Prefabricated screw pile construction method

A construction method and screw technology, applied in sheet pile wall, foundation structure engineering, construction and other directions, can solve the problems of low pile bearing capacity, construction efficiency of broken piles, small adaptability range, etc. Pile speed, effect of reducing drilling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

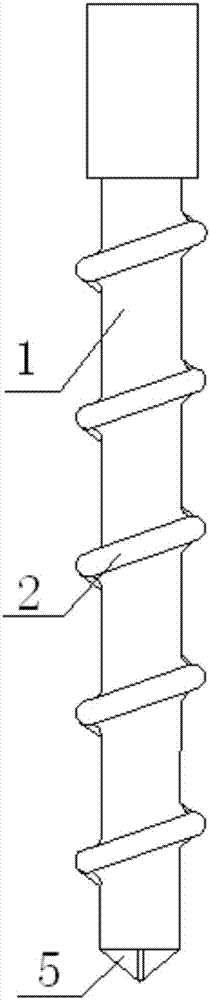

[0048] Specific implementation mode one: combine Figure 1-11 Describe this embodiment, this embodiment is a kind of prefabricated screw pile construction method, and this method is carried out according to the following steps:

[0049] 1. Installation:

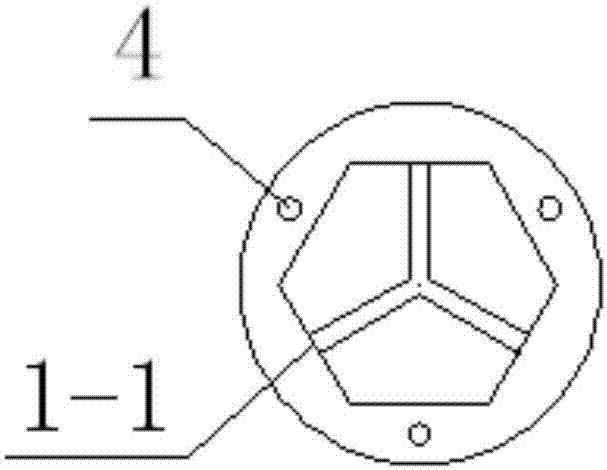

[0050] Install the prefabricated screw pile vertically on the tower of the rotary drilling rig, and connect it with the power head of the high-pressure rotary device; connect the compressed air output pipeline of the air compressor with the compressed air input pipeline of the high-pressure rotary device; connect the grouting pump The liquid output pipeline is communicated with the liquid input pipeline of the high-pressure rotary device; the compressed air output pipeline and the liquid output pipeline of the high-pressure rotary device are respectively communicated with the through hole 4 of the prefabricated screw pile;

[0051] 2. Pile planting:

[0052] Use the rotary power of the rotary drilling rig to screw the prefa...

specific Embodiment approach 2

[0060] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the specific steps of the high-pressure rotary spraying method described in step two are: when the soil body is a sand layer, the prefabricated screw pile is screwed by the rotary power of the rotary drilling rig. Inserting into the soil body, step c is firstly used in the process of screwing into the soil body, and step d is used when step c cannot complete the reaming and pile planting;

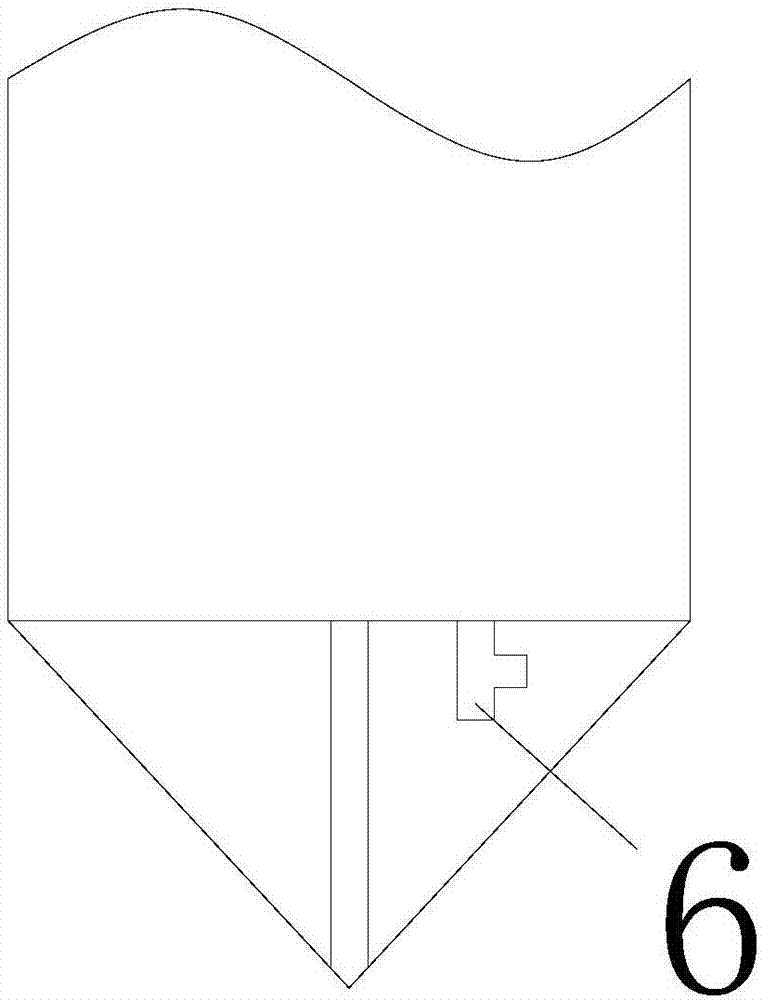

[0061] Said step c is: in the process of screwing into the soil, pass high-pressure cement slurry into a through hole 4, and install a nozzle with a 45° outlet nozzle and a vertical outlet at the outlet of the high-pressure cement slurry of the drill bit to perform high pressure on the soil body. cutting and mixing;

[0062] Said step d is: in the process of screwing into the soil body, feed high-pressure cement slurry and compressed air into the two through holes 4 respectively, install a...

specific Embodiment approach 3

[0063] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that: the specific steps of the high-pressure rotary spraying method described in step two are: when the soil is a cohesive soil condition, the rotary power of the rotary drilling rig is used to turn the prefabricated screw The pile is screwed into the soil; step e is firstly adopted in the process of screwing into the soil, and step f is adopted when step e cannot complete reaming and pile planting, and step g is adopted when step f cannot complete reaming and pile planting;

[0064] Said step e is: in the process of screwing into the soil, pass high-pressure cement slurry into a through hole 4, and install a pair of vertical outlet nozzles, 45° outlet nozzles and horizontal outlet nozzles at the drill bit high-pressure cement slurry outlet. High-pressure cutting and mixing of soil;

[0065] Said step f is: in the process of screwing into the soil body, feed high-pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com