A kind of box structure based on perforated steel plate and preparation method thereof

A box structure and steel box technology, which is applied in shaft equipment, mining equipment, earthwork drilling and mining, etc., can solve the problems of short service life and achieve the effects of improving service life, good durability and protection performance, and ensuring bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

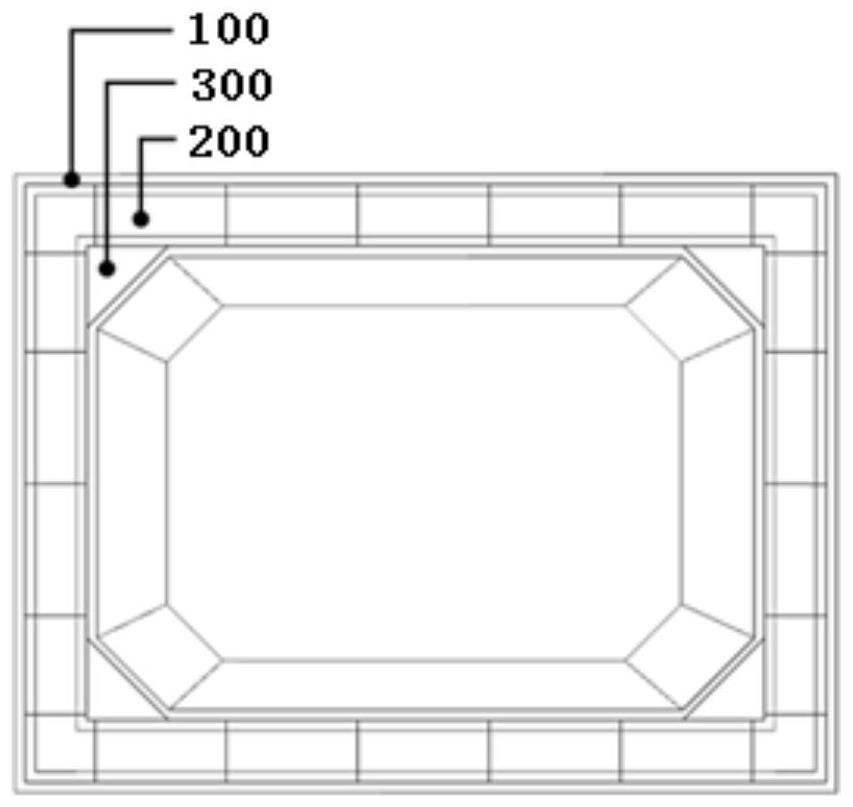

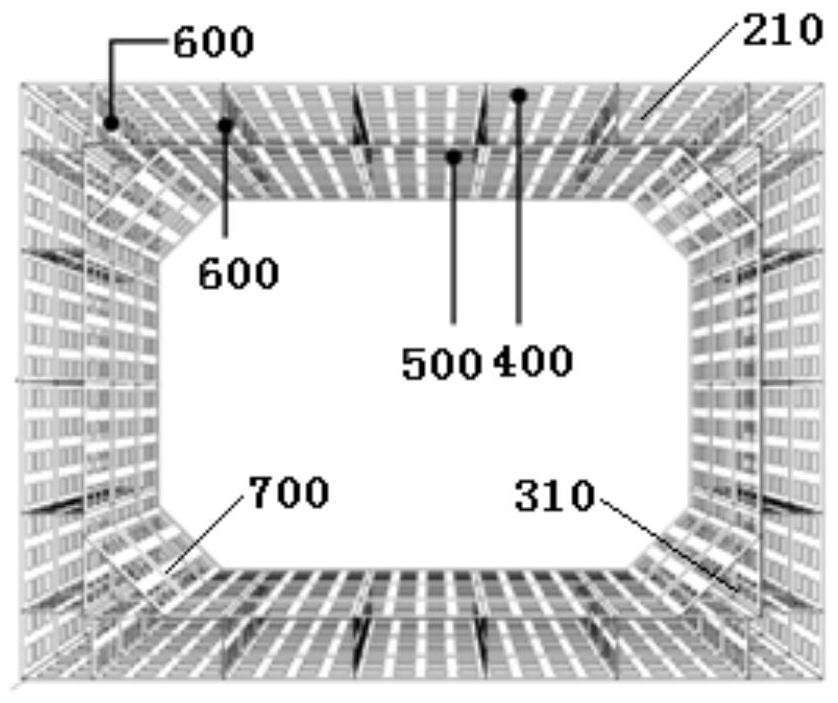

[0039] The present invention discloses a box structure based on perforated steel plates, please refer to figure 1 and figure 2 . The box structure based on the perforated steel plate (hereinafter referred to as the box structure) includes: a box body, and the box body includes: a perforated steel plate forming a box shape, and a protective layer arranged on the outside of the perforated steel plate 100 , a filling layer 200 disposed in the perforated steel plate and connected to the protective layer 100 , and a fire-resistant crack control layer 300 disposed inside the perforated steel plate and connected to the filling layer 200 .

[0040] In the embodiment of the present invention, the box body may be a quadrilateral box body or a polygonal box body, and it should be understood that the present invention is not limited thereto. It should be understood that the specific material of the perforated steel plate should be adjusted according to actual needs, which is not limite...

Embodiment 2

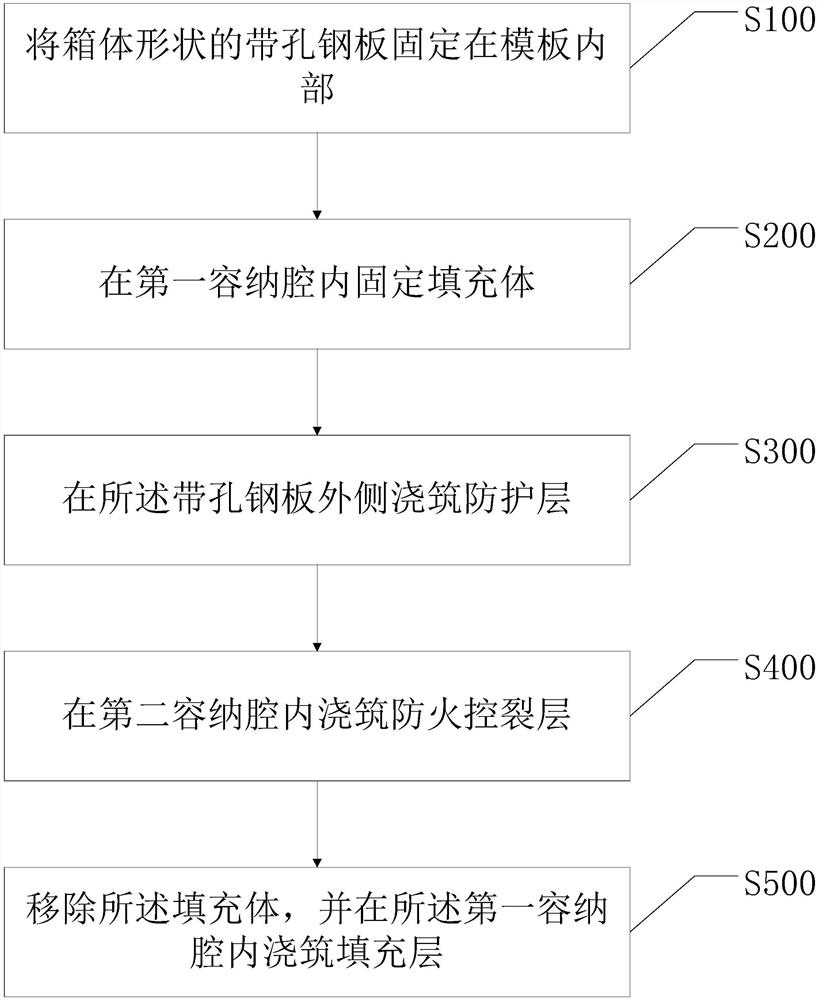

[0055] On the basis of the above box structure based on perforated steel plate, the present invention also discloses a preparation method of the box structure based on perforated steel plate. For details, please refer to image 3 , the preparation method includes:

[0056] S100, fixing the box-shaped perforated steel plate inside the template 10;

[0057] S200, fixing the filling body 20 in the first accommodating cavity 210;

[0058] S300, pouring a protective layer 100 on the outer side of the perforated steel plate;

[0059] S400 , pouring the fire prevention and crack control layer 300 in the second accommodating cavity 310 ;

[0060] S500, removing the filling body 20, and pouring the filling layer 200 in the first accommodating cavity 210;

[0061] In the embodiments of the present invention, please refer to Figure 4 to Figure 8 . Before the manufacturing process of the box structure, a plurality of third steel plates 600 are firstly connected between the first ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com