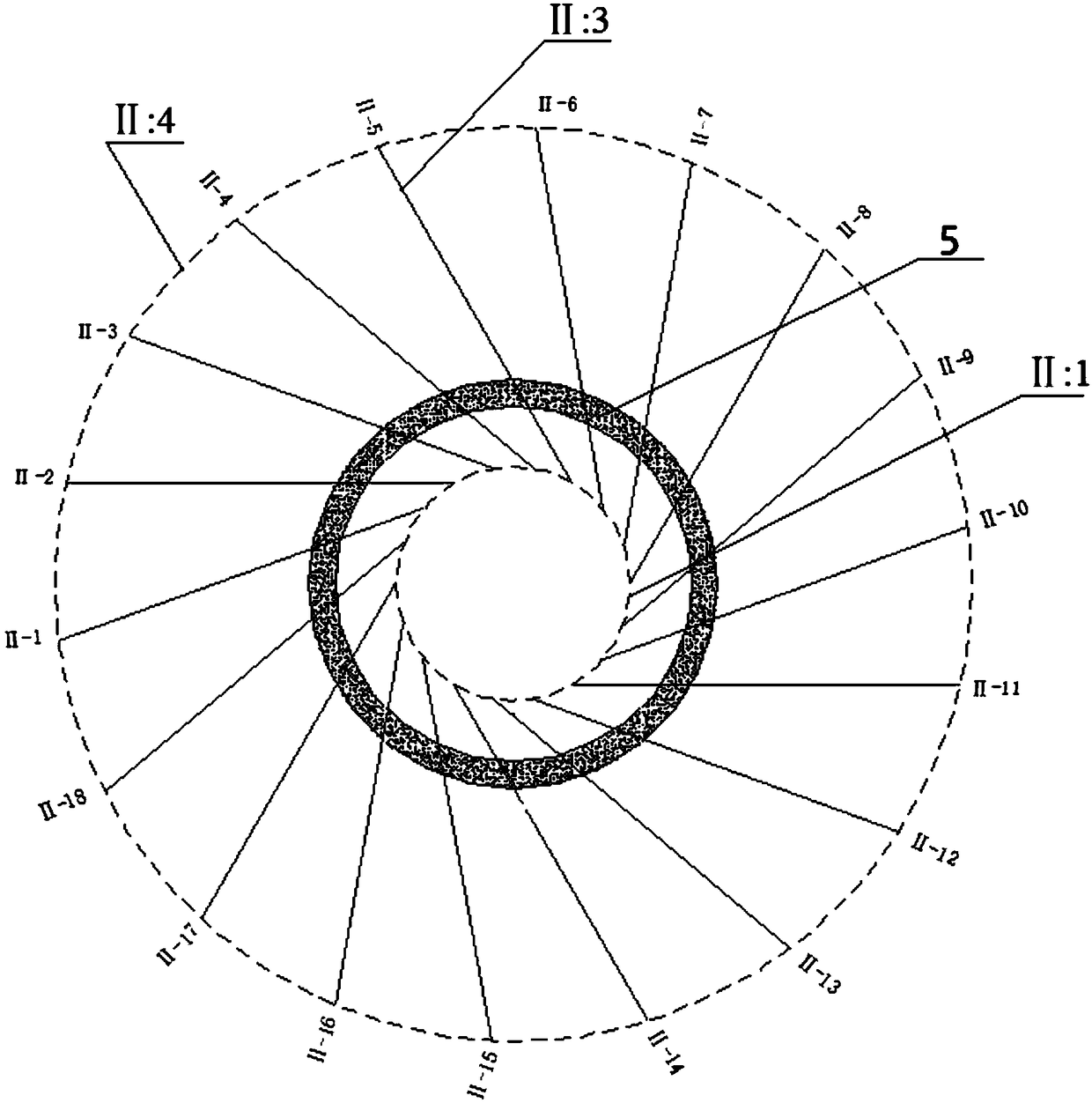

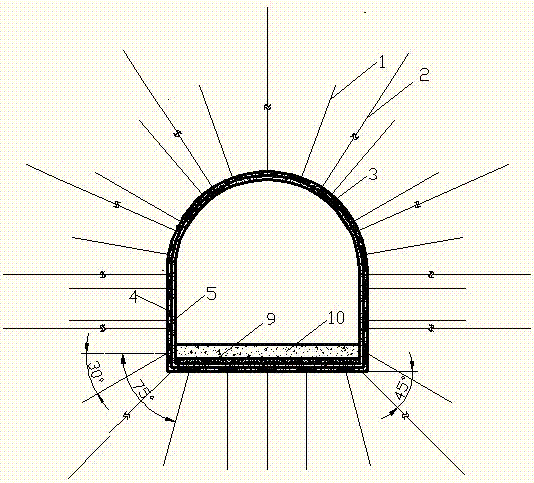

Ground pre-grouting reinforcing process for subway tunnel surrounding rock

ActiveCN106837382AGood reinforcement effectExpand the scope of reinforcementUnderground chambersTunnel liningHole makingGrout

The invention discloses a ground pre-grouting reinforcing process for subway tunnel surrounding rock. The ground pre-grouting reinforcing process comprises the following steps that (1) the subway tunnel surrounding rock range needing to be reinforced is determined as a target rock body area; (2) an oblique hole making section is constructed, specifically, oblique drilling holes are constructed close to the target rock body area from far to near, gradually become horizontal drilling holes in a transition mode and are internally provided with sleeves; (3) a horizontal grouting section is constructed, specifically, the horizontal holes are constructed, and a horizontal drilling section is determined according to the length of the pre-grouting reinforced surrounding rock; (4) grouting reinforcing is conducted, specifically, grout is conveyed into a target rock body through a drilling rod; and (5) after grouting of all the horizontal drilling holes is completed, the sleeves in the oblique drilling holes are pulled out, and then hole sealing is conducted. By adoption of the ground pre-grouting reinforcing process for the subway tunnel surrounding rock, the subway tunnel surrounding rock can be effectively reinforced, the phenomena such as surrounding rock collapse or roof fall after subway tunnel excavation are prevented, subway construction efficiency is improved, and the supporting effect of the subway tunnel surrounding rock is improved.

Owner:BEIJING CHINA COAL MINE ENG CO LTD

Segmented curtain grouting method for fault working face with too large inclination angle of shaft

ActiveCN109209287AReduce in quantityImprove drilling efficiencySealing/packingWater blockCement slurry

The invention discloses a segmented curtain grouting method for a fault working face with a too large inclination angle of a shaft. The driving working face of the shaft is casted with a concrete grouting stop cushion, an initial drilling stage of construction is started in the grouting stop cushion along the concentric circumference of the shaft, an orifice pipe is mounted in a boring orifice position, construction drilling is continued via the orifice pipe till a grouting depth position, a flange is installed in the orifice pipe, and connected with a high-pressure grouting hose and a grouting device, the orifice pipe is sealed and fixed in a gravity grouting manner, and space between the orifice pipe and a boring is filled tightly by a cement slurry. A segmented boring grouting manner isused to avoid construction of multiple grouting holes in a narrow space of the shaft, the number of grouting holes is reduced much, the drilling efficiency is improved, and shaft construction periodis shortened; and grouting is carried out in a cyclic manner by alternation among penetration, soil compaction and cleavage, the water blocking performance of grouting is improved, fragmented surrounding rocks are more reliable, and it is ensured that the shaft penetrates the fault efficiently and safely.

Owner:CHINA UNIV OF MINING & TECH

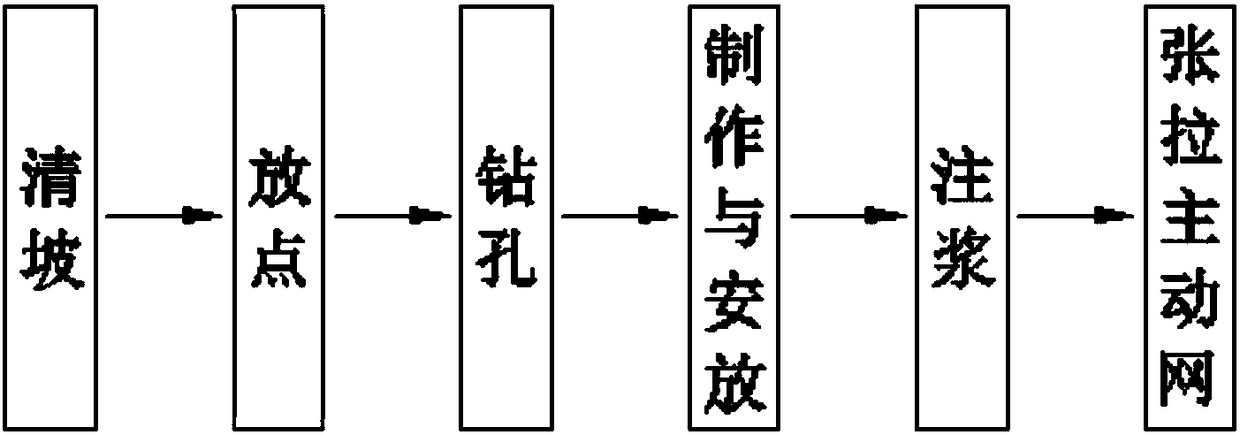

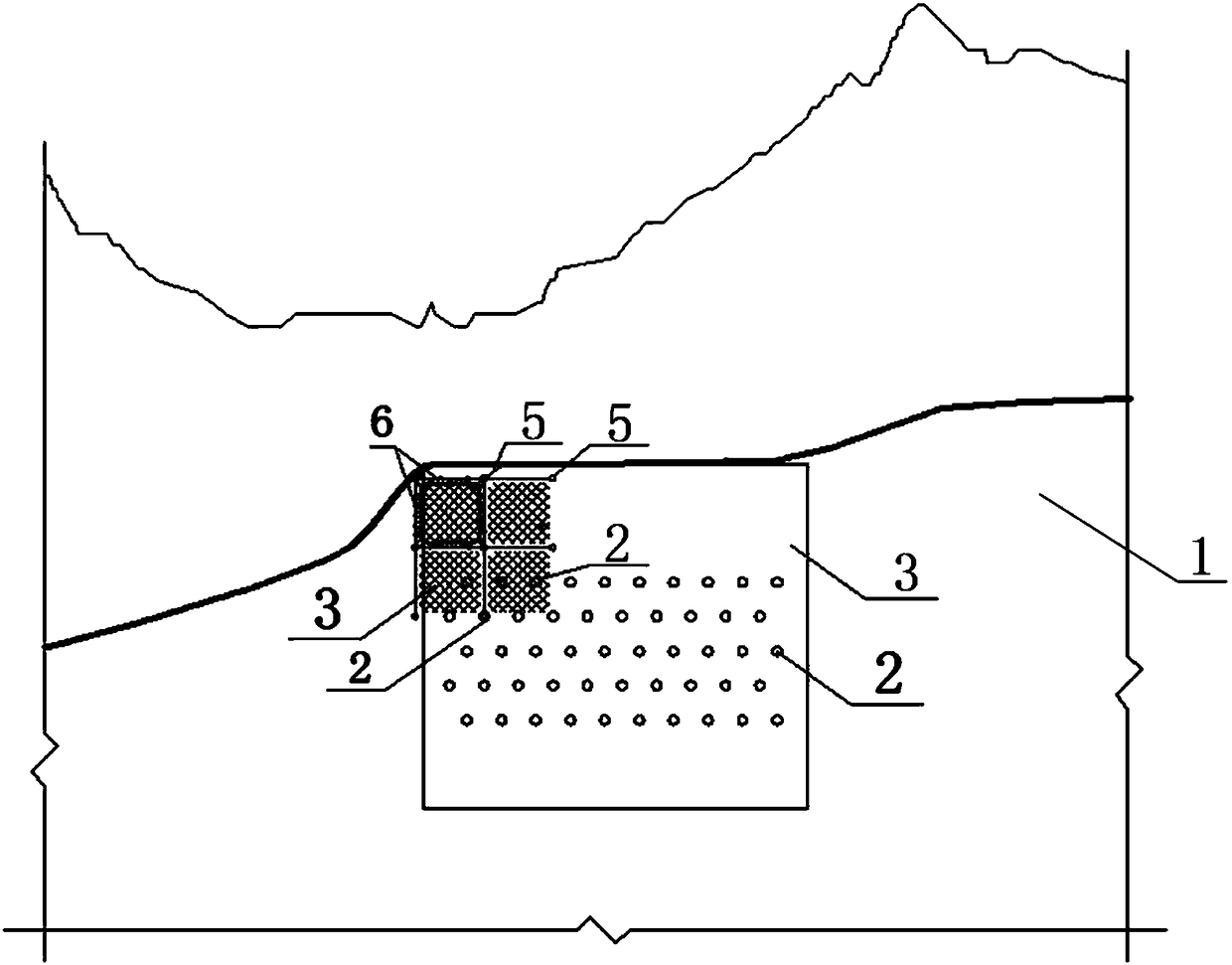

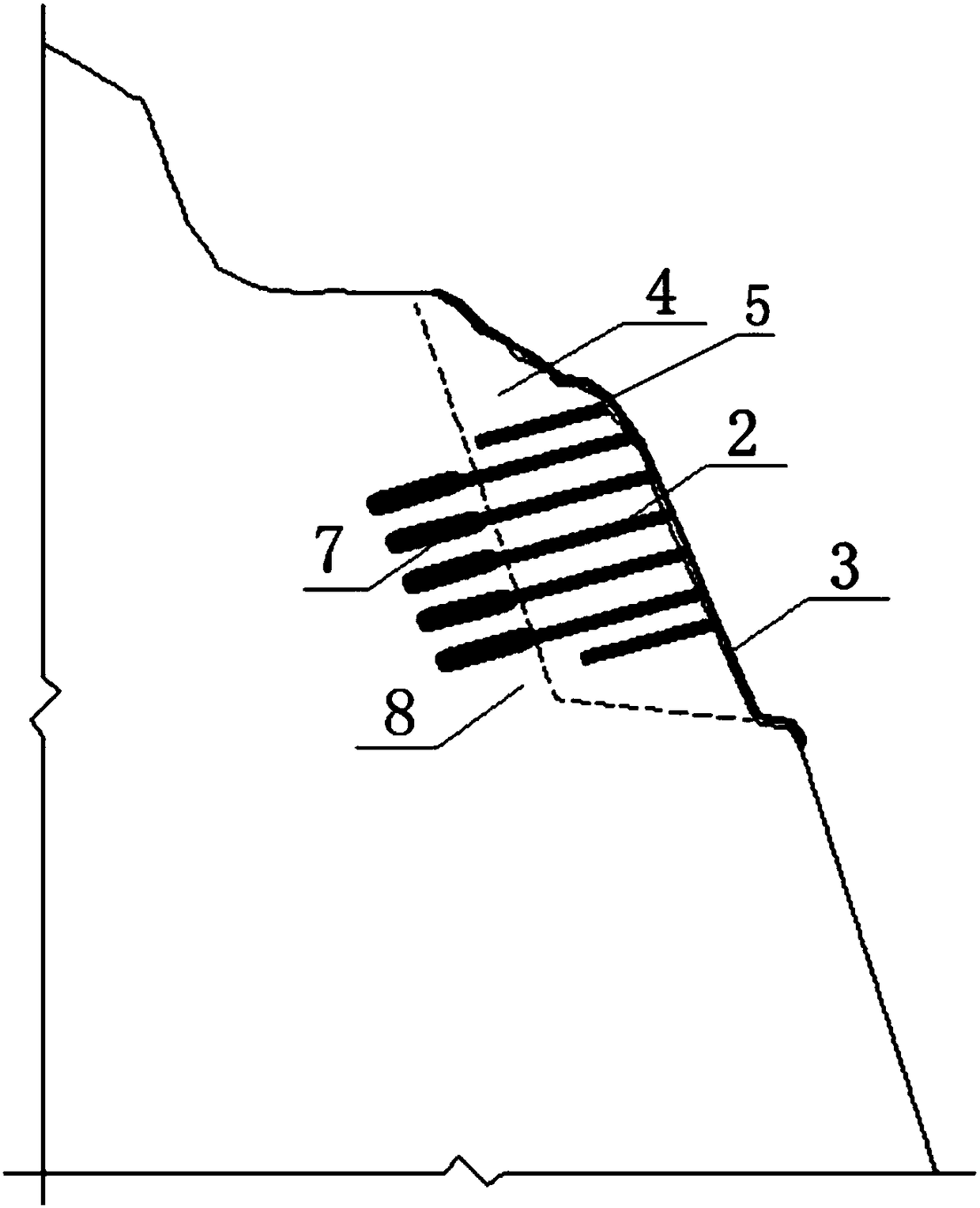

Dangerous rock body anchor net supporting method

InactiveCN108203984AReduce volumeSolve support technical problemsExcavationsBulkheads/pilesRock boltRock body

The invention relates to a dangerous rock body anchor net supporting method. The method comprises the following steps that (1), hole setting out and hole drilling are performed on a slope dangerous rock body according to a design drawing, wherein drilling holes comprise anchor rope drilling holes and anchor rod drilling holes; (2), anchor ropes are arranged and anchored in the anchor rope drillingholes, and anchor rods are arranged and anchored in the anchor rod drilling holes; and (3), a protection net is stretched on the dangerous rock body, wherein the protection net comprises supporting ropes and a net body connected to the supporting ropes, and the supporting ropes are fixed to the dangerous rock body through the anchor rods and the anchor ropes. According to the dangerous rock bodyanchor net supporting method, the anchor ropes, the anchor rods and an active net are combined, and the flexible anchor ropes and the rigid anchor rods are combined for supporting, so that the methodis applicable to supporting of large-scale dangerous rock bodies.

Owner:WUHAN UNIV OF TECH

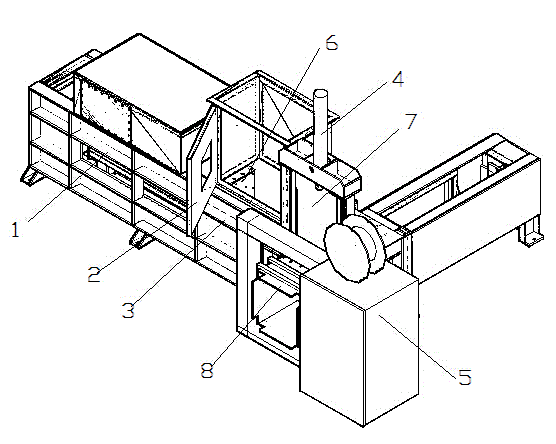

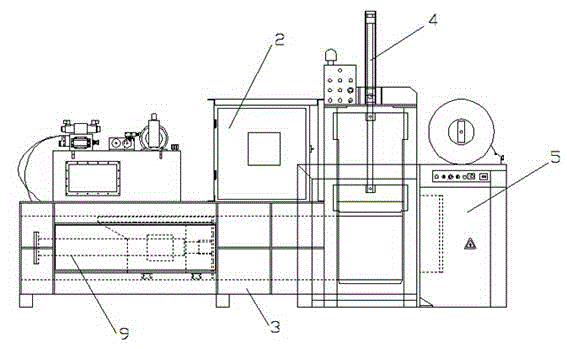

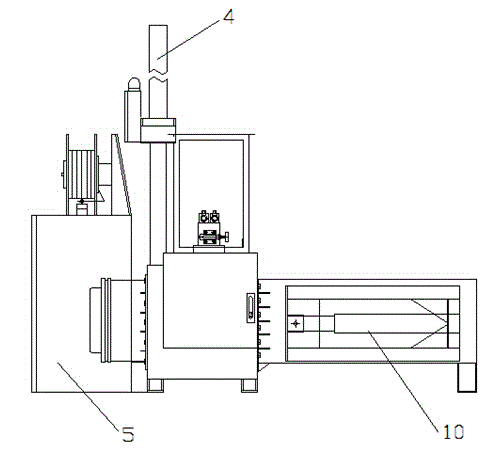

Full-automatic polypropylene (PP) ribbon automatic compression packer

The invention relates to a full-automatic polypropylene (PP) ribbon automatic compression packer which comprises a stand, a feeding mechanism, a pressing mechanism, a discharge mechanism, a pushing mechanism and a banding mechanism, wherein the pressing mechanism, the feeding mechanism, the pushing mechanism and the discharge mechanism are sequentially distributed on the stand; the pressing mechanism and the feeding mechanism are positioned on the same plane; the pushing mechanism and the discharge mechanism are positioned on the same plane; the two planes are vertical to each other; the banding mechanism is arranged beside the discharge mechanism. The full-automatic PP ribbon automatic compression packer has the advantages that the pressing mechanism, the feeding mechanism, the pushing mechanism and the discharge mechanism are reasonably distributed; during packaging, a material is extruded by the pressing mechanism; the pressed material is pushed out of the discharge mechanism by the pushing mechanism; finally, the banding mechanism is used for PP ribbon packaging; a way of packaging for once while pressing is carried out for once is utilized, so that the loose phenomenon of the material is well avoided, and the volume is reduced.

Owner:NANTONG JIABAO MACHINERY

Device for reinforcing foundation through microbial ultrasonic grouting and construction method thereof

ActiveCN112813953ASpeed up the flowImprove reinforcement uniformitySoil preservationMicroorganismTransformer

The invention discloses a device for reinforcing a foundation through microbial ultrasonic grouting and a construction method thereof. The device comprises a grouting pipe, the upper side of the grouting pipe is connected with an ultrasonic energy concentrator, the ultrasonic energy concentrator comprises an ultrasonic amplitude transformer and an ultrasonic transducer, the ultrasonic transducer is connected with the upper end of the ultrasonic amplitude transformer and the upper end of the grouting pipe, a pulse generator is arranged at the bottom of a grouting hole, an ultrasonic sensor is arranged on the ground on one side of the grouting pipe, the ultrasonic sensor is connected with an oscilloscope, the upper end of the grouting pipe is connected with a grout inlet pipe, the grout inlet pipe is connected with two grout inlet barrels through a grouting pump, and the two grout inlet barrels are filled with bacterial liquid and cementation solution respectively. According to the device, the reinforcement uniformity can be improved, deeper soil bodies can be reinforced, grout can be diffused to the periphery from the grouting pipe with holes in the pipe wall in cooperation with the ultrasonic effect, the reinforcement range is larger, the integrity is higher, the reinforcement uniformity is guaranteed, and the applicable soil body types are wide.

Owner:NANJING UNIV OF TECH +1

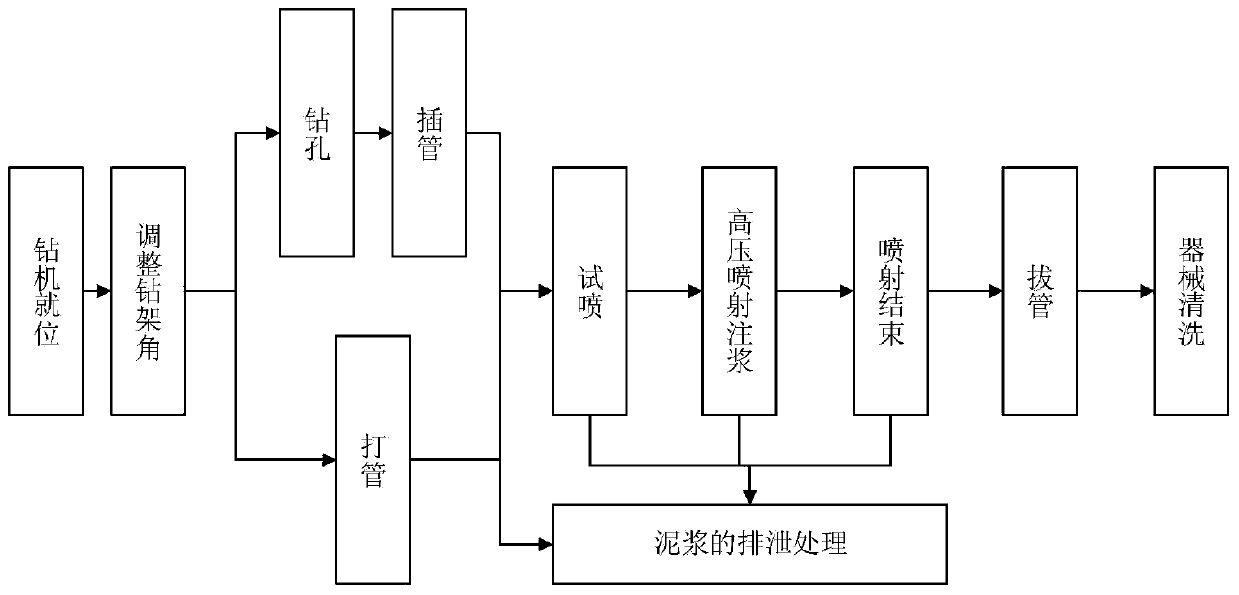

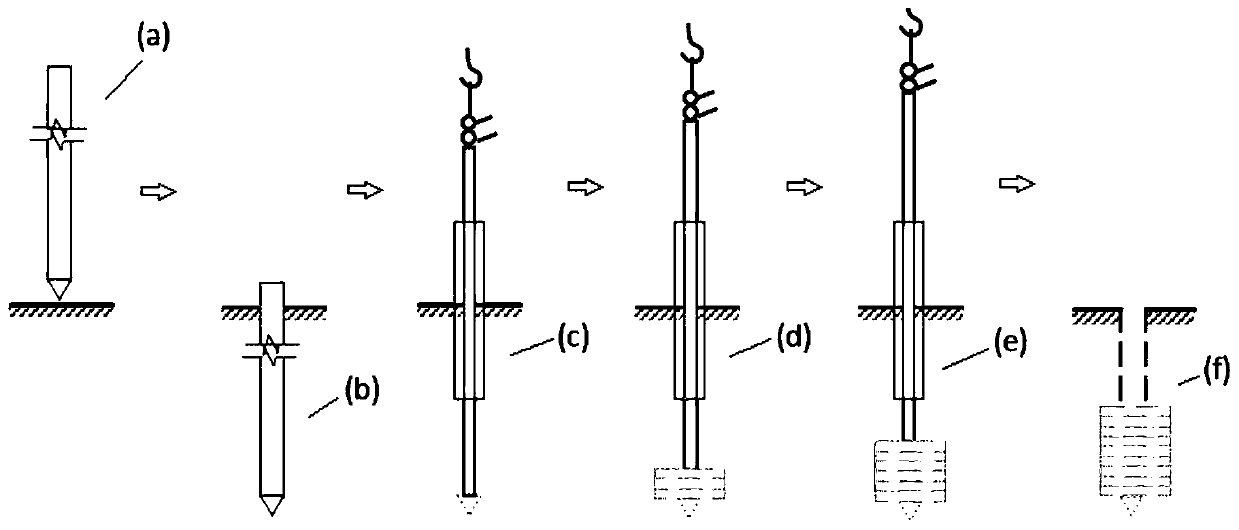

Rock cross-cut coal uncovering method with horizontal jet grouting piles for reinforcement

ActiveCN105221150AExpand the scope of reinforcementImprove reinforcement strengthUnderground miningLiquid/gas jet drillingCoalDrill hole

The invention discloses a rock cross-cut coal uncovering method with horizontal jet grouting piles for reinforcement. The method is applicable to medium-thickness coal seams with outburst risks and includes the steps: stopping tunneling when a minimum normal distance between a working face of coal uncovering and an uncovered coal seam is smaller than 7m; using a drilling rig for drilling holes, penetrating a coal seam roof, in the working face of coal uncovering; connecting with a gas extraction pipe for gas extraction; when gas content and gas pressure are reduced to permitted ranges, using a jet grouting pile machine for realizing horizontal jet grouting of each drill hole to form firm horizontal jet grouting piles in the drill holes, so that coal seam reinforcement range is widened while coal seam reinforcement strength is improved greatly, and coal seam outburst risks are reduced; after the horizontal jet grouting piles are thoroughly solidified, continuing to tunnel until a whole coal uncovering process is finished. The rock cross-cut coal uncovering method with the horizontal jet grouting piles for reinforcement has the advantages of safety and quickness in completion of coal uncovering operations and reduction of input of manpower, material resources and financial resources.

Owner:CHINA UNIV OF MINING & TECH

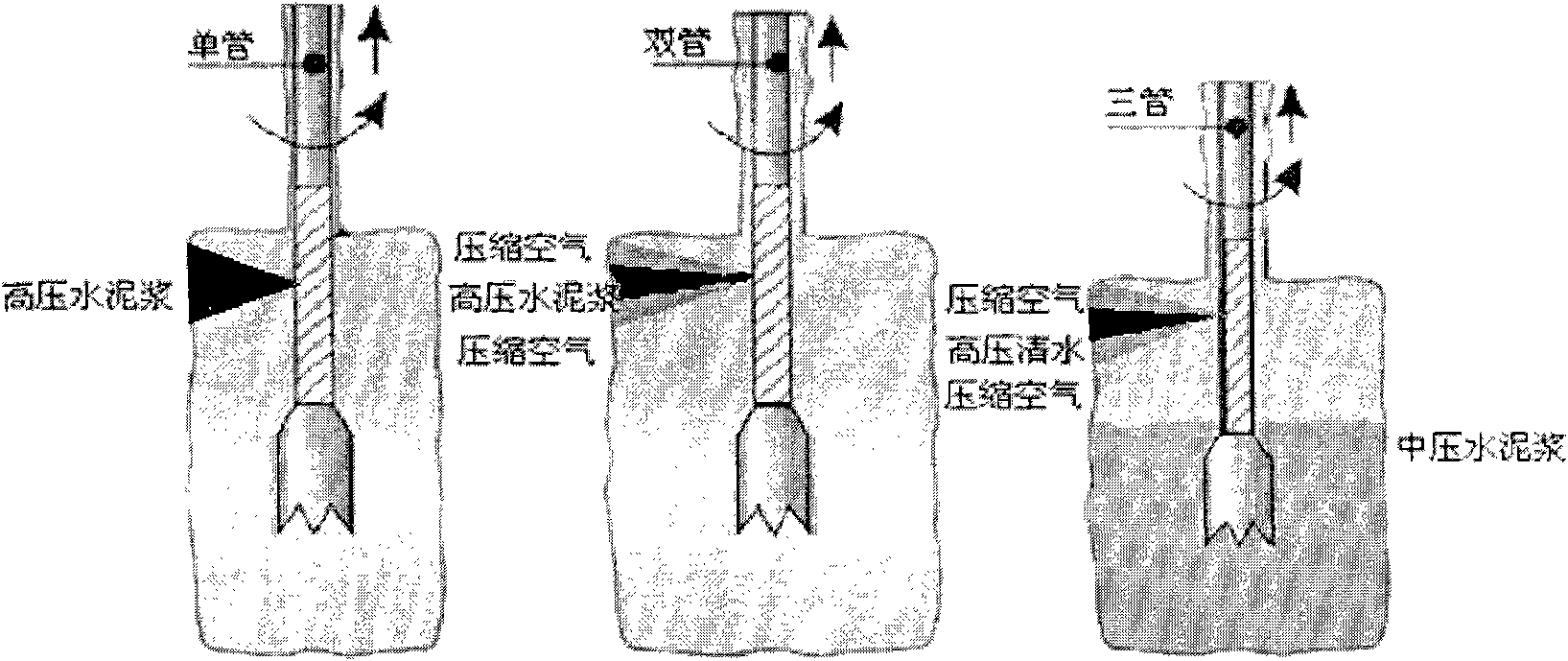

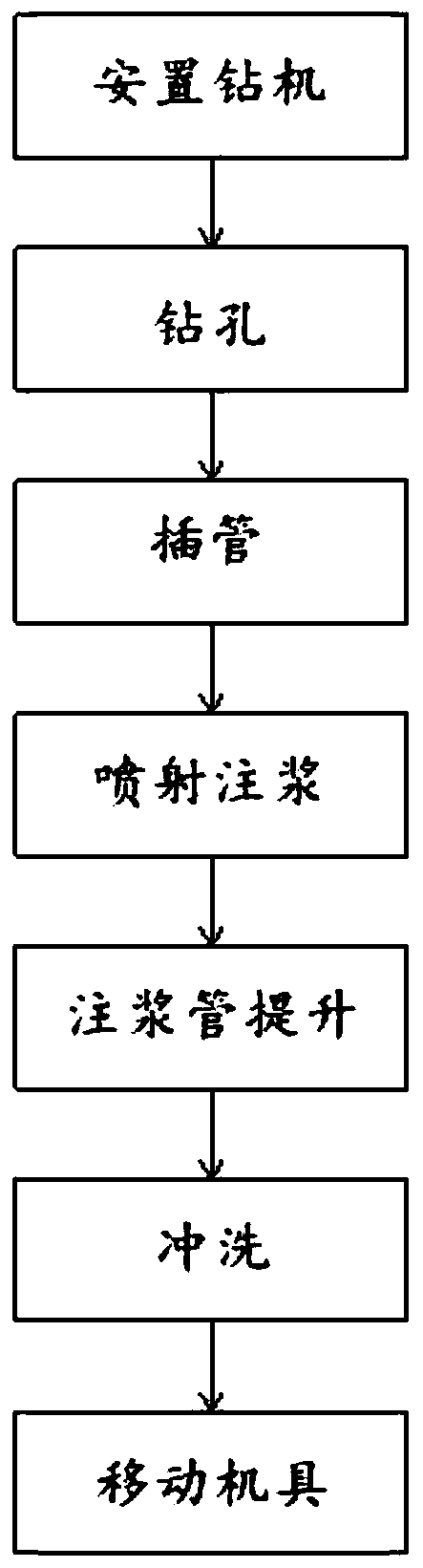

High-pressure jet grouting pile construction method

InactiveCN111455988AAdequate fitIncrease the amount of slurryBulkheads/pilesStructural engineeringCement slurry

The invention provides a high-pressure jet grouting pile construction method which achieves the technical effects of reducing construction cost and further adapting to the construction environment ofa silt geological layer by improving an existing high-pressure jet grouting pile construction technology. The method comprises the following steps that a drilling machine is installed, specifically, the drilling machine is arranged on a set hole position, inclination of a jet grouting pipe is less than or equal to 1.5%, and the distance between an injection hole and a high-pressure grouting pump is less than or equal to 50 m; drilling is carried out, specifically, the deviation between a drilling position and design is less than or equal to 50 mm, the drill bit inclination is smaller than or equal to 1.5%, and a core barrel is pulled out after drilling; pipe inserting is carried out, specifically, the jet grouting pipe is inserted into the stratum by a preset depth; spraying and grouting are carried out, specifically, spraying and grouting are carried out from bottom to top, and after rotating and spraying are carried out by 1 min at the bottom of a pile, rotation, lifting and sprayingare simultaneously carried out; the grouting pipe is lifted up, specifically, when the grouting pipe is lifted, a drilling rod is synchronously and continuously rotated without interruption, and theslurry discharge amount is between 10% and 20%; the overlapping length of subsection lifting of the grouting pipe is greater than or equal to 100 mm; washing is carried out, specifically, the groutingpipe and an operation machine are washed until no residual cement slurry exists; and equipment is moved, specifically, relevant equipment such as the drilling machine is moved to a new hole positionto carry out next pile construction.

Owner:珠海十字门中央商务区建设控股有限公司

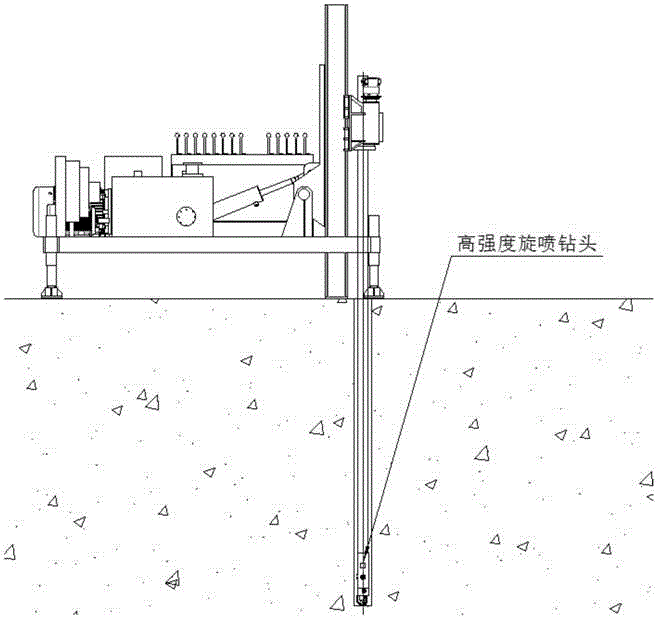

High-performance rotary jet drill

PendingCN106759362AImprove the construction environmentOvercoming design needsBulkheads/pilesBridge engineeringArchitectural engineering

The invention relates to a high-performance rotary jet drill. The high-performance rotary jet drill is mainly used in construction of bridge engineering, municipal engineering, water supply and drainage engineering, tunnel engineering and civil building engineering. The high-performance rotary jet drill comprises a drill pipe, an inner core, a nozzle sleeve, an alloy nozzle, a sealing disc, a seal ring and a drill. The high-performance rotary jet drill has the characteristics that the engineering cost is reduced, the construction period is shortened, and the construction effect is good; the range of cement paste and protective gases is farther at the same pressure, the rotary jet diameter is large, the diameter of the nozzle of the high-performance rotary jet drill is large, the rotary jet range is added, and the construction effect is good; the problems that the jet distance cannot be met, the working conditions are complex and the construction quality cannot be guaranteed through traditional rotary jet are solved; construction is easy, the construction cost is reduced, solidified bodies formed through jet flow are flexible in shape, and various solidification requirements are met; and the design requirements can be met, the construction quality is greatly improved, and the high-performance rotary jet drill has positive significance for improving the construction environment of workers.

Owner:BEIJING ZHONGYAN DADI TECH CO LTD

Full-section closed-type deep-shallow coupling yielding anchoring and grouting support method for broken soft rock roadway

InactiveCN105178981BImprove support strengthWatch protection effect is goodUnderground chambersTunnel liningStructure of the EarthCoupling

The invention relates to a full-section closed-type deep-shallow coupling yield pressure anchor grouting support method for broken soft rock roadway. The pressure-reinforced arch, the full-section closed grouting reinforcement ring and the deep grout diffusion reinforcement arch, the suspension effect of the high-strength grouting anchor cable will combine the four to form a multi-level effective composite arch, which will support the pressure, anchor and grouting The organic combination of the advantages of deep-shallow coupling support has significantly improved the bearing range, integrity and bearing capacity of the support structure. The deformation characteristics such as pressure around the rock and obvious bottom drum have outstanding control effects, and can effectively control various deformations of the surrounding rock of the broken soft rock roadway. It is especially suitable for deep mine large-section broken soft rock roadways. The cost is low, and it has high on-site promotion and application value.

Owner:CHINA UNIV OF MINING & TECH

Method of composite electroosmosis, vacuum precipitation and vacuum preload reinforcement foundation and device thereof

ActiveCN101182709BGuaranteed closureExpand the scope of reinforcementSoil preservationMaterials sciencePrecipitation

Owner:广西华业建筑工程有限公司

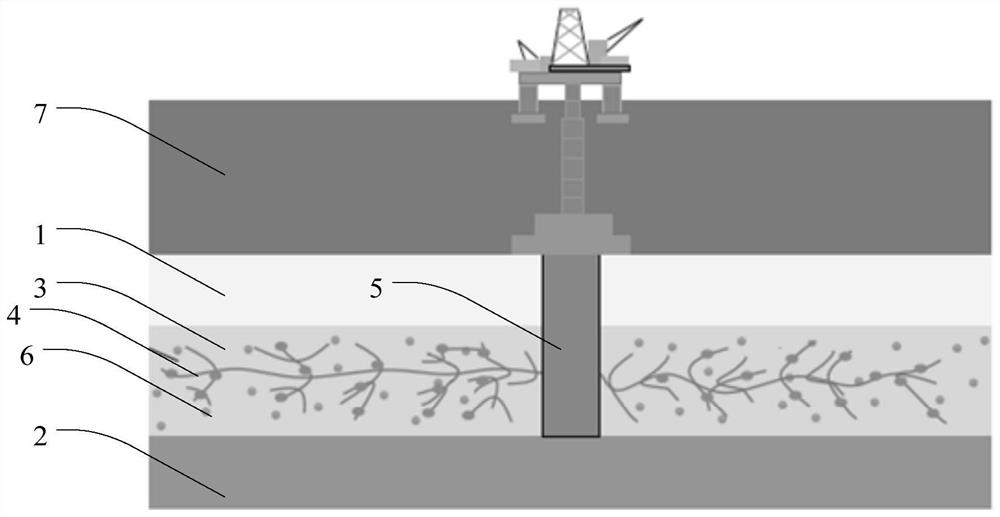

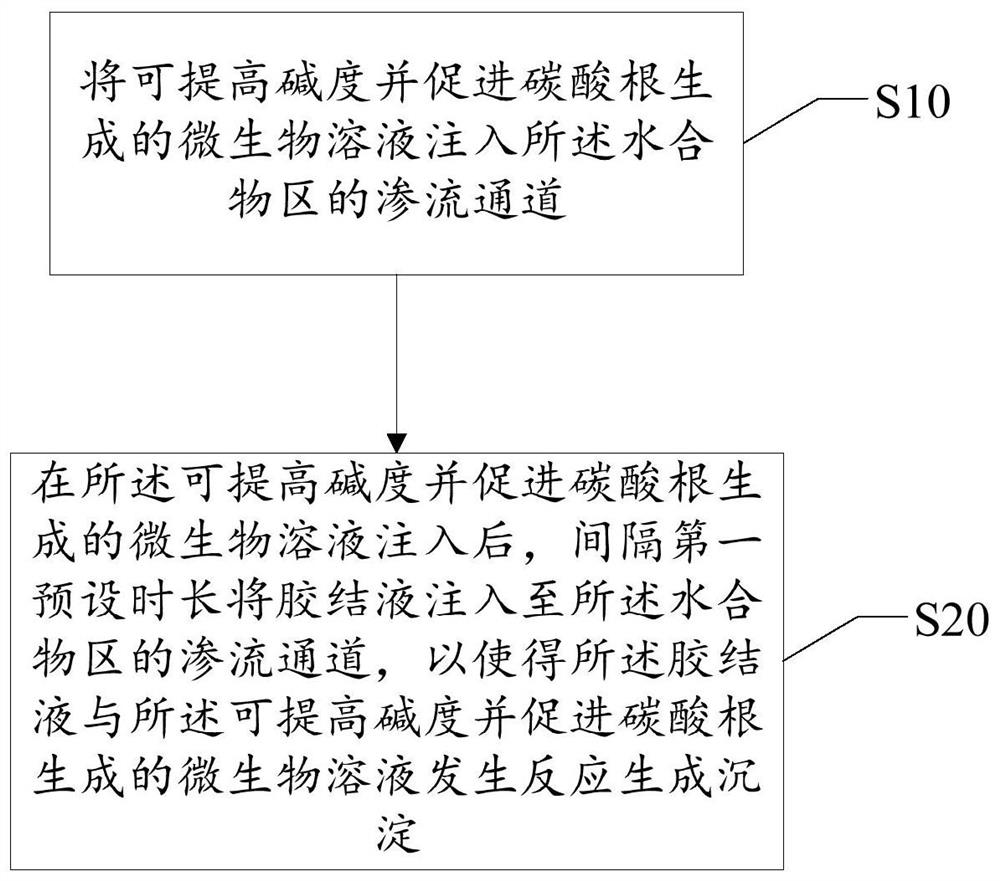

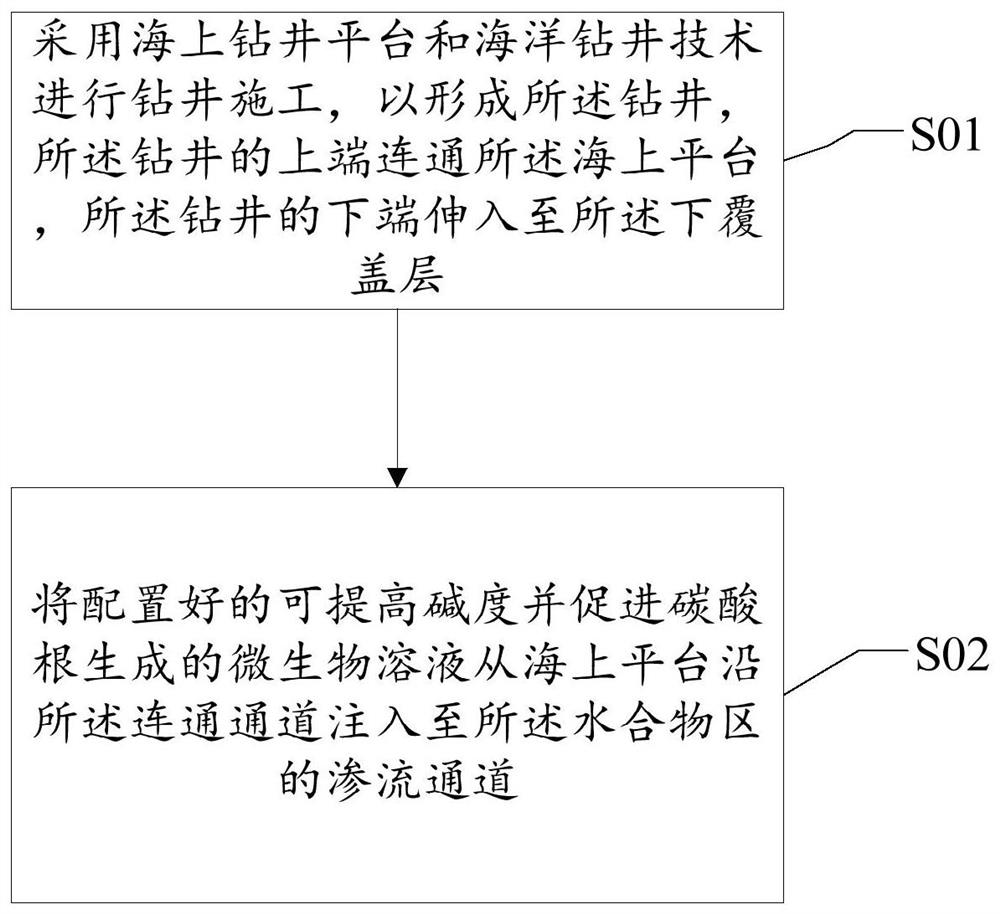

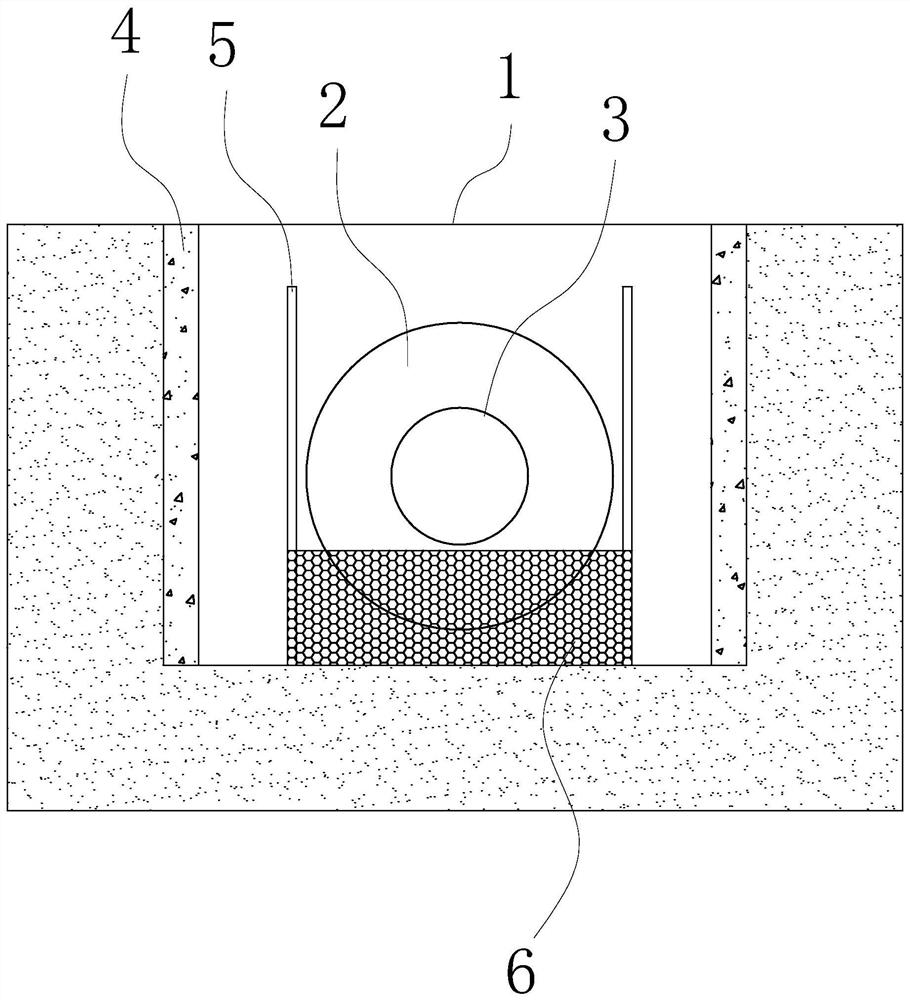

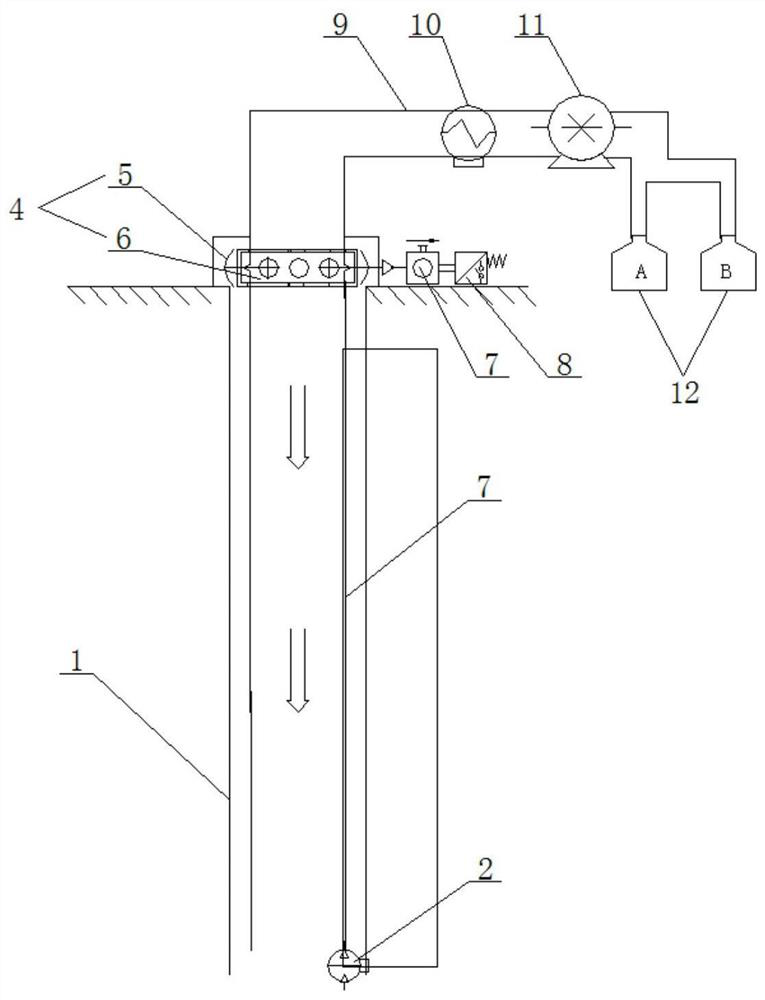

Natural gas hydrate reservoir reinforcing method

PendingCN113202444AExpand the scope of reinforcementGuaranteed stabilitySealing/packingMicroorganismSoil science

The invention discloses a natural gas hydrate reservoir reinforcing method. A natural gas hydrate reservoir comprises an upper covering layer and a lower covering layer, wherein a hydrate area where a natural gas hydrate exists is arranged between the upper covering layer and the lower covering layer, and a seepage channel exists in the hydrate area. The natural gas hydrate reservoir reinforcing method comprises the steps of injecting a microbial solution capable of improving alkalinity and promoting generation of carbonate into the seepage channel of the hydrate area; and injecting a cementing fluid into the seepage channel of the hydrate area at a first preset time interval after injecting the microbial solution capable of improving the alkalinity and promoting the carbonate generation so as to enable the cementing fluid to react with the microbial solution capable of improving the alkalinity and promoting the carbonate generation to generate a precipitate. According to the natural gas hydrate reservoir reinforcing method, the reinforcing range of an argillaceous silt hydrate reservoir can be enlarged, the permeability of the argillaceous silt hydrate reservoir is improved while the argillaceous silt hydrate reservoir is reinforced, and the non-uniformity of the reinforcing effect of the hydrate reservoir along with the change of the horizontal distance, the particle size distribution of the hydrate and the proportion of soil components are improved.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

Pipe-jacking well opening soil body reinforcing process for soft soil foundation

ActiveCN113737771AExpand the scope of reinforcementPass safelyProtective foundationSoil preservationStructural engineeringPipe

The invention relates to the technical field of pipe-jacking construction, in particular to a pipe-jacking well opening soil body reinforcing process for a soft soil foundation, and relates to the technical field of pipe jacking construction. Soil bodies around the pipe-jacking well opening are reinforced by two ways: tamping and compaction grouting. In the tamping step, the soil bodies around a pipe jacking well opening are tamped in the advancing direction of a jacking pipe, and then a pit left after tamping is filled and leveled up with soil, then the next round of tamping is conducted, and soil filling and tamping are conducted circularly till the condition of stopping circulation is met. The method has the effect of improving the defects of long construction period, high cost and low tunneling efficiency when a pipe jacking machine goes in and out of the opening of the pipe jacking well.

Owner:广东一新长城建筑集团有限公司

A device and construction method for strengthening foundation by microbial ultrasonic grouting

ActiveCN112813953BSpeed up the flowImprove reinforcement uniformitySoil preservationMicroorganismSoil type

The invention discloses a device for strengthening foundation by microbial ultrasonic grouting and a construction method thereof. The device includes a grouting pipe, and an ultrasonic concentrator is connected to the upper side of the grouting pipe. The ultrasonic concentrator includes an ultrasonic horn and an ultrasonic transducer. Connection, the bottom of the grouting hole is equipped with a pulse generator, the ground on one side of the grouting pipe is equipped with an ultrasonic sensor, the ultrasonic sensor is connected to the oscilloscope, the upper end of the grouting pipe is connected to the grouting pipe, and the grouting pipe passes the grouting pump It is connected with two pulp feeding barrels, and the two pulp feeding barrels are respectively filled with bacteria solution and cementing solution. The invention can improve the uniformity of reinforcement, and can reinforce the soil in deeper layers. The grout can be diffused from the grouting pipe with holes in the pipe wall to the surroundings in cooperation with the action of ultrasonic waves. The reinforcement range is larger, the integrity is higher, and the uniformity of reinforcement is ensured. , applicable to a wide range of soil types.

Owner:NANJING TECH UNIV +1

Moving device for controlling upward floating of shield tunnel and reinforcing method

PendingCN114658441AWeight increaseEnsure structural safetyMining devicesUnderground chambersWater storageWater storage tank

The invention discloses a moving device for controlling upward floating of a shield tunnel and a reinforcing method, the moving device at least comprises battery cars, water storage tanks, drainage pipes, sheet-shaped steel frames and profile steel connecting pieces, and the water storage tanks are erected on the bodies of the battery cars; each duct piece hole in the shield tunnel duct piece is connected with the water storage tank through a drainage pipe; the multiple sets of sheet-shaped steel frames are arranged in the radial direction of the shield tunnel and arranged between the periphery of the water storage tank and shield tunnel segments. The profile steel connecting pieces are connected with the sheet-shaped steel frames in the radial direction of the shield tunnel. The reinforcing method comprises the following steps: (1) draining water in the tunnel hole through the duct piece holes; (2) a plurality of battery cars are adopted in the tunnel to support the water storage tank, and all sets of sheet-shaped steel frames and profile steel connecting pieces on the periphery of the water storage tank serve as steel frame supports and are used for reinforcing and supporting shield tunnel segments; the method has the advantages of rapidness, mobility, real-time performance and the like, floating of the shield tunnel can be controlled, and the safety of the shield tunnel structure is ensured.

Owner:GUANGXI UNIV +1

Post-grouting gravel pile with sand wall wing plates and construction method

InactiveCN103061328BUniform consolidationRealize three-dimensional drainageBulkheads/pilesSoil preservationReinforced concreteWhole body

The invention relates to a post-grouting gravel pile with sand wall wing plates. The post-grouting gravel pile with the sand wall wing plates is characterized by mainly comprising a grouting gravel pile, a plurality of sets of sand wall wing plates and precast reinforced concrete pile tips, wherein the sand wall wing plates are uniformly distributed along the ring direction of the grouting gravel pile and are connected with the grouting gravel pile to form a whole body, the top part of a pile body extends into a sound cushion layer, the precast reinforced concrete pile tips comprise a gravel pile tip and a sand wall pile tip and are respectively arranged at the bottoms of the gravel pile and a sand wall, a grouting pipe is preset in the middle of the grouting gravel pile body, and the bottom of the grouting pipe is connected with the precast pile tips. With the adoption of the post-grouting gravel pile, the performance of water drainage of a granular material during a prepressing period can be exerted, and the grout can also be grouted into the pile body by a grouting pipe according to the sedimentation condition to form a rigid composite pile type, thus increasing the effective reinforcing depth of a gravel pile foundation and realizing effective unification of a drainage consolidation method and a composite foundation method.

Owner:FANGTAI CONSTR GRP +1

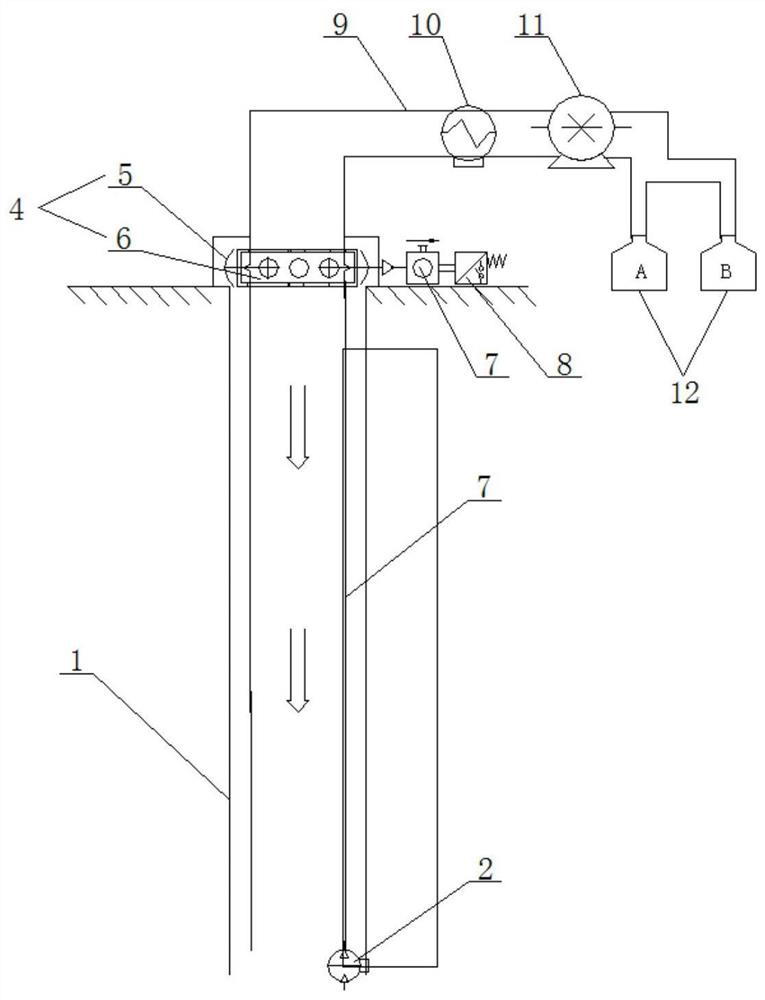

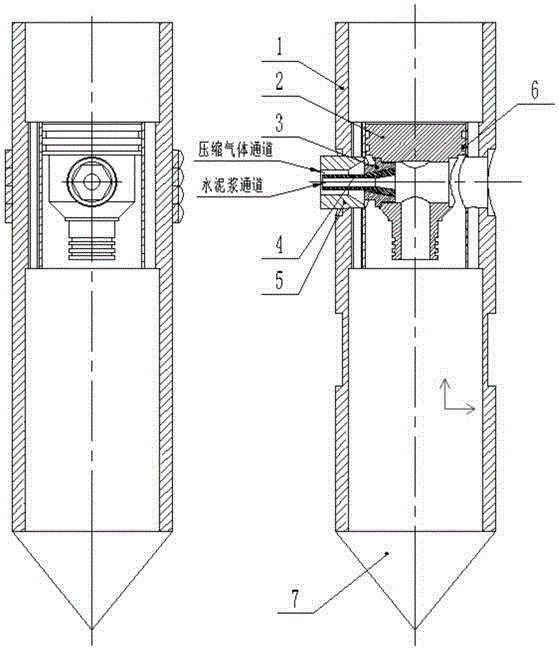

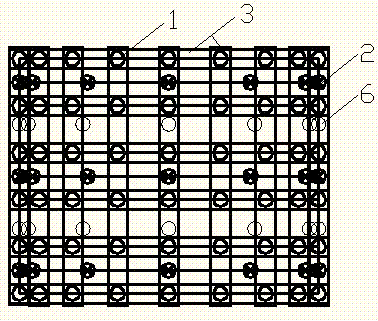

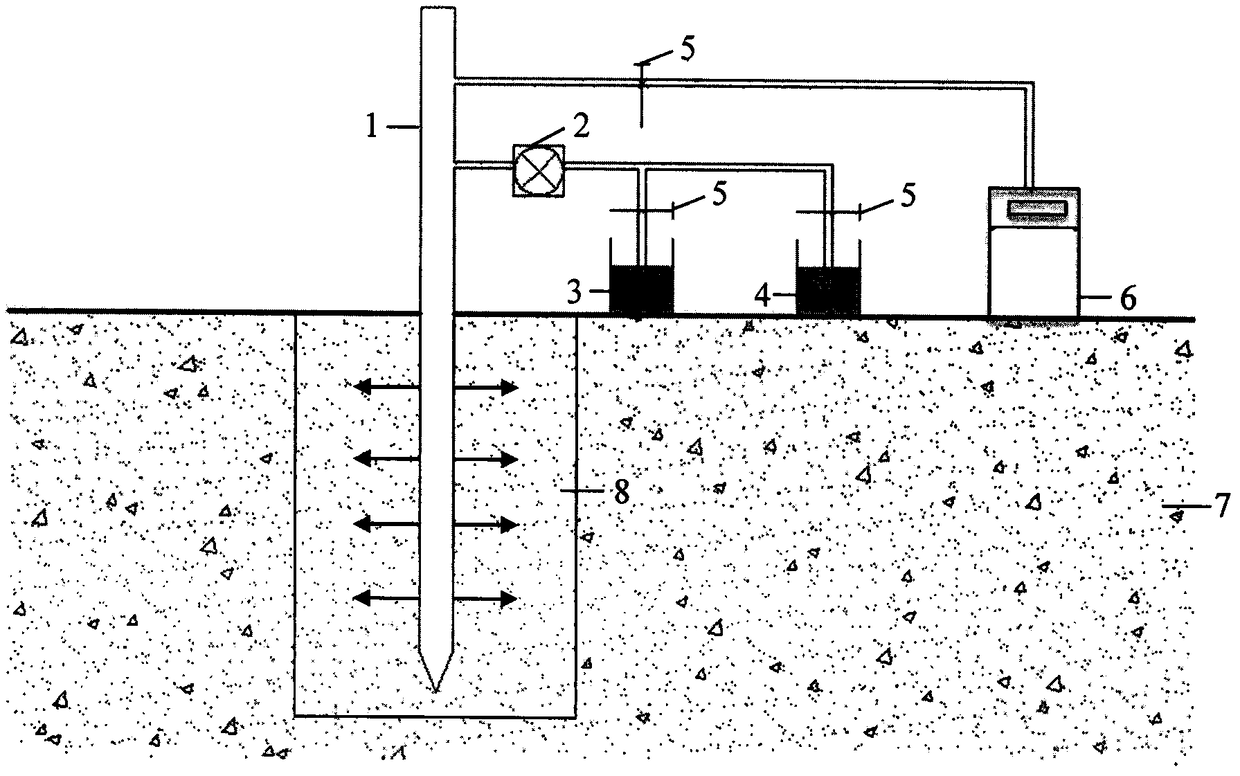

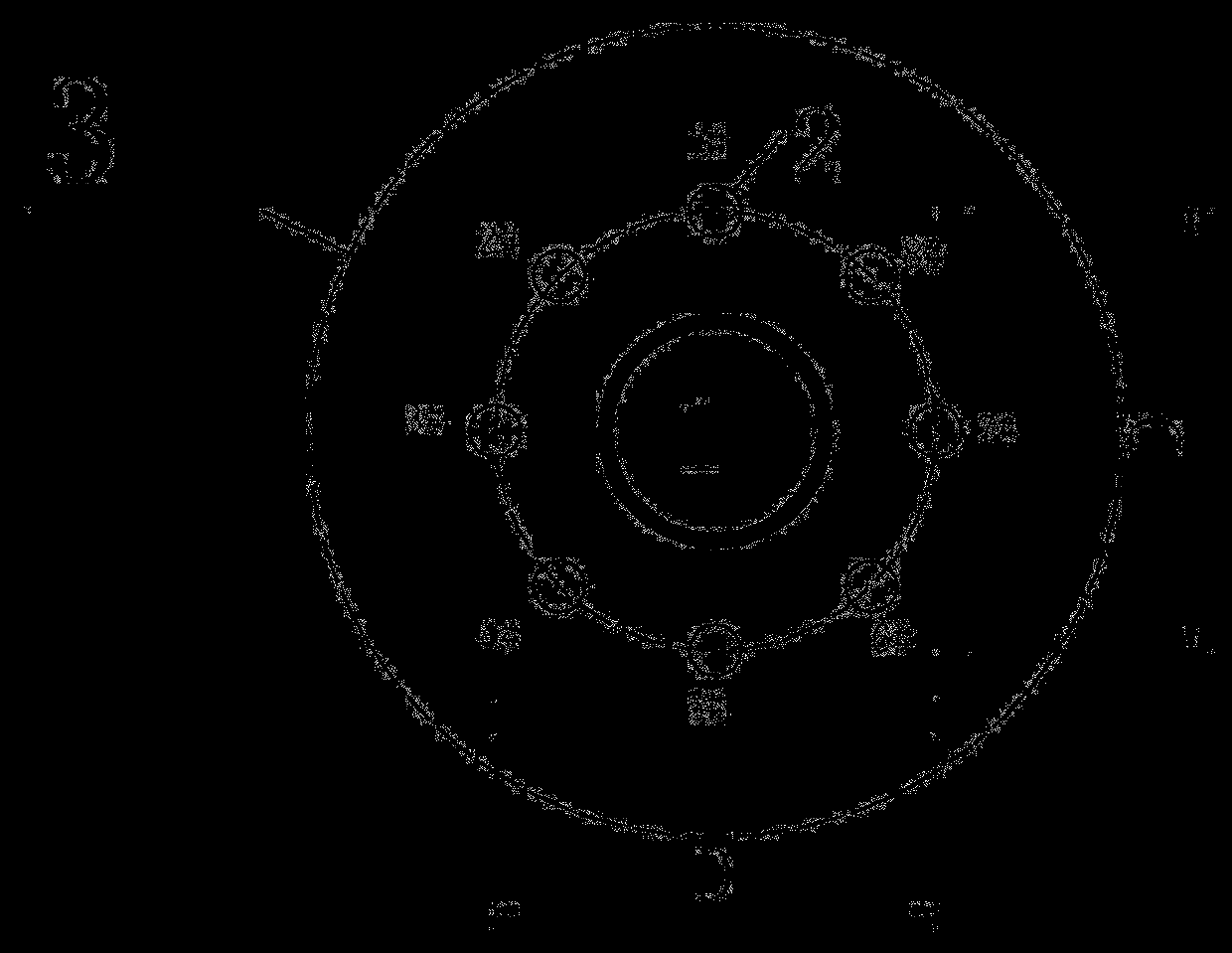

A method for soil consolidation by microbial gas-liquid circulation grouting

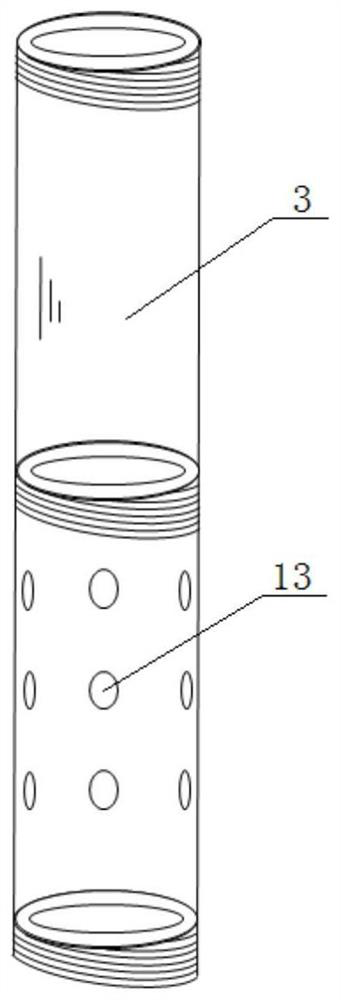

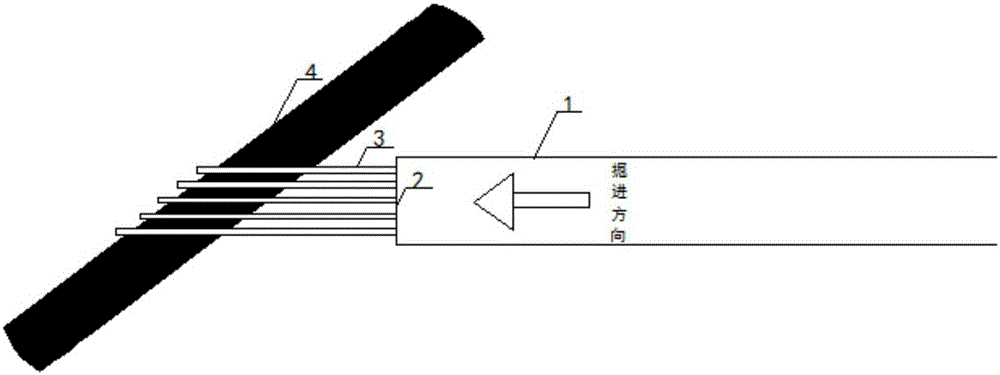

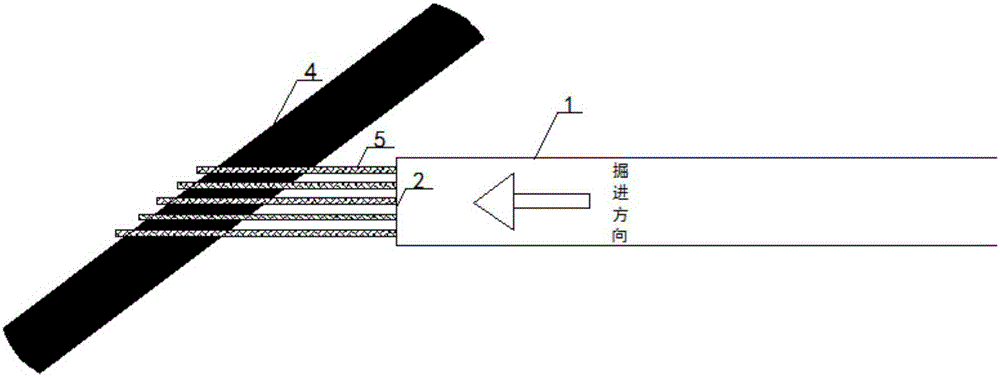

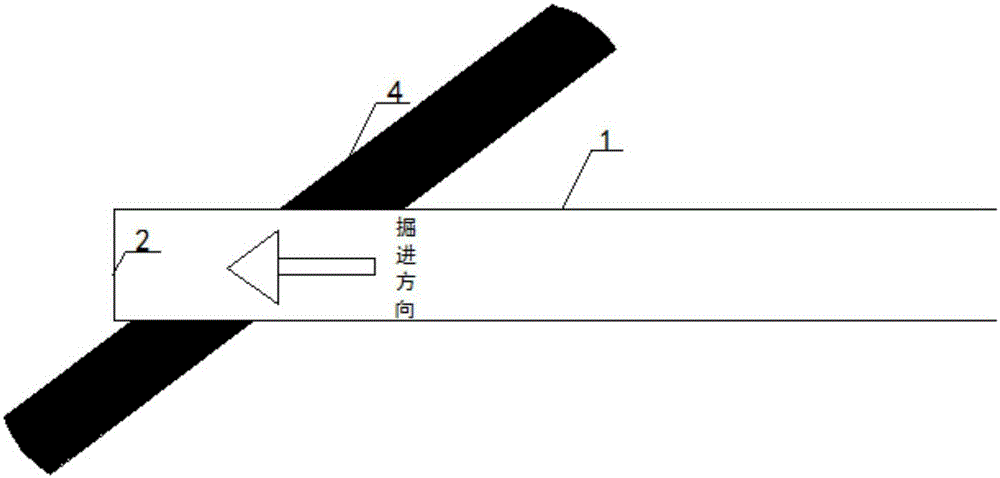

A microbial gas-liquid circulation grouting method for soil consolidation, the steps comprising: a. vertically driving the grouting flower tube 1 into the foundation 7; b. injecting the soil body 8 to be consolidated into the soil body 8 to be consolidated through the grouting flower tube 1 OD of 1.5 times the pore volume 600 = 1.2 of the bacterial solution 3, then inject urea and CaCl with a concentration equal to the volume of the bacterial solution 3 of 0.5mol / L to 1.0mol / L 2 The mixed cementing liquid 4; c. Utilize the air compressor 6 to inject compressed air with a pressure of 100KPa~200KPa and a volume of 1.5 times the pore volume of the soil to be consolidated into the soil to be consolidated 8, and place the soil to be consolidated in the soil 8 The pore liquid is ejected, so that the soil body 8 to be consolidated is in an unsaturated state, and left to stand for 12 hours; d. Inject the cementing fluid 4 of 1.5 times the pore volume of the soil to be consolidated 8 into the soil to be consolidated 8, and stand for 12 hours; e. . Repeat operation d once; f. Repeat operations b, c, d, and e until the strength of the soil body 8 to be consolidated reaches the requirement or the grouting liquid (bacteria liquid 3 or cementation liquid 4) cannot be injected into the soil body 8 to be consolidated , stop grouting.

Owner:NANJING FORESTRY UNIV

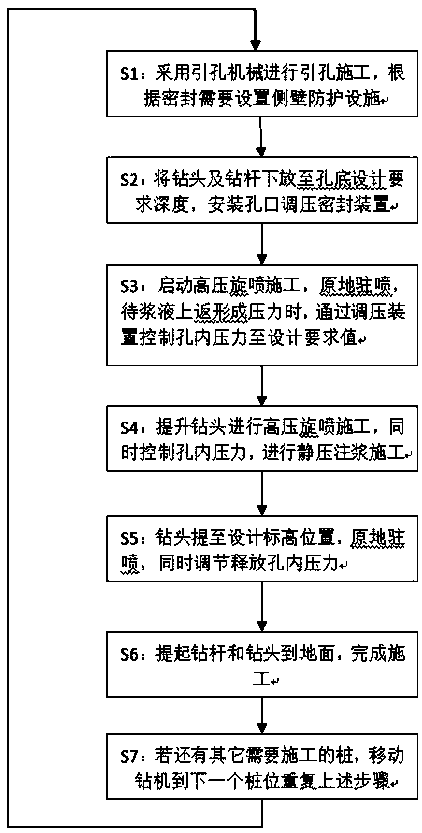

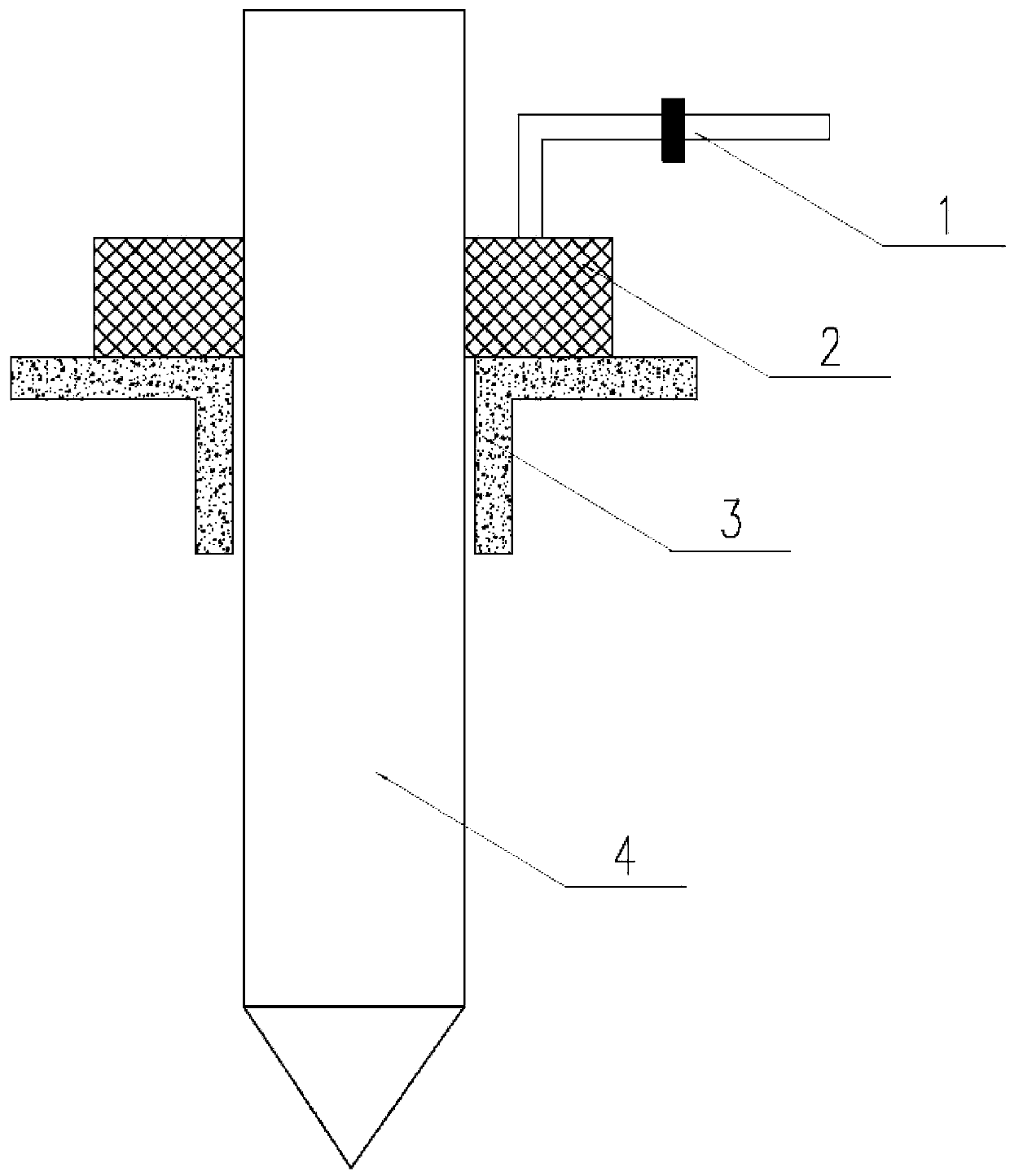

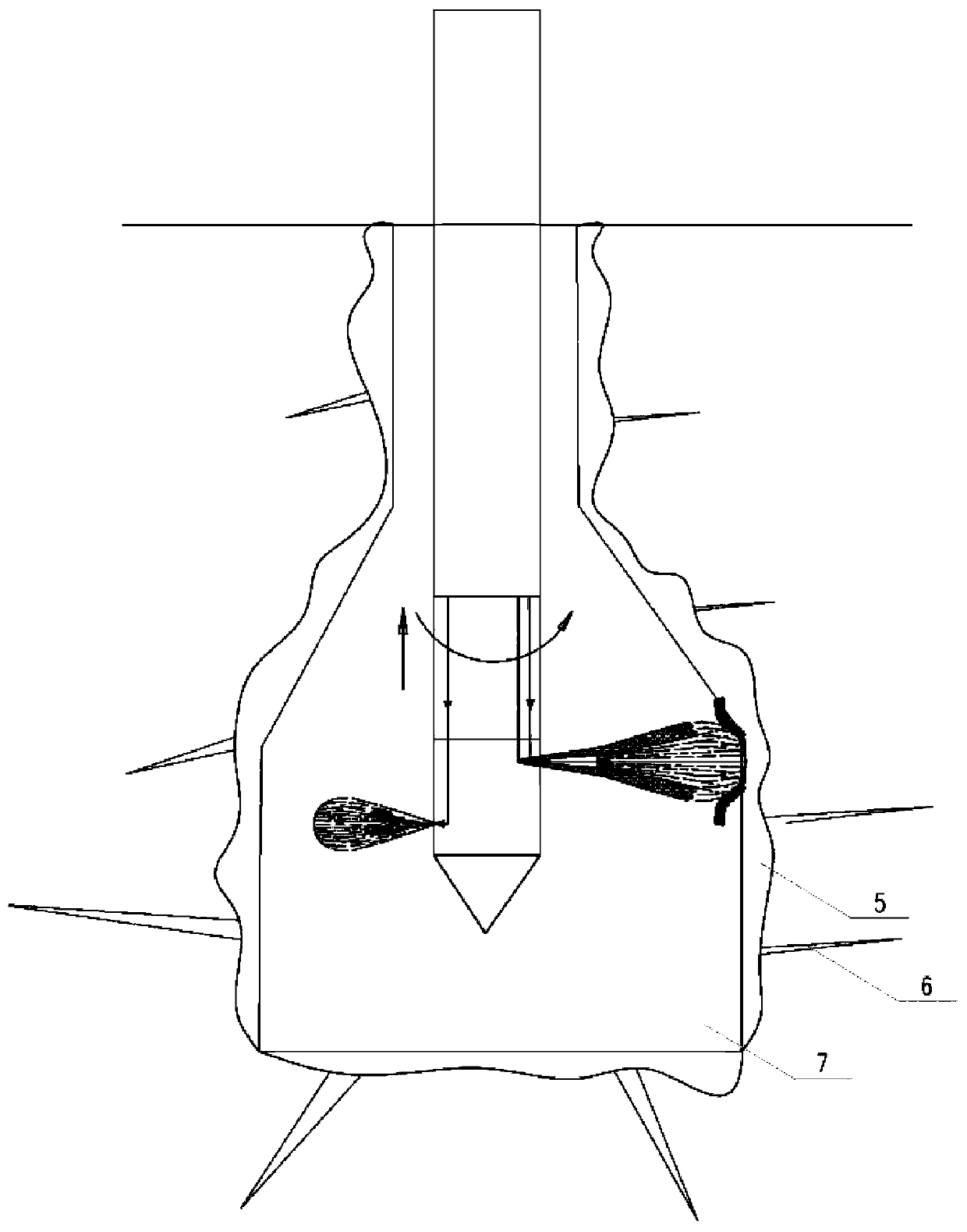

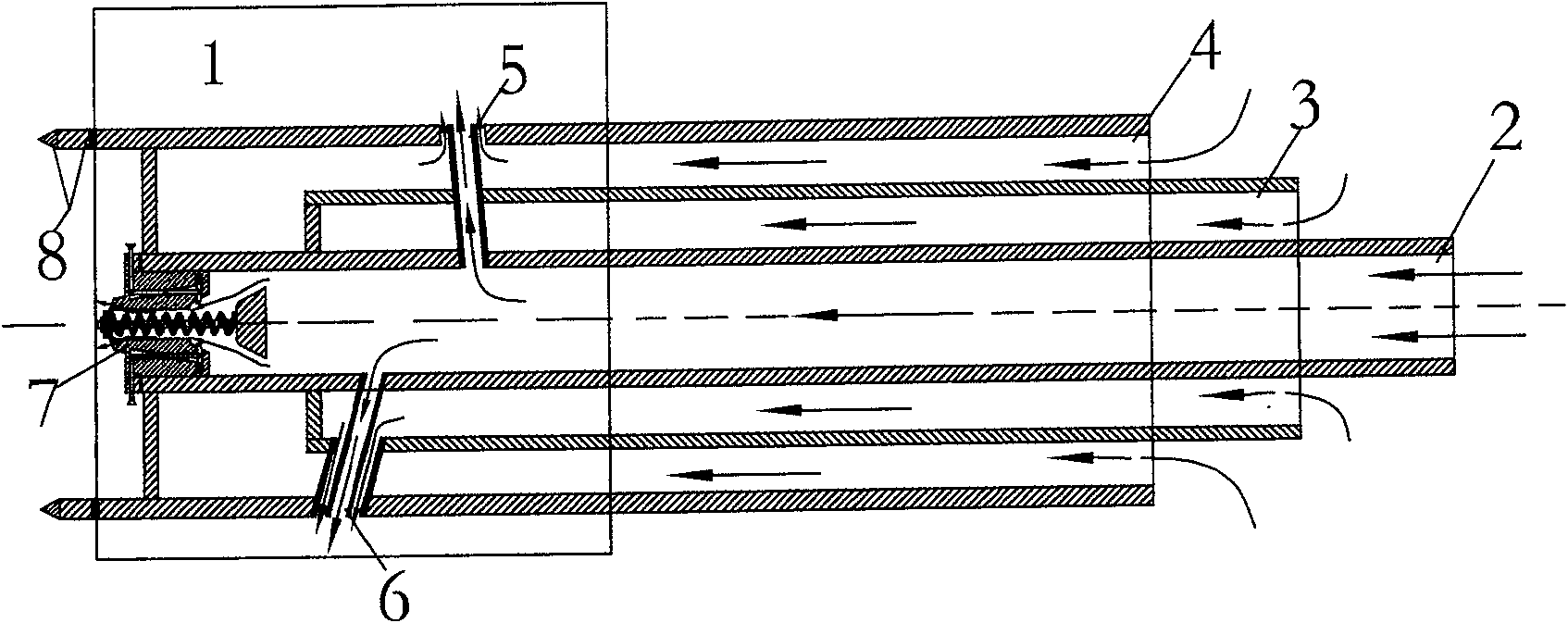

Combined dynamic and static grouting foundation reinforcement method

The invention discloses a dynamic and static combined grouting foundation reinforcement method. The method comprises the following steps of S1, hole-guiding construction is carried out by adopting a hole-guiding machine, and a side wall protection device is arranged; S2, injection reinforcement slurry treatment is carried out by adopting a high-pressure jet drilling tool, an orifice sealing deviceis installed at an orifice before injection, and an orifice pressure regulating device is connected to the orifice sealing device; S3, a high-pressure rotary spraying construction is started, and parking and spraying construction is carried out in situ, and the pressure in the orifice is controlled through the orifice pressure regulating device to reach a design requirement value; S4, the high-pressure jet drilling tool is lifted to carry out high-pressure rotary spraying construction, the rotating speed of the high-pressure jet drilling tool is 8 -25 r / min, the lifting speed is 6-25 cm / min,and meanwhile, the pressure in the control hole is adjusted; S5, the drill bit is lifted to a designed elevation position, in-situ parking is carried out and the pressure in the release hole is adjusted; S6, the drill rod and the drill bit are lifted to the ground, and construction of the pile body is completed; and S7, the drilling machine is moved to the next pile position, the step S1 to the step S6 are repeated, and finally the work is completed.

Owner:SHENZHEN YJY BUILDING TECH +1

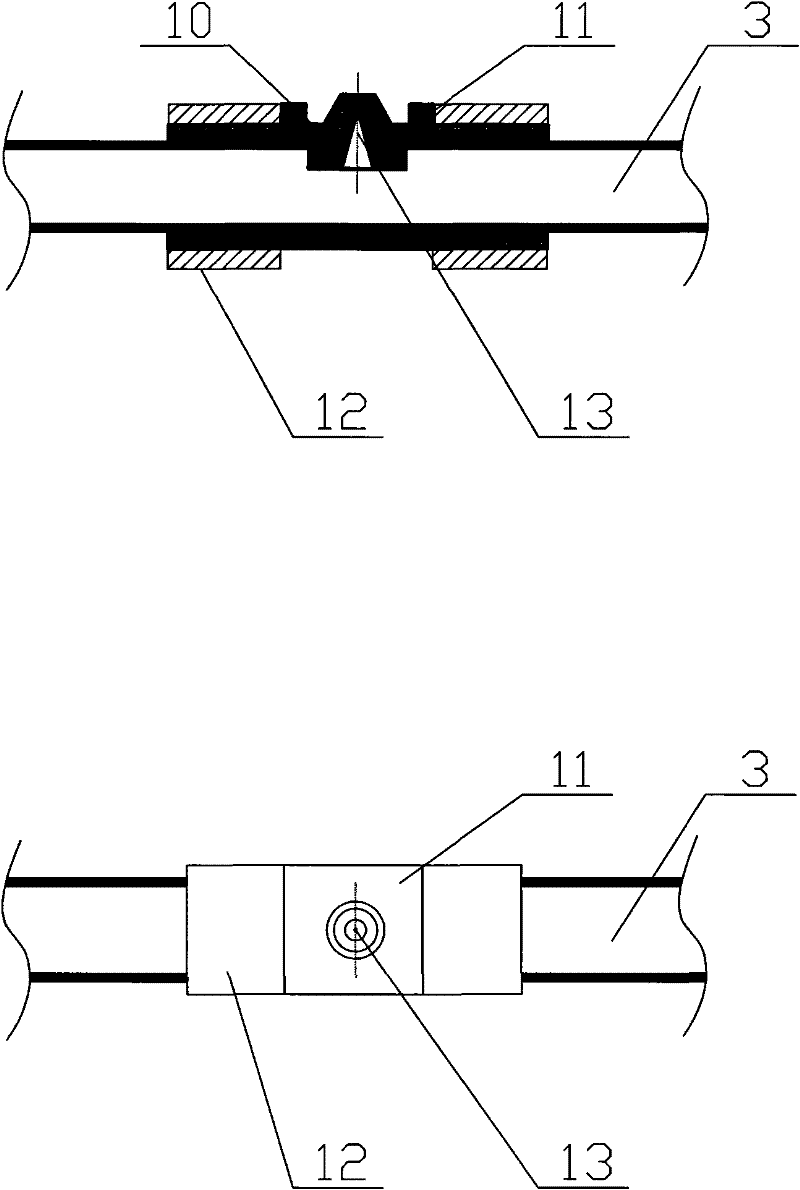

Disposal pore-forming and rotary-spraying construction equipment and method in horizontal rotary-spraying construction

InactiveCN100595392CExpand the scope of reinforcementImprove construction efficiencyBulkheads/pilesSoil preservationArchitectural engineeringAlloy

A disposable pore-creating and rotary spray construction equipment and method in the horizontal rotary spray construction of the architectural engineering technique field is disclosed. The equipment includes a multifunction showerhead, a wolframi steel alloy drill, and an one-way valve. In the one-way valve, a valve is mounted at the upper portion of the bracket support through a joint lever, thejoint lever thrills through a first spring to connect the bracket support, a bottom nozzle is mounted at the bottom of the bracket support, a horizontal plug is mounted in the bracket support, the bottom of the horizontal plug is connected to a second spring, the middle part of the horizontal plug is connected to an upright connection conductive pole mounted in the bracket support through pin bolts, the upright connection conductive pole is fixed in the bracket support through a pin bolt and can freely rotate by taking the pin bolt as center, and a horizontal connection conductive pole is mounted in the bracket support to have a tail connection with the upright connection conductive pole. The inventive device and method can greatly improve construction efficiency and reinforced scope, andcan avoid the affect to ambient environment.

Owner:SHANGHAI JIAOTONG UNIV

A Pre-grouting Reinforcement Process for Subway Tunnel Surrounding Rock Ground

ActiveCN106837382BReduced number of drilled holesReduce the number of drilled holesUnderground chambersTunnel liningSlurryHole making

The invention discloses a ground pre-grouting reinforcing process for subway tunnel surrounding rock. The ground pre-grouting reinforcing process comprises the following steps that (1) the subway tunnel surrounding rock range needing to be reinforced is determined as a target rock body area; (2) an oblique hole making section is constructed, specifically, oblique drilling holes are constructed close to the target rock body area from far to near, gradually become horizontal drilling holes in a transition mode and are internally provided with sleeves; (3) a horizontal grouting section is constructed, specifically, the horizontal holes are constructed, and a horizontal drilling section is determined according to the length of the pre-grouting reinforced surrounding rock; (4) grouting reinforcing is conducted, specifically, grout is conveyed into a target rock body through a drilling rod; and (5) after grouting of all the horizontal drilling holes is completed, the sleeves in the oblique drilling holes are pulled out, and then hole sealing is conducted. By adoption of the ground pre-grouting reinforcing process for the subway tunnel surrounding rock, the subway tunnel surrounding rock can be effectively reinforced, the phenomena such as surrounding rock collapse or roof fall after subway tunnel excavation are prevented, subway construction efficiency is improved, and the supporting effect of the subway tunnel surrounding rock is improved.

Owner:BEIJING CHINA COAL MINE ENG CO LTD

Side slope reinforcing method and structure

ActiveCN102021911BExpand the scope of reinforcementPrevent slidingExcavationsEngineeringStructural engineering

Owner:CHINA HYDROELECTRIC ENGINEERING CONSULTING GROUP CHENGDU RESEARCH HYDROELECTRIC INVESTIGATION DESIGN AND INSTITUTE

A Construction Method of Segmented Curtain Grouting in Fault Working Face with Excessive Dip Angle of Shaft Shaft

ActiveCN109209287BReduce in quantityImprove drilling efficiencySealing/packingWater blockCement slurry

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com