Disposal pore-forming and rotary-spraying construction equipment and method in horizontal rotary-spraying construction

A technology of horizontal rotary spraying and construction equipment, applied in soil protection, infrastructure engineering, sheet pile wall and other directions, can solve the problems of reducing the scope of reinforcement, complex construction process, poor economy, etc., to improve construction efficiency and application range, improving construction efficiency, and the effect of increasing the speed of rotary spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The equipment and process of the embodiment of the present invention are illustrated below in conjunction with the accompanying drawings by taking the triple pipe method as an example: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but this embodiment The scope of protection of the invention is not limited to the following examples.

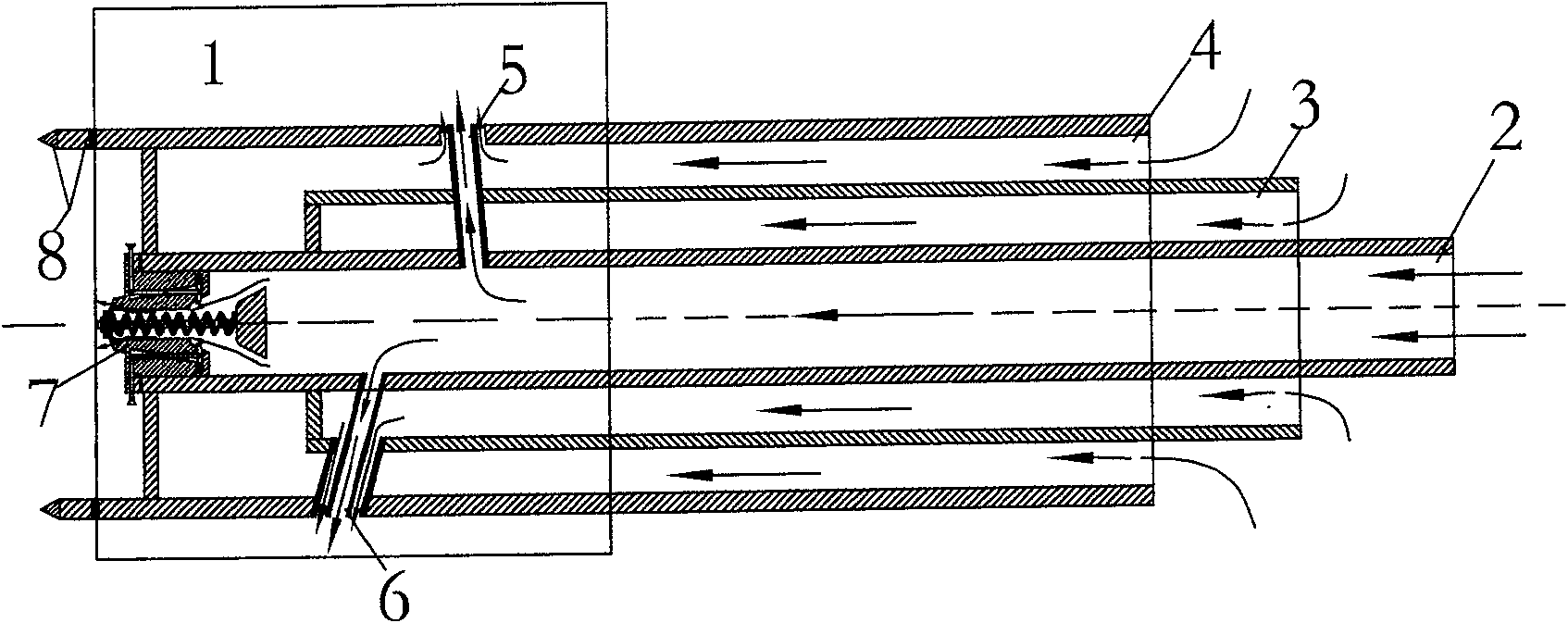

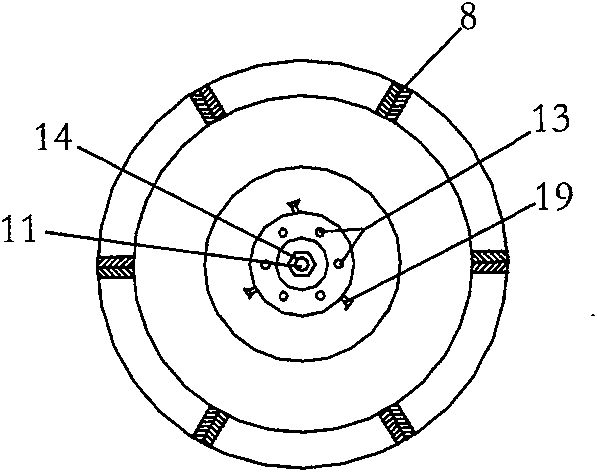

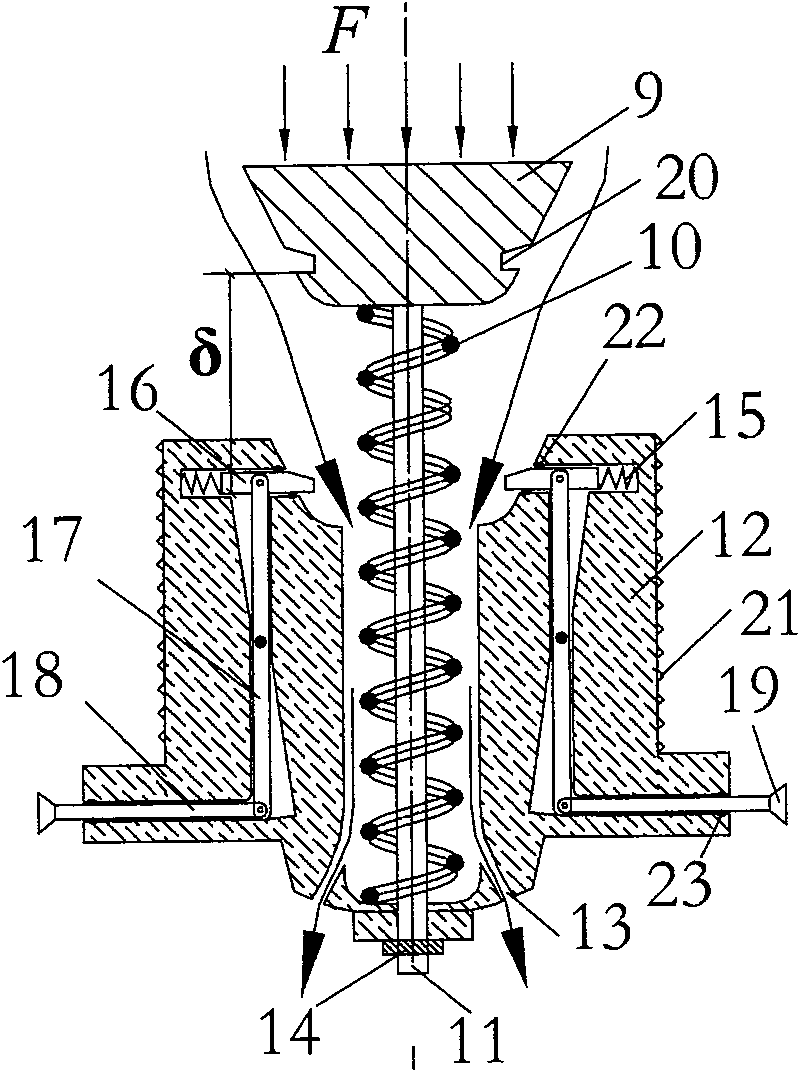

[0029] figure 1 It shows the fluid delivery mode of the double-fluid horizontal swirling jet during the drilling process of the multi-function nozzle 1, including the first channel 2, the second channel 3, the third channel 4, the front nozzle 5, the rear nozzle 6, and the one-way valve 7. Tungsten carbide drill bit 8, the first channel 2 inputs compressed air; the second channel 3 inputs accelerator (such as water glass, etc.), and the third channel 4 inputs cement slurry or clear water. One end of the mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com