Patents

Literature

61results about How to "Reduce drilling resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

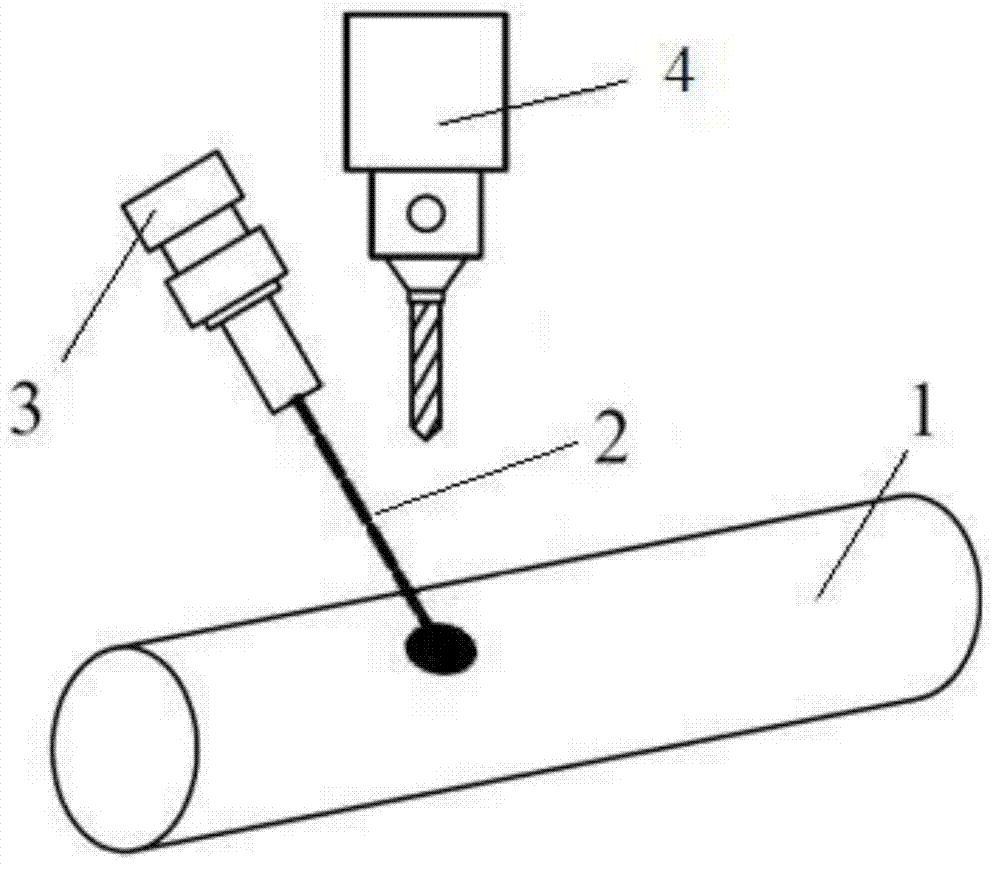

Laser-assisted drilling method and device

InactiveCN103753223AImprove machinabilityReduce wearOther manufacturing equipments/toolsMetal working apparatusLaser assistedHigh energy laser beam

The invention provides a laser-assisted drilling method and a laser-assisted drilling device. The laser-assisted drilling device comprises a workbench, a fixture mounted on the workbench, a drill bit and a laser device, wherein the drill bit and the laser device are respectively arranged on the workbench through a movable device and arranged above the fixture, and the laser device and the drill bit are arranged to be provided with an included angle therebetween. According to the laser-assisted drilling method, the to-be-drilled area of a workpiece is preheated by a high-energy laser beam, so that, in a very short time, part of the to-be-drilled area is heated to have a very high temperature, meanwhile, the physical performance of the material is changed under the high temperature, and the to-be-drilled area of the workpiece material is softened. Once the laser heating is completed, drilling starts rapidly. Thus the drilling resistance can be reduced, the machinability of the material can be improved, the tool wear can be reduced, the success of drilling can be ensured, and the machining precision and the machining efficiency can be improved.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI

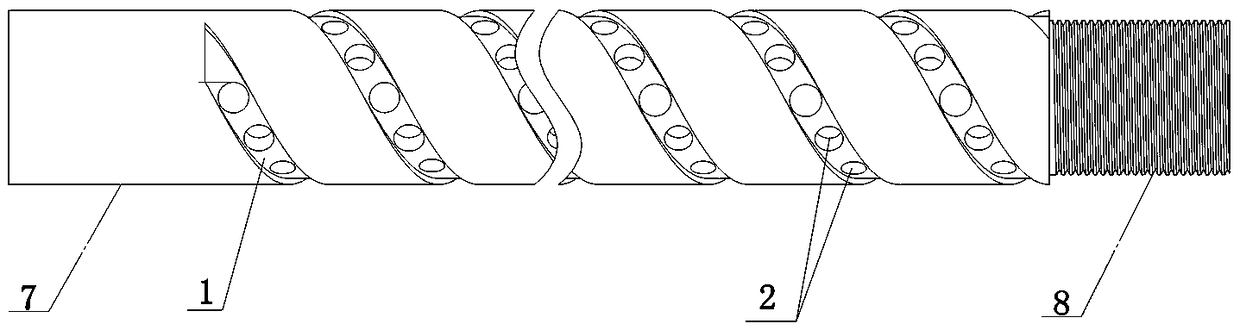

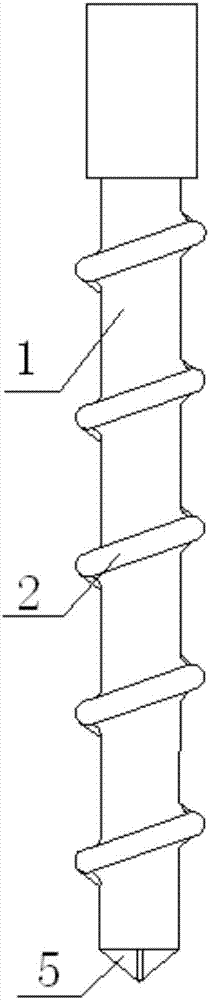

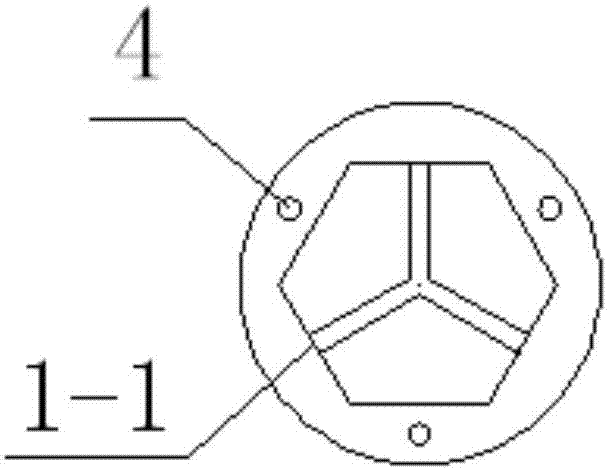

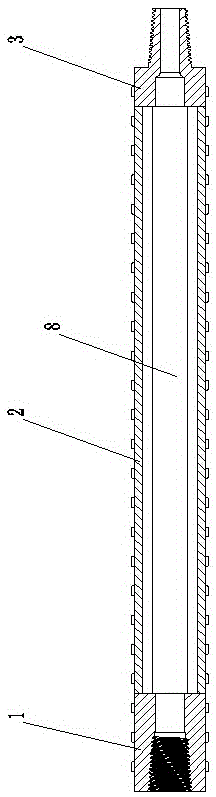

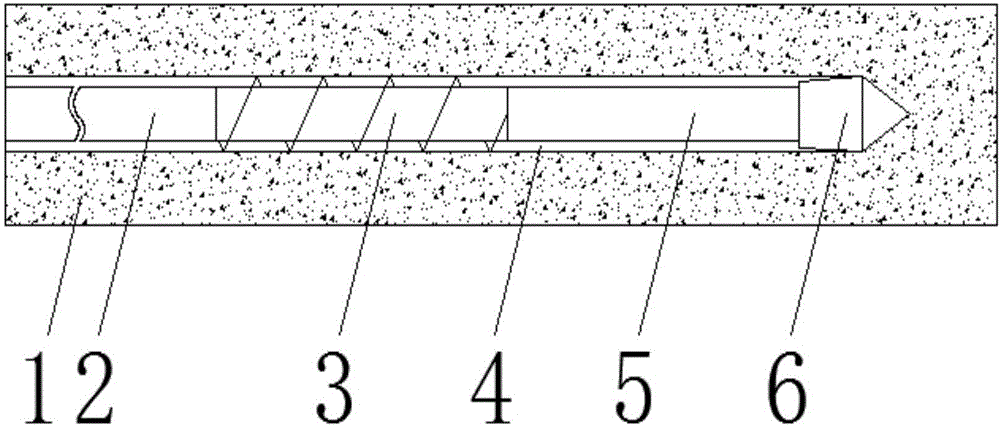

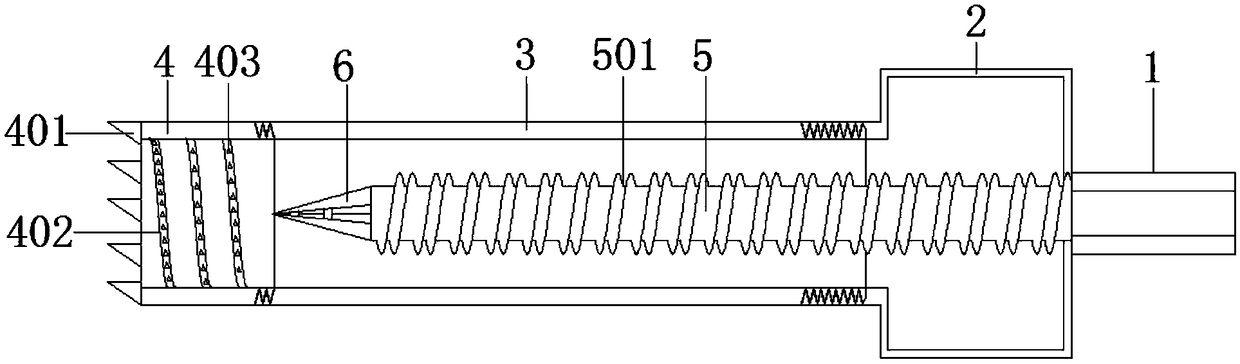

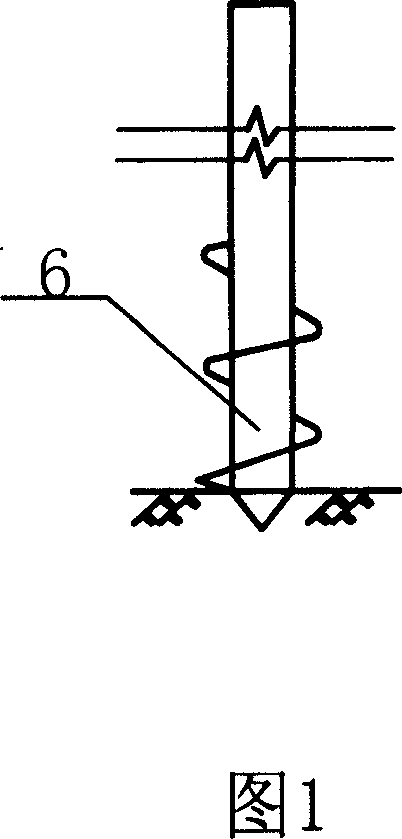

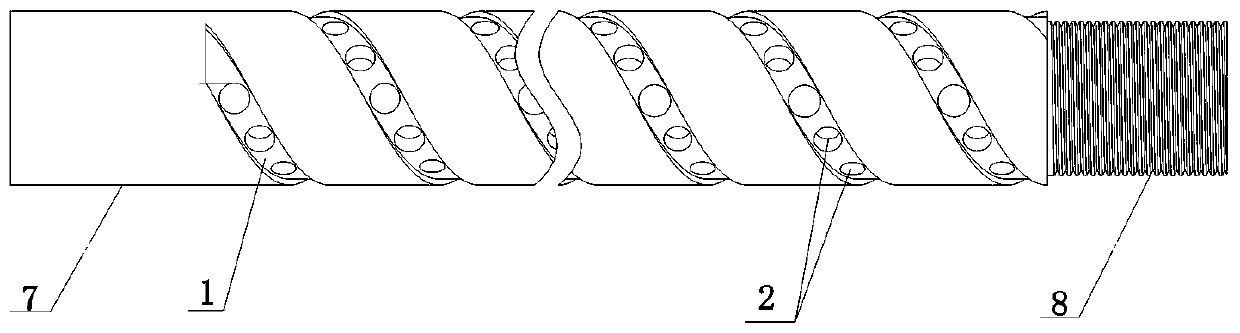

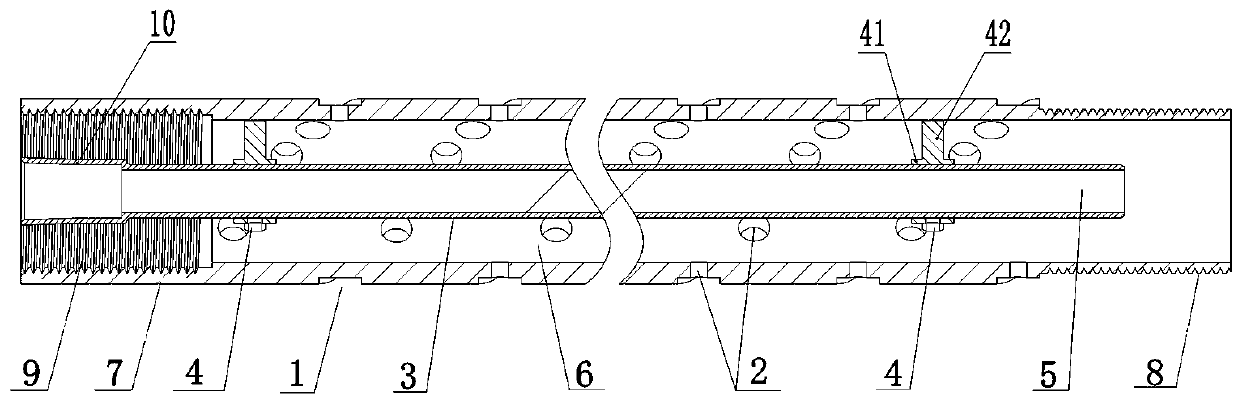

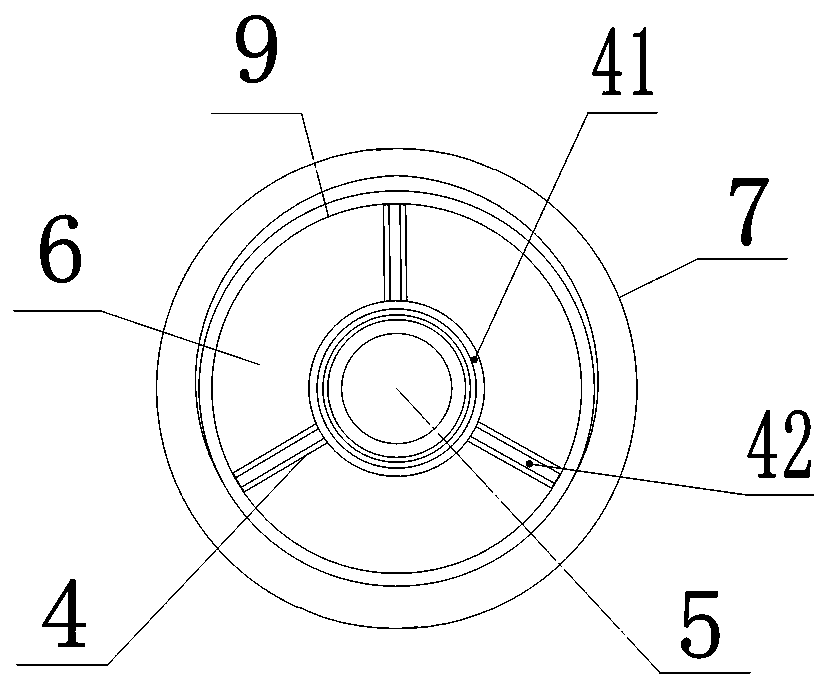

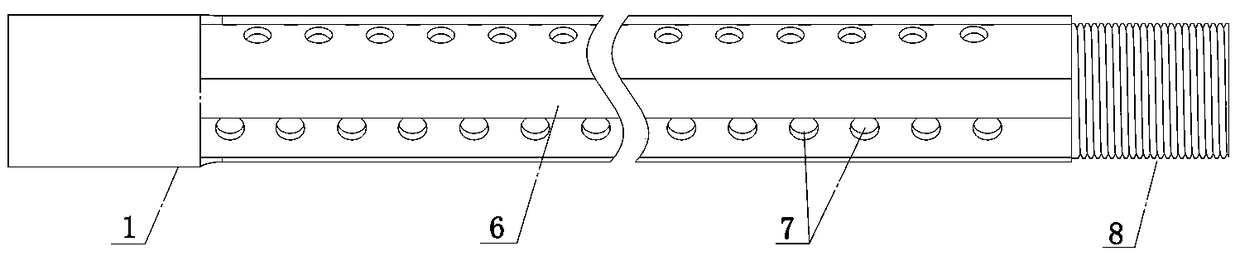

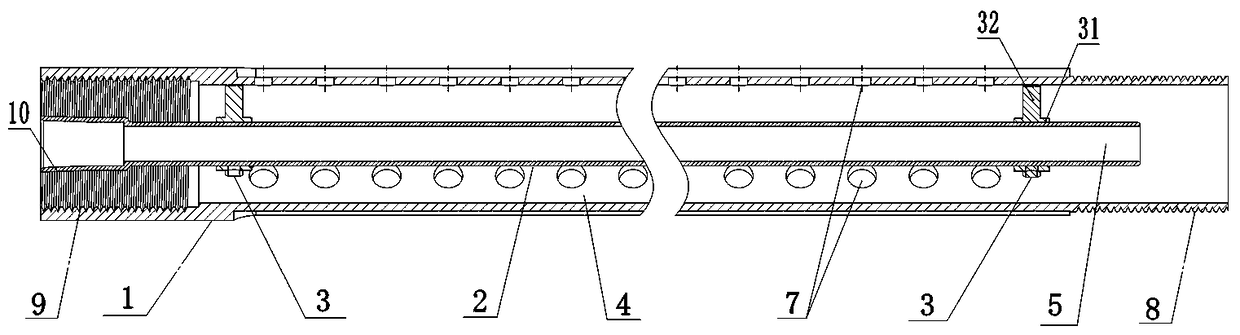

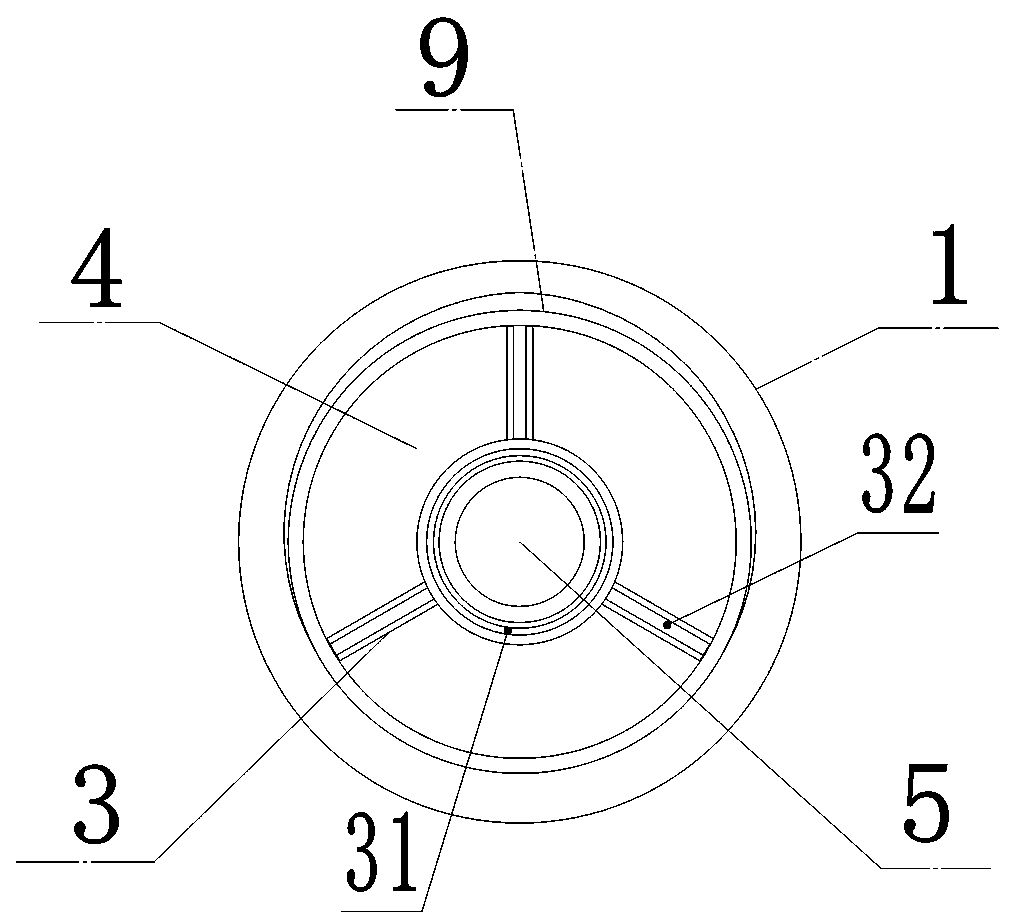

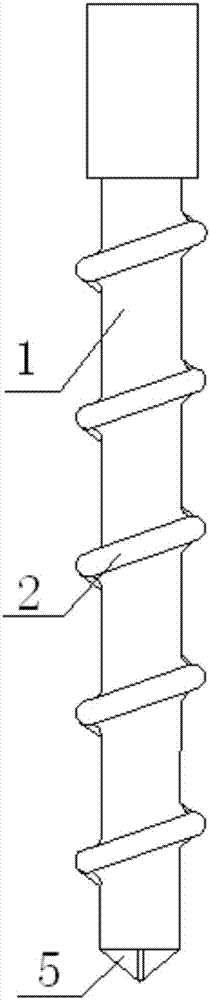

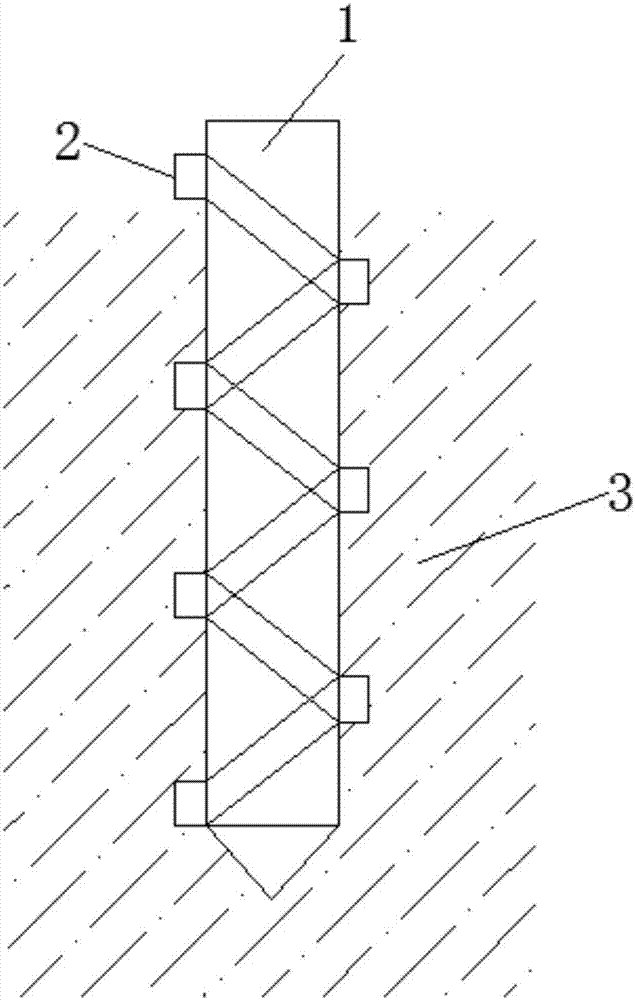

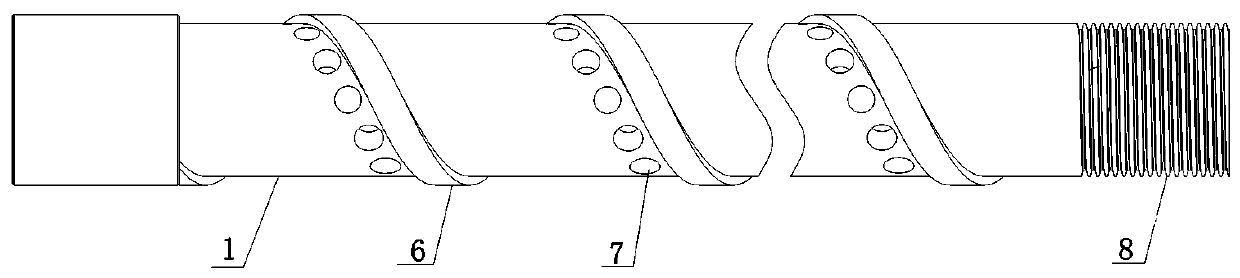

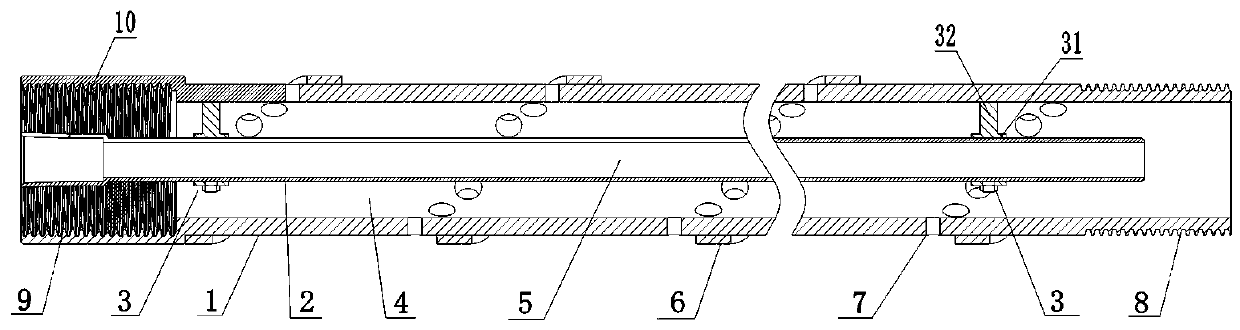

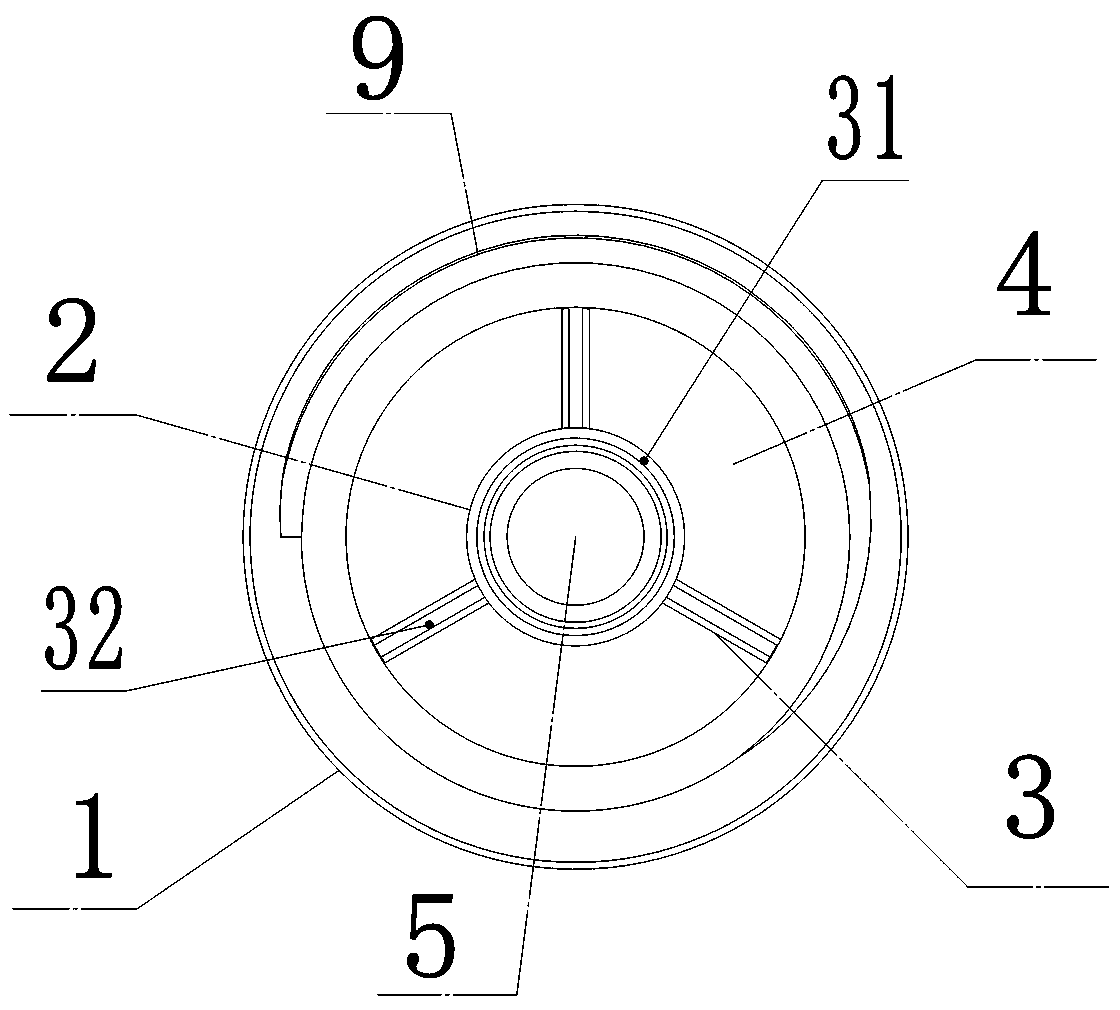

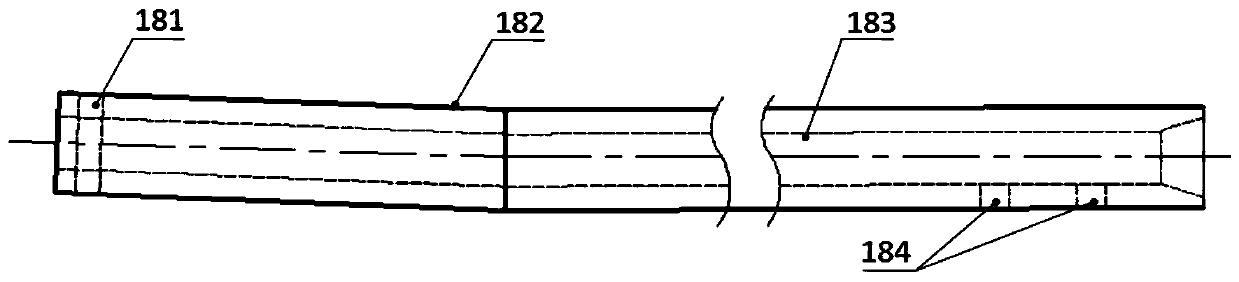

Drill rod with functions of hole protecting, pressure relief and internal slag discharging

ActiveCN108505955ASolve the problem of high drilling resistance and easy drill stickingReduce drilling resistanceDrilling rodsFlushingInlet channelSlag

The invention discloses a drill rod with functions of hole protecting, pressure relief and internal slag discharging. The drill rod comprises hollow rod bodies, flow injecting pipes coaxially arrangedin the rod bodies, and supporting pieces connecting the rod bodies with the flow injecting pipes; slag discharging channels are formed between the inner walls of the rod bodies and the outer walls ofthe flow injecting pipes; the flow injecting pipes are internally provided with air inlet and water inlet channels; and with the direction opposite to the rotating direction during drilling of the drill rod bodies as the reverse direction, the outer cylindrical surfaces of the rod bodies are provided with spiral grooves rising in the reverse direction and in cylindrical spiral shapes, and a plurality of pressure relief holes communicating with inner cavities in the rod bodies are formed in the spiral grooves. During drilling of a soft coal seam and an outburst coal seam, the drill rod has theadvantages that the hole protecting ability is high, the slag discharging channels are not prone to being plugged, the hole forming effect is good, the slag discharging and temperature reducing abilities are high, and the hole collapse area is automatically dredged.

Owner:HENAN POLYTECHNIC UNIV

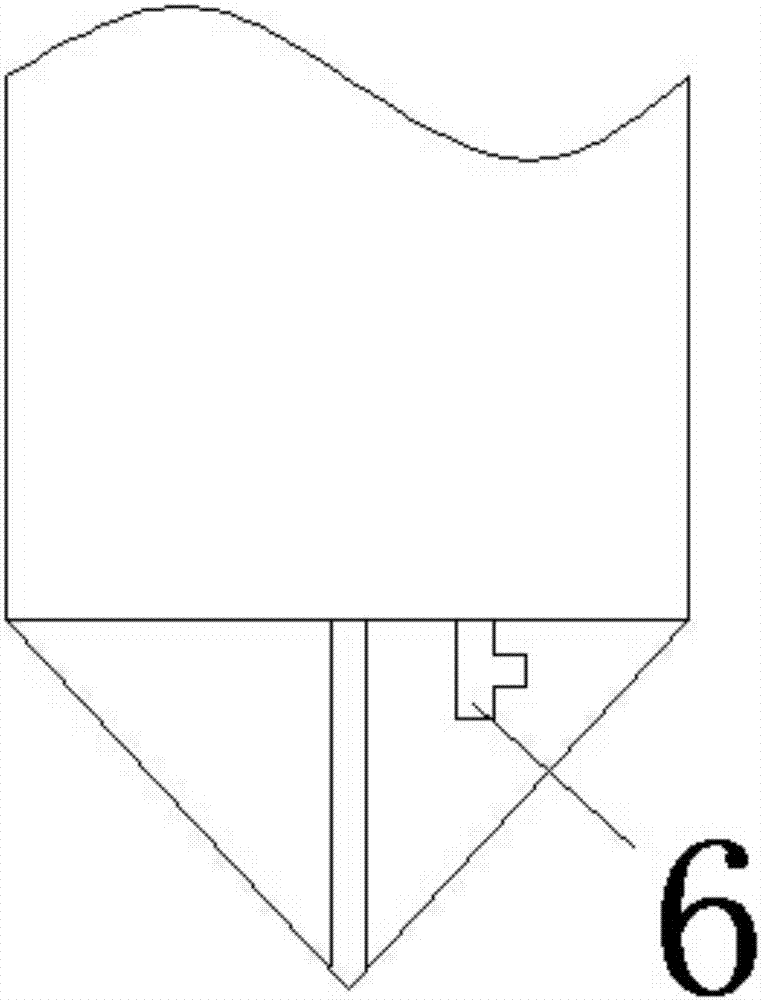

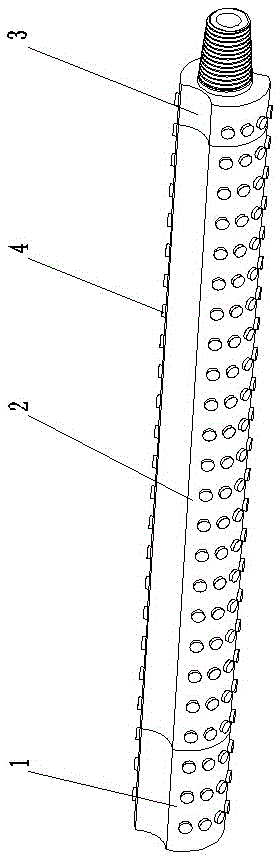

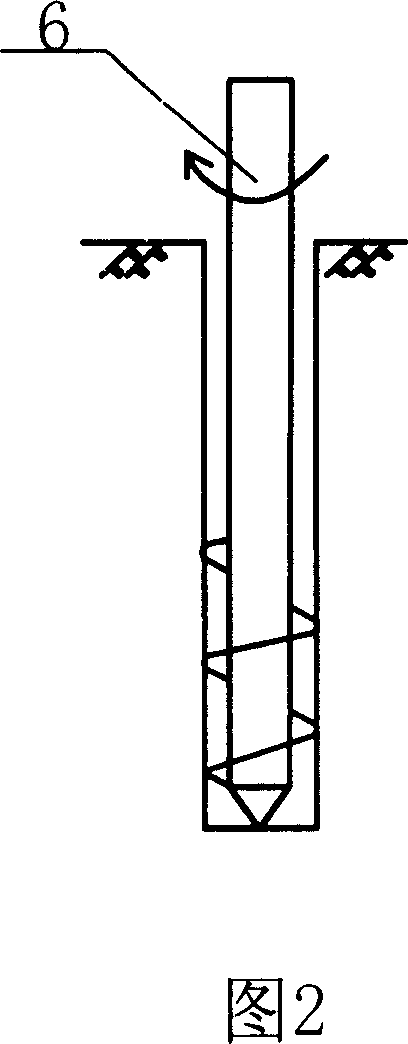

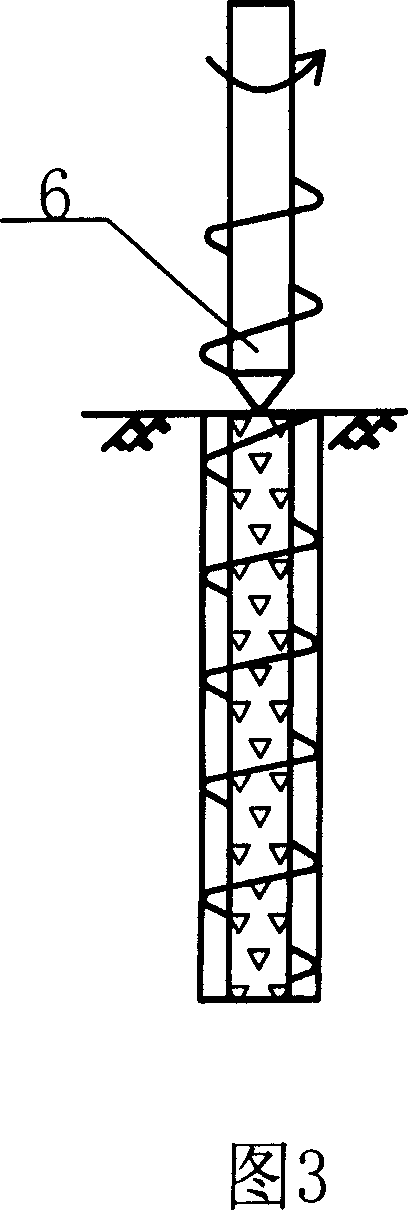

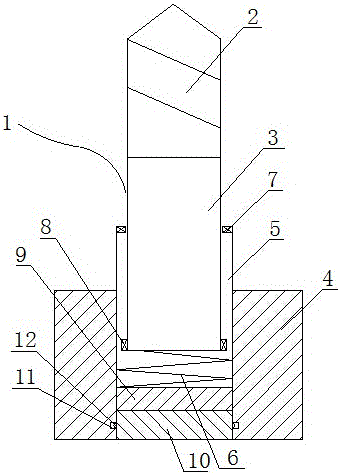

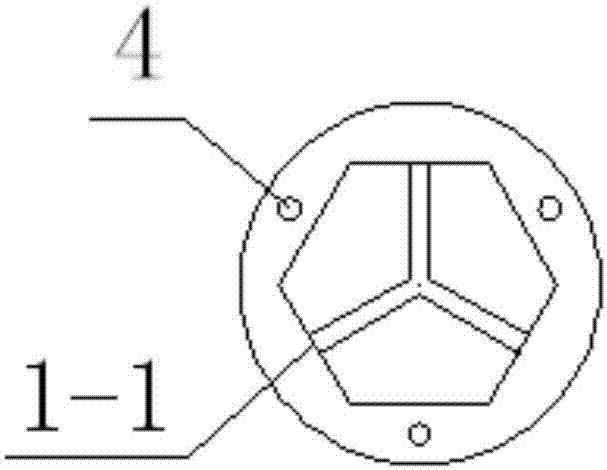

Prefabricated screw spike pile

InactiveCN106917404AImprove bearing capacityResilienceBulkheads/pilesHigh strength concreteEngineering

The invention discloses a prefabricated screw spike pile, belongs to the field of civil construction engineering and aims at solving the problem an existing foundation pile has lower bearing capacity, low pile body strength and low construction efficiency. The prefabricated screw spike pile disclosed by the invention is formed by a single prefabricated screw pile base body or a plurality of screw spike pile base bodies which are connected, wherein a pile body of the prefabricated screw spike pile base body is a concrete tube body or a hollow conical body, an inner hole of the pile body is in a round or polygon shape, a continuous thread or a continuous buttless thread is arranged on the outer surface of the pile body, at least one through hole is formed in a pipe wall in the axial direction of the pile body, and a pile toe is arranged on the bottom end face of the prefabricated screw spike pile. A prefabricated pile body of the prefabricated screw spike pile disclosed by the invention is formed by high-strength concrete, hole forming can be performed under rotary condition, the prefabricated screw spike pile can be embedded into a soil layer to achieve compression-resistance and tension-resistance effects; the through hole in the pipe wall can form nozzles at the front end of a drill bit in different directions, the purpose of cutting soil can be achieved through high-pressure spraying jet, and pile forming speed is improved.

Owner:王景军

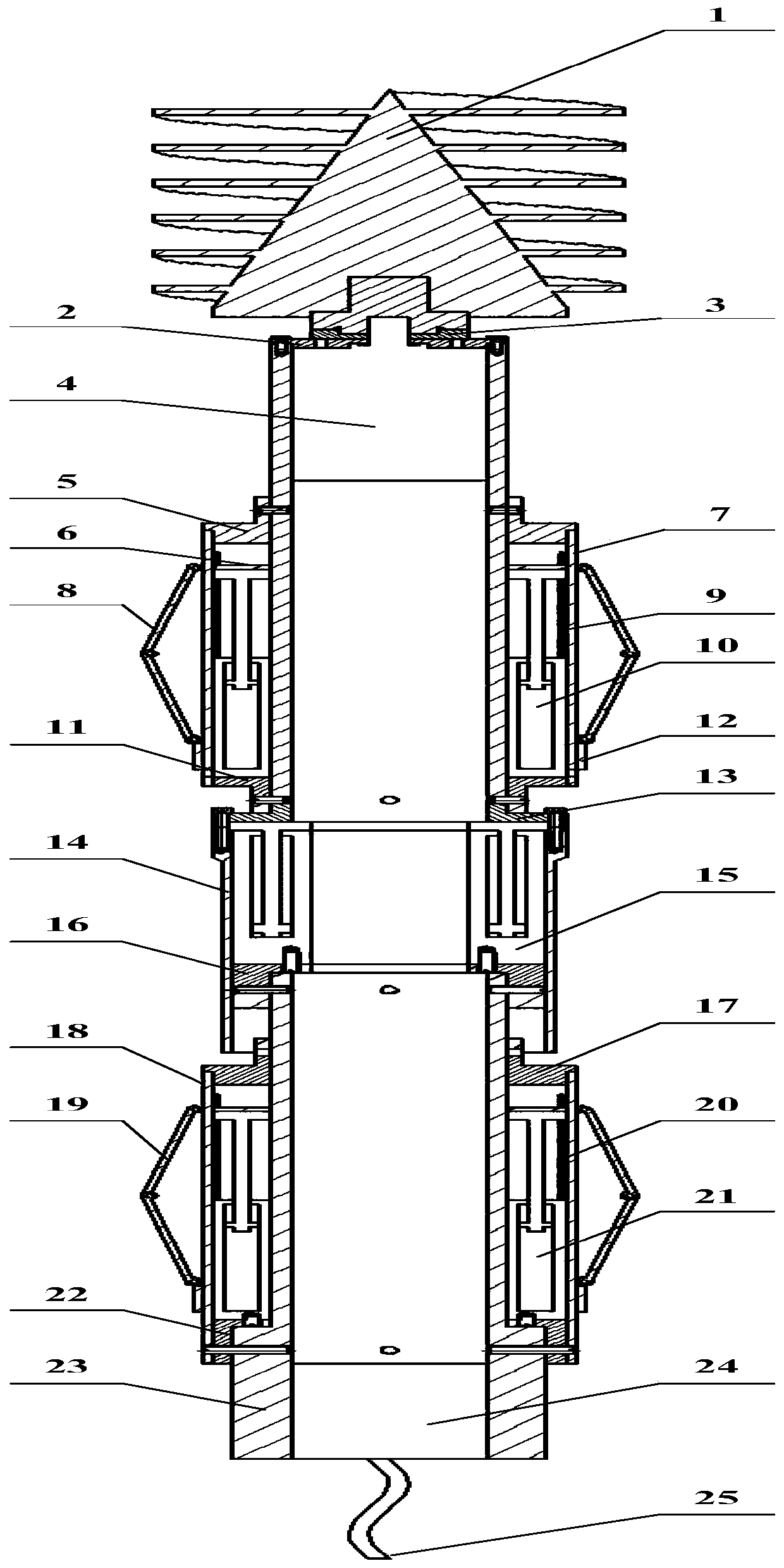

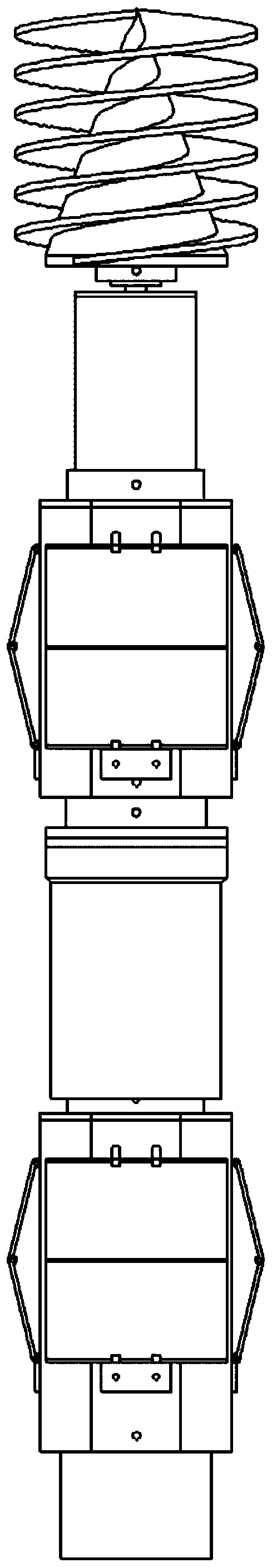

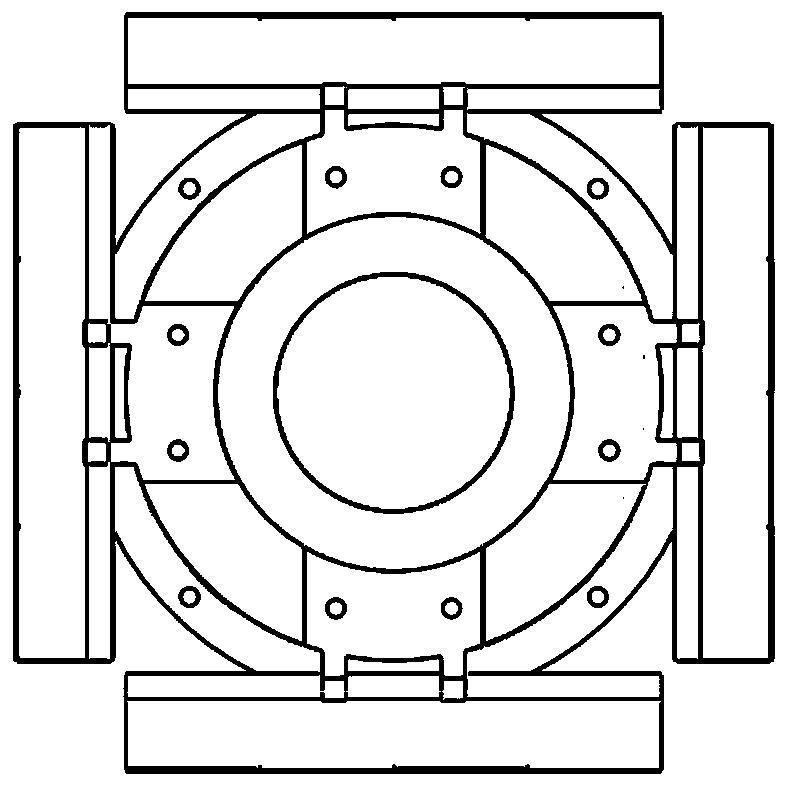

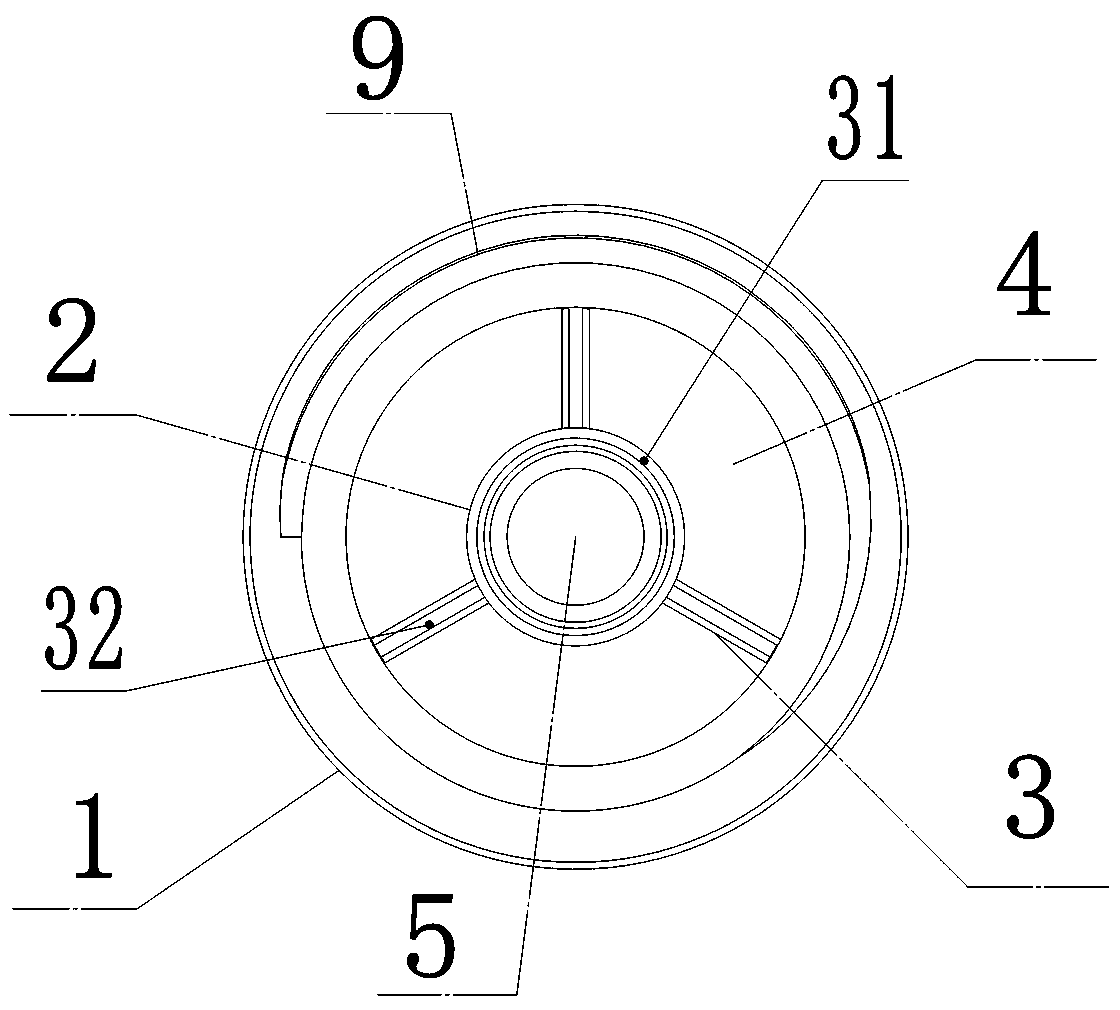

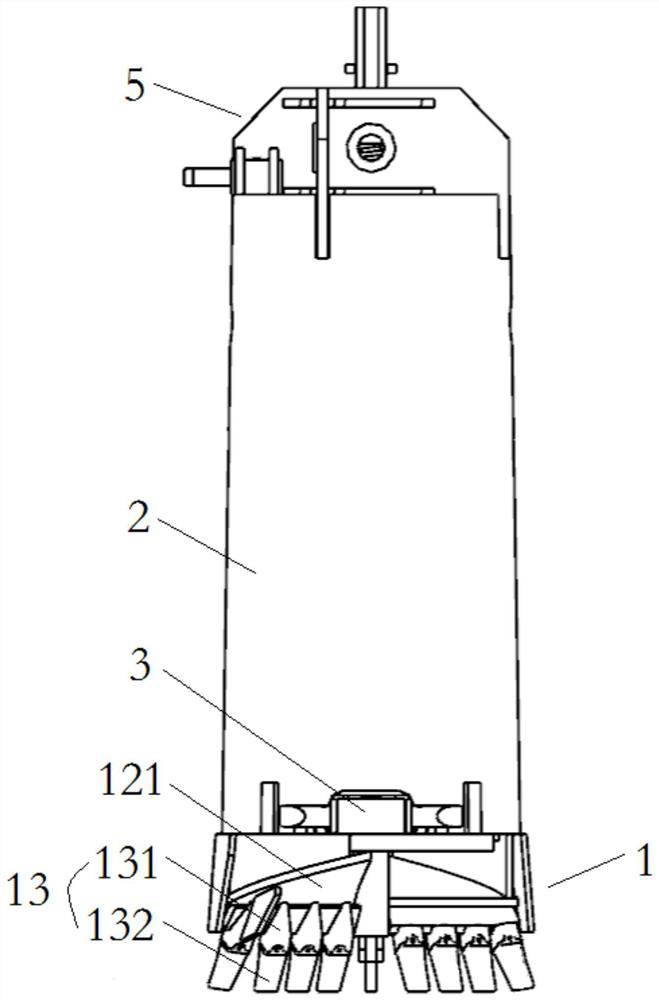

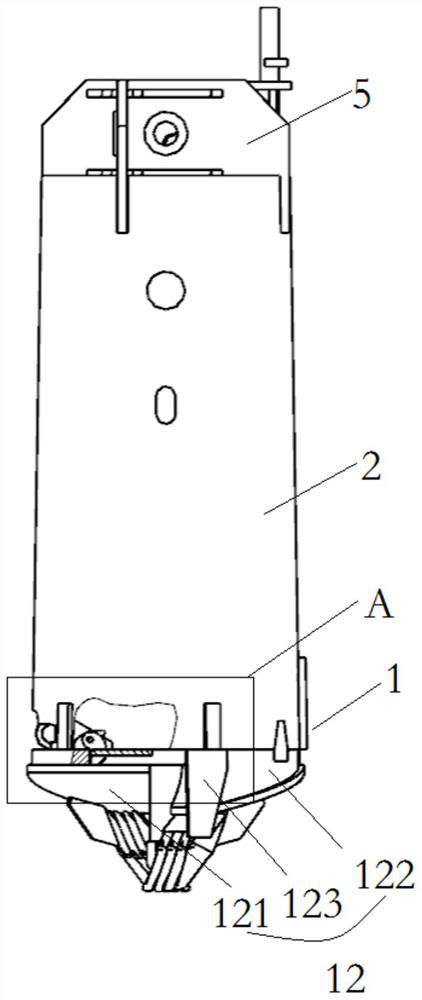

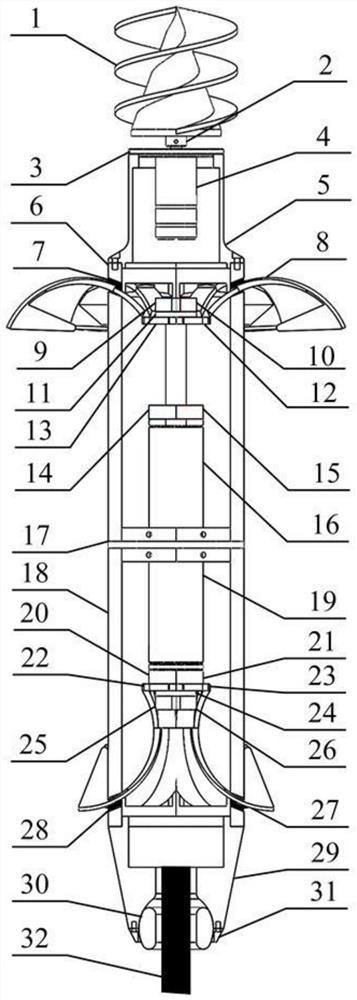

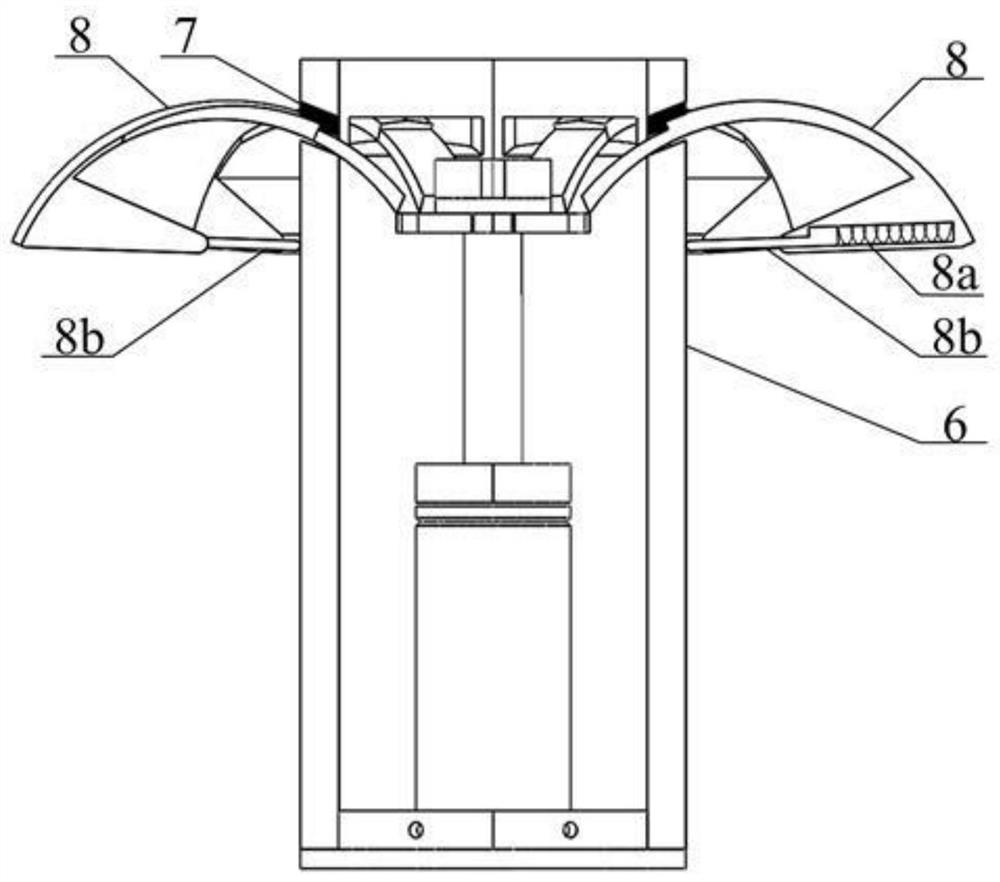

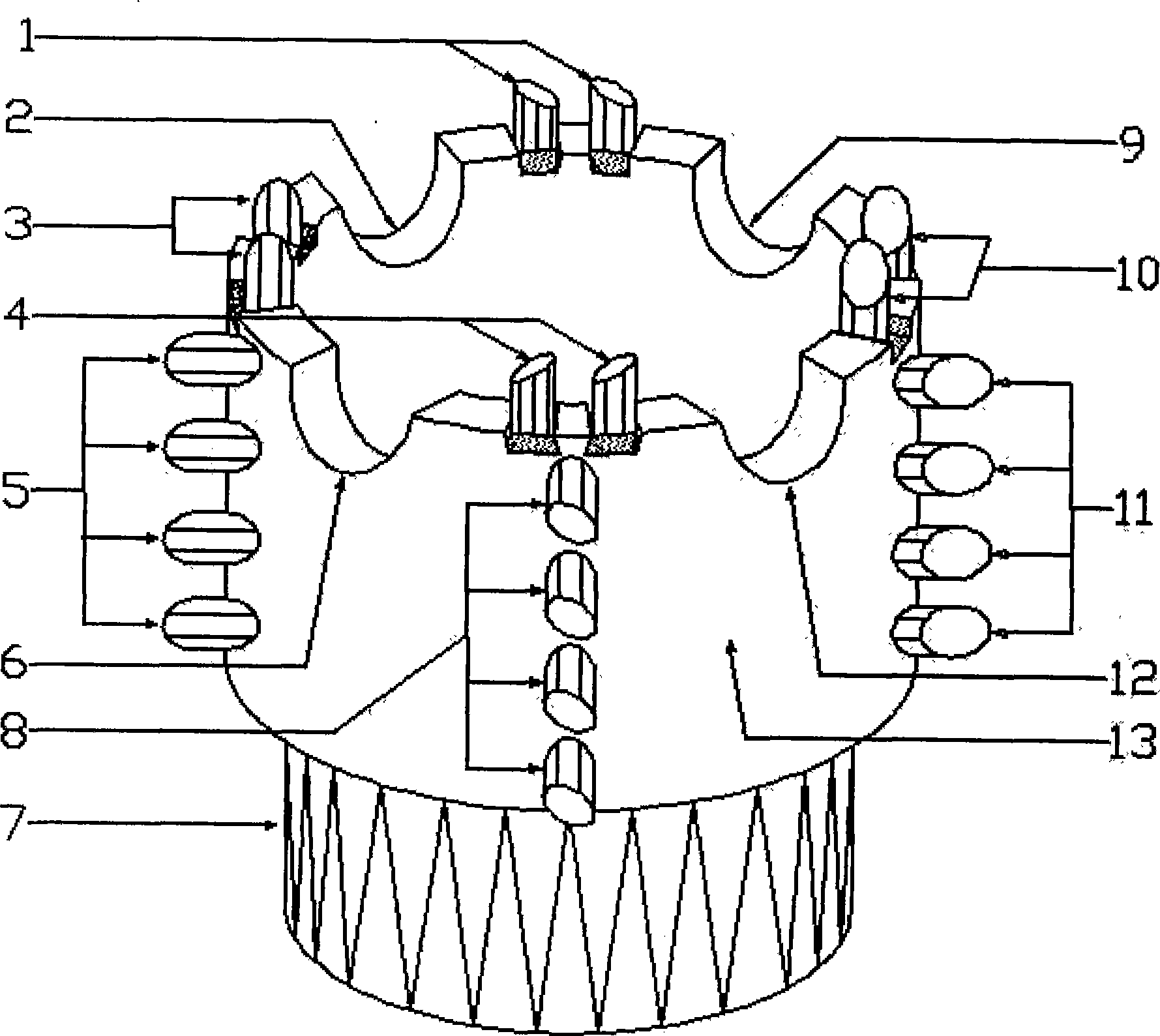

Autonomous seabed deep stratum drilling robot

ActiveCN110847823AAvoid interferenceReduce drilling resistanceConstructionsDerricks/mastsHydraulic cylinderClassical mechanics

The invention relates to a robot, in particular to an autonomous seabed deep stratum drilling robot. The autonomous seabed deep stratum drilling robot comprises a head drilling mechanism, a front supporting body section, a pushing body section, a rear supporting body section and a tail control cabin from top to bottom in sequence; the front supporting body section and the rear supporting body section comprise supporting outer cylinders, and a plurality of straight notches are symmetrically formed in the supporting outer cylinders at equal intervals in the axial direction; hydraulic cylinders are arranged in the positions, corresponding to the straight notches, of the supporting outer cylinders, and the hollow hydraulic cylinders are positioned and fixed through connecting flanges; two supporting baffles are vertically arranged on the outer edge of each straight notch, and one ends of the two supporting baffles on each straight notch are connected to form a hinge rotating mechanism; andthe bottom ends of the supporting baffles at the lower ends are positioned and fixed at the tails of the outer walls of the supporting outer cylinders through rectangular fixing pieces, and the top ends of the supporting baffles at the upper ends are positioned and and fixed to the front ends of piston rods of the hollow hydraulic cylinders through rectangular fixing pieces. According to the robot, a multi-section structure is designed, the function of each body section is independent, and the interference problem during assembly and operation is effectively avoided.

Owner:ZHEJIANG UNIV

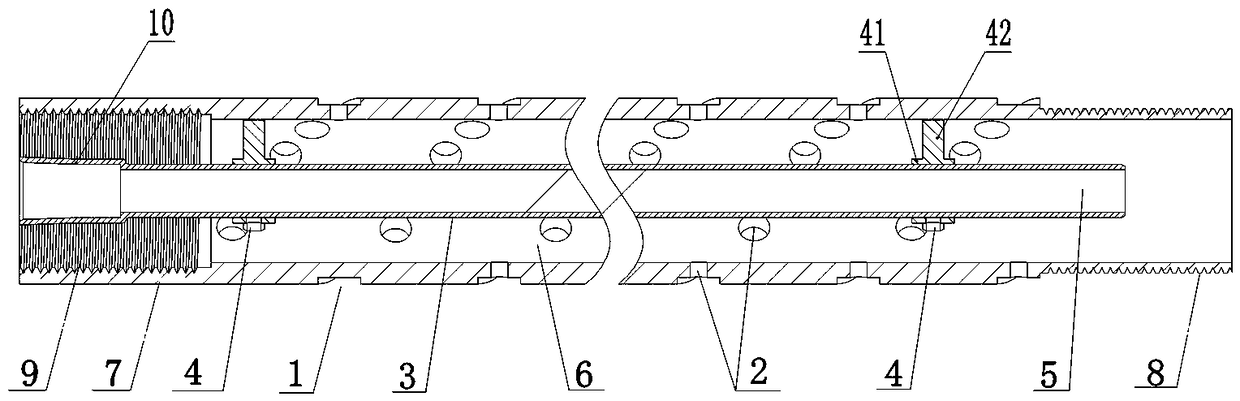

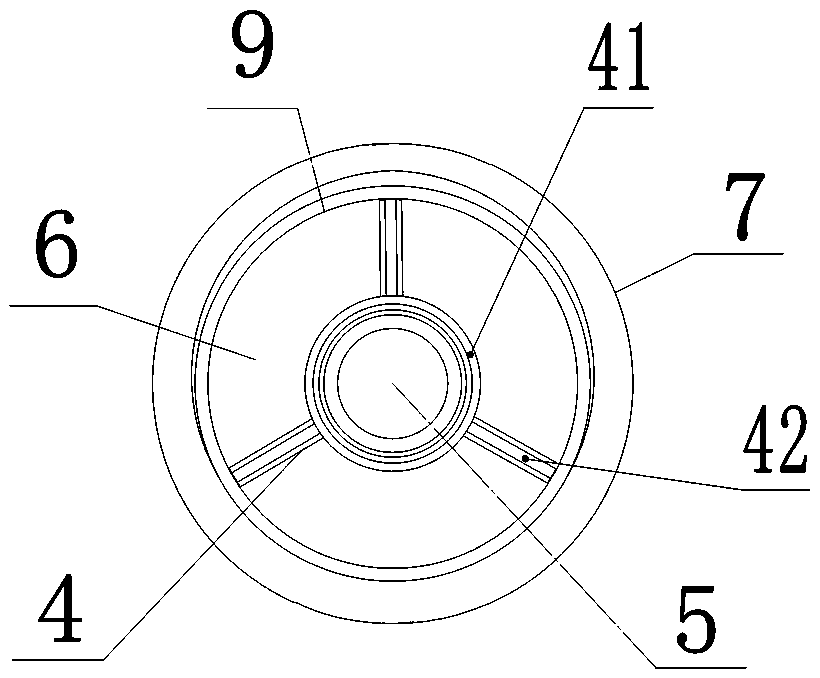

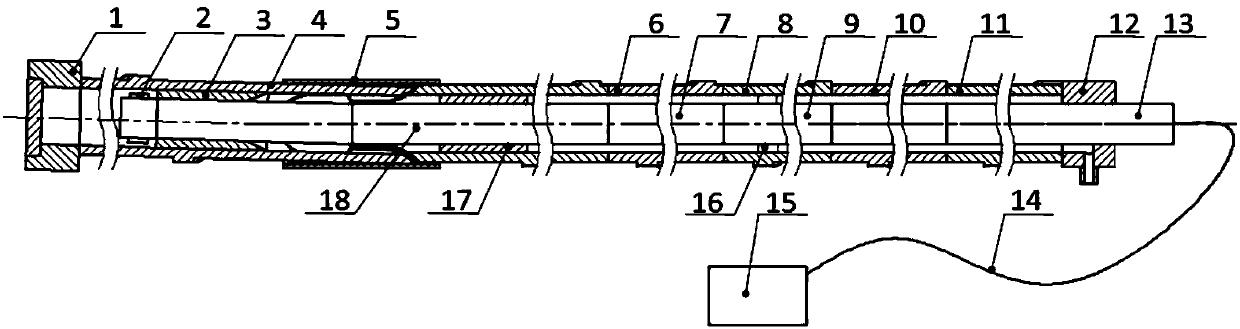

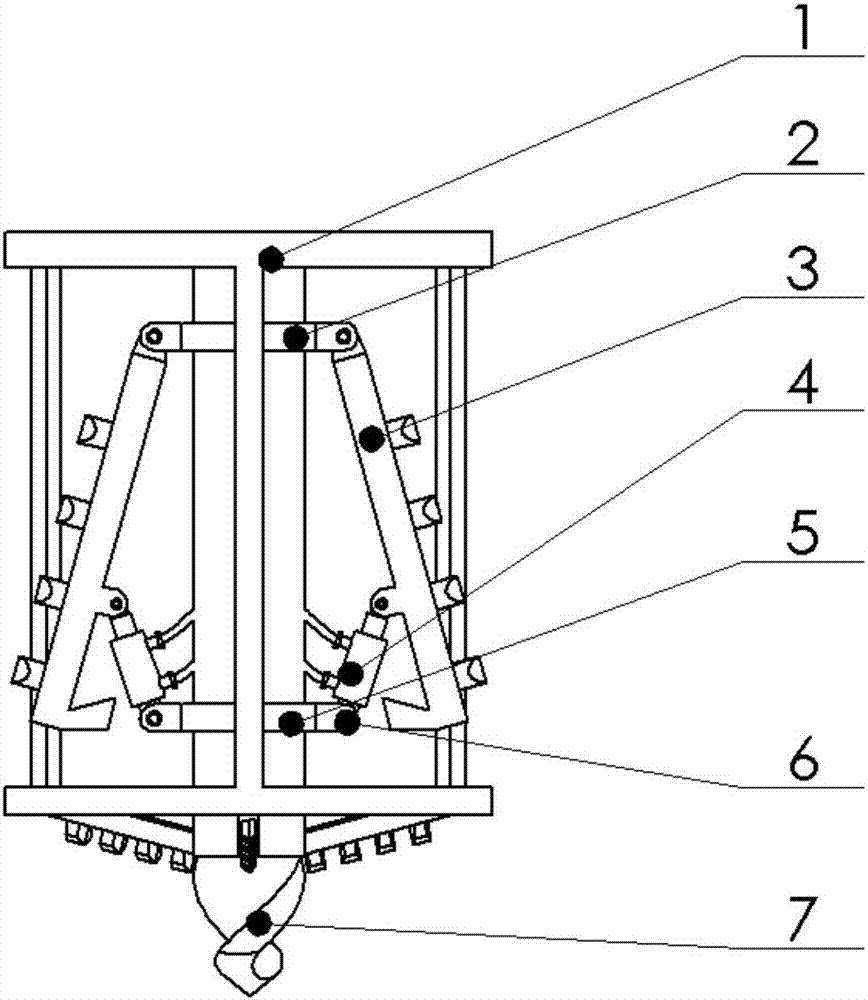

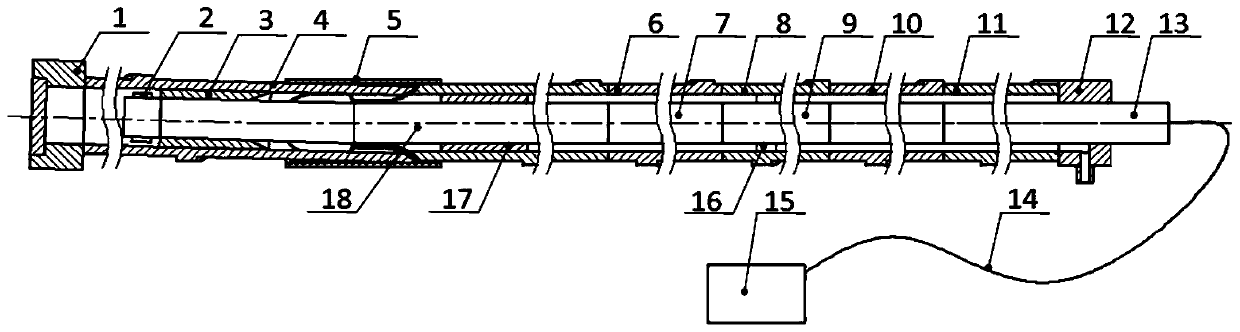

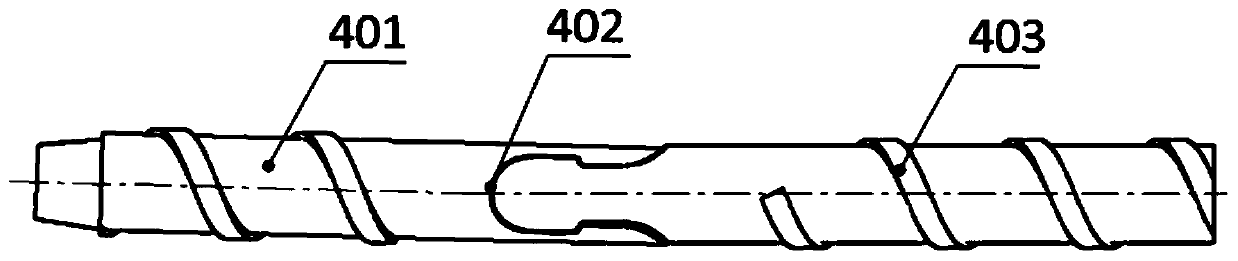

Coal-mine broken-soft-coal-seam flexible internal control rotary directional drilling system and method

ActiveCN107605402AIncrease the encounter rateImprove the extraction effectDirectional drillingGas removalNon magneticDrilling system

The invention discloses a coal-mine broken-soft-coal-seam flexible internal control rotary directional drilling system and method. The drilling system comprises a flexible internal control rotary directional drilling tool, a positioning system, a spiral drill pipe, an openable drill bit and a double-power-head drilling machine; the flexible internal control rotary directional drilling tool is located between the spiral drill pipe and the openable drill bit to achieve rotary directional drilling, the positioning system penetrates the spiral drill pipe to have drilling traces measured, the double-power-head drilling machine includes a large power head and a small power head to provide drilling power, the flexible internal control rotary directional drilling tool comprises a flexible outer pipe, a core bending shaft, a bearing pack and a sleeve, the positioning system comprises an upper non-magnetic drill pipe, a lower non-magnetic drill pipe, an outer exploring pipe, a measuring exploring pipe, a cable-through inner pipe and an explosion-proof computer. By the arrangement, directional drilling and hole protecting of a sieve pipe are realized in a coal-mine broken-soft-coal-seam rotary drilling mode, drilling safety and drilling efficiency are improved, and coal seam drilling-encounter ratio and gas extraction effect are thereby improved.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

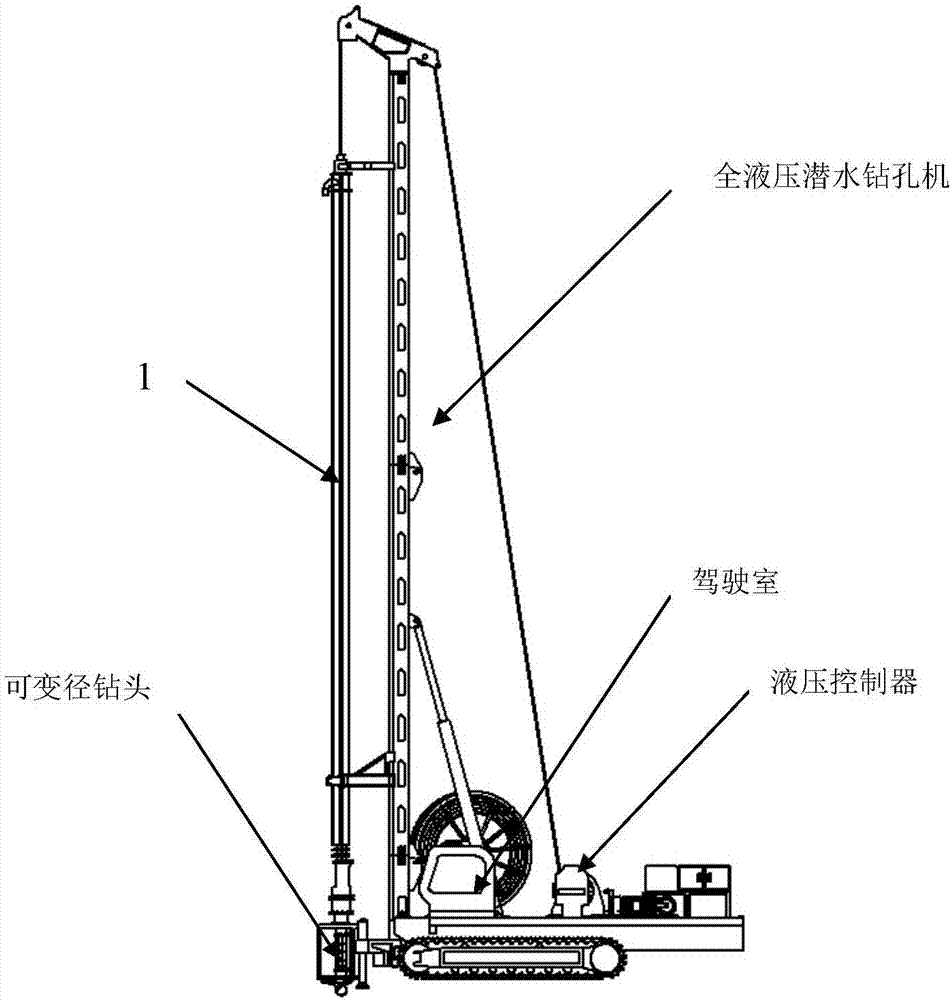

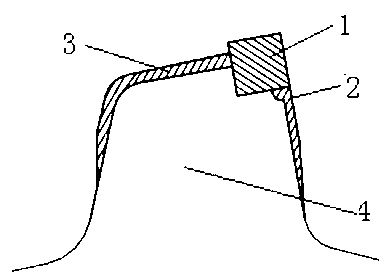

Drill bit device for variable diameter drilling and construction method

PendingCN107882510AReduce drilling resistanceReduced risk of stuck pipeDrill bitsServomotorsDrill bitPetroleum engineering

The invention belongs to drilling tools for pile foundation engineering, and relates to a drill bit for variable diameter drilling. The device is modified and optimized on the basis of a traditional drill bit. The device comprises a drill pipe, a movable knife row mounting base, a movable knife row, an oil cylinder, an oil cylinder mounting base, a pin, a spiral drill bit, the movable knife row isinstalled on the movable knife row base and tightened by the oil cylinder, and the size of opening of movable knife row blades can be controlled by controlling telescoping of the oil cylinder so as to achieve the variable diameter effect. Compared with the prior art, the drill bit has the advantages that drilling and hole expanding are conducted simultaneously, the hole collapse probability is effectively lowered, drilling resistance can be reduced, the drilling efficiency is high, the drilling sticking risk is reduced, and the drilling safety is guaranteed.

Owner:SHANGHAI CHENGDI CONSTR +1

Pile core constructing method

InactiveCN1584222AReduce generalizationReduce ubiquityBulkheads/pilesDrilling machines and methodsSlagEngineering

The present invention relates to a pile hole construction method. Said method includes the following 9 drilling and slag-discharging processes: slurry circulation clash rotary grab drilling; slurry circulation impact rotary grab drilling; slurry circulation rotary grab driling; slurry circulation hydraulic force horizontal static pressure grab drilling; slurry circulation hydraulic force active feeding submerged grab drilling; impact rotary grab drilling; rotary grab drilling; slurry circulation rotary grab drilling; hydraulic force horizontal static pressure grab drilling; slurry circulation hydraulic force horizontal static pressure drilling; hydraulic force active feeding submerged yrab drilling and slurry icrculation hydaulic force active feeding submerged grab drilling. said invented various drilling methods and slag-discharge methods and their combination can be used for various strata, and have the advantages of quick hole-forming speed, small drilling resistance and small slurry pollution.

Owner:程天森

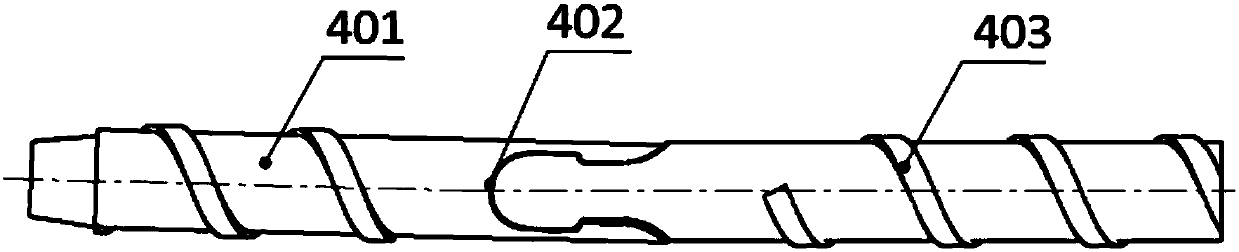

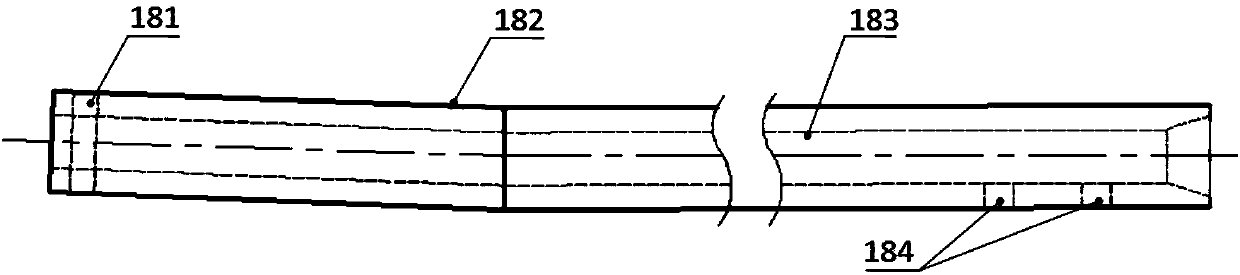

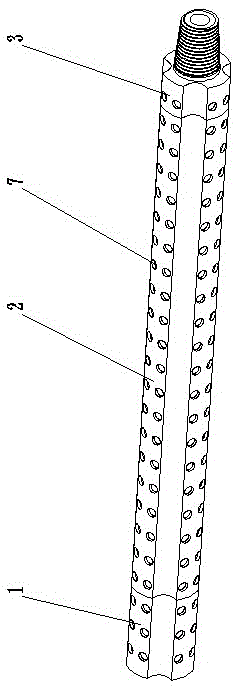

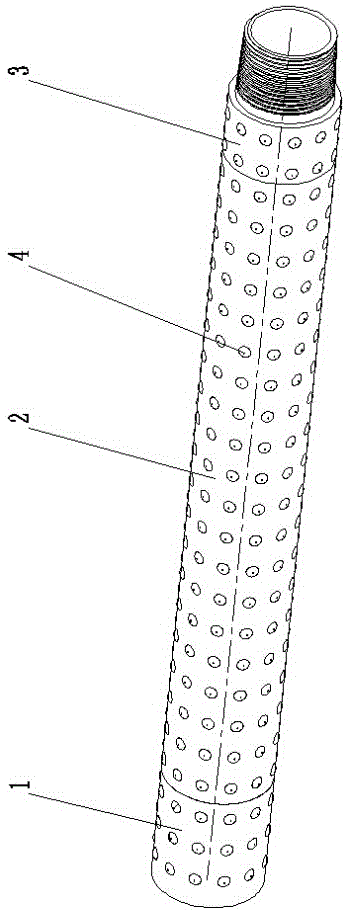

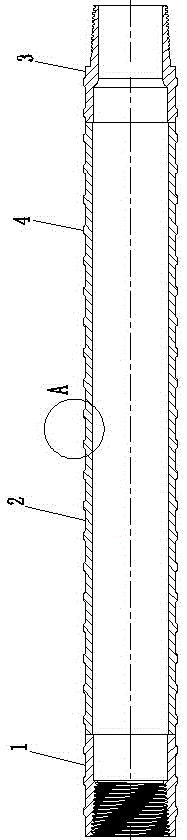

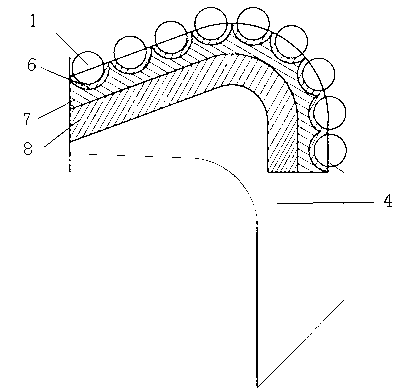

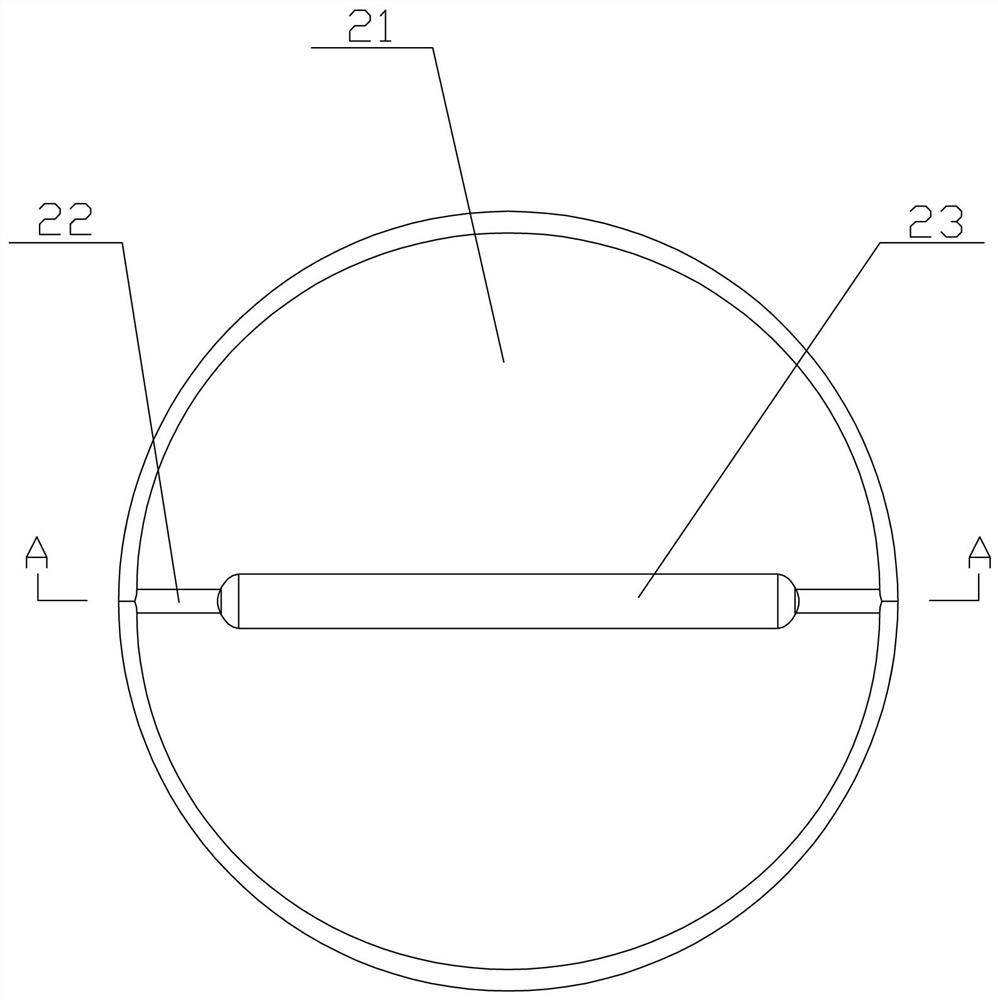

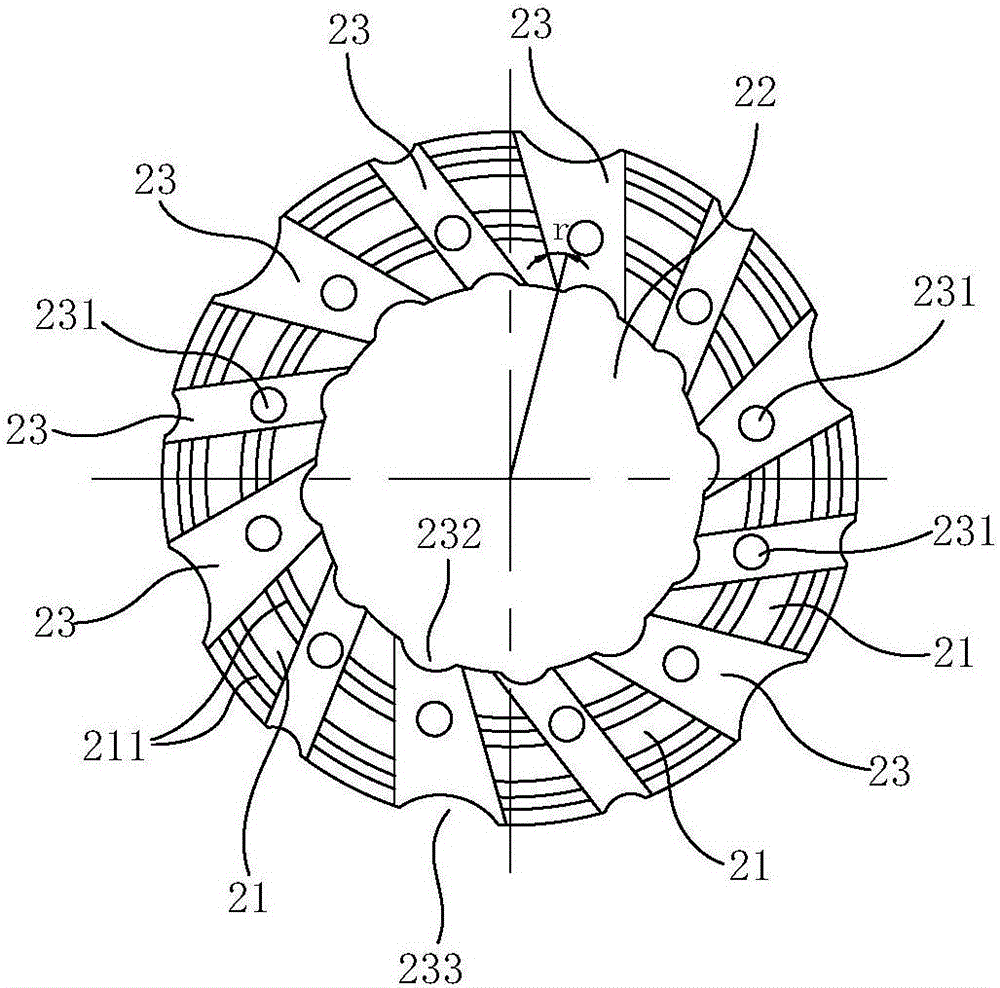

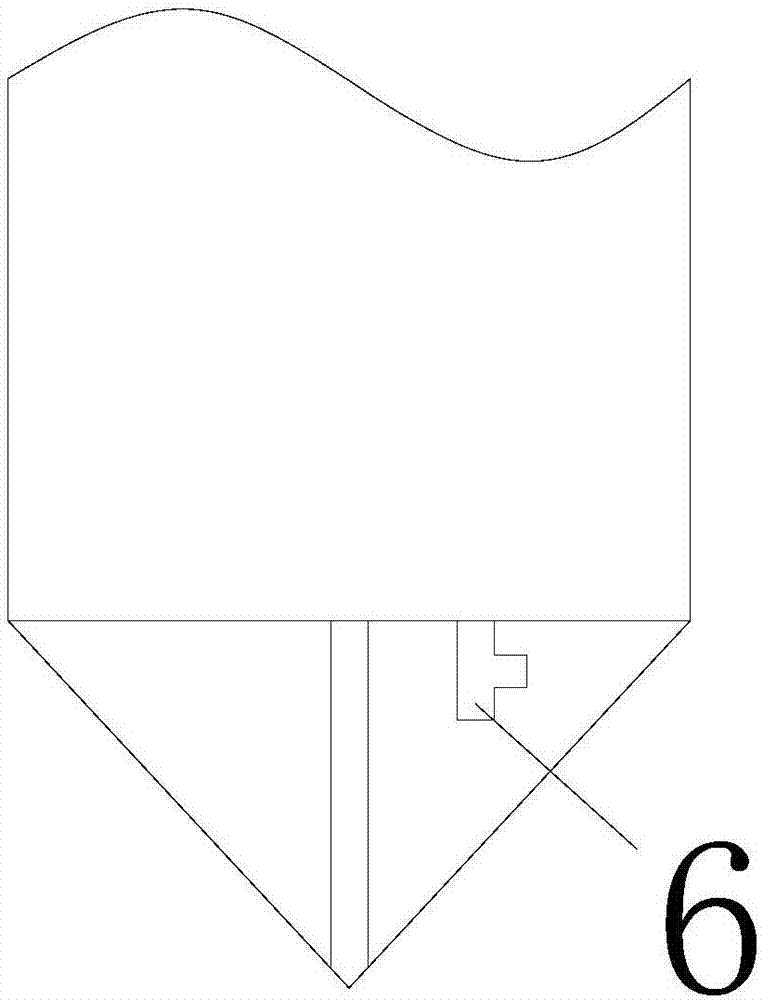

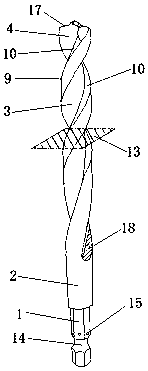

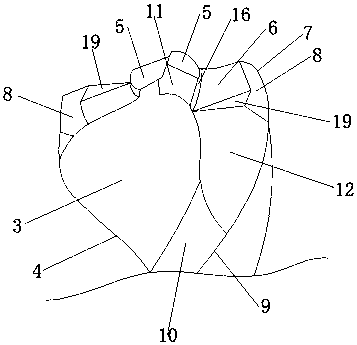

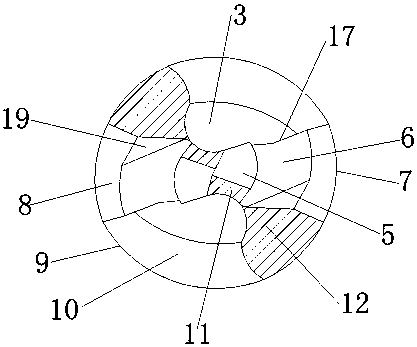

Multi-blade inwards-concave open-type bionic drag-reduction hole-protection drill rod for soft coal seam drilling and drilling method

ActiveCN105545218AReduce drilling resistanceIncreased drilling depthDrilling rodsDrilling casingsPetroleum engineeringSoft Coals

Provided is a multi-blade inwards-concave open-type bionic drag-reduction hole-protection drill rod for soft coal seam drilling. The drill rod comprises a multi-blade inwards-concave open-type concave connecting part, a multi-blade inwards-concave open-type hollow rod body and a multi-blade inwards-concave open-type convex connecting part; at least two long grooves are formed in the surfaces of the multi-blade inwards-concave open-type concave connecting part, the multi-blade inwards-concave open-type hollow rod body and the multi-blade inwards-concave open-type convex connecting part in the axial direction, all the long grooves are evenly arranged in the peripheral direction, and the cross section of each long groove is of an arc-shaped structure; the peripheral surfaces of the multi-blade inwards-concave open-type concave connecting part, the multi-blade inwards-concave open-type hollow rod body and the multi-blade inwards-concave open-type convex connecting part are separated by the long grooves to form arc-shaped wings for high-speed rotating drilling, bionic structures are evenly arranged on the outer peripheral surfaces of the multi-blade inwards-concave open-type concave connecting part, the multi-blade inwards-concave open-type hollow rod body and the multi-blade inwards-concave open-type convex connecting part, and the bionic structures are grooves and / or protrusions. By means of the multi-blade inwards-concave open-type bionic drag-reduction hole-protection drill rod for soft coal seam drilling, the drilling resistance of the drill rod is effectively reduced, and improvement of the drilling depth and drilling efficiency of soft coal rock is facilitated.

Owner:HENAN POLYTECHNIC UNIV +1

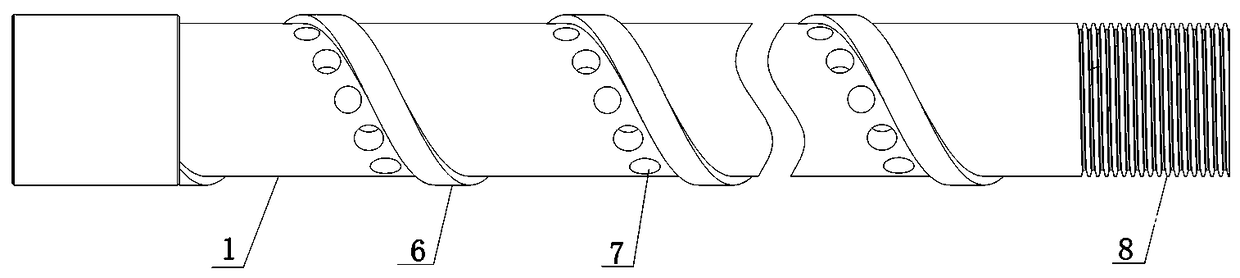

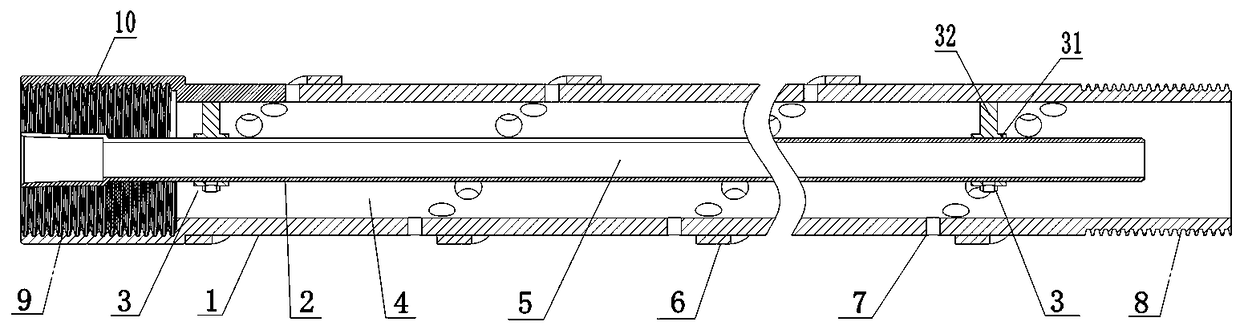

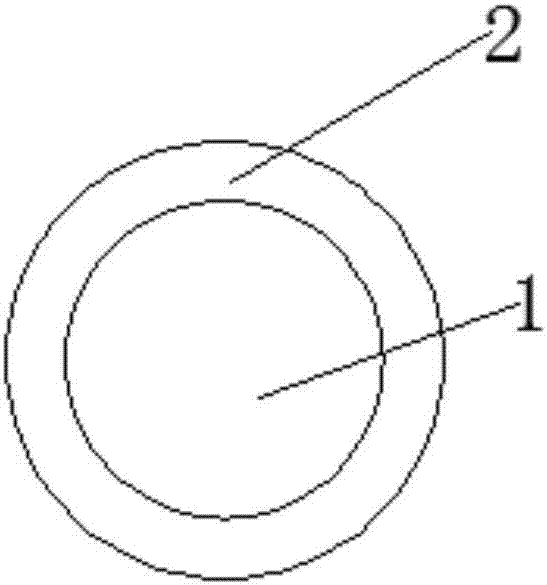

Internal slag discharging drill rod provided with spiral convex ribs for cutting and holes for pressure relief

ActiveCN108798540AWith blockageSolve the problem of high drilling resistance and easy drill stickingDrilling rodsDrilling casingsInlet channelSlag

The invention discloses an internal slag discharging drill rod provided with spiral convex ribs for cutting and holes for pressure relief. The internal slag discharging drill rod comprises a hollow rod body, a flow injecting pipe coaxially arranged in the rod body, and a supporting piece for connecting the rod body with the flow injecting pipe. A slag discharging channel is formed between the inner wall of the rod body and the outer wall of the flow injecting pipe; an air inlet and water inlet channel is formed in the flow injecting pipe; with the direction opposite to the rotating direction of the drill rod body during drilling as the reverse direction, the spiral convex ribs ascending in a cylindrical spiral shape in the reverse direction are arranged on the outer cylindrical face of therod body; and the multiple pressure relief holes are formed in the outer cylindrical face of the rod body along one sides of the spiral convex ribs. If hole collapse occurs during drilling, coal slagcan enter the slag discharging channel through the pressure relief holes, the acting force of the coal slag on the drill rod is released, meanwhile, the spiral convex ribs have the hole raking capability, and thus the coal slag is in a loose state and enters the slag discharging channel through the pressure relief holes till the hole collapse area is smooth.

Owner:HENAN POLYTECHNIC UNIV

Straight hole drilling method for drilling machine

InactiveCN106593297AAvoid offsetReduce resistanceDrilling rodsDrilling casingsHole drilling methodGeneral method

The invention provides a straight hole drilling method for a drilling machine, and the straight hole drilling method for the drilling machine is suitable for drilling a gas drainage borehole in an underground coal mine. A drill bit is arranged on a section of round drill rod to start hole drilling operation, after a borehole is drilled by the depth of one section of drill rod, a section of threaded drill rod of which the outer diameter is the same as that of the drill bit is connected with the drill bit, drilling continues to be conducted, a common round drill rod is connected after the threaded drill rod enters the borehole, and drilling is conducted according to a general method till the drill bit reaches the designated position. The straight hole drilling method has the advantages that the drilling trace is straight, operation is simple, and slagging is effective; the problem that the borehole deviates the preset trace due to the fact that the drill bit is unevenly stressed can be effectively solved; and meanwhile, the threaded drill rod is convenient to buy, the cost is low, and the drilling cost is low.

Owner:CHINA UNIV OF MINING & TECH

Reinforced drill

InactiveCN108999572AReduce drilling resistanceAvoid deformation damageEarth drilling toolsDrill bitsGeotechnical engineeringDrill pipe

The present invention provides a reinforced drill comprising a first drilling device and a second drilling device. The first drilling device comprises a connecting rod, a connecting barrel, a connecting pipe and a drill pipe. One end of the connecting barrel is closed, and the other end of the connecting barrel is opened. The connecting rod is fixedly connected with the closed end of the connecting barrel. One end of the connecting pipe is in threaded connection with the opened end of the connecting barrel. The other end of the connecting pipe is in threaded connection with the drill pipe. Thediameter of the connecting barrel is greater than that of the connecting pipe. The second drilling device is connected to an inner wall of the connecting barrel. Axes of the second drilling device, the connecting rod, the connecting barrel, the connecting pipe and the drill pipe are in the same straight line. The reinforced drill has multiple purposes, and sampling and drilling can be carried outwithout replacing the drill efficiently and conveniently; drilling resistance can be effectively reduced, slag can be exported, enough activity space is provided, deformation and damage of the drillare avoided, and cost is saved; the exact drilling position can also be positioned to avoid the error of the drilling position.

Owner:ZOUCHENG YANKUANG TAIDE IND & TRADE CO LTD

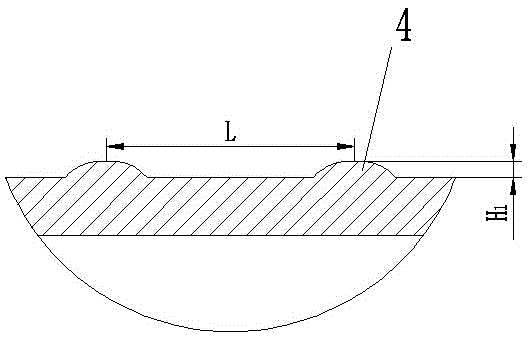

Bionic drilling method and drill rod for resistance reduction and heat dissipation of soft coal petrography

InactiveCN105464589AReduce drilling resistanceIncreased drilling depthDrilling rodsDrilling casingsThermodynamicsPetroleum engineering

The invention discloses a bionic drilling method and drill rod for resistance reduction and heat dissipation of soft coal petrography. According to the geological condition of coal seams, based on the bionic drilling method for resistance reduction and heat dissipation of soft coal petrography, the contraction ratio d[c]of a drill hole is evaluated, and the rotation outer diameter d[1] of the drill rod, the height of convex or concave structures on the surface of the drill rod, the distance between the convex or concave structures on the surface of the drill rod, and the drilling speed are determined. The bionic drill rod comprises a rod body, a convex connecting part and a concave connecting part. The convex or concave structures are arranged on the surface of the drill rod. Aiming at the technical problem that soft coal petrography drilling is hard and considering the geological condition of coal seams, the bionic drilling method and drill rod for resistance reduction and heat dissipation of soft coal petrography are provided. In the drilling process, drilling is conducted by means of the bionic drill rod for resistance reduction and heat dissipation, a low-resistance and low-temperature integral drilling technological system is obtained, and the soft coal petrography drilling effect can be effectively improved.

Owner:HENAN POLYTECHNIC UNIV

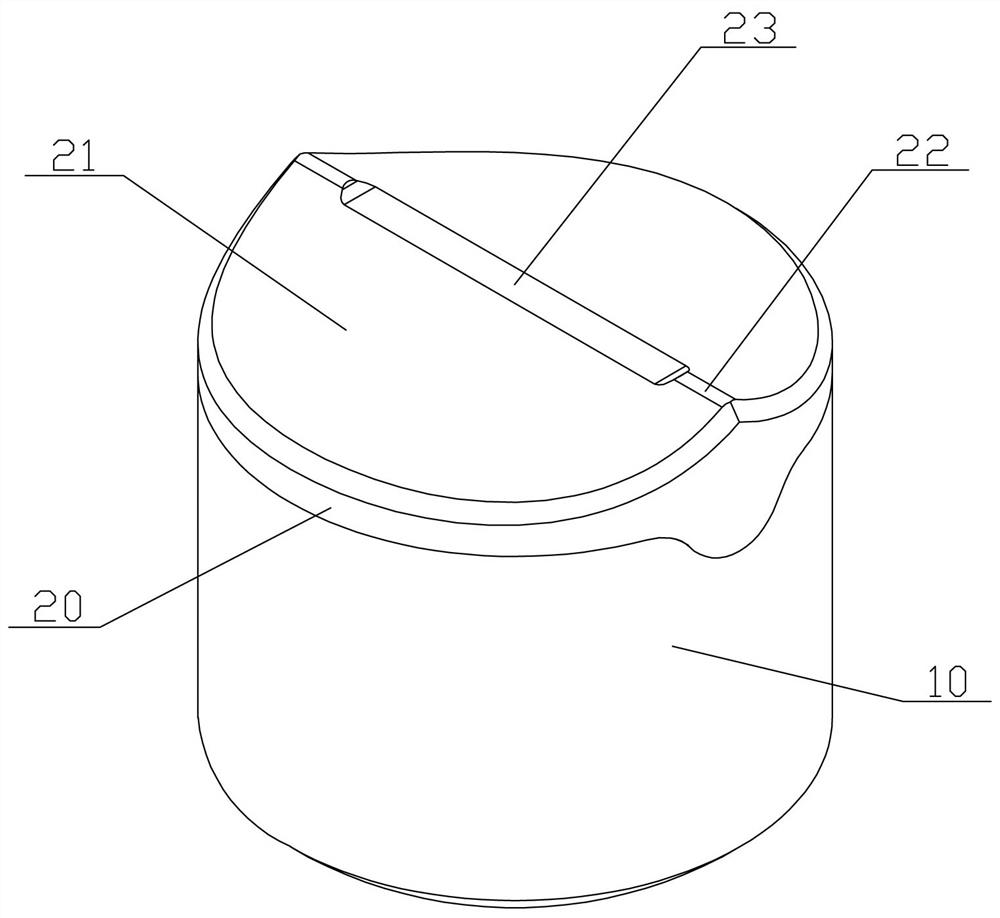

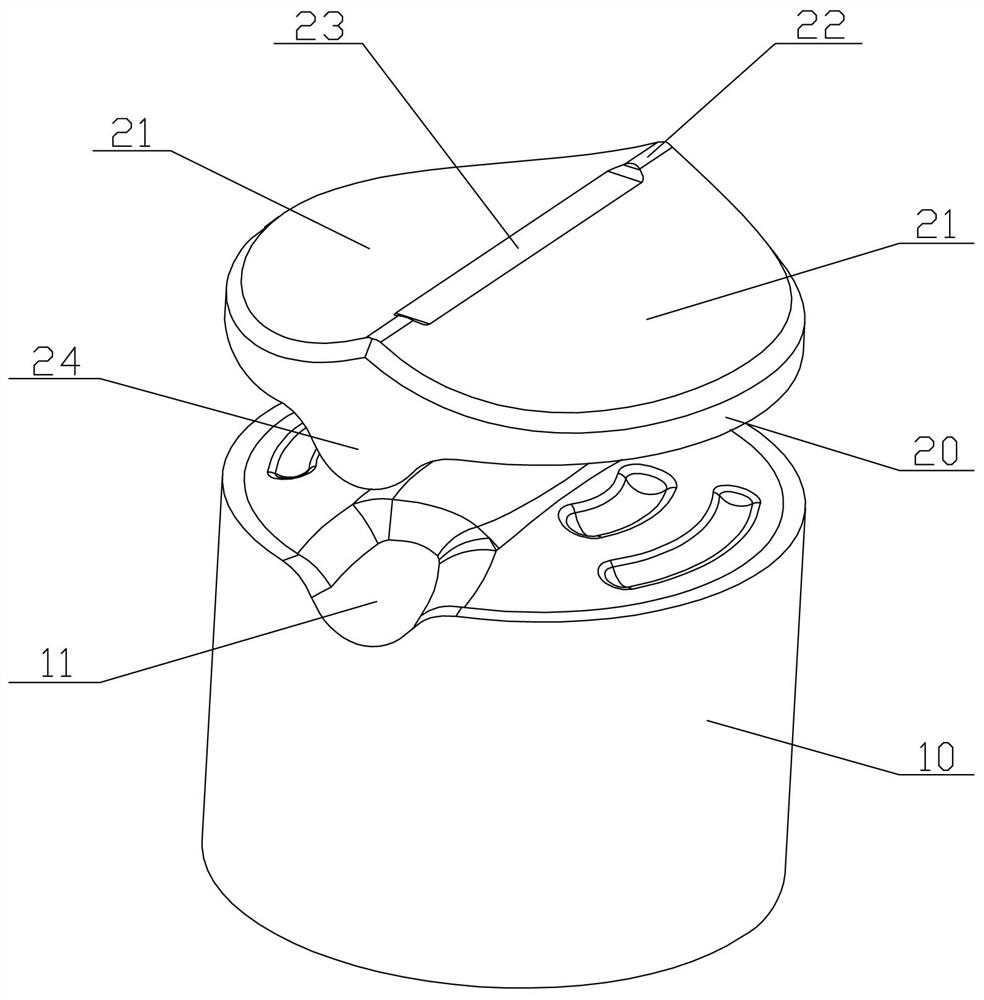

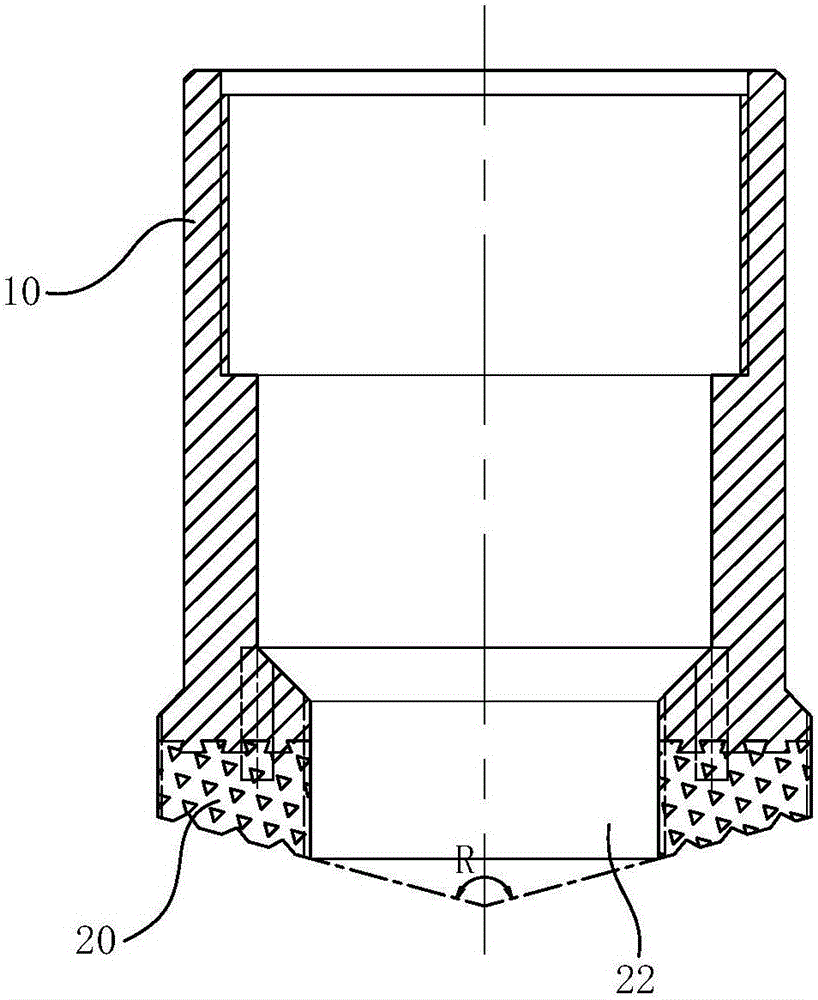

Bottom drilling structure, rotary drilling bucket and rotary drilling rig

ActiveCN113356780AIncrease distanceIncreased slag intakeEarth drilling toolsBorehole/well accessoriesSpiral bladeSlag

The invention relates to the technical field of rotary drilling construction, in particular to a bottom drilling structure, a rotary drilling bucket and a rotary drilling rig. The bottom drilling structure comprises a bottom plate, a spiral structure and a cutting structure, and a notch is formed in the bottom plate; and the spiral structure comprises spiral blades, one end of each spiral blade is connected to the bottom plate, and the other end of each spiral blade extends below the bottom plate. The cutting structure is connected to the other end of the spiral blade and matched with the notch to form a slag inlet. According to the bottom drilling structure, the cutting structure is connected to the lower portion of the bottom plate through the spiral blades, the cutting structure moves downwards, the slag inlet is enlarged, the slag inlet amount in unit time is increased accordingly, and the slag inlet efficiency is improved.

Owner:BEIJING SANY INTELLIGENT MFG TECH CO LTD

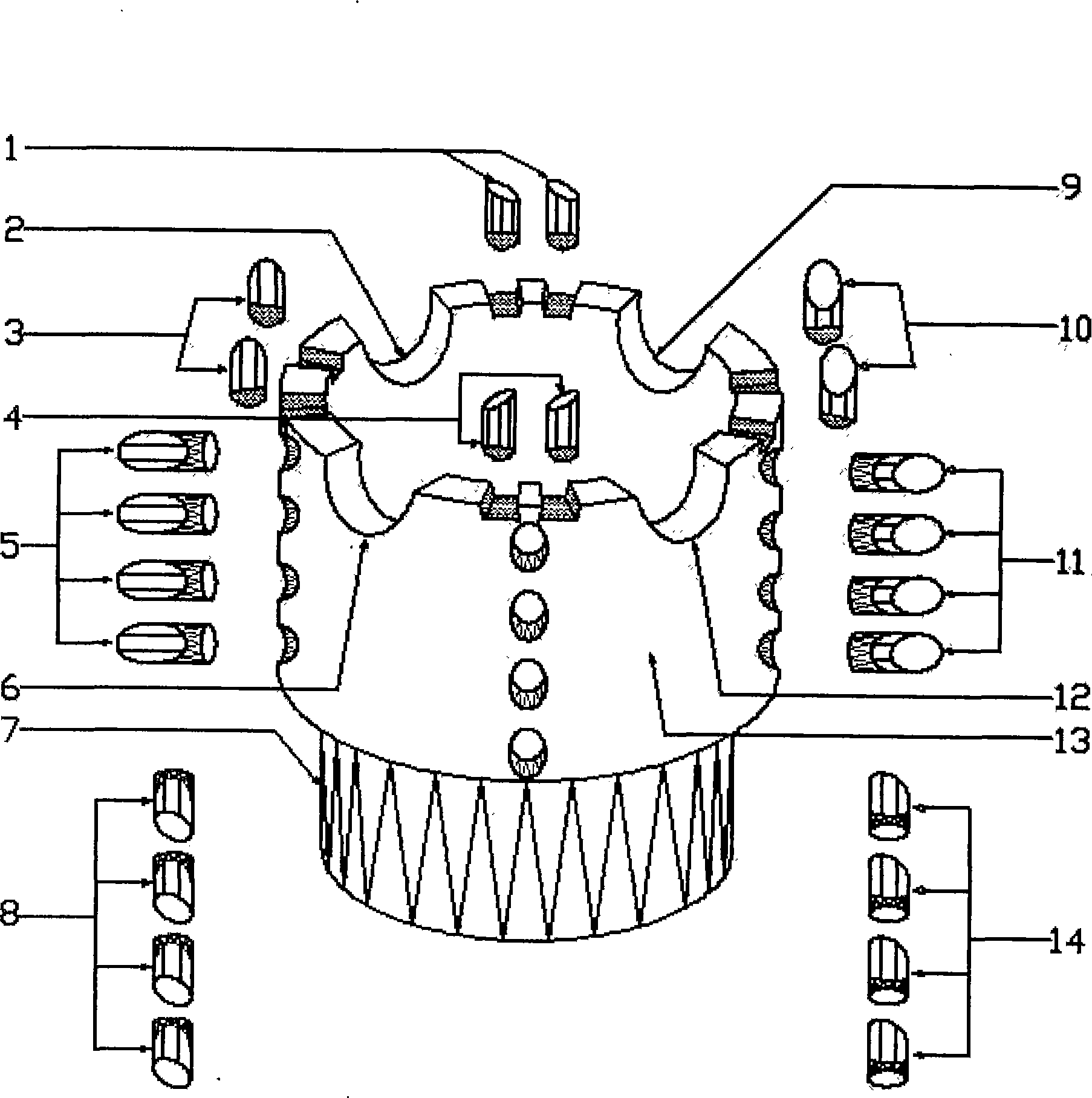

Steel PDC drilling bit with erosion-proof tooth cavities

ActiveCN103343667AImprove erosion resistanceExtended service lifeDrill bitsConstructionsWell drillingNose parts

The invention relates to a steel PDC drilling bit with erosion-proof tooth cavities which is used in the field of petroleum and geological drilling. The steel PDC drilling bit with the erosion-proof teeth comprises a drilling bit body and a knife wing, wearing layers are welded on the front face and the back face of the knife wing, the tooth cavities are formed in the upper portion of the front face of the knife wing, and clad sheet cutting teeth are arranged in the tooth cavities. The steel PDC drilling bit with the erosion-proof tooth cavities is characterized in that cavity grooves are formed in the front ends of the tooth cavities along the edges of the tooth cavities, and wearing layers are welded on the cavity grooves. According to the steel PDC drilling bit with the erosion-proof tooth cavities, the erosion-proof capacity of the front portions of the tooth cavities is enhanced, and thus the service life of the steel PDC drilling bit is prolonged. Further, more welding material is coated on certain parts around the tooth cavities, the thickness of the wearing layers is decreased gradually, the wearing layers around the tooth cavities are distributed reasonably, less welding material is used, and the machining cost of the drilling bit is decreased on the premise that the erosion-proof capacity of the tooth cavities is enhanced. Further, due to the fact that slopes which incline inwards are arranged on the back of the nose part and the shoulder parts of the knife wing, the interference between the back side of rock debris and a well bottom face behind the knife wing is reduced effectively, the drilling resistance of the drilling bit is decreased, the rock breaking efficiency of the drilling bit is improved, and the mechanical drilling speed of the drilling bit is increased.

Owner:KINGDREAM PLC CO +1

Long-life ridge type polycrystalline diamond compact

The invention discloses a long-life ridge type polycrystalline diamond compact. The long-life ridge type polycrystalline diamond compact comprises a hard alloy matrix and a polycrystalline diamond layer fixed on the hard alloy matrix, wherein the end face of the polycrystalline diamond layer comprises two or more sections; every two adjacent sections are intersected to form a ridge; a plurality ofbulges corresponding to the radial edges of the ridges are arranged at the outer edge of the bottom of the polycrystalline diamond layer and extend along the direction of the hard alloy matrix; and the hard alloy matrix is correspondingly provided with a plurality of grooves matched with the bulges. The plurality of bulges corresponding to the radial edges of the ridges are arranged at the outeredge of the bottom of the polycrystalline diamond layer, and the hard alloy matrix is correspondingly provided with the plurality of grooves. By adopting a mode of matching the bulges with the grooves, the service life of a working part of the polycrystalline diamond layer can be effectively prolonged under the condition of considering the cost, and the impact toughness of the polycrystalline diamond layer can be improved.

Owner:福建省万龙新材料科技有限公司

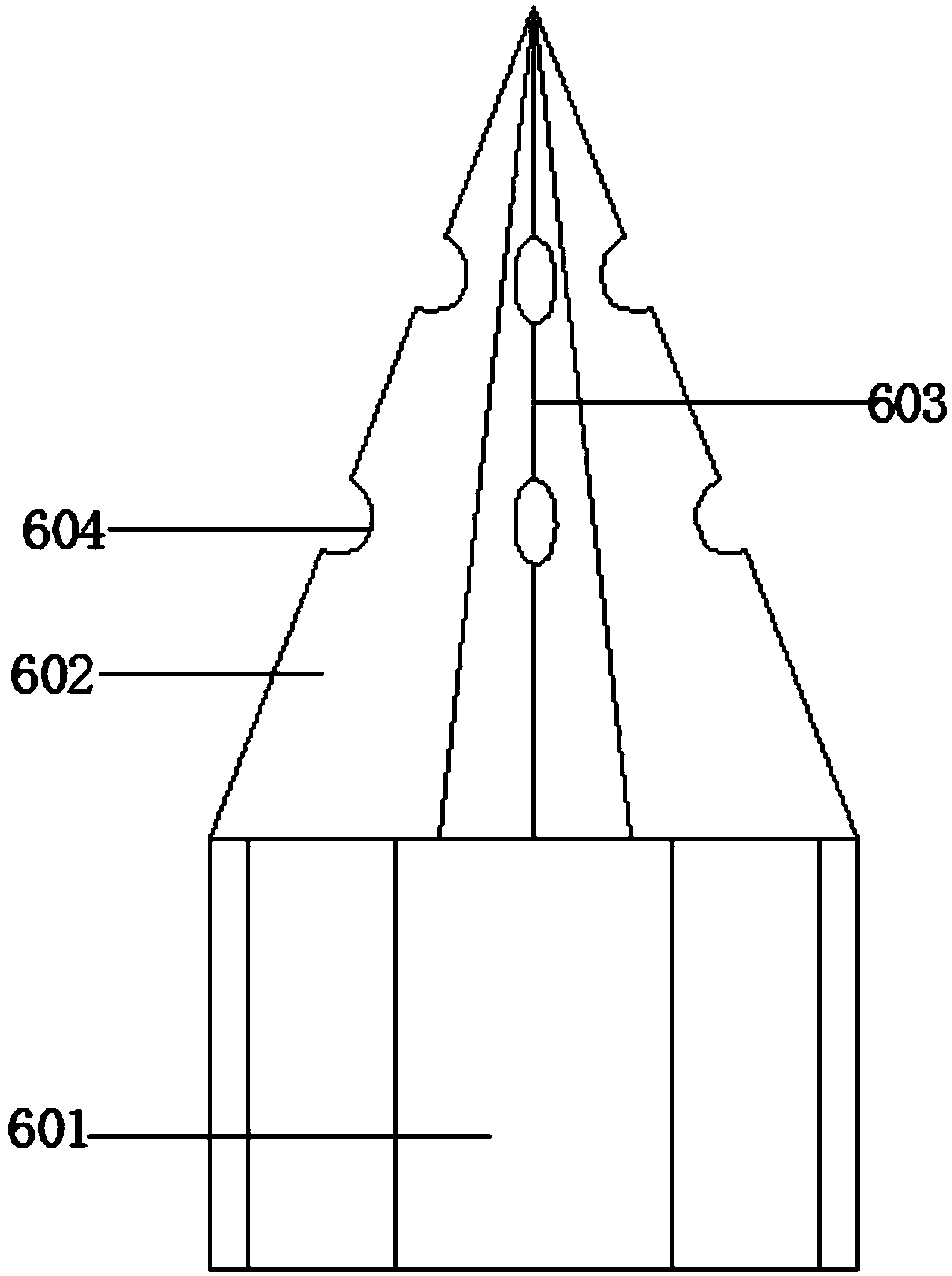

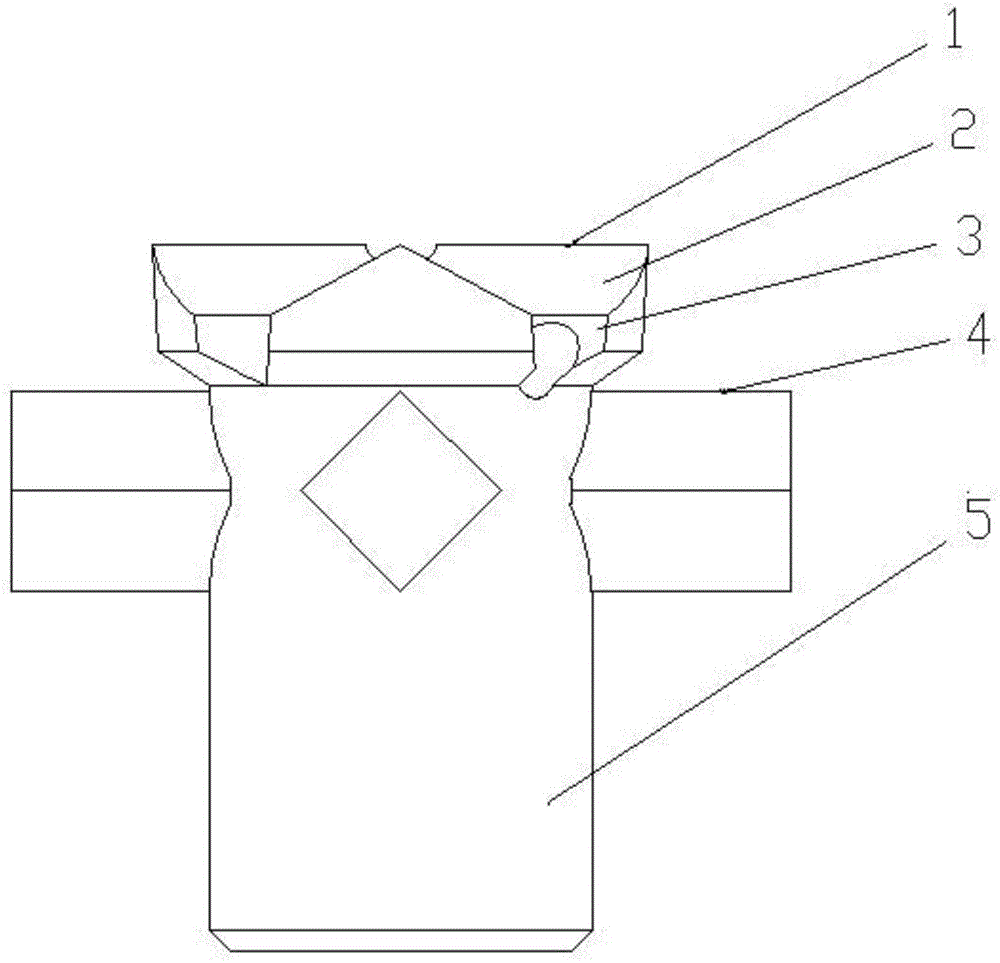

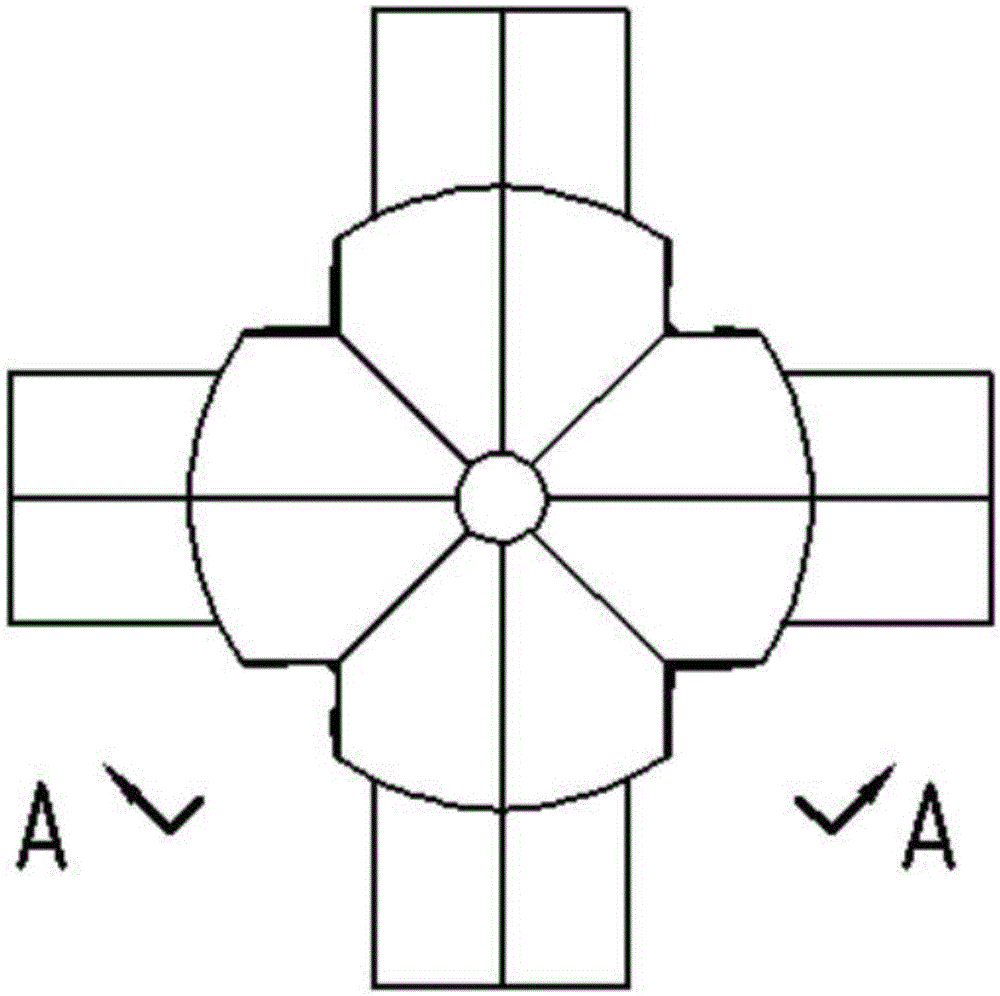

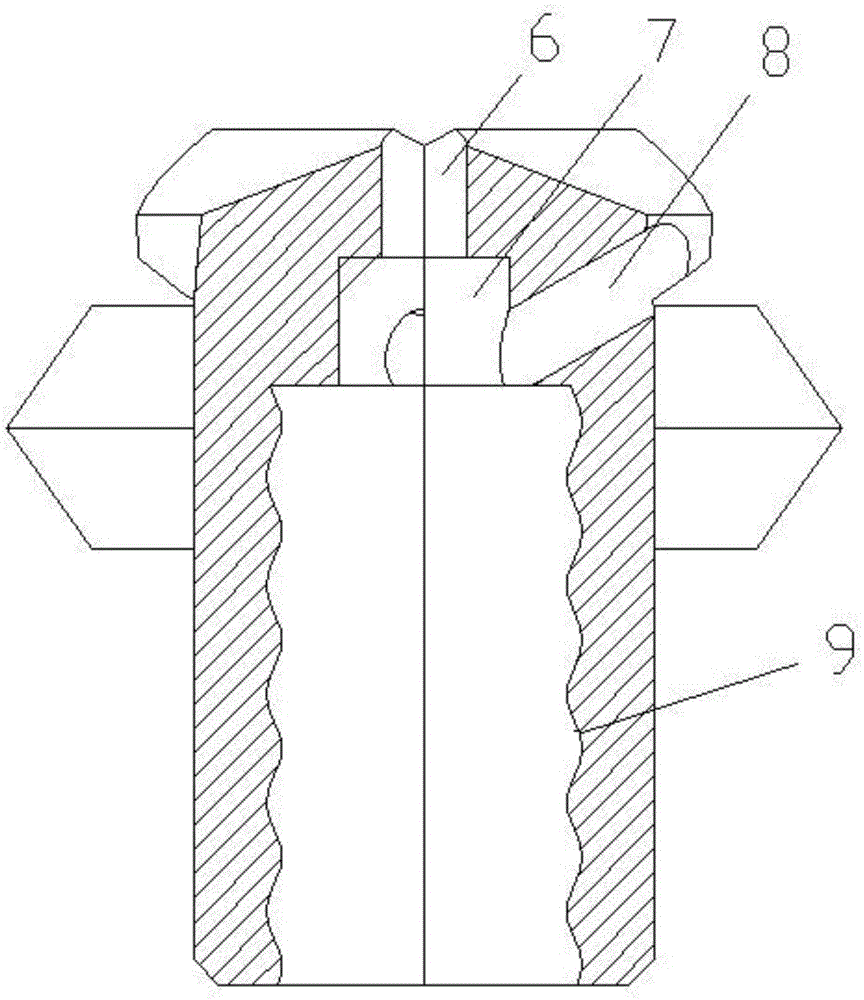

Double-layer cross-shaped self-drilling anchor bolt drill bit

The invention discloses a double-layer cross-shaped self-drilling anchor bolt drill bit. The double-layer cross-shaped self-drilling anchor bolt drill bit comprises a main cutting edge, four auxiliary cutting edges, four upper symmetrical residue discharging grooves, four lower symmetrical residue discharging grooves, one upper water hole, two lateral water holes, a drill bit trouser, an internal thread and a transition hole. The main cutting edge is a cross-shaped edge where edge parts are connected, the four auxiliary cutting edges are evenly distributed around the trouser in a cross shape, and the edge parts of the auxiliary cutting edges face the top of the drill bit. The upper residue discharging grooves and the cross-shaped edge are distributed in a spaced mode, the lower residue discharging grooves are connected with the upper residue discharging grooves, and the upper and lower residue discharging grooves are of V-type structures. The upper water hole is a through hole, and the axis of the upper water hole coincides with the axis of the drill bit. The lateral water holes are through holes, one end of each lateral water hole is through the transition hole, and the other end of each lateral water hole is located at the junction point of the corresponding upper residue discharging groove and the corresponding lower residue discharging groove. The internal thread is located at the tail of the drill bit, and the transition hole is located in the bottom of the internal thread. The guiding capacity and the residue discharging capacity of the drill bit can be enhanced, then hole collapse in soft soil layer drilling is improved, and the drilling depth is increased.

Owner:洛阳中岩工程材料有限公司

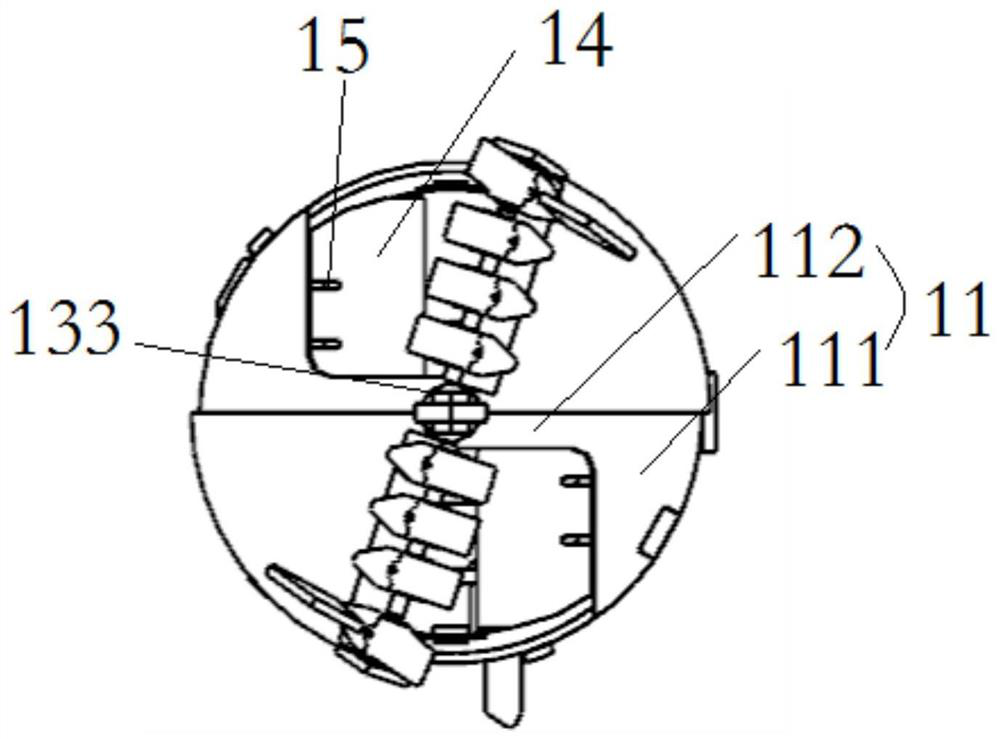

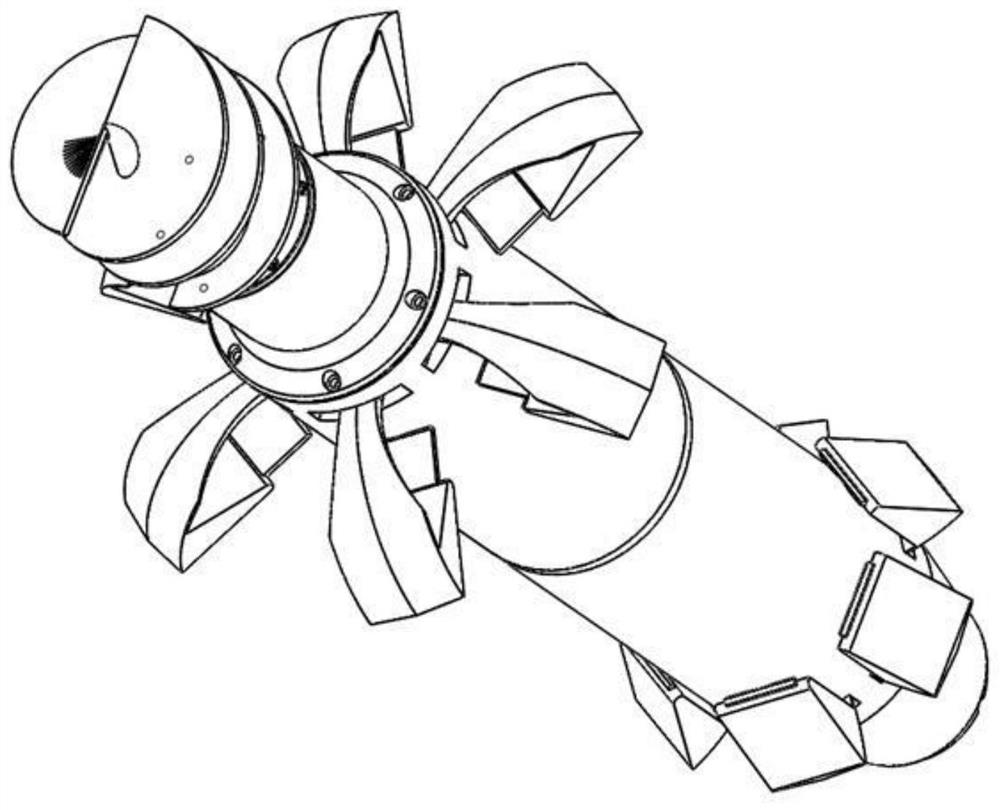

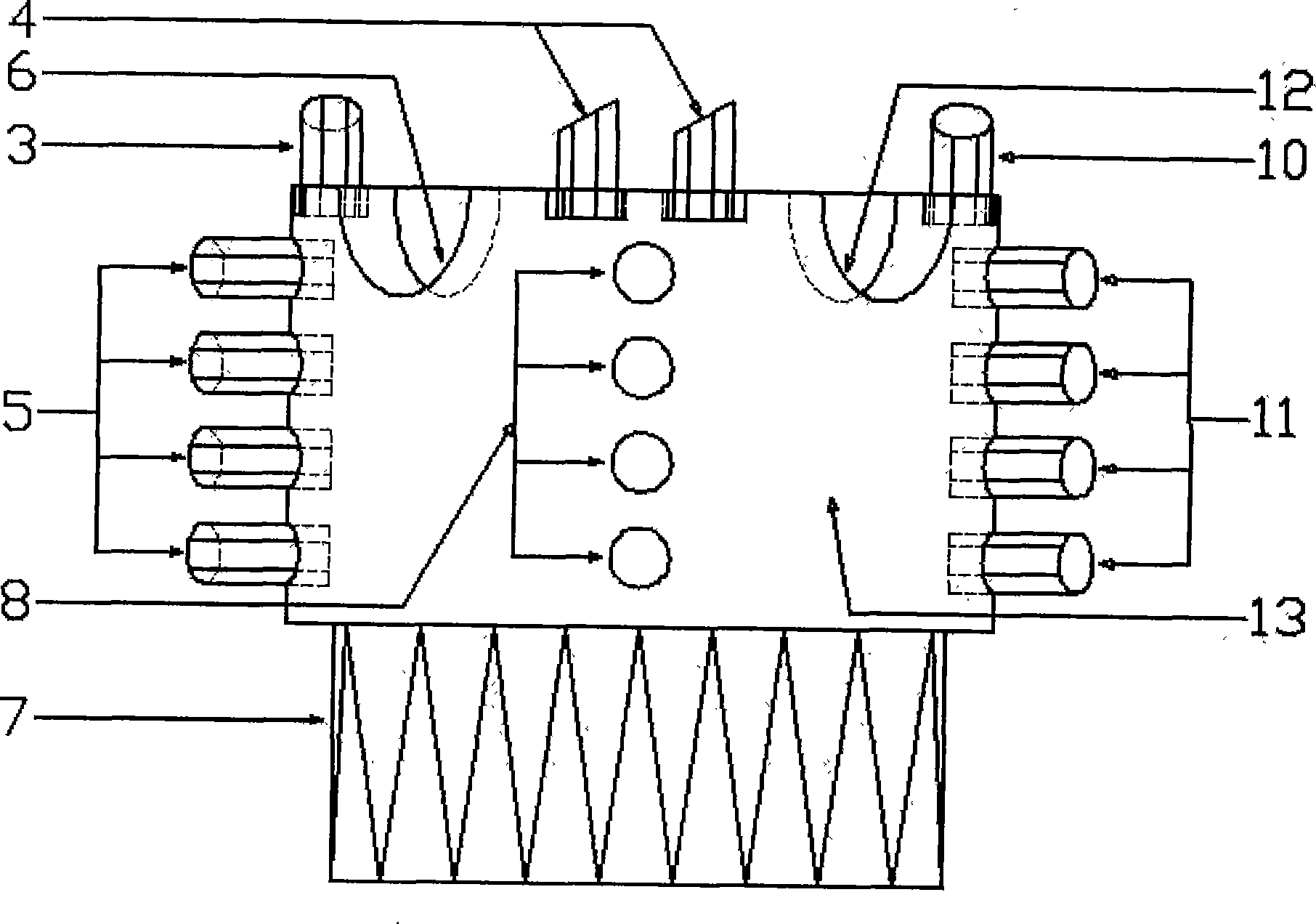

Submarine sediment stratum space drilling robot

PendingCN113843806AImprove athletic abilityImprove drilling powerDrill bitsManipulatorHydraulic cylinderSediment stratigraphy

The invention relates to a soil drilling robot, and aims to provide a submarine sediment stratum space drilling robot. The submarine sediment stratum space drilling robot comprises a lateral mud discharge drill bit mechanism composed of a drill bit and a transmission system, a front excavation supporting body section and a rear excavation supporting body section which are arranged along the axis, wherein the lateral mud discharge drill bit mechanism is located at the front end of the front excavation supporting body section, and a tail oil cable connector is arranged at the tail end of the rear excavation support body section. A front excavating propelling body section comprises an outer barrel, a hydraulic cylinder is arranged in the outer barrel, and the operation mode of telescopic claws can be changed through cooperation of the attraction effect of electromagnets and connecting flanges and a push rod of the hydraulic cylinder. The rear excavation supporting body section is provided with structural components which are the same as the front excavation propelling body section but arranged oppositely in the axis direction, and push rods and telescopic claws of the rear excavation supporting body section and the front excavation propelling body section have opposite action directions. According to the submarine sediment stratum space drilling robot, the body sections are independent in function, and the excavating propelling body sections can be increased according to specific working conditions so as to improve the movement capacity; and by means of the innovative excavating mode, soil around the robot can be squeezed backwards, pushed and excavated.

Owner:ZHEJIANG UNIV

Simple construction method of screw pile

InactiveCN101063307AEasy to transformReduce drilling resistanceBulkheads/pilesElectric driveEngineering

The invention relates to the screw post simple construct method, the whole screw post and half screw post construct method used in the prior architecture market both emphasizes that the drilling screw and the threading screw is a trace matching problem, to generate the construct difficulty of the construct machinery, and it is not easy to realize manually, the complexity and the product cost is increased to realize the absolutely matching and compatibility of the drilling and threading screw, The invention could effectively solve the problem, The invention uses the prior spiral driller provided with an electric drive carousel unit head, a non-screw drilling post, a screw driller, and a hoister steel wire pressure adding device, the hoister steel wire pulls the top of the hoister steel wire pressure adding device and the drive the bottom screw driller to normally drill, when the driller drills to the original depth, the driller will reversely drill and rise, and concrete is injected to the original height, at last the steel post will be arranged. The utility is applicable to use in the architecture base construct method.

Owner:曹兴明

Cutter convenient to detach

InactiveCN106738371AEasy to processSpeed controlStone-like material working toolsEngineeringHardness

The invention discloses a cutter convenient to detach. The cutter comprises a cutter body. The cutter body comprises a cutter head, a cutter body and a cutter base. A through hole is formed in the center position of the cutter base. The cutter body is arranged in the through hole. A detachable buffering base is arranged at the end portion of the through hole. Limiting blocks are arranged at the two ends of the buffering base. The cutter base is provided with grooves matched with the limiting blocks. The cutter head is connected to the bottom end of the cutter body. A spring is arranged in the through hole. A baffle ring is arranged on the inner edge of the through hole, a check ring is arranged at the top end of the cutter body, and the check ring is located on the inner side of the stop ring. The cutter has the beneficial effects that the structure is simple, using is convenient, the spring is additionally arranged, the cutter can rotate at a high speed, the drilling resistance is small, and the strength is high; meanwhile, stability is guaranteed as well, machining of some natural stone and high-hardness brittle materials is easier, and the speed of the cutter head can be controlled; and meanwhile, the spring can be dismounted and installed according to requirements, the application range is wide, and requirements of different customers are met.

Owner:SUZHOU SAIYITE ENVIRONMENTAL TECH CO LTD

Helical tooth ladder bottom-spraying type diamond bit

ActiveCN106050149AImprove drilling efficiencySmall footprintDrill bitsConstructionsRock coreWater spray

The invention relates to a helical tooth ladder bottom-spraying type diamond bit comprising a drilling bit steel body and a diamond working layer installed on one end part of the drilling bit steel body; the drilling bit steel body has a tubular structure on the whole; the diamond working layer is installed at the tube end of the drilling bit steel body and has a cone structure on the whole; a cone-type end of the diamond working layer is provided with a rock core inlet; the surface where buses of the diamond working layer are positioned is provided with right-handed screw fan-shaped blocks; multiple fan-shaped blocks are installed in the circumferential direction of the diamond working layer with intervals; the total projection area of the fan-shaped blocks is less than 40% of the projection area of a bit bottom lip part; a fan-shape recess is formed between two fan-shaped blocks; the bottom of each of the fan-shape recess is provided with a water spray hole; the water spray hole is communicated with a tube chamber of the drilling bit steel body. The lip powder discharging and cooling performance of the diamond bit is improved. The helical tooth ladder bottom-spraying type diamond bit has high drilling efficiency and long drilling bit service life.

Owner:安徽省地质矿产勘查局313地质队

A hole protection drill pipe for pressure relief and internal slag discharge

ActiveCN108505955BSolve the problem of high drilling resistance and easy drill stickingReduce drilling resistanceDrilling rodsFlushingThermodynamicsSlag

The invention discloses a drill rod with functions of hole protecting, pressure relief and internal slag discharging. The drill rod comprises hollow rod bodies, flow injecting pipes coaxially arrangedin the rod bodies, and supporting pieces connecting the rod bodies with the flow injecting pipes; slag discharging channels are formed between the inner walls of the rod bodies and the outer walls ofthe flow injecting pipes; the flow injecting pipes are internally provided with air inlet and water inlet channels; and with the direction opposite to the rotating direction during drilling of the drill rod bodies as the reverse direction, the outer cylindrical surfaces of the rod bodies are provided with spiral grooves rising in the reverse direction and in cylindrical spiral shapes, and a plurality of pressure relief holes communicating with inner cavities in the rod bodies are formed in the spiral grooves. During drilling of a soft coal seam and an outburst coal seam, the drill rod has theadvantages that the hole protecting ability is high, the slag discharging channels are not prone to being plugged, the hole forming effect is good, the slag discharging and temperature reducing abilities are high, and the hole collapse area is automatically dredged.

Owner:HENAN POLYTECHNIC UNIV

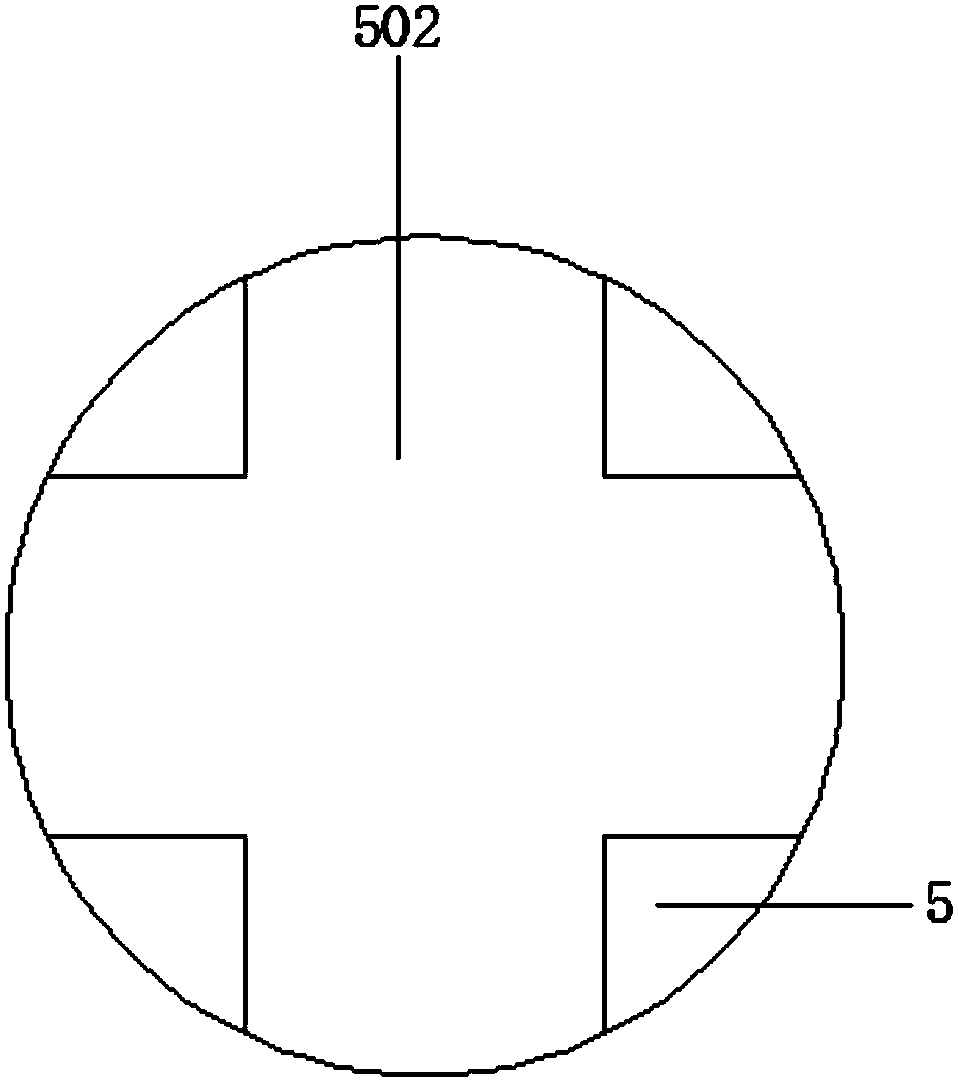

Axial convex rib hole-cutting, pressure-relief and internal slag discharging drill rod

ActiveCN108798541ASolve the problem of high drilling resistance and easy drill stickingHigh strengthDrilling rodsDrilling casingsInlet channelSlag

The invention discloses an axial convex rib hole-cutting, pressure-relief and internal slag discharging drill rod comprises hollow rod bodies, flow injecting pipes coaxially arranged inside the rod bodies and supporting pieces for connecting the rod bodies with the flow injecting pipes. Slag discharging channels are formed between the inner walls of the rod bodies and the outer walls of the flow injecting pipes, and air inlet and water inlet channels are formed inside the flow injecting pipes; and axial convex ribs parallel to the axial direction of the rod bodies are arranged on the externalcylindrical faces of the rod bodies, and a plurality of pressure-relief holes are formed in the sides, along the axial convex ribs, of the external cylindrical faces of the rod bodies. When the interior of a drilled hole collapses, coal slag can enter the slag discharging channels through the pressure-relief holes, and thus acting force of the coal slag to the drill rod is released; and meanwhile,the axial convex ribs has the hole digging capability, so that the coal slag is in a thoroughly loose state to enter the slag discharging channels through the pressure-relief holes till a hole collapse area is unblocked.

Owner:HENAN POLYTECHNIC UNIV

Lock body steel easy to drill and fast in chip removal and preparation method thereof

The invention discloses lock body steel easy to drill and fast in chip removal and a preparation method thereof, and belongs to the technical field of locks. The steel comprises the following chemical components in percentage by mass of 0.01-0.03% of C, 0-0.04% of Si, 1.6%-2.0% of Mn, 0.010%-0.030% of P, 0.40%-0.55% of S, 0.15%-0.22% of Bi, 0.005%-0.01% of Se, 0.003%-0.006% of T[O], 0.004%-0.006% of B and the balance of Fe and inevitable impurities. According to the steel, a certain amount of Bi and Se are compositely added, and the content of Mn and S in the steel is optimized, so that the sizes and forms of Mn (S, Se), ferrite and pearlite of the lock body steel are effectively controlled, the hardness of the steel is further reduced, the chip removal and breaking capabilities in the drilling process of the steel are improved, and the service life of a drill bit is prolonged; and in the preparation process, through forging, hot rolling, staged cooling and shot blasting processes, a lock body steel product with a matrix ferritic structure, a small amount of pearlite structures and excellent drilling performance is finally obtained, and the product is low in hardness, easy to drill, fast in chip removal, fast in heat dissipation and small in abrasion to a high-speed drill bit and can be widely used for manufacturing padlocks and calabash lock bodies.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Pile core constructing method

InactiveCN100441828CReduce generalizationReduce ubiquityBulkheads/pilesDrilling machines and methodsSlagSlurry

The present invention relates to a pile hole construction method. Said method includes the following 9 drilling and slag-discharging processes: slurry circulation clash rotary grab drilling; slurry circulation impact rotary grab drilling; slurry circulation rotary grab driling; slurry circulation hydraulic force horizontal static pressure grab drilling; slurry circulation hydraulic force active feeding submerged grab drilling; impact rotary grab drilling; rotary grab drilling; slurry circulation rotary grab drilling; hydraulic force horizontal static pressure grab drilling; slurry circulation hydraulic force horizontal static pressure drilling; hydraulic force active feeding submerged yrab drilling and slurry icrculation hydaulic force active feeding submerged grab drilling. said invented various drilling methods and slag-discharge methods and their combination can be used for various strata, and have the advantages of quick hole-forming speed, small drilling resistance and small slurry pollution.

Owner:程天森

Ultra-deep drilling bit apparatus for high tailing dam

The invention discloses a drilling head device used for ultra-deep drilling of high tailing dam, which is characterized in that four pairs of V-shaped grooves are symmetrically opened on a bottom lip surface of a tyre foundation, the size of the V-shaped groove is supposed to match the diameter of the bottom part of cemented carbide, four round grooves are arranged on the central axis of the V-shaped grooves at the lateral side of the tyre foundation, the size of the round grooves is supposed to match the diameter of surface embedded alloy, a water gap is arranged at the lateral bottom surface of the tyre foundation, thread tapping is carried out on the upper part of the drilling head, the cemented carbide is arranged on the bottom lip surface of the tyre foundation, the surface embedded alloy is arranged at the lateral side of the tyre foundation; the cemented carbide is welded and embedded in the V-shaped grooves on the bottom lip surface of the drilling head, an inner exit lip is arranged on the cemented carbide while the surface embedded alloy is welded and embedded in the round grooves at the lateral side of the tyre foundation. The device features not only simple structure but also convenient use, in addition, adopted for deep well drilling of tailing dam, the device greatly reduces resistance in the process of drilling and avoids jamming during drilling ahead and hoisting, so that the drilling fluid can be recycled in a rapid and smooth manner, thus accelerating drilling ahead speed and preventing abrasion of the tyre foundation in the process of drilling ahead.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

Prefabricated screw pile construction method

InactiveCN107012868ATo achieve common workTo achieve a compact effectBulkheads/pilesLine tubingHigh pressure

The invention discloses a prefabricated screw pile construction method, relates to a pile construction method, and aims to solve such problems as small adaption range, difficult pile plantation, lower side friction of piles, low strength of pile bodies, lower bearing capacity of the pile bodies, and easiness in necking, pile breakage phenomenon and low construction efficiency in the pile forming process to different extents in a traditional pile forming method by cast-in-place piles and prefabricated piles. The method comprises the following steps: (1) prefabricated screw piles and connecting pipelines are mounted; (2) the prefabricated screw piles are directly screwed into soil by the rotating power of a slewing drilling machine for pile plantation, or the spraying hole expansion pile plantation is performed by a high-pressure jet grouting mode; and (3) the post-grouting is performed for pile ends. As the method adopts the high-pressure spraying in through holes in pipe walls, the scene pulp discharge quantity is greatly reduced, no soil is discarded, no water falls, residents are not disturbed, the construction scene is tidy, the single-pile bearing capacity is high, the number and the length of the piles can be reduced, the raw materials are saved, and the effects of low carbon and energy conservation are achieved. The method is suitable for prefabricated screw pile construction.

Owner:王景军

Novel prefabricated threaded tubular pile and construction method thereof

PendingCN107059855AIncrease stiffnessImprove bearing capacityBulkheads/pilesEngineeringBearing capacity

The invention provides a novel prefabricated threaded tubular pile and a construction method thereof, and relates to the technical field of buildings. The novel prefabricated threaded tubular pile comprises a tubular pile body and a threaded on the outer side of the prefabricated threaded tubular pile body. The width of the thread ranges from 2 cm to 30 cm, and the thickness of the thread ranges from 2 cm to 6 cm. The thread space ranges from 10 cm to 80 cm, and the spiral included between the thread and the horizontal plane ranges from 10 degrees to 40 degrees. During construction, the prefabricated threaded tubular pile is transported to the site section by section, piling is carried out after positioning, the pile sections are connected in a welding manner, and finally a welding connection opening is reserved at the pile head. Due to the fact that the side thread is designed, the rigidity of a foundation pile is improved, and the bending resisting and shear resisting capacity of the foundation pile is improved. During construction, a thread drilling construction manner is adopted, drilling resistance is reduced, the drilling speed is increased, and the construction efficiency is improved. Under the same geological conditions, the bearing force of the foundation pile is improved, the design pile length is reduced, and the project cost is reduced.

Owner:陈溯源 +1

Spiral convex rib cutting hole pressure relief internal slag discharge drill pipe

ActiveCN108798540BWith blockageSolve the problem of high drilling resistance and easy drill stickingDrilling rodsDrilling casingsThermodynamicsSlag

The invention discloses an internal slag discharging drill rod provided with spiral convex ribs for cutting and holes for pressure relief. The internal slag discharging drill rod comprises a hollow rod body, a flow injecting pipe coaxially arranged in the rod body, and a supporting piece for connecting the rod body with the flow injecting pipe. A slag discharging channel is formed between the inner wall of the rod body and the outer wall of the flow injecting pipe; an air inlet and water inlet channel is formed in the flow injecting pipe; with the direction opposite to the rotating direction of the drill rod body during drilling as the reverse direction, the spiral convex ribs ascending in a cylindrical spiral shape in the reverse direction are arranged on the outer cylindrical face of therod body; and the multiple pressure relief holes are formed in the outer cylindrical face of the rod body along one sides of the spiral convex ribs. If hole collapse occurs during drilling, coal slagcan enter the slag discharging channel through the pressure relief holes, the acting force of the coal slag on the drill rod is released, meanwhile, the spiral convex ribs have the hole raking capability, and thus the coal slag is in a loose state and enters the slag discharging channel through the pressure relief holes till the hole collapse area is smooth.

Owner:HENAN POLYTECHNIC UNIV

Quick change chip removing drill bit

The invention provides a quick change chip removing drill bit. The quick change chip removing drill bit comprises a drill handle and a cutter body coaxial with the drill handle. A spiral groove is formed in the cutter body, a drill point is arranged at the top end of the cutter body, and two rear cutter faces in central symmetry are arranged on the drill point. Each rear cutter face comprises a stepped first cutter face, a stepped second cutter face, and a third cutter face formed by coping towards the second cutter face along a back ridge of a drill bit, a spiral chip guide cambered face is arranged in the spiral groove along a tail ridge of the drill bit, rear ditch ridges of the first cutter face, the second cutter face and the third cutter face and the tail ridge of the top of the cutter body are simultaneously coped in the chisel edge direction, a first coping face and a second coping face are formed on the front face of the cutter body, an annular groove is formed in the drill handle along the outer peripheral face, and multiple hemispherical blind holes are formed in the drill handle.

Owner:JIANGSU TIANGONG PRECISION TOOLS CO LTD

Flexible Internal Control Rotary Directional Drilling System and Drilling Method for Underground Broken Coal Seam in Coal Mine

ActiveCN107605402BIncrease the encounter rateImprove the extraction effectDirectional drillingGas removalNon magneticDrilling system

A flexible internal control rotary directional drilling system and drilling method for underground soft coal seams in coal mines. The drilling system includes a flexible internal control rotary directional drilling tool, a directional system, an auger rod, an openable and closed drill bit and a double power head drilling rig. The flexible internal control rotary directional drilling tool is located between the auger rod and the openable and closable drill bit to realize rotary directional drilling. The directional system runs through the auger rod to measure the drilling trajectory. The dual power head drill It includes a large power head and a small power head to provide drilling power. The flexible internal control rotary directional drilling tool includes a flexible outer tube, a bent mandrel, a bearing set and a sleeve. The directional system includes an upper non-magnetic drill rod, Lower non-magnetic drill pipe, probe outer tube, measuring probe, cable inner tube and explosion-proof computer; thus, the present invention realizes the directional drilling and screen tube completion under the coal mine's broken soft coal seam drilling rotation mode. Hole protection, improve drilling safety and drilling efficiency, and then improve the coal seam drilling rate and gas drainage effect.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com